Professional Documents

Culture Documents

"Rebars" - Reinforcing Bar Development and Splice Lengths: Program Description

Uploaded by

Abu BiduOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

"Rebars" - Reinforcing Bar Development and Splice Lengths: Program Description

Uploaded by

Abu BiduCopyright:

Available Formats

"REBARS" --- REINFORCING BAR DEVELOPMENT AND SPLICE LENGTHS

Program Description:

"REBARS" is a spreadsheet program written in MS-Excel for the purpose of determining reinforcing bar

development and splice lengths. Specifically, the development lengths and splice lengths for straight bars in

tension as well as compression are determined. Also, the development length for standard hook bars is

determined. The provisions for development and splice lengths are included for high seismic risk applications

per ACI 318M-05, Chapter 21. There is also a worksheet which contains reinforcing bar data tables.

This METRIC version is based on the ACI 318M-05 Code.

This program is a workbook consisting of five (5) worksheets, described as follows:

Worksheet Name

Description

Doc

Calc Development (Soft Metric)

Calc Development (Euro Metric)

Rebar Data (Soft Metric)

Rebar Data (Euro Metric)

This documentation sheet

Reinforcing Bar Development and Splice Lengths (ACI "Soft" Metric Bars)

Reinforcing Bar Development and Splice Lengths (European Metric Bars)

Reinforcing Bar Data Tables (ACI "Soft" Metric Bars)

Reinforcing Bar Data Tables (European Metric Bars)

Program Assumptions and Limitations:

1. This program follows the procedures and guidelines of the ACI 318M-05 Building Code, Chapters 12 and 21.

2. The "Calc Development (Soft Metric)" worksheet, for a given reinforcing bar size, determines the straight

development and splice lengths for a "top" bar and an "other" bar in tension, the straight development and

splice lengths for the bar in compression, and the tension development length of the bar as a standard hook,

all at one time. A complete table of reinforcing bar development and splice lengths is also created.

3. The ACI "Soft Metric" reinforcing bar sizes are #10, #13, #16, #19, #22, #25, #29, #32, #36, #43, and #57.

These correspond directly to the U.S. bar sizes #3, #4, #5, #6, #7, #8, #9, #10, #11, #14, and #18, as the bar

designations represent the exact metric conversion of bar diameter rounded to the nearest whole millimeter.

4. The "Calc Development (Euro Metric)" worksheet, for a given reinforcing bar size, determines the straight

development and splice lengths for a "top" bar and an "other" bar in tension, the straight development and

splice lengths for the bar in compression, and the tension development length of the bar as a standard hook,

all at one time. A complete table of reinforcing bar development and splice lengths is also created.

This worksheet can be utilized for cases where the design concrete code used is ACI 318-05, but where the

reinforcing bars to be provided are European (British Standard) bar sizes, not U.S. bar sizes.

5. The "European Metric" reinforcing bar sizes are D6, D8, D10, D12, D14, D16, D20, D25, D28, D32, D40,

and D50. These do not correspond directly to the U.S. bar sizes nor to the "Soft Metric" bar sizes, as the bar

designations represent the exact bar diameter expressed in millimeters.

6. The "Rebar Data (Soft Metric)" worksheet contains two tables of reinforcing bar data which include various

bar properties as well as reinforcing bar areas based on spacing using units of mm^2/m.

7. The "Rebar Data (Euro Metric)" worksheet contains two tables of reinforcing bar data which include various

bar properties as well as reinforcing bar areas based on spacing using units of mm^2/m.

8. This program contains numerous comment boxes which contain a wide variety of information including

explanations of input or output items, equations used, data tables, etc. (Note: presence of a comment box

is denoted by a red triangle in the upper right-hand corner of a cell. Merely move the mouse pointer to the

desired cell to view the contents of that particular "comment box".)

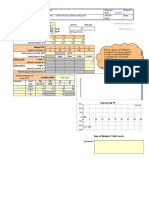

"REBARS (318M-05).xls" Program

Version 1.0

REINFORCING BAR DEVELOPMENT AND SPLICE LENGTHS

Per ACI 318M-05 Building Code - Chapters 12 and 21

For Low & High Seismic Risk Applications - Using ACI "Soft" Metric Bar Sizes

Job Name:

Subject:

Job Number:

Originator:

Checker:

No

#4

#5

Input Data:

#6

#7

General Information:

ACI "Soft" Metric Reinf. Bar Size =

Reinforcing Yield Strength, fy =

Concrete Comp. Strength, f 'c =

Lightweight Concrete?

Epoxy Coated Bars?

