Professional Documents

Culture Documents

Industrial Steam Steam Flow Deaerator

Uploaded by

hendraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industrial Steam Steam Flow Deaerator

Uploaded by

hendraCopyright:

Available Formats

Steam Flow

Steam Flow Deaerator

Pressurized .005 cc/liter

Pressurized and Atmospheric Deaerators

CONSTANT RECYCLING guarantees deaeration

of all dissolved oxygen in excess of .005 cc/liter

from 0% to 100% of deaerator capacity.

industrialsteam.com

industrialsteam.com

Components and Sizing

Steam Flow Deaerator

Pressurized .005 cc/liter

When to use

100% Makeup

0% condensate

Yes

30% Makeup

70% condensate

Yes

High Pressure

condensate returns

Yes

100% Turndown

Yes

Load Swings

Yes

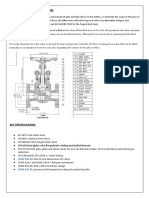

FFEATURES

CONSTANT RECYCLING guarantees deaeration

of all dissolved oxygen in excess of .005 cc/liter from 0% to 100% of

deaerator capacity.

ELECTRONIC INSTRUMENTATION FOR

MODULATING LEVEL

includes a HART compatible differential pressure transmitter, PID controller,

and motorized control valve.

SEPARATE DEAERATING & MIXING SECTIONS offer a two stage

continuous cycle which provides .005 cc/l deaerated water during all load

conditions regardless of surges from the system.

ONLY STAINLESS STEEL

components come in contact with

undeaerated water.

A.S.M.E. CODE and NATIONAL BOARD

stamped receivers at 50 psig is standard.

CUSTOM ENGINEERED PACKAGED

SYSTEM and low NPSH pumps require

a small foot print and minimal headroom.

Testing Requirements

This system requires steady state conditions per the ABMA

testing procedure.

1

2

3

4

5

6

7

Gate Valve (Vent)

Level Transmitter

Level Controller

Make-up Control Valve

Spence Valve

Starter

Discharge Pressure

Gauges w/cock

8 Spray Nozzles

9 Spray Scrubbing Manifold

10 Recycle Pump Motor

11

12

13

14

15

16

17

18

19

20

21

Recycle Pump

Boiler Feed Pump Motor

Boiler Feed Pump

Suction Coupling

Suction Ball Valve

Ball Valve (Column Drain)

Control Panel (Nema 1)

Globe Valve (Make-up Inlet)

Ball Valves (Make-up Inlet)

Y-strainer (Make-up Inlet)

Suction Discharge Coupling

(Recycle)

MAXIMUM

LOAD

MODEL

NUMBER LBS/HR

1SF5-CS

2SF5-CS

3SF5-CS

4SF5-CS

6SF5-CS

8SF5-CS

10SF5-CS

12SF5-CS

15SF5-CS

18SF5-CS

21SF5-CS

24SF5-CS

30SF5-CS

36SF5-CS

45SF5-CS

60SF5-CS

75SF5-CS

90SF5-CS

3,450

6,900

10,350

13,800

20,700

27,600

34,500

41,400

51,750

62,100

72,450

82,800

100,000

125,000

150,000

200,000

250,000

300,000

RECEIVER

SIZE

22

23

24

25

26

27

28

29

30

31

Suction Gate Valve (Recycle)

Safety Valve (Set @ 50#)

Sentinal Relief Valve: (Set @ 50#)

Temperature Gauge w/thermowell

(50 DEGREE - 500 DEGREE F)

Sight Glass Assembly

Orifice Union

Ball Valve (Recirculating)

Check Valve (Recirculating)

Discharge Pressure Gauges

w/cock (Recycle)

Discharge Ball Valve (Recycle)

SYSTEM CAP.

TO OVERFLOW

RECYCLE

PUMP

32

33

34

35

36

37

38

39

40

Discharge Check Valve (Recycle)

Low Water Alarm & Cut-off Switch

High Water Alarm Switch

Emergency By-pass

Ball Valve (Drain)

Y-strainer (Steam Inlet)

Overflow Trap

Chemical Feed Quill

Ball Valve (Column Isolation Valve)

APPROX OVERALL

DIMENSIONS

HP

INCHES

GALS

MIN.

