Professional Documents

Culture Documents

Wellhead Plug Catcher (WPC)

Uploaded by

Wade DavisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wellhead Plug Catcher (WPC)

Uploaded by

Wade DavisCopyright:

Available Formats

www.hunting-intl.

com/well-testing

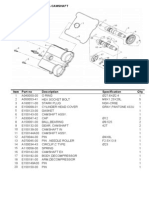

Wellhead Plug Catcher

Well Testing

Features

Catcher line with internal perforated pipe

By-pass line

Optional drain line for debris removal

In-line perforated pipes in various sizes

Benefits

Prevents damage and plugging of the downstream equipment

Allows collection, inspection and measurement of larger well debris

The Plug / Junk Catcher is designed to remove larger pieces of

well debris from the well effluent during operations such as frac

flowback, sand consolidation testing and completion clean-up

after perforating or drilling out a bridge plug.

It is positioned upstream of the wellhead sand separator or choke

manifold to avoid damage and plugging of the downstream process.

The Hunting Plug Catcher consists of a horizontal mounted manifold

with a catcher chamber with an internal perforated pipe to collect debris

and a by pass line to allow the screen to be isolated, de-pressurised

and the debris to be collected and measured as required.

The perforating pipe is available in several sizes depending on the type

of well debris to be removed.

The drain feature allows debris such as frac balls to be removed

without removing the perforated pipe.

Hunting plug catchers are available in a range of sizes, working

pressures and configurations and can be customized to the clients

requirements including dual catcher line designs to allow continuous

debris removal and various sizes of perforated pipes.

Hunting Energy Services / v4.0

well.testing@hunting-intl.com

www.hunting-intl.com/well-testing

Wellhead Plug Catcher

Well Testing

Wellhead Plug Catcher / Specifications

Model

WPC 5-1/8 5K

WPC 3-1/16 10K

WPC 4-1/16 15K

Service

H2S

H2S

H2S

Fluid Class

DD

DD

DD

Working Pressure psi [bar]

5,000 [345]

10,000 [690]

15,000 [1035]

Working Temperature C [F]

-29 [0] up to 180 [350]

-29 [0] up to 180 [350]

-29 [0] up to 180 [350]

Filter Sizes [mu]

As per customer requirement

As per customer requirement

As per customer requirement

Gas, Mmscf [m / day]

25 [750.000]

50 [1.500.000]

75 [2.250.000]

Oil, bbls /day

5000

5000

5000

Gas / Oil Inlet

API Flange 5-1/8 5K

API Flange 3-1/16 10K

API Flange 4-1/16 15K

Gas / Oil Outlet

API Flange 5-1/8 5K

API Flange 3-1/16 10K

API Flange 4-1/16 15K

(1)

Flow Capacity

(2)

Standard Connections

Drain

API Flange 2-1/16 5K

API Flange 2-1/16 5K

API Flange 2-1/16 5K

Operational Footprint, LxB cm

400 x200 Sizes can be customized

400 x200 Sizes can be customized

526 x 200 Sizes can be customized

Transport Size, LxBxH cm

400 x 200 x 150

Sizes can be customized

400 x 200 x 150

Sizes can be customized

526 x 200 x 150

Sizes can be customized

Weight, kg [lbm]

5000 [11,023]

6000 [13,227]

7000 [15,432]

Design

DVR

DVR

DVR

Certifications

Manufacturing

Declaration of Conformity

Declaration of Conformity

Declaration of Conformity

Documentation

Quality File

Quality File

Quality File

Applicable Codes

PED 97/23/EC

PED 97/23/EC

PED 97/23/EC

ASME B31.3

ASME B31.3

ASME B31.3

API 6A

API 6A

API 6A

NACE MR 01-75 (ISO 15156-1,-2)

NACE MR 01-75 (ISO 15156-1,-2)

NACE MR 01-75 (ISO 15156-1,-2)

Optional DNV 2.7-1

Optional DNV 2.7-1

Optional DNV 2.7-1

(1) Flow capacity is depending on many factors. Please contact Hunting for advice.

(2) Connections cross-overs can be added as per customer requirements.