Ratio: As(required)/As(provided) =

High Seismic Risk (Chapter 21) =

#8

25

420

28

No

No

1.000

No

Ldt=970 mm

#10

MPa

bc=50 mm

#14

>50 mm #18

Ldo=745 mm

For Straight Reinforcing Tension Bars:

Center-to-Center Bar Spacing, bs =

300

Clear Cover to Face of Bar, bc =

50

Transverse Reinforcing Index, Ktr =

0.000

mm

mm

For Straight Reinforcing Compression Bars:

Enclosed w/#13 Ties @ <=100mm?

No

For Standard Hooks in Tension:

Side Cover to Face of Bar, sc =

Clear Cover to Bar Hook, hc =

Enclosed with Ties @ <= 3*db?

65

50

No

mm

25.4

mm

mm

Results:

Reinforcing Bar Diameter, db =

For Straight Reinforcing Tension Bars:

Top Bar Development, Ldt =

970

Other Bar Development, Ldo =

745

Top Bar Class "A" Splice, Lat =

970

Other Bar Class "A" Splice, Lao =

745

Top Bar Class "B" Splice, Lbt =

1255

Other Bar Class "B" Splice, Lbo =

970

#9

MPa

Select:

bc=50 mm

db =

Straight Bar Development

Location Factor, t =

Location Factor, t =

Coating Factor, e =

Top Bar Limit: t*e =

Bar Size Factor, s =

Lat=970 mm

Lightweight Factor, =

Lbt=1255 mm

c=

bc=50 mm

Limit: (c+Ktr)/db =

>300 mm

As/As(prov)

=

Top Bar, Ldt =

Other Bar, Ldo =

Lao=745 mm

Top Bar 'A' Splice, Lat =

Lbo=970 mm

Straight Bar Splices

' Splice, Lao =

Top Bar 'B' Splice, Lbt =

Other Bar 'B' Splice, Lbo =

mm

mm

mm

mm

Ldh=340 mm

mm

mm

Develop. Tie Factor =

Splice Tie

Factor

hc=50

mm =

As/As(prov) =

sc=65 mm

Ldc =

For Straight Reinforcing Compression Bars:

Development Length, Ldc =

485

Splice Length =

760

Lh=410 mm

mm

mm

Cover Factor =

Tie Factor =

Coating

Factor,

e =

340

Standard

Hook

Development

mm

Lightweight

Factor,

=

410

mm

As/As(prov) =

Ldh =

Note: All development and splice lengths have been rounded up to the nearest 5mm.

D=155 mm

For Standard Hook Tension Bars:

Development Length, Ldh =

Standard Hook Leg Length, Lh =

2 of 11

07/02/2016 22:32:37

"REBARS (318M-05).xls" Program

Version 1.0

3 of 11

07/02/2016 22:32:37

"REBARS (318M-05).xls" Program

Version 1.0

Tabulation of Calculated Results for All ACI "Soft" Metric Bar Sizes Based on Specific Input:

#3

db =

Reinforcing Bar Development and Splice Lengths for f 'c = 28 MPa and fy = 420 MPa

Tension Development Class "B" Tens. Splice

Std. 90 deg. Hook

Compression Bars

Top

Bar

Other

Bar

Top

Bar

Other

Bar

Embed.

Leg

Length

Develop.

"Soft" Metric

Splice

Ldt

Ldo

Lbt

Lbo

Ldh

Lh

Ldc

Bar Size

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

#10

300

300

375

300

150

155

200

300

#13

385

300

500

385

170

205

245

380

#16

480

370

620

480

215

255

305

475

#19

575

440

745

575

255

305

365

570

#22

835

645

1085

835

300

360

425

665

#25

970

745

1255

970

340

410

485

760

#29

1200

925

1560

1200

385

490

550

855

#32

1480

1140

1920

1480

435

550

615

965

#36

1775

1365

2305

1775

480

610

685

1070

#43

2430

1870

N.A.

N.A.

820

775

820

N.A.

#57

3920

3015

N.A.

N.A.

1095

1035

1095

N.A.

Notes:

1. Straight development and Class "B" splice lengths shown in above table are

based on uncoated bars assuming center-to-center bar spacing = 300mm without

Develop. Tie Factor =

ties or stirrups and bar clear cover = 50mm.

Splice Tie Factor =

Normal weight concrete with no transverse reinforcing are both assumed.

As/As(prov) =

No excess reinforcing is assumed.

f 'c Factor =

2. Standard 90 deg. hook embedment lengths are based on bar side cover = 65mm

Ldb =

and bar end cover = 50mm without ties around hook.

