Professional Documents

Culture Documents

Isolating Joint General Data Sheet

Uploaded by

Gerardo GonzálezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Isolating Joint General Data Sheet

Uploaded by

Gerardo GonzálezCopyright:

Available Formats

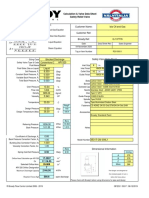

ISOLATING JOINT GENERAL DATA SHEET

ADDITIONAL DESIGN DETAIL

TS

Si

OR

TL

ALLOWABLE LOADS

W3

S2-12%

A 0.5%

DFT2

B 1%

+15%

DFT1

+15%

W1

Identification Lable

S1-12%

Detail 1

W2

50

50

D 1%

C

Standard Total Design Load 50 % Pipe SMYS

(Special Total Design Load 75 % Pipe SMYS)

(Special Total Design Load 90 % Pipe SMYS)

(Special Total Design Load 95 % Pipe SMYS)

50

DESCRIPTION

ITEM

INSTALLATION

HYDROSTATIC TEST

DIELECTRIC TEST

ELECTRIC INSULATION TEST

NDE TEST

WELDS

CERTIFICATION

INSULATING JOINTS, Monolithic Type

ASME B 31.3 - ASME B 31.4 - ASME B 31.8 - ASME VIII Div.I Appx. 2

6 to 1034,5

Standard Application 0 to 90 - Special Application -173 to 180C

150 to 2500 "ANSI/ASA" - 3000 to 15000 "API"

BUTT WELDED - API 5L / B16.25 / B16.5 / MSS SP75

Standard Application 0.5 (Special Project Requirements 0.2 to 0.72 )

15 to 3000 / 1/2" to 120"

2.7 to 152.4 / 0.154" to 6"

150 to 12000 (OVER 3000 INSULATION JOINT + EXTENSION PIPE )

"T" PIPELINE ( ISO3183 - API 5L

All Grade + low Alloy & Alloy Steel

)

ASTM / ASME / UNS / EN Materials

"S-L-G" BODY PARTS

NEMA G10

ASTM

D709D 2000 FPM

"F" ISOLATING ELEMENTS

Double

O-Ring

ASTM

(Viton)

"OR" GASKET

Silicon Neutral Low Module

"Si" BACK SEAL

Epoxy Resin Cold Cured

"R" FILLER ISOLATOR

EN 10025 235JR (Carbon Steel)

"P" CABLE LUGS M10

Amine Cure Epoxy Resin 200500

"DFT1" INTERNAL COATING

microns

Amine Cure Epoxy Resin 200500

"DFT2" EXTERNAL COATING

microns

ABOVEGROUND / UNDERGROUND/SUBSEA

1.5 Times the Design Pressure ( Or as per Customer Requirements )

1.5 to 5 KV @ 1 minute AC 5060 Hz (Special 20 KV @ 1 minute AC

5060 Hz)

> 200 M @ 1000 Volt DC ( Special > 100 G @ 5000 Volt DC )

W1-W2-W3:

MT & UT, Bevel Ends MT - According to ASME V

W1-W2-W3:

According To ASME IX - API 1104

EN 10204 - 3.1 ( EN 10204 - 3.2 if request )

INSPECTION & TEST/ACCEPTANCE

Manufacturer Standard / Customer Applicable Requirements

TYPE

DESIGN CODE

DESIGN PRESSURE (BarG)

DESIGN TEMPERATURE (C)

RATING (ASME/ANSI #) Class

ENDS "BW"

DESIGN FACTOR

CONNECTION PIPE DN "D" (mm/in.)

CONNECTION PIPE THK "t" (mm/in.)

JOINT OVERALL LENGTH

"OL"(mm)

MATERIAL

SOUR SERVICE

CORROSION ALLOWANCE

SERVICE

PIPING CLASSE

QUANTITY

NOTES :

NOTES

1, 4

2, 3

2, 3

2

2

5

5

6

1, 2

1, 5

YES

NO

As per Customer Requirements

Gas, Hydrocarbons, Oil, Chemical Fluids, Water,Toxic, ETC

As per Customer Requirements

As per Customer Requirements

1)

A Length of 50 mm at each end shall be left uncoated to allow welding

2)

All pressure containing materials including steel parts, insulating materials, seal gaskets and internal coating are suitable for resistance to H2S environments.

3)

All pressure containing steel parts shall be in strict accordance with NACE MR-0175/ISO 15156 (latest edition).

4)

This information is approximate. The exact value shall be checked and specified during the PO Stage

5)

Material not in contact to the fluid

6)

Cables Lugs will be installed on Isolating Joint only if request from Cathodic Protection Requirements.

