Professional Documents

Culture Documents

Pipenet News Spring 2012

Uploaded by

Bánh Cuốn Tôm ThịtCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipenet News Spring 2012

Uploaded by

Bánh Cuốn Tôm ThịtCopyright:

Available Formats

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

WE ARE PARTICIPATING IN OTC 2012 .......................................................................................................... 2

STANDARD MATERIALS SUPPLIED FREE TO ALL PIPENET USERS WITH MUS .................................. 2

BRAND NEW DRY PIPE MODELING CAPABILITY ........................................................................................3

START-UP OF A FIREWATER SYSTEM ..................................................................................................................3

SHUT DOWN OF A DELUGE SYSTEM ...................................................................................................................9

START UP AND SHUT DOWN OF A LOADING SYSTEM ..................................................................................... 11

Start-Up of Loading System without Including Loading Arm ...................................................................... 12

Start-Up of Loading System Including Loading Arm ................................................................................... 13

Shut down of Loading System - Channel Cavitation with Shut Off Valve Closure ................................... 15

PUMP ON/OFF CAPABILITY AND VARIABLE SPEED PUMP................................................................... 17

NEW FEATURES IN PIPENET VISION 1.6 ..................................................................................................... 21

PIPENET TRANSIENT MODULE ........................................................................................................................... 21

PIPENET SPRAY/SPRINKLER MODULE ............................................................................................................... 21

PIPENET STANDARD AND SPRAY/SPRINKLER MODULES ................................................................................. 22

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

WE ARE PARTICIPATING IN OTC 2012

Everyone has heard of OTC Offshore Technology Conference. It is the foremost trade show for the

offshore oil & gas industry. Sunrise Systems is participating in OTC 2012 to be held April 30 May 3 2012.

Please see us in Booth 11504, the Pavilion, Reliant Park, Houston, Texas. We will be there to give live

demonstrations and answer questions. We would be delighted to see friends old and new.

STANDARD MATERIALS SUPPLIED FREE TO ALL PIPENET USERS WITH

MUS

We know that PIPENET is only as successful as how well our customers can use it. We have a technically

brilliant program in PIPENET, but in order to help our customers to get the best value from their investment

in PIPENET we must provide effective tools for its. It is becoming apparent that some of our customers are

not aware of what tool are provided with PIPENET software. The following screen shots of the PIPENET

folder shows what is supplied as standard delivery. You will find these in the PIPENET folder after version

1.6 is installed.

The training materials contain not only our training manuals but also the data files for the examples used in

them. The utility programs are for converting steady state data files to transient data files. We have

invested heavily in developing these materials and we encourage our customers to make full use of these

powerful resources.

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

BRAND NEW DRY PIPE MODELING CAPABILITY

This is a unique development in version 1.6 of PIPENET Vision. The need for modeling priming of dry

systems has been has been recognised by the engineering community for a long time. Hitherto there has

been no rigorous way of modeling such systems. No longer! PIPENET Transient module can now model

priming of dry systems rigorously with no compromises. Two example are shown below. The first one is

concerned with the priming and shut down of a dry deluge system. The second example shows a

hydrocarbon loading system and its priming.

START-UP OF A FIREWATER SYSTEM

The offshore fire protection system under consideration protects a platform complex, with several fire

pumps, caissons, overboard dump valves, deluge valves and deluge nozzles. The scenario of interest is

one fire pump starting on one platform and the deluge valve opening on another platform. The firewater

ringmain is flooded and the deluge system is initially dry. The aim of the simulation is to estimate the

priming time of the deluge system rigorously. The firewater system under consideration is shown below.

In this model we will consider a clack shut deluge valve. PIPENET Transient module can also model

elastomeric sleeve type deluge valve which regulate the pressure. We will not consider such a valve in this

model. The PIPENET schematic of the system is shown below.

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

Deluge valve which

opens/closes

Fire pump which will

operate

Deluge system which

will operate

PIPENET Vision version 1.6. can calculate how each pipe in the deluge system will be primed and

when each nozzle will deliver water.