Splice =

3. Table does not reflect special seismic considerations from ACI 318M-05, Chapter 21.

Cover Factor =

Tie Factor =

Coating Factor, e =

Lightweight Factor, =

As/As(prov) =

Ldh =

#4

db =

Location Factor, t =

Location Factor, t =

Coating Factor, e =

Top Bar Limit: t*e =

Bar Size Factor, s =

Lightweight Factor, =

c=

Ktr =

Limit: (c+Ktr)/db =

As/As(prov) =

4 of 11

07/02/2016 22:32:37

"REBARS (318M-05).xls" Program

Version 1.0

Top Bar, Ldt =

5 of 11

07/02/2016 22:32:37

"REBARS (318M-05).xls" Program

Version 1.0

REINFORCING BAR DEVELOPMENT AND SPLICE LENGTHS

Per ACI 318M-05 Building Code - Chapters 12 and 21

For Low & High Seismic Risk Applications - Using European Metric Bar Sizes

Job Name:

Subject:

Job Number:

Originator:

Checker:

No

D

D

D

D

D

D

D

Input Data:

General Information:

European Metric Reinf. Bar Size =

Reinforcing Yield Strength, fy =

Concrete Comp. Strength, f 'c =

Lightweight Concrete?

Epoxy Coated Bars?

Ratio: As(required)/As(provided) =

High Seismic Risk (Chapter 21) =

25

460

28

No

No

1.000

No

Ldt=1030 mm

MPa

MPa

bc=50 mm

>50 mm

Ldo=795 mm

For Straight Reinforcing Tension Bars:

Center-to-Center Bar Spacing, bs =

300

Clear Cover to Face of Bar, bc =

50

Transverse Reinforcing Index, Ktr =

0.000

mm

mm

For Straight Reinforcing Compression Bars:

Enclosed w/D14 Ties @ <=100mm?

No

For Standard Hooks in Tension:

Side Cover to Face of Bar, sc =

Clear Cover to Bar Hook, hc =

Enclosed with Ties @ <= 3*db?

65

50

No

mm

25

mm

mm

Results:

Reinforcing Bar Diameter, db =

For Straight Reinforcing Tension Bars:

Top Bar Development, Ldt =

1030

Other Bar Development, Ldo =

795

Top Bar Class "A" Splice, Lat =

1030

Other Bar Class "A" Splice, Lao =

795

Top Bar Class "B" Splice, Lbt =

1340

Other Bar Class "B" Splice, Lbo =

1030

Select:

bc=50 mm

D

D

D

db =

Straight Bar Development

Location Factor, t =

Location Factor, t =

Coating Factor, e =

Top Bar Limit: t*e =

Bar Size Factor, s =

Lat=1030 mm

Lightweight Factor, =

Lbt=1340 mm

c=

bc=50 mm

Limit: (c+Ktr)/db =

>300 mm

As/As(prov)

=

Top Bar, Ldt =

Other Bar, Ldo =

Lao=795 mm

Top Bar 'A' Splice, Lat =

Lbo=1030 mm

Straight Bar Splices

' Splice, Lao =

Top Bar 'B' Splice, Lbt =

Other Bar 'B' Splice, Lbo =

mm

mm

mm

mm

Ldh=370 mm

mm

mm

Develop. Tie Factor =

Splice Tie

Factor

hc=50

mm =

As/As(prov) =

sc=65 mm

Ldc =

For Straight Reinforcing Compression Bars:

Development Length, Ldc =

525

Splice Length =

895

Lh=400 mm

mm

mm

Cover Factor =

Tie Factor =

Coating

Factor,

e =

370

Standard

Hook

Development

mm

Lightweight

Factor,

=

400

mm

As/As(prov) =

Ldh =

Note: All development and splice lengths have been rounded up to the nearest 5mm.

D=150 mm

For Standard Hook Tension Bars:

Development Length, Ldh =

Standard Hook Leg Length, Lh =

6 of 11

07/02/2016 22:32:37

"REBARS (318M-05).xls" Program

Version 1.0

7 of 11

07/02/2016 22:32:37

"REBARS (318M-05).xls" Program

Version 1.0

Tabulation of Calculated Results for All European Metric Bar Sizes Based on Specific Input:

For D

db =

Reinforcing Bar Development and Splice Lengths for f 'c = 28 MPa and fy = 460 MPa

Tension Development Class "B" Tens. Splice

Std. 90 deg. Hook

Compression Bars

European

Top Bar Other Bar

Top Bar

Other Bar Embed. Leg Length Develop.

Metric Bar

Splice

Ldt

Ldo

Lbt

Lbo

Ldh

Lh

Ldc

Size

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

D6

300

300

300

300

150

100

200

300

D8

300

300

345

300

150

130

200

300

D10

330

300

430

330

150

160

210

300

D12

395

305

515

395

180

195

255

300

D14

465

355

600

465

205

225

295

300

D16

530

405

685

530

235

260

335

300

D20

660

510

855

660

295

320

420

300

D25

1030

795

1340

1030

370

400

525

300

D28

1260

970

1640

1260

410

480

585

300

D32

1595

1230

2075

1595

470

545

670

300

D40

2350

1810

N.A.