Hunting Energy Services / v4.0

well.testing@hunting-intl.com

You might also like

- Flowback Audit: Sample Oil CompanyDocument11 pagesFlowback Audit: Sample Oil CompanyWade Davis0% (1)

- Drilling Rig AuditDocument19 pagesDrilling Rig AuditWade Davis100% (5)

- Sample Valve Material CertificatesDocument18 pagesSample Valve Material CertificatesFLOW VALVE AUTOMATION100% (2)

- NA OG: Cable Reheading Made Simple (After GOI)Document4 pagesNA OG: Cable Reheading Made Simple (After GOI)RoyNo ratings yet

- Drilling Fluids, Drill String, CirculatingDocument10 pagesDrilling Fluids, Drill String, CirculatingBianca Quiroga AndiaNo ratings yet

- P&ID of CCPDocument74 pagesP&ID of CCPNguyễnTrường80% (10)

- Ash Handling Piping Systems: Chapter C14Document28 pagesAsh Handling Piping Systems: Chapter C14abhilash nairNo ratings yet

- Floating EquipmentDocument9 pagesFloating Equipmentkaveh-bahiraeeNo ratings yet

- Ring Type Joint Gaskets Styles: R, RX, BXDocument2 pagesRing Type Joint Gaskets Styles: R, RX, BXiswantmachooNo ratings yet

- QBH Ram Bop'S: 4-1/16" 15,000 Psi WPDocument32 pagesQBH Ram Bop'S: 4-1/16" 15,000 Psi WPjuan olarte0% (1)

- Tc1350 Drilling ChokeDocument26 pagesTc1350 Drilling ChokeazeazeazeNo ratings yet

- Powerchokes: Standard Choke SCB All-Purpose Severe ServiceDocument2 pagesPowerchokes: Standard Choke SCB All-Purpose Severe ServiceZeeshan KhanNo ratings yet

- 1057-GOAL-L-DB-1001 - Rev C - Piping Design Basis PDFDocument38 pages1057-GOAL-L-DB-1001 - Rev C - Piping Design Basis PDFermusat100% (1)

- Surge Anticipation ValveDocument4 pagesSurge Anticipation ValveMathiTwadCNo ratings yet

- Strata RCDDocument2 pagesStrata RCDDavid VilchesNo ratings yet

- Well Stimulation VesselsDocument2 pagesWell Stimulation VesselsOscar RamirezNo ratings yet

- Valve Procurement SpecsDocument39 pagesValve Procurement Specsjoseph.maquez24100% (2)

- 26 Mill-EZ Composite Bridge PlugDocument2 pages26 Mill-EZ Composite Bridge PlugzbhdzpNo ratings yet

- D&L Double Grip Pkr-Asi-Xpacker1c PDFDocument2 pagesD&L Double Grip Pkr-Asi-Xpacker1c PDFMoh Syamsul BahriNo ratings yet

- Burn BodyDocument32 pagesBurn BodyMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Cable Ladder AccessoriesDocument5 pagesCable Ladder AccessoriesbenNo ratings yet

- MSS SP-125-2018Document18 pagesMSS SP-125-2018david fernando almeyda gamboaNo ratings yet

- What Is Piping MTO or Material Take-OffDocument4 pagesWhat Is Piping MTO or Material Take-Offvenkatraju.Y100% (1)

- TITO B0P DimensionDocument13 pagesTITO B0P DimensionHeris SitompulNo ratings yet

- Installation & Routine Maintenance Manual: FOR Type: 3" Mud Gate Valve (Model I)Document8 pagesInstallation & Routine Maintenance Manual: FOR Type: 3" Mud Gate Valve (Model I)Sergio Fabian VasicekNo ratings yet

- 30 - WELL CONTROL DATA SHEET For DRILLER'S METHODDocument1 page30 - WELL CONTROL DATA SHEET For DRILLER'S METHODJunaid Mateen100% (1)

- Smart Mag™ Non Rotating String Magnet WhiteDocument4 pagesSmart Mag™ Non Rotating String Magnet WhiteAjith MohandasNo ratings yet

- Autochoke Drilling Choke Ps PDFDocument3 pagesAutochoke Drilling Choke Ps PDFCristiTancuNo ratings yet

- Managed Pressure Drilling (SPE MPD Seminar Abstracts)Document6 pagesManaged Pressure Drilling (SPE MPD Seminar Abstracts)Anonymous H9n5g3aaCENo ratings yet

- Haliburton - Surface Manifold Evaluation ManualDocument206 pagesHaliburton - Surface Manifold Evaluation Manualdavorp1402100% (4)

