Professional Documents

Culture Documents

Weld Component Machine

Uploaded by

Hardiyan Tri Wijayanto0 ratings0% found this document useful (0 votes)

40 views2 pagesits about welding

Original Title

Weld Component machine

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentits about welding

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

40 views2 pagesWeld Component Machine

Uploaded by

Hardiyan Tri Wijayantoits about welding

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

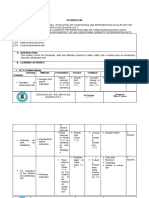

BTW INSTYTUT GAMMA

EDDY CURRENT OF WELDS AND COMPONENT TESTING

BTW Instytut Gamma specializes in advanced Non-Destructive

Testing with their main focus on Eddy Current inspection services and

solutions. Our clients are Oil and Gas companies, Power Generation, Pulp

and Paper, Chemical, Cranes, Bridges and Aerospace industry.

Eddy current testing of welds is the newest industry sector of activity.

ECT for crack inspection can surpass Magnetic Particle Inspection (MPI)

and Dye Penetrant Inspection (DPI) sensitivity with no additional

clean-up required. Rapid inspection can be easily repeated with ECT over

both conductive and nonconductive coating eliminating grinding and

repainting eorts, unlike MT and PT method.

Zetec's MIZ-21B battery operated hand-held equipment with weld scan

probes is very suitable in eld inspections, especially in hard-to-reach or

limited visibility locations. Bad weather conditions like rain, high

humidity, low or very high temperatures are not a problem for such

testing.

Main examples of eddy current testing are:

n Welds also ferromagnetic and non-ferromagnetic materials

n Flaw detection in nuts, bolts, bearings, turbine blades, shafts, etc.

n Austenitic cladding steals on carbon steel in petrochemical reactors

n Padding layer for reclamation and repair purposes

n Seal welds of tubes heat exchangers

n Sorting of metals of dissimilar composition, heat treatment or

microstructures

n Measuring thickness of non-conductive coatings on metals

n Measuring thickness of metallic coatings

n Evaluating of heat treatment and the chemical action results on

metal components

n Conductivity measurement, hardness

BIURO TECHNICZNO WDROENIOWE "INSTYTUT GAMMA" Sp. z o.o. n 05-400 OTWOCK, WIERK bud. 47, PO Box 1, POLAND

BTW INSTYTUT GAMMA

EDDY CURRENT OF WELDS AND COMPONENT TESTING

Instytut Gamma qualified engineers and technicians perform

maintenance and inspection services.

n Engineers with competence in maintenance analysis and planning,

inspection planning, damage evaluation, material technology and

risk based inspection.

n NDT senior inspectors on level 2 and 3 in accordance with

EN-473/PCN-BIND certification system an EN-4179 for Aerospace

sector.

n Welding inspectors in accordance with European Welding

Federation requirements and EN-719 standard.

Instytut Gamma performs eddy current testing services for the

aerospace industry. All engineers are high qualified personnel according

to EN-4179 standard and have PCN level II qualifications as a minimum.

Our inspection services are available to be performed at the customer

site or in our Laboratory facilities.

When it is necessary to inspect components for cracking in surface

defects such as fatigue, it is the norm to consider PT or/and MT method.

Unfortunately to successfully apply these techniques it is necessary to

remove the protective coatings and prepare the surface of the

component by grit blasting or needle gunning. This preparation &

subsequent reinstatement of the coating system constitutes most of the

cost of the inspection.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Ashrae Cooling and Heating Load Calculation ManualDocument2 pagesAshrae Cooling and Heating Load Calculation ManualTorus Engenharia0% (1)

- Maintenance Manual: Models 8300, 8400, and 8500 Pallet Trucks and Model 8600 Tow TractorDocument291 pagesMaintenance Manual: Models 8300, 8400, and 8500 Pallet Trucks and Model 8600 Tow TractorJosé Luis Ang Soto92% (13)

- Cleaning Companies in UaeDocument5 pagesCleaning Companies in UaeurgentincleaningseoNo ratings yet

- AST F2033 Hip JointDocument5 pagesAST F2033 Hip Jointdeepdreamx6400No ratings yet