N.A.

835

720

835

N.A.

D50

3425

2635

N.A.

N.A.

1045

900

1045

N.A.

Notes:

1. Straight development and Class "B" splice lengths shown in above table areDevelop. Tie Factor =

based on uncoated bars assuming center-to-center bar spacing = 300mm without

Splice Tie Factor =

ties or stirrups and bar clear cover = 50mm.

As/As(prov) =

Normal weight concrete with no transverse reinforcing are both assumed.

f 'c Factor =

No excess reinforcing is assumed.

Ldb =

2. Standard 90 deg. hook embedment lengths are based on bar side cover = 65mm

Splice =

and bar end cover = 50mm without ties around hook.

3. Table does not reflect special seismic considerations from ACI 318M-05, Chapter 21.

Cover Factor =

Tie Factor =

Coating Factor, e =

Lightweight Factor, =

As/As(prov) =

Ldh =

For D

db =

Location Factor, t =

Location Factor, t =

Coating Factor, e =

Top Bar Limit: t*e =

Bar Size Factor, s =

Lightweight Factor, =

c=

Ktr =

Limit: (c+Ktr)/db =

As/As(prov) =

8 of 11

07/02/2016 22:32:37

"REBARS (318M-05).xls" Program

Version 1.0

Top Bar, Ldt =

9 of 11

07/02/2016 22:32:37

ACI "SOFT" METRIC REINFORCING BAR DATA TABLES:

Bar Size

#10

#13

#16

#19

#22

#25

#29

#32

#36

#43

#57

75

80

90

100

110

120

125

130

140

150

160

175

180

200

220

225

240

250

275

300

Reinforcing Bar Properties

Area

Perimeter

(mm)

(mm^2)

(mm)

#10

947

888

789

710

645

592

568

546

507

473

444

406

394

355

323

316

296

284

258

237

Reinforcing Bar Area for Various Bar Spacings

ACI "Soft" Metric Bar Size

#13

#16

#19

#22

#25

1720

2667

3787

5160

6787

1613

2500

3550

4838

6363

1433

2222

3156

4300

5656

1290

2000

2840

3870

5090

1173

1818

2582

3518

4627

1075

1667

2367

3225

4242

1032

1600

2272

3096

4072

992

1538

2185

2977

3915

921

1429

2029

2764

3636

860

1333

1893

2580

3393

806

1250

1775

2419

3181

737

1143

1623

2211

2909

717

1111

1578

2150

2828

645

1000

1420

1935

2545

586

909

1291

1759

2314

573

889

1262

1720

2262

538

833

1183

1613

2121

516

800

1136

1548

2036

469

727

1033

1407

1851

430

667

947

1290

1697

Weight

(kg/m)

9.525

71

29.924

12.700

129

39.898

15.875

200

49.873

19.050

284

59.847

22.225

387

69.822

25.400

509

79.796

28.650

645

90.007

32.260

819

101.348

35.810

1006

112.500

43.000

1452

135.088

57.330

2581

180.108

Typical specification: ASTM A615M Grade 420 (MPa) Deformed Bars

Spacing

(mm)

Diameter

0.561

0.996

1.556

2.240

3.049

3.982

5.071

6.418

7.924

11.410

20.284

(mm^2/m)

#29

8600

8063

7167

6450

5864

5375

5160

4962

4607

4300

4031

3686

3583

3225

2932

2867

2688

2580

2345

2150

#32

10920

10238

9100

8190

7445

6825

6552

6300

5850

5460

5119

4680

4550

4095

3723

3640

3413

3276

2978

2730

#36

13413

12575

11178

10060

9145

8383

8048

7738

7186

6707

6288

5749

5589

5030

4573

4471

4192

4024

3658

3353

EUROPEAN METRIC REINFORCING BAR DATA TABLES:

Bar Size

Reinforcing Bar Properties

Diameter

Area

Perimeter

(mm)

D6

D8

D10

D12

D14

D16

D20

D25

D28

D32

D40

D50

Typical specification:

Spacing

(mm)

75

80

90

100

110

120

125

130

140

150

160

175

180

200

220

225

240

250

275

300

D6

377

354

314

283

257

236

226

218

202

189

177

162

157

142

129

126

118

113

103

94

D8

671

629

559

503

457

419

402

387

359

335

314

287

279

252

229

224

210

201

183

168

(mm^2)

(mm)

Weight

(kg/m)