There are actually two parts of the overall system which are dry at the start of the operation.

(i)

The first part is the caisson with the fire pump impeller. The caisson is only partly filled with

water and the rest of it is dry. After the fire pump starts the water level will rise, expelling the air

and finally fully priming the caisson. After the caisson is fully primed the water will go out

through the overboard dump valve. As the overboard dump valve closes the water from the fire

pump will go into the firewater ringmain. This model is described below in the section entitles

Pump priming and the overboard dump valve operation.

(ii)

The second part which is dry is the deluge system itself. Typically the deluge valve will open

before the overboard dump valve has closed. As the water from the fire pump goes into the

firewater ringmain after the overboard dump valve has closed, it will increase the pressure and

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

the deluge system will begin to get primed. This is described in the section Deluge Valve

5

Opening and Deluge System Priming.

Modeling of the above two aspects are described separately below.

Part 1 - Pump priming and the overboard dump valve operation

A two-node caisson type 1 is used to model the fact that during the quiescent state of the fire protection

system, the fire pump would be stopped and the caisson (sometimes called the riser pipe) is only partially

filled with water. When the fire pump starts air will get expelled from the caisson through to air release and

the water level will rise. Ultimately, the caisson will become fully primed, and the fire pump will deliver

water initially through the overboard dump and subsequently into the firewater ringmain when the

overboard dump valve closes.

The use of the overboard dump valve is a fairly standard configuration these days. This is modeled by an

operating valve which closes linearly from 12 to 17 secs on the assumption that the caisson would have

fully primed before 12 secs.

Overboard dump valve closes

after caisson primes

Caisson primes after

fire pump starts

Part 2 - Deluge Valve Opening and Deluge System Priming

Typically the deluge valve opens at the same time as the fire pump receives a signal to start. Although the

deluge valve can open there will not be sustained flow through it because the ringmain would lose

pressure. After the pump begins to deliver water, the pressure will rise and the deluge system will also

begin to prime.

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

Deluge Valve which opens

Nozzles to be considered in

the graphs are shown in red

Graphical Results

In the first graph below, the plots of some of the variables near the pump are shown.

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

The second graph below shows what happens in the vicinity of the deluge valve and how air gets pushed

out of the deluge system.

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

The third graph below shows the flowrate through some of the nozzles in the deluge system after the

8

deluge valve opens.

Nozzle Priming Times

PIPENET has the capability of showing the results in the data window. This is a very convenient way of

looking at the nozzle priming times. Please note that these are the times at which the initial flow through

the nozzles will start. This can happen because of cavity formation in the higher points in the system

leading to draining of the firewater ringmain. This may not indicate the time at which full flow is established

full flow through the nozzles is established.

It can be seen below that the last nozzles to start to delivering water do so at 6.6 secs. The first nozzle on

the other hand starts to deliver water at 4.5 secs. The sorting facility of PIPENET is very useful for this.

Nozzle 2 and 4

It can be seen below that the first nozzles to start to delivering water do so at 4.5 secs. The sorting facility

of PIPENET is very useful for this.

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

Nozzle 16

Please note that these are the times at which the nozzles start delivering water. In order to determine

when the full flow is established in the nozzles we should look at the graphical results. It can be seen that

the deluge system reaches fully established flow at around 18 secs by looking at the third graph in the

Graphical Results section above.

SHUT DOWN OF A DELUGE SYSTEM

Deluge Valve Closure and Deluge System Draining

One of the points to bear in mind in modeling system draining is the fact that the driving force will become

less as the system drains. Finally, the driving force will become negligible and the flow will cease even

before the system is completely dry. In the following example, three of the nozzles are chosen for study.

The graphs show the sequence and the times when the flow through these three nozzles will stop.

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

10

Line from Deluge

Valve

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

11

START UP AND SHUT DOWN OF A LOADING SYSTEM

In this application we consider three different simulations and they illustrate different points.