You might also like

- Design Data Sheet: Insulating JointsDocument1 pageDesign Data Sheet: Insulating Jointsibra benaNo ratings yet

- Datasheet Anchor FlangeDocument1 pageDatasheet Anchor FlangeHafiz Ashadi100% (1)

- Steel Pipe Design Calculation For SeamlessDocument4 pagesSteel Pipe Design Calculation For SeamlessA SubinNo ratings yet

- B-7-005 MR Induction Bends Rev A1Document19 pagesB-7-005 MR Induction Bends Rev A1Advis100% (3)

- Bolt Tightening Procedure GuideDocument6 pagesBolt Tightening Procedure Guideal arabiNo ratings yet

- Data Sheet For Barred Tee 010719 PDFDocument1 pageData Sheet For Barred Tee 010719 PDFkandraNo ratings yet

- L&T GateGlobe&CheckValves-API 600Document31 pagesL&T GateGlobe&CheckValves-API 600vsvineesh100% (1)

- Sizing CalcDocument1 pageSizing CalcHilary AbaratuNo ratings yet

- QuillsDocument4 pagesQuillsajostosNo ratings yet

- External Coatings For Corrosion Protection of Steel Pipes and ComponentsDocument120 pagesExternal Coatings For Corrosion Protection of Steel Pipes and ComponentsadelNo ratings yet

- Oil & Gas Pipeline Design, Maintenance & Repairs CourseDocument27 pagesOil & Gas Pipeline Design, Maintenance & Repairs CourseernmrajaNo ratings yet

- 6.1 Data Sheet For Pipeline Ball ValveDocument3 pages6.1 Data Sheet For Pipeline Ball ValveDeepak PalNo ratings yet

- Anchor FlangeDocument2 pagesAnchor Flangeannu300100% (1)

- SP Item DatasheetsDocument21 pagesSP Item DatasheetsSELVAMANINo ratings yet

- Data Sheet - Pipeline Induction Bend: Category Sl. Attribute ValueDocument2 pagesData Sheet - Pipeline Induction Bend: Category Sl. Attribute ValueYusri FakhrizalNo ratings yet

- Wall Theo PDFDocument23 pagesWall Theo PDFFranklin UkaohaNo ratings yet

- Process & Piping Design Section Plug Valves Technical SpecificationDocument14 pagesProcess & Piping Design Section Plug Valves Technical Specificationashish.mathur1100% (1)

- Bs en Iso 15848 2pdf Ebook and ManualDocument1 pageBs en Iso 15848 2pdf Ebook and Manualyulianus_srNo ratings yet

- Monolithic Insulated Joint BrochureDocument8 pagesMonolithic Insulated Joint Brochuremarita_msNo ratings yet

- Piping Material Specification - Tsmto 99fu M 99 Pt0 001 Rev0!3!65Document64 pagesPiping Material Specification - Tsmto 99fu M 99 Pt0 001 Rev0!3!65epbamdad100% (1)

- Valve Material ApplicationDocument16 pagesValve Material Applicationswapneel_kulkarniNo ratings yet

- Pipeline Wall Thickness Calculation: 3.2 Calculated Using SCH WT W/o CorrosionDocument2 pagesPipeline Wall Thickness Calculation: 3.2 Calculated Using SCH WT W/o CorrosionImmanuel SNo ratings yet

- Pipeline Anchor Length Calculation PDFDocument3 pagesPipeline Anchor Length Calculation PDFAlvin SmithNo ratings yet

- Data Sheet For Barred Tee 010719Document1 pageData Sheet For Barred Tee 010719Heru Agung SetyantoNo ratings yet

- Piping Design Requirements PDFDocument6 pagesPiping Design Requirements PDFkarunaNo ratings yet

- Hdpe Pipe Wall Thickness CalculationsDocument1 pageHdpe Pipe Wall Thickness CalculationsTsouki TsoukiNo ratings yet

- Comparision of Piping CodeDocument14 pagesComparision of Piping CodeAnonymous J1vjrU2No ratings yet

- Ac 036630 001Document1 pageAc 036630 001navaronefraNo ratings yet

- Data Sheet - Pipeline Barred Tee: Category Sl. Attribute ValueDocument2 pagesData Sheet - Pipeline Barred Tee: Category Sl. Attribute ValueYusri Fakhrizal100% (1)

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocument8 pages8 AS4041 ASME B31 3 Pipe Wall ThicknessĐinh Thiện SỹNo ratings yet

- Pipe Wall Thickness Sample CalculationDocument1 pagePipe Wall Thickness Sample CalculationjkahamedNo ratings yet

- Piping Support Design ManualDocument4 pagesPiping Support Design ManualxkokarcaxNo ratings yet

- Standard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Document31 pagesStandard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Agniva DuttaNo ratings yet

- VMS PaliDocument61 pagesVMS Palichintan100% (2)