6

28.3

18.850

0.222

8

50.3

25.133

0.395

10

78.5

31.416

0.617

12

113.0

37.699

0.888

14

154.0

43.982

1.210

16

201.0

50.265

1.579

20

314.0

62.832

2.467

25

491.0

78.540

3.855

28

616.0

87.965

4.830

32

804.0

100.531

6.316

40

1257.0

125.664

9.868

50

1963.0

157.080

15.413

BS 4449 or DIN EN 10080-1 Grade 460 (MPa) Deformed Bars

Reinforcing Bar Area for Various Bar Spacings (mm^2/m)

European Metric Bar Size

D10

D12

D14

D16

D20

D25

D28

1047

1507

2053

2680

4187

6547

8213

981

1413

1925

2513

3925

6138

7700

872

1256

1711

2233

3489

5456

6844

785

1130

1540

2010

3140

4910

6160

714

1027

1400

1827

2855

4464

5600

654

942

1283

1675

2617

4092

5133

628

904

1232

1608

2512

3928

4928

604

869

1185

1546

2415

3777

4738

561

807

1100

1436

2243

3507

4400

523

753

1027

1340

2093

3273

4107

491

706

963

1256

1963

3069

3850

449

646

880

1149

1794

2806

3520

436

628

856

1117

1744

2728

3422

393

565

770

1005

1570

2455

3080

357

514

700

914

1427

2232

2800

349

502

684

893

1396

2182

2738

327

471

642

838

1308

2046

2567

314

452

616

804

1256

1964

2464

285

411

560

731

1142

1785

2240

262

377

513

670

1047

1637

2053

D32

10720

10050

8933

8040

7309

6700

6432

6185

5743

5360

5025

4594

4467

4020

3655

3573

3350

3216

2924

2680

D40

16760

15713

13967

12570

11427

10475

10056

9669

8979

8380

7856

7183

6983

6285

5714

5587

5238

5028

4571

4190

D50

26173

24538

21811

19630

17845

16358

15704

15100

14021

13087

12269

11217

10906

9815

8923

8724

8179

7852

7138

6543

You might also like

- REBARS (318-05) (Engineersdaily - Com)Document8 pagesREBARS (318-05) (Engineersdaily - Com)sawahNo ratings yet

- Rebars (318M-05)Document2 pagesRebars (318M-05)Jordy CoolNo ratings yet

- "Rebars" - Reinforcing Bar Development and Splice Lengths: Program DescriptionDocument8 pages"Rebars" - Reinforcing Bar Development and Splice Lengths: Program DescriptionEngr SwapanNo ratings yet

- Rebars (318-05)Document8 pagesRebars (318-05)Sana UllahNo ratings yet

- Base Plate Anchor Bolt DesignDocument8 pagesBase Plate Anchor Bolt DesignVivek AnandanNo ratings yet

- REBARS (318-11).xlsDocument9 pagesREBARS (318-11).xlsmotiur basum100% (1)

- Reinforcing Bar Development and Splice Lengths ACI 318-11Document1 pageReinforcing Bar Development and Splice Lengths ACI 318-11Edgardo ArriesgadoNo ratings yet

- "Baseplt9" - Steel Column Base Plate Analysis: Program DescriptionDocument7 pages"Baseplt9" - Steel Column Base Plate Analysis: Program Descriptionsivasan10006098No ratings yet

- Clip Steel Connection TableDocument10 pagesClip Steel Connection Tableafloresr01No ratings yet

- Brgplt9 - Beam Bearing Plate DesignDocument3 pagesBrgplt9 - Beam Bearing Plate DesignAsdNo ratings yet

- User Guid Supp LV 2 Very PreliminaryDocument21 pagesUser Guid Supp LV 2 Very PreliminaryAhmedMahmoudNo ratings yet

- PSC Design (Aashto-Lrfd Tyu07) TutorialDocument44 pagesPSC Design (Aashto-Lrfd Tyu07) TutorialMohammad Tawfiq WaraNo ratings yet

- SYS Bolt ManualDocument64 pagesSYS Bolt ManualNoppolNorasriNo ratings yet

- American Structural Design CalculationDocument295 pagesAmerican Structural Design CalculationIgnatius Samraj100% (1)

- Dev and Lap Splice Lengths - ETN-D-1-15Document9 pagesDev and Lap Splice Lengths - ETN-D-1-15erleosNo ratings yet

- Copedwbeamseat - Xls (Revision 1.1)Document4 pagesCopedwbeamseat - Xls (Revision 1.1)sergiooiNo ratings yet

- Anchorbolt (318 08)Document28 pagesAnchorbolt (318 08)cklconNo ratings yet

- ACI Detailing ManualDocument9 pagesACI Detailing Manualwinard21No ratings yet

- "Anchor Bolt (318-08) " - Embedment Strength Per ACI 318-08 Appendix DDocument11 pages"Anchor Bolt (318-08) " - Embedment Strength Per ACI 318-08 Appendix DMian M KhurramNo ratings yet