Start-Up of Loading System without Including Loading Arm The purpose of this simulation is to show

how long it takes for the product to reach the end of the loading line.

Start-Up of Loading System Including Loading Arm The purpose of this simulation is to show that the

pump can take the product through the high point in the loading arm. Please note that during normal

operation the static head loss on the riser part is compensated by the static head gain on the down comer.

During pump start up, as the riser is primed, the down comer is empty and the static head loss will not be

compensated.

Channel Cavitation with Shut Off Valve Closure and Pump Running The purpose of this simulation is

to show the role of the channel cavitation model during system shut down. When the system shuts down

potentially a large cavity can form in the down comer if the shut off valve is closed without closing the

loading arm valve. There will be no cavity on the riser side.

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

Start-Up of Loading System without Including Loading Arm

The above system transfers lube oil from a plant to a sea tanker. Closure of the shutoff valve, the ERC

valve and pump failure are classic applications of PIPENET Transient module. What is new in version 1.6

is the capability of modeling the start-up and priming of the pipeline.

The above loading system consists of a product pump, a pipeline 5697 m long, a shutoff valve, a jetty pipe

150 m long and an ERC (Emergency Relief Coupling) valve. In the first case, which is shown by the above

schematic, the loading arm is not explicitly modeled. In the second case the loading arm is explicitly

modeled. The pump runs up from 5 secs to 10 secs (i.e. 5 secs run up time). The shutoff valve and the

ERC valve remain fully open throughout the simulation.

It can be seen from the graph below that the product will reach the shut off valve at around 2600 secs after

the pump starts. It can be seen how the throughput of the pump decreases as the pipeline gets primed. It

can also be seen how the main pipeline is primed first and then the jetty pipe is primed.

12

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

13

Start-Up of Loading System Including Loading Arm

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

14

The first graph below shows a zoomed view available in PIPENET Graph Viewer. It can be seen that the

pressure at the inlet of the riser increases as the pressure at its inlet also increases. On the other hand, the

pressure at the top of the down comer remains at atmospheric until the air is completely expelled.

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

15

Shut down of Loading System - Channel Cavitation with Shut Off Valve Closure

As described in the introduction, in this scenario, the tanker valve is open while the shut off valve closes.

The pump keeps running at full speed.

The results upstream of the shut off valve are much as expected. On the other hand, the results at the

loading arm are worth of examination. It can be seen that the product continues to flow through the tanker

valve even after the shut off valve closes. This is because a cavity forms at the top of the loading arm

which grows in size. When the height of the liquid in the down comer is low enough to create vapour

pressure conditions in the down comer. At this point the cavity stops growing and the flow stops.

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

16

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

17

PUMP ON/OFF CAPABILITY AND VARIABLE SPEED PUMP

One of the much requested capabilities in PIPENET is pump on/off switch in the steady state. This is now

available in PIPENET Vision version 1.6. PIPENET can also model variable speed pumps in steady state

now. The relevant properties window is shown before and after the calculation. The first case is where the

pump is on and the second case where the pump is off.

Pump on Case

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

18

Pump on/off switch

Pump speed

Pump Off Case

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

19

Pump switched off

Dot indicates pump is off

Variable Speed Pump

In this simulation the target discharge pressure of the pump is 8.9 barg. The objective is to determine the

pump speed which would give 8.9 barg at the required node.

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

20

Target pressure is 8.9 barg

Input data in the properties window is shown below.

Set point

The pump operating point by way of its speed, discharge pressure and the flow rate are sown in the screen

shot below. It can be seen that the pump needs to operate at 91% speed in order to achieve the set point

of 8.9 barg on node 2.

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

21

NEW FEATURES IN PIPENET VISION 1.6

PIPENET TRANSIENT MODULE

Dry Pipe Modeling

Modeling of pipes which start dry, and then fill up.

Also models pipes that start full and then empty.

Transient effects in these cases now have a significant increase in realism.