GPM

HEAD

HP

HEIGHT*

APPROX

SHIPPING

WEIGHT **

100

200

300

400

600

800

1,000

1,200

1,500

1,800

2,100

2,400

3,000

3,600

4,500

6,000

7,500

9,000

30 x 72

30 x 84

30 x 120

36 x 120

42 x 120

48 x 120

54 x 120

60 x 120

66 x 120

66 x 144

66 x 168

66 x 192

240

280

380

540

750

1,000

1,300

1,600

2,020

2,420

2,800

3,150

34.3

20

18.1

19.3

17.9

17.9

18.6

19

19.2

19.2

19

18.8

10

20

30

40

50

80

90

100

135

170

185

200

60

60

60

60

60

60

3/4

3/4

1

1 1/2

2

2

90

90

90

96

102

108

60

60

60

66

72

78

1,680

1,760

2,000

2,270

2,970

3,680

3

3

5

5

5

5

114

120

126

126

126

126

72 x 192

72 x 216

84 x 192

84 x 240

96 x 216

96 x 240

3,640

4,120

5,020

6,180

7,300

8,100

17.3

16.3

16.3

15.2

14.5

13.3

275

315

375

500

625

750

60

60

70

70

70

60

60

60

60

60

60

60

7 1/2

7 1/2

10

15

15

20

132

132

144

144

156

156

108

120

156

156

156

157

159

162

164

188

214

238

240

264

245

294

267

297

84

90

96

96

96

96

102

102

114

114

126

126

4,195

4,710

5,240

6,215

6,745

7,480

9,210

9,890

11,820

13,615

13,965

14,865

Consult factory for systems above 300,000#/hr * Overall height includes 48" stand. ** Shipping weight does not include boiler feed pumps or any optional equipment

industrialsteam.com

Components and Sizing

Steam Flow Deaerator

Pressurized .005 cc/liter

When to use

100% Makeup

0% condensate

Yes

30% Makeup

70% condensate

Yes

High Pressure

condensate returns

Yes

100% Turndown

Yes

Load Swings

Yes

FFEATURES

CONSTANT RECYCLING guarantees deaeration

of all dissolved oxygen in excess of .005 cc/liter from 0% to 100% of

deaerator capacity.

ELECTRONIC INSTRUMENTATION FOR

MODULATING LEVEL

includes a HART compatible differential pressure transmitter, PID controller,

and motorized control valve.

SEPARATE DEAERATING & MIXING SECTIONS offer a two stage

continuous cycle which provides .005 cc/l deaerated water during all load

conditions regardless of surges from the system.

ONLY STAINLESS STEEL

components come in contact with

undeaerated water.

A.S.M.E. CODE and NATIONAL BOARD

stamped receivers at 50 psig is standard.

CUSTOM ENGINEERED PACKAGED

SYSTEM and low NPSH pumps require

a small foot print and minimal headroom.

Testing Requirements

This system requires steady state conditions per the ABMA

testing procedure.

1

2

3

4

5

6

7

Gate Valve (Vent)

Level Transmitter

Level Controller

Make-up Control Valve

Spence Valve

Starter

Discharge Pressure

Gauges w/cock

8 Spray Nozzles

9 Spray Scrubbing Manifold

10 Recycle Pump Motor

11

12

13

14

15

16

17

18

19

20

21

Recycle Pump

Boiler Feed Pump Motor

Boiler Feed Pump

Suction Coupling

Suction Ball Valve

Ball Valve (Column Drain)

Control Panel (Nema 1)

Globe Valve (Make-up Inlet)

Ball Valves (Make-up Inlet)

Y-strainer (Make-up Inlet)

Suction Discharge Coupling

(Recycle)

MAXIMUM

LOAD

MODEL

NUMBER LBS/HR

1SF5-CS

2SF5-CS

3SF5-CS

4SF5-CS

6SF5-CS

8SF5-CS

10SF5-CS

12SF5-CS

15SF5-CS

18SF5-CS

21SF5-CS

24SF5-CS

30SF5-CS

36SF5-CS

45SF5-CS

60SF5-CS

75SF5-CS

90SF5-CS

3,450

6,900

10,350

13,800

20,700

27,600

34,500

41,400

51,750

62,100

72,450

82,800

100,000

125,000

150,000

200,000

250,000

300,000

RECEIVER

SIZE

22

23

24

25

26

27

28

29

30

31

Suction Gate Valve (Recycle)

Safety Valve (Set @ 50#)

Sentinal Relief Valve: (Set @ 50#)

Temperature Gauge w/thermowell

(50 DEGREE - 500 DEGREE F)

Sight Glass Assembly

Orifice Union

Ball Valve (Recirculating)

Check Valve (Recirculating)

Discharge Pressure Gauges

w/cock (Recycle)

Discharge Ball Valve (Recycle)

SYSTEM CAP.