- MECH56Document4 pagesMECH56Rakesh ReddyNo ratings yet

- Anchor ReinforcementDocument6 pagesAnchor Reinforcementmr.KramNo ratings yet

- Modeling and Analysis of Cotter Joint REPORT R20ER055Document21 pagesModeling and Analysis of Cotter Joint REPORT R20ER055Akash AkashNo ratings yet

- Clean Columns Help GuideDocument16 pagesClean Columns Help GuideTon PhichitNo ratings yet

- Clean Columns Calc V4 0Document16 pagesClean Columns Calc V4 0Lyhalim SethNo ratings yet

- Line Stop Welded To Shoe CalculationDocument16 pagesLine Stop Welded To Shoe CalculationmohdnazirNo ratings yet

- Anchor Reinf. AnalysisDocument5 pagesAnchor Reinf. AnalysisRusdha MaulanaNo ratings yet

- Angleflexseat - Xls (Revision 1.2)Document4 pagesAngleflexseat - Xls (Revision 1.2)cataiceNo ratings yet

- Metsec Design GuideDocument86 pagesMetsec Design GuideRm1262No ratings yet

- Is 7906 1 1997Document37 pagesIs 7906 1 1997paragbholeNo ratings yet

- LEARN FLAT SLAB STEP-BY-STEP GUIDEDocument137 pagesLEARN FLAT SLAB STEP-BY-STEP GUIDEWanda BeasleyNo ratings yet

- Brgplt9-Beam Bearing Plate DesignDocument4 pagesBrgplt9-Beam Bearing Plate DesignRafael ReyesNo ratings yet

- PSC Design (EC2) Tutorial PDFDocument49 pagesPSC Design (EC2) Tutorial PDFGeorge LazarNo ratings yet

- Analysis of Steel Column Base PlateDocument2 pagesAnalysis of Steel Column Base PlateElang MengantukNo ratings yet

- STAAD+PRO - NRC Verfication Manual 2005Document154 pagesSTAAD+PRO - NRC Verfication Manual 2005Jose Rojas-GuzmanNo ratings yet

- Foundation Analysis and DesignDocument43 pagesFoundation Analysis and DesignUmed Abd-alsatarNo ratings yet

- Tension Development PDFDocument0 pagesTension Development PDFAjay SinghNo ratings yet

- Importance & Impact of Stress Intensification Factor (SIF) : A PresentationDocument8 pagesImportance & Impact of Stress Intensification Factor (SIF) : A Presentationcasaean100% (1)

- Calculating Length of Reinforcing BarsDocument3 pagesCalculating Length of Reinforcing BarsswarluNo ratings yet

- MB Structural Design Compendium May16Document52 pagesMB Structural Design Compendium May16aldert_path100% (2)

- SmartBeam Composite Cellular Beam DesignDocument97 pagesSmartBeam Composite Cellular Beam Designirne8350% (2)

- Design Example 2-Way SlabDocument41 pagesDesign Example 2-Way SlabjimmydomingojrNo ratings yet

- Two-Way Slab Parking Structures in Canada Multiple Factors Can Affect Service Life and Safety by Hassan Aoude, William D. Cook, and Denis MitchellDocument8 pagesTwo-Way Slab Parking Structures in Canada Multiple Factors Can Affect Service Life and Safety by Hassan Aoude, William D. Cook, and Denis MitchellBJERNo ratings yet

- SmartBeam Composite Castellated Beam DesignDocument2 pagesSmartBeam Composite Castellated Beam Designirne83100% (2)

- Beam FLexureDocument4 pagesBeam FLexureNikitaBhattaraiAcharyaNo ratings yet

- "Baseplt9" - Steel Column Base Plate Analysis: Program DescriptionDocument7 pages"Baseplt9" - Steel Column Base Plate Analysis: Program DescriptionSkiner Alex ClNo ratings yet

- Offcon DNV Zorro SkidDocument7 pagesOffcon DNV Zorro SkidRAMSINGH CHAUHANNo ratings yet

- Pinned CouplingsDocument16 pagesPinned CouplingsNamNo ratings yet

- Adding FEA Results to Piping and Pressure Vessel Designs with FEAToolsDocument58 pagesAdding FEA Results to Piping and Pressure Vessel Designs with FEAToolsJimmy Alexander Avila100% (1)

- Bond, Anchor and ShearDocument15 pagesBond, Anchor and ShearBatepola BacNo ratings yet

- The Effect of Varying Span On Design of Short Span Reinforced Concrete T-Beam Bridge DeckDocument3 pagesThe Effect of Varying Span On Design of Short Span Reinforced Concrete T-Beam Bridge DeckNitinShepurNo ratings yet