- Wall Thickness CalDocument6 pagesWall Thickness CalNorazlan Shah MahadiNo ratings yet

- Flange Pipe Support for 4-36Document1 pageFlange Pipe Support for 4-36indeskeyNo ratings yet

- Specification For Piping Stress Analysis - REFERENCIA CRITERIODocument18 pagesSpecification For Piping Stress Analysis - REFERENCIA CRITERIOYana ParravanoNo ratings yet

- Jet A1 Fuel Piping SpecificationDocument17 pagesJet A1 Fuel Piping Specificationadel rihana100% (1)

- Ball Valves: Sharma MVSRK 15 October 2013Document49 pagesBall Valves: Sharma MVSRK 15 October 2013Jay Ganta100% (2)

- Piping Stress Critical Lines - Basis For Piping Critical Line List PDFDocument3 pagesPiping Stress Critical Lines - Basis For Piping Critical Line List PDFanup15balagarhNo ratings yet

- Secondary Pipe Support Devices: Secondary Pipe Support DevicesDocument34 pagesSecondary Pipe Support Devices: Secondary Pipe Support DeviceszebmechNo ratings yet

- Barred Tee DatasheetDocument3 pagesBarred Tee DatasheetBiginch67% (3)

- Pipe Wall Thickness Calculation Methods ASME B31.1 vs B31.3Document8 pagesPipe Wall Thickness Calculation Methods ASME B31.1 vs B31.3Ton PhichitNo ratings yet

- SE Sumatra Gas Project Feed Shop Pipe Bend SpecDocument12 pagesSE Sumatra Gas Project Feed Shop Pipe Bend SpecRokan PipelineNo ratings yet

- Piping Module - 3, ASME B31.3Document2 pagesPiping Module - 3, ASME B31.3RAGHVENDRA PRATAP SINGHNo ratings yet

- SPE 76-002 (2006) Flange MaterialsDocument6 pagesSPE 76-002 (2006) Flange Materials김창배No ratings yet

- Flange Leakage Checking in Caesar II Using ASME Section VIII MethodDocument6 pagesFlange Leakage Checking in Caesar II Using ASME Section VIII Methodwisesa100% (1)

- 02 Samss 012 PDFDocument10 pages02 Samss 012 PDFnadeem shaikhNo ratings yet

- UTL G GS-8 Rev10 Piping MaterialsDocument253 pagesUTL G GS-8 Rev10 Piping Materialsmasoud132No ratings yet

- Design Criteria For Gaseous Oxygen Piping Systems 3PI60001: Ngineering TandardDocument43 pagesDesign Criteria For Gaseous Oxygen Piping Systems 3PI60001: Ngineering TandardKom NakNo ratings yet

- Special Piping Materials Brochure PDFDocument9 pagesSpecial Piping Materials Brochure PDFshankarmech04@gmail.comNo ratings yet

- Increase Allowable Stress CodeDocument9 pagesIncrease Allowable Stress Codewenny_tpdNo ratings yet

- Piping Code ComparisonDocument5 pagesPiping Code ComparisonAndy Hakim83% (6)

- Data Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 CompressorDocument4 pagesData Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 Compressortutuli1990No ratings yet

- 2 and 3 Genesis Series PD Meter SpecificationsDocument6 pages2 and 3 Genesis Series PD Meter Specificationsjimbo2032No ratings yet

- WPS MS 01C Rev. 0Document1 pageWPS MS 01C Rev. 0alinor_tnNo ratings yet

- Piping Code ComparisonDocument7 pagesPiping Code ComparisonRenjith GopanNo ratings yet

- Transmitter SML 10Document2 pagesTransmitter SML 10alamsyah_syamNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Natural Gas Distribution SystemDocument20 pagesNatural Gas Distribution SystemGerardo GonzálezNo ratings yet

- K-Tron Premier Rep Catalog Dec 2010 PDFDocument429 pagesK-Tron Premier Rep Catalog Dec 2010 PDFGerardo González33% (3)

- Gas ChromatographyDocument14 pagesGas Chromatographymoo_hokNo ratings yet

- Arrancadores NEMA PDFDocument12 pagesArrancadores NEMA PDFGerardo GonzálezNo ratings yet

- Energy-Efficient Vacuum SystemsDocument11 pagesEnergy-Efficient Vacuum SystemsAhmed SeliemNo ratings yet

- Publications Ventilation GuidelineDocument29 pagesPublications Ventilation GuidelineRatkoA13No ratings yet

- Module4 Plastictheory Rajeshsir 140806043958 Phpapp01 PDFDocument69 pagesModule4 Plastictheory Rajeshsir 140806043958 Phpapp01 PDFEmily ShumNo ratings yet

- EXPERIMENT 1.0: Factors Affecting Rate in A Chemical ReactionDocument2 pagesEXPERIMENT 1.0: Factors Affecting Rate in A Chemical ReactionElla NanaNo ratings yet