Nozzle Modeling

Nozzles can now be directly modeled.

Two behaviours corresponding to Spray versus Standard options.

Nozzle priming sequence.

Tank Type definition

Tanks Type components (receiving vessels, accumulators, simple tanks, and surge tanks) can be

defined by a table of x-section area versus height.

Graph Viewer

Graph viewer can display pressure envelope.

PIPENET SPRAY/SPRINKLER MODULE

New Autolayout shapes

Horizontal cylindrical tank.

Spherical tank.

Design conforms to chosen standards and design rules.

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

New Autolayout user interface

Dynamic inspection of the 3D model.

Draw curved pipes.

Spray Diagrams

Unwrap autolayout shape to show spray patterns.

Use colours to distinguish amount of water at each location.

Results can be printed or included in reports.

PIPENET STANDARD AND SPRAY/SPRINKLER MODULES

Pump on/off

Flow-rate is now guaranteed zero when the pump is off.

Variable Speed Pump

Change the performance curve by specifying the pump setting as a fraction of the maximum speed.

PIPENET STANDARD, SPRAY/SPRINKLER AND TRANSIENT MODULES

New Report Generator

Design the report layouts you want, as Word templates.

New PIPENET feature to generate results in XML format.

New Word plug-in, allowing you to insert required PIPENET quantities and tables into your report.

Combine results from multiple models/calculations.

Enhance the inserted content (fonts, totals, headings ).

Insert other content (text, images, etc) as required.

Automatic update when the calculation is re-run.

Works with all three PIPENET modules.

Pre-1.6 report mechanism is still supported.

Units and precision

Override number of decimal places displayed on schematics.

Overwrite user-defined units with a standard unit.

Limit decimal places for dimensionless values.

Miscellaneous Enhancements

The Delete key now can be used to delete selected components, and text.

New output fields in Spray and Standard reports (static head loss, friction factor).

We have standardised reported version numbers as per the PIPENET release (so in this case, 1.6

which implies the calculator used)

Two node caisson type 2 modelling - transfer functions and liquid surge relief valve algorithms have

been improved..

Messages for orifice plate warnings in Standard and Spray modules have been improved.

REStoCSV.exe is a new program to convert Transient RES files into CSV (comma separated

variable) format, from which they can be displayed in the tabular format of your choice.

Only important messages are displayed during installation

And much more!

22

PIPENET NEWS

VOLUME 2

ISSUE 9

SPRING 2012

23

SUNRISE SYSTEMS LIMITED, CAMBRIDGE CB25 9QZ, UNITED KINGDOM

Web site: www.sunrise-sys.com

Copyright 2012 SUNRISE SYSTEMS LIMITED. All rights reserved.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Centrifugal CastingDocument266 pagesCentrifugal Castinguzairmetallurgist100% (2)

- API 510 Study QuestionsDocument49 pagesAPI 510 Study QuestionsDavid Drolet Tremblay100% (1)

- API 510 Section 8 - 75 QuestionsDocument18 pagesAPI 510 Section 8 - 75 QuestionsBánh Cuốn Tôm ThịtNo ratings yet

- API 510 BasicsDocument40 pagesAPI 510 BasicsBalakumarNo ratings yet

- API 510 Flash Cards - 30 TermsDocument8 pagesAPI 510 Flash Cards - 30 Termshahah100% (1)

- The Mystery of Relationship Charts RevealedDocument5 pagesThe Mystery of Relationship Charts RevealedPhalgun Balaaji0% (1)

- ASME SpreaderBar CalcsDocument5 pagesASME SpreaderBar Calcsganesh100% (1)

- AgitatingDocument24 pagesAgitatingBánh Cuốn Tôm ThịtNo ratings yet

- Review Beer AgeingDocument25 pagesReview Beer AgeingTimothy WestNo ratings yet

- 0901d1968065f1f4 Bearing Preload - TCM - 12 299896Document7 pages0901d1968065f1f4 Bearing Preload - TCM - 12 299896anush_swaminathanNo ratings yet