- Flanges InfoDocument10 pagesFlanges Infomohd farid abdjalilNo ratings yet

- He So Nen UonDocument7 pagesHe So Nen UonTran Van DaiNo ratings yet

- Company Name: Job InformationDocument6 pagesCompany Name: Job InformationAlvin LeongNo ratings yet

- Estimate The Reinforcement in Shallow FoundationDocument12 pagesEstimate The Reinforcement in Shallow FoundationEmdad Yusuf100% (2)

- Angle Seat Detail AllowableDocument4 pagesAngle Seat Detail AllowablepiziyuNo ratings yet

- Manual of Engineering Drawing: British and International StandardsFrom EverandManual of Engineering Drawing: British and International StandardsRating: 3.5 out of 5 stars3.5/5 (4)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Zidarie finalSLUDocument94 pagesZidarie finalSLUAbu BiduNo ratings yet

- Eula Microsoft Visual StudioDocument3 pagesEula Microsoft Visual StudioqwwerttyyNo ratings yet

- DWG TrueView DWG Convert Conversion ReportDocument1 pageDWG TrueView DWG Convert Conversion ReportCosmin CinciNo ratings yet

- Timesheet DraftDocument2 pagesTimesheet DraftAbu BiduNo ratings yet

- GoBeam081 DemoDocument5 pagesGoBeam081 DemoAbu BiduNo ratings yet

- Service Stress and Limits: Bottom Stress Top Stress Bottom Limit Top LimitDocument1 pageService Stress and Limits: Bottom Stress Top Stress Bottom Limit Top LimitAbu BiduNo ratings yet

- Manufacturer Products Span Vs LoadsDocument1 pageManufacturer Products Span Vs LoadsAbu BiduNo ratings yet

- Tolerances and Jacking Force PDFDocument2 pagesTolerances and Jacking Force PDFAbu BiduNo ratings yet

- Solid Slagraph 4 PDFDocument1 pageSolid Slagraph 4 PDFAbu BiduNo ratings yet

- DWG TrueView DWG Convert Conversion ReportDocument1 pageDWG TrueView DWG Convert Conversion ReportCosmin CinciNo ratings yet

- Tolerances, Material Specification and Supplier Load Vs Span GraphDocument4 pagesTolerances, Material Specification and Supplier Load Vs Span GraphAbu BiduNo ratings yet

- 12.7 7 Wire Strand Proprieties VSLDocument1 page12.7 7 Wire Strand Proprieties VSLAbu BiduNo ratings yet

- S14062 Wire and Strand Brochure - Construction ProductsDocument24 pagesS14062 Wire and Strand Brochure - Construction ProductsMohammed Abdulwajid Siddiqui100% (1)

- ممصست صخسةصضDocument11 pagesممصست صخسةصضAbu BiduNo ratings yet

- Solid Slab Prestressed PDFDocument11 pagesSolid Slab Prestressed PDFAbu BiduNo ratings yet

- GRC Glass Reinforced Cement GuideDocument13 pagesGRC Glass Reinforced Cement GuideAbu BiduNo ratings yet

- Questionnaire: We Kindly Ask Your Opinions To Improve The Product and Service Quality of NeobiotechDocument1 pageQuestionnaire: We Kindly Ask Your Opinions To Improve The Product and Service Quality of NeobiotechAbu BiduNo ratings yet

- Solid Slab PrestressDocument20 pagesSolid Slab PrestressAbu BiduNo ratings yet

- IntroductionDocument7 pagesIntroductionNebojsa IvinNo ratings yet

- 35 Cisterna 10 m3 - Verificacion de Acero en Losas y MurosDocument4 pages35 Cisterna 10 m3 - Verificacion de Acero en Losas y MurosJosé Yordy Alb Ibn HasanNo ratings yet

- Sandwich Panels: SpeedhouseDocument25 pagesSandwich Panels: SpeedhouseAbu BiduNo ratings yet

- Installation, Final & Live Load Deflections: No Holes or Notches IncludedDocument1 pageInstallation, Final & Live Load Deflections: No Holes or Notches IncludedAbu BiduNo ratings yet

- FootingDocument9 pagesFootingAbu BiduNo ratings yet

- Lip ReconstructionDocument22 pagesLip ReconstructionAbu BiduNo ratings yet

- Xsteel 3D BrochureDocument10 pagesXsteel 3D BrochureUigresResNo ratings yet

- Autocad Contract 2019Document2 pagesAutocad Contract 2019Abu BiduNo ratings yet

- SapDocument57 pagesSapJose SmithNo ratings yet

- Substation Model Report V13 R0 SummaryDocument1 pageSubstation Model Report V13 R0 SummaryAbu BiduNo ratings yet