TO OVERFLOW

RECYCLE

PUMP

32

33

34

35

36

37

38

39

40

Discharge Check Valve (Recycle)

Low Water Alarm & Cut-off Switch

High Water Alarm Switch

Emergency By-pass

Ball Valve (Drain)

Y-strainer (Steam Inlet)

Overflow Trap

Chemical Feed Quill

Ball Valve (Column Isolation Valve)

APPROX OVERALL

DIMENSIONS

HP

INCHES

GALS

MIN.

GPM

HEAD

HP

HEIGHT*

APPROX

SHIPPING

WEIGHT **

100

200

300

400

600

800

1,000

1,200

1,500

1,800

2,100

2,400

3,000

3,600

4,500

6,000

7,500

9,000

30 x 72

30 x 84

30 x 120

36 x 120

42 x 120

48 x 120

54 x 120

60 x 120

66 x 120

66 x 144

66 x 168

66 x 192

240

280

380

540

750

1,000

1,300

1,600

2,020

2,420

2,800

3,150

34.3

20

18.1

19.3

17.9

17.9

18.6

19

19.2

19.2

19

18.8

10

20

30

40

50

80

90

100

135

170

185

200

60

60

60

60

60

60

3/4

3/4

1

1 1/2

2

2

90

90

90

96

102

108

60

60

60

66

72

78

1,680

1,760

2,000

2,270

2,970

3,680

3

3

5

5

5

5

114

120

126

126

126

126

72 x 192

72 x 216

84 x 192

84 x 240

96 x 216

96 x 240

3,640

4,120

5,020

6,180

7,300

8,100

17.3

16.3

16.3

15.2

14.5

13.3

275

315

375

500

625

750

60

60

70

70

70

60

60

60

60

60

60

60

7 1/2

7 1/2

10

15

15

20

132

132

144

144

156

156

108

120

156

156

156

157

159

162

164

188

214

238

240

264

245

294

267

297

84

90

96

96

96

96

102

102

114

114

126

126

4,195

4,710

5,240

6,215

6,745

7,480

9,210

9,890

11,820

13,615

13,965

14,865

Consult factory for systems above 300,000#/hr * Overall height includes 48" stand. ** Shipping weight does not include boiler feed pumps or any optional equipment

Additional Industrial Products

Tray Type

Pressurized .005 cc/liter

Pressurized Deaerators

Spray Flow I I

.005 cc/Liter Atmospheric

Recycling Deaerators

Jet Spray

.005 cc/Liter Spray Type

Pressurized Deaerators

Blowdown Heat

Recovery Systems,

Blowdown Separators

Have questions or need help specifying this equipment? Email: engineering@industrialsteam.com

Steam Flow

Need help with an existing system or parts? Email: techsupport@industrialsteam.com

.005 cc/Liter Pressurized Deaerator

Looking for a local representative? Email: sales@industrialsteam.com

Literature available for download at industrialsteam.com

Steam Flow Deaerator

Pressurized .005 cc/liter

Pressurized and Atmospheric Deaerators

CONSTANT RECYCLING guarantees deaeration

of all dissolved oxygen in excess of .005 cc/liter

from 0% to 100% of deaerator capacity.

industrialsteam.com

Industrial Steam

Pressurized and Atmospheric Deaerators

1403 SW 7th Street, Atlantic, Iowa 50022

TEL (712) 243-5300 FAX (712) 243-3440

industrialsteam.com

You might also like

- 07 PumpDocument23 pages07 PumpViren ParmarNo ratings yet

- Stanton Premier BoilerDocument28 pagesStanton Premier Boilermyousif63No ratings yet

- Understanding the Concept of AlkalinityDocument12 pagesUnderstanding the Concept of AlkalinityDimas Eko PrasetyoNo ratings yet

- Assignment 1Document4 pagesAssignment 1Ziyad Awali100% (1)

- Stepless Clearance Pocket: Oil & GasDocument4 pagesStepless Clearance Pocket: Oil & Gasshank100No ratings yet

- NG Engineering by Engr DR CIC AnyadiegwuDocument31 pagesNG Engineering by Engr DR CIC Anyadiegwudavidchinedu008No ratings yet

- Cavitation Analysis CFDDocument4 pagesCavitation Analysis CFDshdjjfNo ratings yet