- ASME Sec IX - Questions For API ExamDocument21 pagesASME Sec IX - Questions For API ExamMKAMRANBHATTI87% (31)

- Camlock CatalogoDocument12 pagesCamlock CatalogoPascualSalvador100% (1)

- API 510 Section 6 - 26 QuestionsDocument7 pagesAPI 510 Section 6 - 26 QuestionsBánh Cuốn Tôm ThịtNo ratings yet

- API 510 Section 5 - 68 QuestionsDocument15 pagesAPI 510 Section 5 - 68 QuestionsBánh Cuốn Tôm ThịtNo ratings yet

- API 510 Data SheetsDocument11 pagesAPI 510 Data SheetshahahNo ratings yet

- Complete Phrasal Verbs ListDocument137 pagesComplete Phrasal Verbs ListHermes®No ratings yet

- A First Course in Optimization Theory - ContentDocument8 pagesA First Course in Optimization Theory - ContentSuraj KumarNo ratings yet

- API 510 (Pressure Vessel Inspection Code) 114 TermsDocument24 pagesAPI 510 (Pressure Vessel Inspection Code) 114 TermsBánh Cuốn Tôm ThịtNo ratings yet

- API 510 (Misc. #'S) 27 TermsDocument3 pagesAPI 510 (Misc. #'S) 27 TermszaxaderNo ratings yet

- API 510 Sample QuestionsDocument10 pagesAPI 510 Sample Questionsbichibtech1No ratings yet

- API 510 Section 2 - 4 QuestionsDocument1 pageAPI 510 Section 2 - 4 QuestionsBánh Cuốn Tôm ThịtNo ratings yet

- API 510 Section 3 - 13 QuestionsDocument3 pagesAPI 510 Section 3 - 13 QuestionsBánh Cuốn Tôm ThịtNo ratings yet

- API 510 Section 1 - 17 QuestionsDocument4 pagesAPI 510 Section 1 - 17 QuestionsBánh Cuốn Tôm ThịtNo ratings yet

- API 510 Section 4 - 10 QuestionsDocument3 pagesAPI 510 Section 4 - 10 QuestionsBánh Cuốn Tôm ThịtNo ratings yet

- Kaunas University of Technology Mechanical Engineering and Design FacultyDocument63 pagesKaunas University of Technology Mechanical Engineering and Design FacultyrahulNo ratings yet

- API 510 - 2 TermsDocument1 pageAPI 510 - 2 TermsBánh Cuốn Tôm ThịtNo ratings yet

- Pocket Guide To Chemical HazardsDocument454 pagesPocket Guide To Chemical HazardsG_ARVALIS8470No ratings yet

- Cam and Groove - 2017Document68 pagesCam and Groove - 2017Bánh Cuốn Tôm ThịtNo ratings yet

- Mechanical Agitator Power Requirements for Liquid BatchesDocument24 pagesMechanical Agitator Power Requirements for Liquid BatchesAixa BerchiNo ratings yet

- Exproof Standartlari Karsilastirma Tablosu 20110210 164702Document1 pageExproof Standartlari Karsilastirma Tablosu 20110210 164702HoangNo ratings yet

- Comparison of Power Number For Paddle Type Impellers by Three Methods-UnlockedDocument4 pagesComparison of Power Number For Paddle Type Impellers by Three Methods-UnlockedBánh Cuốn Tôm ThịtNo ratings yet

- Rockwool ThicknessDocument36 pagesRockwool ThicknessDevrim Gürsel100% (1)

- Asme Seccion Viii Div. 1 Ed 2015 CalculoDocument72 pagesAsme Seccion Viii Div. 1 Ed 2015 CalculoBánh Cuốn Tôm ThịtNo ratings yet

- Phrasal Verbs in Use McCarthyDocument210 pagesPhrasal Verbs in Use McCarthyAnamaria BabataNo ratings yet