- BTech Seminar on MICROPILES: ADVANCED FOUNDATION ENGINEERINGDocument17 pagesBTech Seminar on MICROPILES: ADVANCED FOUNDATION ENGINEERINGTrudeep DaveNo ratings yet

- Oscillation SDocument485 pagesOscillation SSabir Ali100% (1)

- BBU - Maintenance User GuideDocument578 pagesBBU - Maintenance User GuideSibte Hassan100% (2)

- Jis PDFDocument145 pagesJis PDFtoepal67% (6)

- 17542731211226772Document17 pages17542731211226772Hardiyan Tri WijayantoNo ratings yet

- Women Entrepreneurs From IndiaDocument22 pagesWomen Entrepreneurs From Indiamaverik_machNo ratings yet

- Jurnal Internasional PDFDocument16 pagesJurnal Internasional PDFHardiyan Tri WijayantoNo ratings yet

- Jihad Vs Mcworld AbstractDocument26 pagesJihad Vs Mcworld Abstractvalentin18No ratings yet

- Instytut Gamma: Eddy Current of Welds and Component TestingDocument2 pagesInstytut Gamma: Eddy Current of Welds and Component TestingHardiyan Tri WijayantoNo ratings yet

- Industrie Papierfabrik Hainsberg Freital HP EnglischDocument2 pagesIndustrie Papierfabrik Hainsberg Freital HP EnglischHardiyan Tri WijayantoNo ratings yet

- Cylinder Head Valve Guide and Seat Inspection and RepairDocument1 pageCylinder Head Valve Guide and Seat Inspection and Repairnetifig352No ratings yet

- Pitch Error BacklachDocument12 pagesPitch Error BacklachmcspvNo ratings yet

- Bassett-jones-The Paradox of DiversityDocument8 pagesBassett-jones-The Paradox of DiversityKenneth WhitfieldNo ratings yet

- MFXi MPMi User Guide 02122010 DraggedDocument1 pageMFXi MPMi User Guide 02122010 DraggedDani BalanNo ratings yet

- Slice 3 Choice BoardDocument3 pagesSlice 3 Choice Boardapi-463991923No ratings yet

- Data Book: Automotive TechnicalDocument1 pageData Book: Automotive Technicallucian07No ratings yet

- Biodegradabilty Prediction Using Deep LearningDocument9 pagesBiodegradabilty Prediction Using Deep LearningMadhuri DNo ratings yet

- Broadcast Servers for all WorkflowsDocument2 pagesBroadcast Servers for all WorkflowsJosé FélixNo ratings yet

- 23 - Eave StrutsDocument2 pages23 - Eave StrutsTuanQuachNo ratings yet

- Document 1Document14 pagesDocument 1Lê Quyên VõNo ratings yet

- Virial Equation of State2Document46 pagesVirial Equation of State2ShainaBagonNo ratings yet

- Bill of Materials for Gate ValveDocument6 pagesBill of Materials for Gate Valveflasher_for_nokiaNo ratings yet

- Masterseal Plus CatalogueDocument8 pagesMasterseal Plus CataloguePeter ManNo ratings yet

- Marlin Ch14 PDFDocument26 pagesMarlin Ch14 PDFAlyaNo ratings yet

- Bhatia CPD 20001Document1 pageBhatia CPD 20001bilalaimsNo ratings yet

- Business Functional Areas Functions ProcessesDocument4 pagesBusiness Functional Areas Functions ProcessesDan MaliwatNo ratings yet

- Session Plan (Julaps)Document10 pagesSession Plan (Julaps)Wiljhon Espinola JulapongNo ratings yet

- General CRT tester notesDocument64 pagesGeneral CRT tester notesImran AliNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentNajaf BatoolNo ratings yet

- M.tech Lab Manual JNTUHDocument80 pagesM.tech Lab Manual JNTUHSivarama Prasad PamarthyNo ratings yet

- 4 V2 2250 PR Pid 000001 - 1 - PDFDocument1 page4 V2 2250 PR Pid 000001 - 1 - PDFdavidNo ratings yet

- Analyzing Kernel Crash On Red HatDocument9 pagesAnalyzing Kernel Crash On Red Hatalexms10No ratings yet

- Introduction To Data Analytics - AnnouncementsDocument16 pagesIntroduction To Data Analytics - AnnouncementsAmit GuptaNo ratings yet