- Pump PrimingDocument1 pagePump PrimingronakuchNo ratings yet

- The Affinity Laws of Centrifugal PumpsDocument8 pagesThe Affinity Laws of Centrifugal PumpsArunkumar SubramanianNo ratings yet

- KMBD BP(国外罗茨泵ROOTS)Document2 pagesKMBD BP(国外罗茨泵ROOTS)tutuli1990No ratings yet

- Steam Jet Refrigeration and Vapour Absorption SystemDocument21 pagesSteam Jet Refrigeration and Vapour Absorption SystemmohitNo ratings yet

- Flowcheck Guide To PumpsDocument3 pagesFlowcheck Guide To PumpsFA AyNo ratings yet

- AgitatingDocument24 pagesAgitatingBánh Cuốn Tôm ThịtNo ratings yet

- Ejector BrochureDocument8 pagesEjector Brochurebabis1980No ratings yet

- Pump & Compressor PositioningDocument32 pagesPump & Compressor PositioningAeffandii SamawiNo ratings yet

- PumpsDocument54 pagesPumpsMark SantosNo ratings yet

- Flash Steam SystemDocument4 pagesFlash Steam SystemAnonymous CX51waINo ratings yet

- The Mathematics of Pumping Water: AECOM Design BuildDocument9 pagesThe Mathematics of Pumping Water: AECOM Design Buildmabrouk2013No ratings yet

- Lecture 2 Petchem 2021 MoodleDocument28 pagesLecture 2 Petchem 2021 MoodleCarlos francisco PerézNo ratings yet

- Globe Valve Bs 1873 and Api 602: ASME B16.10Document7 pagesGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILNo ratings yet

- Venta: Two-Way Pressure Balanced Valve PN 16 (232 Psi)Document5 pagesVenta: Two-Way Pressure Balanced Valve PN 16 (232 Psi)DedeKurniawanNo ratings yet

- Subsonic Ejector RamjetDocument99 pagesSubsonic Ejector Ramjetmarco20874No ratings yet

- Pump Cavitation and NPSHDocument10 pagesPump Cavitation and NPSHshiel175No ratings yet

- Understanding Refrigeration SystemsDocument19 pagesUnderstanding Refrigeration SystemsVinesh TalpankarNo ratings yet

- TURBOMACHINES: Pumps PerformanceDocument35 pagesTURBOMACHINES: Pumps PerformanceBaber H. ElahiNo ratings yet

- Ultradryer HreDocument3 pagesUltradryer HreDiego MorenoNo ratings yet

- Jet Pump Technical Data for Pumping GasesDocument11 pagesJet Pump Technical Data for Pumping GasesIdelia Cutipa Yauri100% (1)

- At AssignmentDocument3 pagesAt AssignmentYogesh PatilNo ratings yet

- Pumps and Cooling TowersDocument51 pagesPumps and Cooling TowersMikho SaligueNo ratings yet

- DIA Glass Lined Reactor PIDDocument1 pageDIA Glass Lined Reactor PIDSandiip JogdankarNo ratings yet

- Tank Calculation Inlet Outlet Flows Capacity FlashpointDocument1 pageTank Calculation Inlet Outlet Flows Capacity FlashpointSagarNo ratings yet

- Heat Exchanger Descaling Chemical Condenser Descalant PDFDocument2 pagesHeat Exchanger Descaling Chemical Condenser Descalant PDFsanjay ukalkarNo ratings yet

- Boiler SystemDocument22 pagesBoiler SystemchaozbudhaNo ratings yet

- Pump MathsDocument10 pagesPump MathsSakib RafeeNo ratings yet

- Process Intensification in Industrial Wastewater Treatment FinalDocument10 pagesProcess Intensification in Industrial Wastewater Treatment FinalSantanu BiswasNo ratings yet

- Mavazwag Agitated Nutsche Filters & Filter DryersDocument4 pagesMavazwag Agitated Nutsche Filters & Filter Dryersdhavalesh1No ratings yet

- 6 Crude Oil RefiningDocument57 pages6 Crude Oil RefiningAkashNo ratings yet

- Distillation Application in PetroleumDocument46 pagesDistillation Application in Petroleumamirthalingam_b671No ratings yet

- ECO-Seal Liquid-Ring Vacuum Pump Needs No Cooling WaterDocument1 pageECO-Seal Liquid-Ring Vacuum Pump Needs No Cooling Watersaa6383No ratings yet