- The Technology of Tail Gases Purifying in Nitric ADocument27 pagesThe Technology of Tail Gases Purifying in Nitric AbalayogeshNo ratings yet

- Corr21334a Sds Usa (GHS) EnglishDocument10 pagesCorr21334a Sds Usa (GHS) EnglishJosé Eduardo Narváez CampechanoNo ratings yet

- Chemistry IGCSE NotesDocument38 pagesChemistry IGCSE NotesRaneem94% (16)

- Prelog-Djerassi LactoneDocument4 pagesPrelog-Djerassi Lactonealchemist90No ratings yet

- Potentiometry JournalDocument10 pagesPotentiometry JournalDian MustikasariNo ratings yet

- Boyle's Law ExperimentDocument9 pagesBoyle's Law Experimentحسين كاظم ياسينNo ratings yet

- Rhenoslab Tac50 MSDSDocument2 pagesRhenoslab Tac50 MSDSNisa SutopoNo ratings yet

- 1NH16CV129Document66 pages1NH16CV129Sumit Bhavsar100% (1)

- Synthesis and Characterization of Carbazole DerivativeDocument7 pagesSynthesis and Characterization of Carbazole DerivativeDavid MoralesNo ratings yet

- ASTM Volume 15.01, March 2019 Refractories, Activated Carbon Advanced CeramicsDocument4 pagesASTM Volume 15.01, March 2019 Refractories, Activated Carbon Advanced CeramicsMoulham ShahinNo ratings yet

- Sizing and Selecting Pressure Relief ValvesDocument70 pagesSizing and Selecting Pressure Relief ValvesSagar Naduvinamani100% (1)

- Interfacial Phenomena in Pharmaceutical FormulationDocument21 pagesInterfacial Phenomena in Pharmaceutical FormulationNickson DrabeNo ratings yet

- X-Ray Diffraction and The Bragg EquationDocument3 pagesX-Ray Diffraction and The Bragg EquationJorge Andres Hernandez GaleanoNo ratings yet

- Combined oxidative leaching and electrowinning for mercury recoveryDocument5 pagesCombined oxidative leaching and electrowinning for mercury recoveryJuan CachayaNo ratings yet

- Chemical Safety Following The Globally Harmonized System (GHS)Document6 pagesChemical Safety Following The Globally Harmonized System (GHS)Hazel Sanne CachaperoNo ratings yet

- (CC1) LAB-W14-Carbohydrates (Diagnosis)Document3 pages(CC1) LAB-W14-Carbohydrates (Diagnosis)Aira UsiNo ratings yet

- CAMPUS® Datasheet: Akulon® F223-D - PA6 DSM Engineering MaterialsDocument7 pagesCAMPUS® Datasheet: Akulon® F223-D - PA6 DSM Engineering MaterialsAgoenk KertawijayaNo ratings yet

- High strength epoxy resin grout for heavy duty applicationsDocument4 pagesHigh strength epoxy resin grout for heavy duty applicationsHamkarNo ratings yet

- DAN169Document8 pagesDAN169BorjaNo ratings yet

- Introduction To Vacuum GaugesDocument11 pagesIntroduction To Vacuum GaugesNouroz BalochNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument11 pagesSafety Data Sheet: 1. Product and Company IdentificationAdelaida CruzNo ratings yet

- Evaluation of Concrete Structures Affected by Alkali-Silica ReactionDocument59 pagesEvaluation of Concrete Structures Affected by Alkali-Silica ReactionCarlos Augusto Sánchez RondónNo ratings yet

- Toolox 44 DatenblattDocument4 pagesToolox 44 DatenblattJosevi Jiménez MerinoNo ratings yet

- Selective Biomass Photoreforming For Valuable Chemicals and Fuels - A Critical ReviewDocument13 pagesSelective Biomass Photoreforming For Valuable Chemicals and Fuels - A Critical ReviewNguyễn Hoàng TuấnNo ratings yet

- Iit Jam Physics 2008Document5 pagesIit Jam Physics 2008s_adhyaNo ratings yet

- Cartridge MsdsDocument9 pagesCartridge MsdseserNo ratings yet

- BREECH LOCK Presentation Dec2004 Tcm24 226146Document24 pagesBREECH LOCK Presentation Dec2004 Tcm24 226146Harinarayanan Samsari Kizhake VeetilNo ratings yet

- Heat Transfer Through Composite Wall: Iii Sem/Basic Mechanical Engineering/Dr.R.Sudhakaran 1/3Document32 pagesHeat Transfer Through Composite Wall: Iii Sem/Basic Mechanical Engineering/Dr.R.Sudhakaran 1/3Narayanan SubramanianNo ratings yet