- Wireline Set Retrievable Bridge Plug PsDocument1 pageWireline Set Retrievable Bridge Plug Pssufyan khalidNo ratings yet

- Gate Valve Trim ChartDocument5 pagesGate Valve Trim ChartWaseem IqbalNo ratings yet

- Well Stimulation VesselDocument8 pagesWell Stimulation VesselHossein ramezaniNo ratings yet

- U-23 Well HeadDocument3 pagesU-23 Well HeadNoel BowmanNo ratings yet

- ABOP ElementsDocument1 pageABOP ElementsArdalan FezziNo ratings yet

- Blow Out PreventorDocument6 pagesBlow Out PreventorCesar Valdivia MontañoNo ratings yet

- 1 - 5 Well Test Equipment 26.03.2015Document49 pages1 - 5 Well Test Equipment 26.03.2015Lakshman Kumar JulapalliNo ratings yet

- Lista de Normas API RefinacionDocument10 pagesLista de Normas API RefinacionFrancisco SalazarNo ratings yet

- Model FC BookletDocument52 pagesModel FC BookletJuan PabloNo ratings yet

- BOPRAMS Series700-1Document3 pagesBOPRAMS Series700-1Surya Prakash DubeyNo ratings yet

- SWT PreSolidsSeparation H011840 A4Document2 pagesSWT PreSolidsSeparation H011840 A4slbclqrkNo ratings yet

- Cyclo TechDocument27 pagesCyclo TechAli AliievNo ratings yet

- Sand Filter BrochureDocument2 pagesSand Filter BrochureadrianioantomaNo ratings yet

- Hydraulic System For Stacker Instruction ManualDocument367 pagesHydraulic System For Stacker Instruction ManualTuấn100% (1)

- 18 Best Practice For Stand Alone Screens Ian WattieDocument30 pages18 Best Practice For Stand Alone Screens Ian WattieQaiser HafeezNo ratings yet

- Wellhead Desander Brochure SpanishDocument2 pagesWellhead Desander Brochure SpanishRichard MangutaNo ratings yet

- Petrotrim Services - Jason BeckDocument3 pagesPetrotrim Services - Jason BeckPetrotrim ServicesNo ratings yet

- Product CatalogDocument106 pagesProduct CatalogAri AzadNo ratings yet

- Basic Oilfield IntroDocument10 pagesBasic Oilfield Introbassam abutraabNo ratings yet

- CRP Lined Pipe BrochureDocument43 pagesCRP Lined Pipe BrochurepamlidNo ratings yet

- Drill Stem Components: 95 YearsDocument28 pagesDrill Stem Components: 95 YearsAdel RafikNo ratings yet

- Dual-Pot Sand Filter Type A (DSF-A)Document2 pagesDual-Pot Sand Filter Type A (DSF-A)Balaji SelvarajNo ratings yet

- Nit 1 1Document102 pagesNit 1 1Gaurav TripathiNo ratings yet

- API 6A, 16A, BX Ring Gaskets, BX Ring Gasket DimensionsDocument1 pageAPI 6A, 16A, BX Ring Gaskets, BX Ring Gasket DimensionsKaleem UllahNo ratings yet

- Blowout Preventers: Prepared byDocument19 pagesBlowout Preventers: Prepared byruts_147No ratings yet

- MPD Dhs 1400 RCDDocument2 pagesMPD Dhs 1400 RCDali_yy2003No ratings yet

- Maintenance and Operation Manual Hydraulic Choke and Control ConsoleDocument42 pagesMaintenance and Operation Manual Hydraulic Choke and Control ConsoleMehdi Hajd KacemNo ratings yet

- H07127 Three Phase Horz Test Separator HLBDocument2 pagesH07127 Three Phase Horz Test Separator HLBsyazwanNo ratings yet

- 1289-Hari Prastowo-#2 Pipes Class & Thickness (Rev) Hand-OutDocument17 pages1289-Hari Prastowo-#2 Pipes Class & Thickness (Rev) Hand-OutSupriadi TansiNo ratings yet

- JT Assembly English A4Document2 pagesJT Assembly English A4HectorNo ratings yet

- D392005428-MKT-001 6012 Bop PDFDocument2 pagesD392005428-MKT-001 6012 Bop PDFMitul PatelNo ratings yet