- Application Data: PAC 353 Combustion Management Solutions Furnace (Draft) Pressure Control BenefitsDocument3 pagesApplication Data: PAC 353 Combustion Management Solutions Furnace (Draft) Pressure Control BenefitsmanishjainshahNo ratings yet

- Vapor Absorption Refrigeration SystemsDocument12 pagesVapor Absorption Refrigeration SystemstbijnresdcNo ratings yet

- Dry Vacuum Pump Cobra Busch enDocument2 pagesDry Vacuum Pump Cobra Busch enJessica ChandlerNo ratings yet

- 750-326 Blowdown Separator 11 2015Document10 pages750-326 Blowdown Separator 11 2015osamaNo ratings yet

- Ped IDocument92 pagesPed IPriyank KhirsariyaNo ratings yet

- AgitatorDocument8 pagesAgitatorMugesh KannaNo ratings yet

- Reciprocating PumpDocument20 pagesReciprocating Pumpsonpvms100% (1)

- Mihir's Handbook Chapter 7Document10 pagesMihir's Handbook Chapter 7heyheyNo ratings yet

- Introduction To BoilersDocument22 pagesIntroduction To BoilersaravindsnistNo ratings yet

- Equivalent Length of A Reducer - Google SearchDocument3 pagesEquivalent Length of A Reducer - Google SearchzoksiNo ratings yet

- Gas Compressor AvanceDocument36 pagesGas Compressor AvanceLina VargasNo ratings yet

- Multi-Effect Plate Distiller MEP SeriesDocument4 pagesMulti-Effect Plate Distiller MEP Seriesgochi bestNo ratings yet

- Thermal Conversion ProcessesDocument24 pagesThermal Conversion ProcessesAl JawadNo ratings yet

- Divided Wall Column 496Document6 pagesDivided Wall Column 496GeorgeNo ratings yet

- 13 - Oxygen Removal From Boiler WaterDocument12 pages13 - Oxygen Removal From Boiler Waterarunkumar23101100% (1)

- Plate Hydraulic Design ExampleDocument53 pagesPlate Hydraulic Design ExampleChristopher RileyNo ratings yet

- CECO Environmental Presentaton - Gabelli Q122 Waste Environ. Serv. Symposium - 033122Document28 pagesCECO Environmental Presentaton - Gabelli Q122 Waste Environ. Serv. Symposium - 033122teddyfang21No ratings yet

- Some of The Basics You Need To Understand Centrifugal PumpsDocument16 pagesSome of The Basics You Need To Understand Centrifugal PumpsGauravNo ratings yet

- Funke Quality Heat Exchangers - SmallDocument77 pagesFunke Quality Heat Exchangers - Smallrini mokoagowNo ratings yet

- Industrial Steam Tray ST5 PDFDocument4 pagesIndustrial Steam Tray ST5 PDFKim Swee LimNo ratings yet

- Low Loss Header Tech Data ManualDocument8 pagesLow Loss Header Tech Data ManualBobbyB2No ratings yet

- Table Steam 1Document1 pageTable Steam 1hendraNo ratings yet

- Full Page PhotoDocument1 pageFull Page PhotohendraNo ratings yet

- Thermal Oil Heaters for High TemperaturesDocument10 pagesThermal Oil Heaters for High TemperatureshendraNo ratings yet

- Flange Tables - Compare Common FlangesDocument20 pagesFlange Tables - Compare Common FlangeshendraNo ratings yet

- Overflow ValveDocument1 pageOverflow ValvehendraNo ratings yet

- Oil Circulation Tank 674 GB Register 7Document6 pagesOil Circulation Tank 674 GB Register 7hendraNo ratings yet

- Lesson 9 - Estimating & Comparing Weld Metal CostsDocument1 pageLesson 9 - Estimating & Comparing Weld Metal CostshendraNo ratings yet

- Boiler PDFDocument1 pageBoiler PDFhendraNo ratings yet

- Industrial Steam Steam Flow Deaerator PDFDocument4 pagesIndustrial Steam Steam Flow Deaerator PDFhendraNo ratings yet

- Simboli Cevovod SD230511-17Document1 pageSimboli Cevovod SD230511-17tekijacNo ratings yet

- Klinger Marine Valves & GasketsDocument279 pagesKlinger Marine Valves & GasketsAndy Luthor100% (1)

- Simboli Cevovod SD230511-17Document1 pageSimboli Cevovod SD230511-17tekijacNo ratings yet