- General Piping Code SystemDocument19 pagesGeneral Piping Code SystemBánh Cuốn Tôm ThịtNo ratings yet

- MIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma ComplexesDocument7 pagesMIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma Complexessanskarid94No ratings yet

- Chapter 1 - Introduction To Differential EquationsDocument16 pagesChapter 1 - Introduction To Differential EquationsnawidwardakNo ratings yet

- The Basic Differential Equation For Radial Flow in A Porous MediumDocument8 pagesThe Basic Differential Equation For Radial Flow in A Porous MediumrestofficalNo ratings yet

- Phet ReflectionDocument3 pagesPhet Reflectionapi-260335088No ratings yet

- LNG SamplingSystemDocument2 pagesLNG SamplingSystemGuillermo Lopez-FloresNo ratings yet

- Vibration assignment on 3DOF cantilever beam systemDocument5 pagesVibration assignment on 3DOF cantilever beam systemIzzah 'AtirahNo ratings yet

- Design Project: SEV200 - Geotechnical Investigation and Design Last Update: 09/05/2020Document12 pagesDesign Project: SEV200 - Geotechnical Investigation and Design Last Update: 09/05/2020abdulqadirghoriNo ratings yet

- 37eb PDFDocument29 pages37eb PDFZikriaKMuhammadNo ratings yet

- Mechanics of Solids: Bela I. Sandor Ryan Roloff Stephen M. Birn Maan H. Jawad Michael L. BrownDocument1 pageMechanics of Solids: Bela I. Sandor Ryan Roloff Stephen M. Birn Maan H. Jawad Michael L. BrownkprasannanNo ratings yet

- Levee Drain Analysis in SlideDocument12 pagesLevee Drain Analysis in SlideAdriRGNo ratings yet

- Isaacs. Differential GamesDocument13 pagesIsaacs. Differential GamescrovaxIIINo ratings yet

- A Simple Lamina Flow Engine PDFDocument2 pagesA Simple Lamina Flow Engine PDFSelva KumarNo ratings yet

- Metalic AsDocument16 pagesMetalic AsKarencita Genesis LapibaNo ratings yet

- 06.-Medidor Cloro CL4000enDocument18 pages06.-Medidor Cloro CL4000enLeonel RubioNo ratings yet

- SOAL ElmesDocument16 pagesSOAL ElmesNurul HanifahNo ratings yet

- Field-Weakening Control Algorithm For Interior Permanent Magnet Synchronous Motor Based On Space-Vector Modulation TechniqueDocument9 pagesField-Weakening Control Algorithm For Interior Permanent Magnet Synchronous Motor Based On Space-Vector Modulation TechniqueArpan GayenNo ratings yet

- MarriageDocument3 pagesMarriageAstrologerAnjaanNo ratings yet

- Journal of Power Sources: Pedro O. Lopez-Montesinos, Amit V. Desai, Paul J.A. KenisDocument8 pagesJournal of Power Sources: Pedro O. Lopez-Montesinos, Amit V. Desai, Paul J.A. KenisbernardNo ratings yet

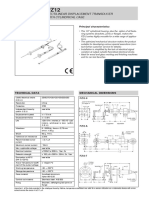

- Rectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical Dimensionsl561926No ratings yet

- Comparing Masses of Reactants and ProductsDocument4 pagesComparing Masses of Reactants and ProductsDaniel TriumbariNo ratings yet

- 79 PDFDocument4 pages79 PDFHolayilNo ratings yet

- KIT-DISSOLVED OXYGEN CHEMets® Refills, ULR CHEMets®-KITDocument2 pagesKIT-DISSOLVED OXYGEN CHEMets® Refills, ULR CHEMets®-KITSorinNo ratings yet

- ANSYS Model of A Cylindrical Fused Silica Fibre-01Document15 pagesANSYS Model of A Cylindrical Fused Silica Fibre-01lamia97No ratings yet

- ROCKYDocument4 pagesROCKYNelson Alexander Aponte SimbronNo ratings yet