- Dailey Hydraulic Fishing Jar 6 PDFDocument1 pageDailey Hydraulic Fishing Jar 6 PDFMuhammad ShahrukhNo ratings yet

- Peco CatalogDocument152 pagesPeco CatalogClaudio Israel Godinez SomeraNo ratings yet

- SARA Ring GasketDocument4 pagesSARA Ring Gasketbehnam197No ratings yet

- C 06.C Wellhead DesignDocument6 pagesC 06.C Wellhead DesignJose David Hernandez OteroNo ratings yet

- Ex-Proof Class & Zone-ElwoodDocument26 pagesEx-Proof Class & Zone-ElwoodghostinshellNo ratings yet

- Plaster & Wald Consulting Corp.: Fill in Shaded AreasDocument2 pagesPlaster & Wald Consulting Corp.: Fill in Shaded AreasmarvinNo ratings yet

- Bop Pressure Test ReportDocument1 pageBop Pressure Test ReportsamNo ratings yet

- Choke Manifold EXPRODocument2 pagesChoke Manifold EXPROfurnaNo ratings yet

- HPB Brochure 0708Document12 pagesHPB Brochure 0708musaluddinNo ratings yet

- Shear Force For SBRDocument14 pagesShear Force For SBRnjava1978No ratings yet

- Bop CanDocument1 pageBop CanJerrydawangNo ratings yet

- Sandface ScreenDocument1 pageSandface ScreenMoujahed FarésNo ratings yet

- HP Auto Clave FittingsDocument1 pageHP Auto Clave FittingsRavi Chaitanya VelamarthyNo ratings yet

- ControlFlow PipeTensionersDocument1 pageControlFlow PipeTensionersWade DavisNo ratings yet

- Sand CatcherDocument1 pageSand CatcherWade DavisNo ratings yet

- XTVDocument2 pagesXTVWade DavisNo ratings yet

- Lts High Pressure Products: Dedicated To Quality & ExcellenceDocument2 pagesLts High Pressure Products: Dedicated To Quality & ExcellenceWade DavisNo ratings yet

- Frac Support A4Document20 pagesFrac Support A4Wade Davis100% (1)

- AGA Flow Calc DLL FunctionsDocument5 pagesAGA Flow Calc DLL FunctionsWade DavisNo ratings yet

- Weco Butterfly Valve ActuatorsDocument20 pagesWeco Butterfly Valve ActuatorsimmanjNo ratings yet

- Hydrowa Piston AccumulatorDocument2 pagesHydrowa Piston AccumulatorAshish JhaNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System SpecificationAwais CheemaNo ratings yet

- KVC 01Document35 pagesKVC 01hamidreza_m85No ratings yet

- Farris Maintenance ManualDocument12 pagesFarris Maintenance ManualAcep WahyudinNo ratings yet

- Dinli 700 Parts BookDocument45 pagesDinli 700 Parts BookNeacsu Eugen0% (1)

- BR9 001 ManualDocument32 pagesBR9 001 ManualRodrigo Jechéla BarriosNo ratings yet

- GPT 1-15 LineBackerDocument4 pagesGPT 1-15 LineBackerfakmiloNo ratings yet

- 73 TMSS 04 R0Document22 pages73 TMSS 04 R0Azhar AliNo ratings yet

- GS14 - Supply and Delivery of Steel Pipes and Fittings Rev 7 (2021 05 21)Document57 pagesGS14 - Supply and Delivery of Steel Pipes and Fittings Rev 7 (2021 05 21)Irham AfiqNo ratings yet

- P KjsDocument38 pagesP Kjsmajmor-1No ratings yet

- SR-08 SeriesDocument8 pagesSR-08 SeriesSumit JadhavNo ratings yet

- Table BrenchDocument11 pagesTable BrenchLuis GonzalezNo ratings yet

- Din-2848-Pr - de enDocument32 pagesDin-2848-Pr - de enAhmed AbidNo ratings yet

- PL2013 FPDocument100 pagesPL2013 FPRonald UrizarNo ratings yet

- Grundfosliterature 146012Document20 pagesGrundfosliterature 146012Si ThuNo ratings yet

- Datasheet For Hopper (D-3103)Document1 pageDatasheet For Hopper (D-3103)Joe GrosirNo ratings yet