- Six simple machines that make work easierDocument4 pagesSix simple machines that make work easierRuel GuiangNo ratings yet

- FM Brake DiagramDocument3 pagesFM Brake DiagramJan KrátkýNo ratings yet

- HC 95Document20 pagesHC 95Kenny Huisa100% (1)

- HHF-1600L Drilling Pump Set Parts ListDocument21 pagesHHF-1600L Drilling Pump Set Parts ListAhmed SaeedNo ratings yet

- Pp29aDocument51 pagesPp29aSara Azam100% (1)

- PT GEMILANG BINA LINTAS TIRTA NEAR MISS REPORTDocument2 pagesPT GEMILANG BINA LINTAS TIRTA NEAR MISS REPORTKurniawan Eko PrasetyoNo ratings yet

- Yanmar 6AYM WET DatasheetDocument2 pagesYanmar 6AYM WET Datasheetafandybaharuddin100% (4)

- SERIES WIRING DIAGRAMDocument22 pagesSERIES WIRING DIAGRAMp_janko100% (1)

- Damper Datasheet: Stack Damper Multiple Stack ControlDocument2 pagesDamper Datasheet: Stack Damper Multiple Stack ControlAjay BaggaNo ratings yet

- DDC Serie 60 06r0970255 6067mk62 Partes ComunesDocument3 pagesDDC Serie 60 06r0970255 6067mk62 Partes ComunesAlexis SanchezNo ratings yet

- Planetary Gear Ratio CalculationsDocument5 pagesPlanetary Gear Ratio CalculationsAnonymous 3HTgMDO100% (1)

- Specifi Cations: Mage Shown Is For Radiator Version and Will Be Different For Heat Exchanger VersionDocument7 pagesSpecifi Cations: Mage Shown Is For Radiator Version and Will Be Different For Heat Exchanger VersionariwibowoNo ratings yet

- BECK USA Electrical ActuatorsDocument56 pagesBECK USA Electrical ActuatorsnprashanNo ratings yet

- PSS 5.2-520 V4A - Parts List - 2020Document9 pagesPSS 5.2-520 V4A - Parts List - 2020Centrifugal SeparatorNo ratings yet

- How Is The Installation of Hvac Systems Done? Write in Steps The Various Methods That Are Followed During The Installation of Hvac SystemsDocument3 pagesHow Is The Installation of Hvac Systems Done? Write in Steps The Various Methods That Are Followed During The Installation of Hvac SystemsSandeep TandukarNo ratings yet

- Accent GS 2014Document45 pagesAccent GS 2014EDUARDO ALMARALES MARTINEZNo ratings yet

- Design and Fabrication of Cam ViceDocument3 pagesDesign and Fabrication of Cam Vicesaravanakumar tNo ratings yet

- Diesel Engine Ajm Atj Avb Avf Awx Repair Manual EngDocument172 pagesDiesel Engine Ajm Atj Avb Avf Awx Repair Manual EngAndsanta 130% (1)

- Fuel Supply Pump Inner Parts PDFDocument2 pagesFuel Supply Pump Inner Parts PDFMilorad ZelenovicNo ratings yet

- 6 Electrical Operation: Using The Schematic DiagramDocument6 pages6 Electrical Operation: Using The Schematic DiagramALEJONo ratings yet

- Porsche 997 Part NumbersDocument492 pagesPorsche 997 Part NumberstmfawzyNo ratings yet

- Flexible Pin Bush CouplingsDocument3 pagesFlexible Pin Bush CouplingsMAYURANDULKARNo ratings yet

- Pressure Relief ValvesDocument6 pagesPressure Relief ValvesShashank Sudhakar PathakNo ratings yet

- Riser Diagram 1 Single Line Diagram 2: General Notes and SpecificationDocument11 pagesRiser Diagram 1 Single Line Diagram 2: General Notes and SpecificationCarlo DoragosNo ratings yet

- TOM Thomas Bevan PDFDocument640 pagesTOM Thomas Bevan PDFDebashishNo ratings yet

- 96-98 Engines SM PDFDocument116 pages96-98 Engines SM PDFThoreNo ratings yet

- Introduction To Gate Valves and Gate Valve TypesDocument16 pagesIntroduction To Gate Valves and Gate Valve TypesVinay Sharma100% (1)

- List Tool Mekanik MRCDocument2 pagesList Tool Mekanik MRCDeny IrawanNo ratings yet

- Codigos de Falla C7Document5 pagesCodigos de Falla C7salvador34188% (17)