- Bloom Boundary Wall Structural AnalysisDocument9 pagesBloom Boundary Wall Structural AnalysisAbu BiduNo ratings yet

- Java VM Options Guide for Performance & DebuggingDocument1 pageJava VM Options Guide for Performance & DebuggingAdhiatma Arfian FauziNo ratings yet

- Preface Jindal Saw LimitedDocument7 pagesPreface Jindal Saw LimitedSuraj SinghNo ratings yet

- Project: Owner: Location: SubjectDocument4 pagesProject: Owner: Location: SubjectJose C. Lita JrNo ratings yet

- Henderson, Johnson & Wood 2002 Enhancing The Whole Life Structural Performance of Multi-Storey Car ParksDocument50 pagesHenderson, Johnson & Wood 2002 Enhancing The Whole Life Structural Performance of Multi-Storey Car ParksRm1262No ratings yet

- CC Block Pavement EstimateDocument3 pagesCC Block Pavement EstimateTeng MarakNo ratings yet

- Sample Internship ReportDocument34 pagesSample Internship ReportIsaac Okorie zaku89% (9)

- CoreTen Brochure PDFDocument2 pagesCoreTen Brochure PDFRashid MohammedNo ratings yet

- High-Density Polyethylene (PE) Line Pipe: Standard Specification ForDocument13 pagesHigh-Density Polyethylene (PE) Line Pipe: Standard Specification ForAhmad Zubair RasulyNo ratings yet

- Manual Cutting Machine 1Document4 pagesManual Cutting Machine 1H 5895No ratings yet

- Pickling Paste 101Document2 pagesPickling Paste 101George BogdanNo ratings yet

- DENTAL INVESTMENT MATERIALSDocument30 pagesDENTAL INVESTMENT MATERIALSAnnaAffandie100% (1)

- BOQ for Road and Drainage WorksDocument20 pagesBOQ for Road and Drainage WorksVenkatesha Hebbar50% (2)

- Not For Production Use (For Reference Only) : ASTM A778-01Document1 pageNot For Production Use (For Reference Only) : ASTM A778-01Abu Bakr AsharefNo ratings yet

- PCC and Technique UsedDocument13 pagesPCC and Technique UsedashnaNo ratings yet

- Gate Valve For Piping (Api 600, 602, 603) : Key SpecificationsDocument14 pagesGate Valve For Piping (Api 600, 602, 603) : Key Specificationsswapnil PATILNo ratings yet

- M 295 DesDocument5 pagesM 295 DesJuan Daniel Rojas Palma100% (1)

- High-Strength Stainless Steels With "Microduplex" Structure For Cryogenic ApplicationsDocument3 pagesHigh-Strength Stainless Steels With "Microduplex" Structure For Cryogenic ApplicationsakhileshNo ratings yet

- NSCP 2010Document758 pagesNSCP 2010Chelle Sujetado De Guzman95% (21)

- FRDLDocument3 pagesFRDLrameshNo ratings yet

- Instructions For Welding The Cat Advansys™ Adapters On Excavator and Wheel Loader S (0679, 6001, 6800)Document1 pageInstructions For Welding The Cat Advansys™ Adapters On Excavator and Wheel Loader S (0679, 6001, 6800)arfa ujiantoNo ratings yet

- !0 Brass Industries ProductDocument4 pages!0 Brass Industries ProductSmit MungraNo ratings yet

- EXPANSION JOINTS GUIDEDocument24 pagesEXPANSION JOINTS GUIDEHossein DoudiNo ratings yet

- FD-1600 1.5 Hour Dynamic Rated Multi-Blade Fire DamperDocument6 pagesFD-1600 1.5 Hour Dynamic Rated Multi-Blade Fire DampernuqNo ratings yet

- Drainage, Water Supply & InsulationDocument56 pagesDrainage, Water Supply & InsulationRiddhi PatelNo ratings yet

- Passive Block Foundation DrawingDocument1 pagePassive Block Foundation Drawingapi-426990805100% (1)

- MARAFIQ Pipe Specification Rev 1Document17 pagesMARAFIQ Pipe Specification Rev 1jaseelNo ratings yet

- Epoxy ResinDocument17 pagesEpoxy ResinIrfan AliNo ratings yet

- Cementitious Materials For ConcreteDocument6 pagesCementitious Materials For ConcreteAdhil RamsurupNo ratings yet

- Strip Seal Expansion JointDocument13 pagesStrip Seal Expansion JointsmithNo ratings yet

- Aerospace Material SpecificationDocument7 pagesAerospace Material SpecificationdaNo ratings yet

- Weldon1998 RDocument123 pagesWeldon1998 Rklye zkimunNo ratings yet