Professional Documents

Culture Documents

Kinematic Simulation of Staubli TX40 Robot-ICM

Uploaded by

Ricardo GuerreroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kinematic Simulation of Staubli TX40 Robot-ICM

Uploaded by

Ricardo GuerreroCopyright:

Available Formats

Proceedings of the 2011 IEEE

International Conference on Mechatronics

April 13-15, 2011, Istanbul, Turkey

Dynamic Modeling and Kinematic Simulation of

Staubli TX40 Robot Using MATLAB/ADAMS

Co-simulation

Farzad Cheraghpour, IEEE Membel1, Masoud Vaezi#2, Resam Eddin Shoori Jazeh#3, S. Ali A. Moosavian#4

#

Islamic Azad University, Pardis Branch, Department ofMechanical Engineering, Iran

#

K.N Toosi University of Technology, Department ofMechanical Engineering, Iran

#

K.N Toosi University of Technology, Department ofElectrical Engineering, Iran

#

K.N Toosi University of Technology, Department ofMechanical Engineering, Iran

lsamavati@pardisiau.ac.ir

2masoud.vaezi@gmail.com

3hesam.shoori@gmail.com

4moosavian@kntu.ac.ir

Abstract- This paper presents dynamic modeling and simulation

of the industrial robot, Stiiubli TX40, and proposes a precise

simulator to develop approaches for experimental simulation in

kinematics, dynamics and control analysis. The robot model has

been developed as accurate as the real one by implementing

dynamic model of robot in ADAMS, dynamic modeling software,

and also linking with MA TLAB for motion studies.

simulator

is

verified

by

tracking

predefined

Finally the

pose

with

minimum error.

Keywords---

completely, the model is exported to ADAMS dynamic

modeling software. This software is capable of simulating

kinematics and kinetics behavior of any mechanical system.

As result dynamic behavior of systems with comparison to the

real models can be simulated with an acceptable error.

For obtaining an exact modeling, inertial and geometric

parameters are accurately measured and recorded in the

software database. Also for simulating control algorithms, co

simulation between ADAMS and MATLAB is performed.

Robot, Dynamic Modeling, Simulation, Inverse and

II.

Forward Kinematics, Genetic Algorithm

I.

INTRODUCTION

In recent decades, robot manipulators are widely used in

industrial applications. Of the most important ones, welding

and painting robots in car plants [1], electronic board

assembly, repairing nuclear installations [2], and etc can be

mentioned.

Besides, academic and research Labs try to develop new

methods and algorithms so as to release the results for

industrial uses after validation. The researches are applied to

different areas such as motion planning, manipulation

planning [3,4,5], grasp planning [6,7,8], and control

algorithms like position control [9], force control [10],

Impedance control [11,12], and etc. Real robots are

inaccessible due to high prices therefore creating precise

simulated models are extensively demanded by research Labs.

Prior to this, simulation and analysis of PUMA 560 as one

of the most renowned industrial robots have been performed

[13]. With the advent of new models of robot manipulators by

manufacturers, still there is a need for exact simulated models.

This paper introduces simulated models of 6-DOF Stiiubli

TX40 robot. All procedures presented in this paper are in way

that reader can model specific robot in software environments.

The main advantage of this paper is to use multi-software

environments interactively. After a 3D modeling of robot

manipulator in CATIA software, as it will be mentioned

978-1-61284-985-0/11/$26.00 2011

MODELING

In modeling using CATIA, CAD software, robot model is

divided into seven parts. Each individual part is designed in

"Part Design" separately. The sketches are obtained from the

manufacturer company [14]. Afterwards these parts are

reproduced in "Assembly" environment and assembled with

constraint commands. The process of defining constraints

starts with fixing the base part using "Fix" command and ends

up with reproducing the other parts and applying "Contact"

and "Coincidence" to each couple of them. To validate the

motion of 6-DOF robot, "manipulation" command is used.

The assembled model of robot and the real one are shown in

Figure 1.

IEEE

386

Fig. 1 A. created model in CATIA B. the real Staubli

TX40 robot

III. KINEMATIC S ANALYSIS

A. ADAMS Dynamic Modeling Software

To import the designed model to ADAMS, the initial step is

to transfer each of the seven parts of robot from "Assembly"

to "SolidWork" software. Then each part is saved in

"parasolid" format, since this format is better recognized in

ADAMS. The next step is to import the model into ADAMS.

It should be noted that since the parts are assembled in

CATIA and converted into a defInite format, the parts are put

together with pre-determined positions in ADAMS.

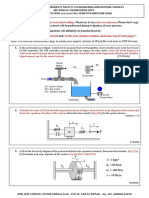

After transferring model, inertial parameters of the parts

such as density, are recorded in software database. The

imported model to ADAMS is without mass and inertia in

default. Determination of exact density of the robot parts is

done by measuring mass and density of the second link lid

(Fig. 2). Thus ADAMS is able to calculate the mass and

moments of inertia of each part automatically. The values are

illustrated in Table 1. The computed parameters are verifIed

by making a comparison between the total weights of

simulated robot with the data given in the corresponding

catalogue. The result shows that the cumulative error is less

than %2.

Before transferring the model into MATLAB software,

forward kinematics equations are considered briefly. SpecifIed

coordinates and ModifIed Denavit-Hartenberg (MDH)

parameters are depicted in Fig. 3 and Table 2.

TABLE II

DENAVIT -HARTENBERG PARAMETERS

lyyX Iff]

luX Iff]

[kg]

Ikg.m2]

Ikg.m2]

Ikg.m2]

base

5.35

26

22

19

8.61

48

47

23

l'

TX40ROBOT ARMS

Ixxx Iff]

Link

4.85

47

45

4.55

12

11

4.09

15

14

0.32

0.23

0.2

0.084

0.02

0.0058

0.003

0.003

ai_l

di

9i

01

-900

O2

0.225

0.035

03

0.225

04

90 0

-900

Os

90 0

0.065

06

.?f z,

Finally in order to place a motor for each Revolute joint of

robot in ADAMS, "motion" command should be applied to

each joint.

Fig. 3 The attached coordinates of robot joints

The transformation matrices are computed in the following

[15]:

T=

2T_

[CO'

[ CO,0

[CO'

00

[C0O'

2

3T =

Fig. 2 A. The designed model of the second lid B. The real lid

1Ij-1

z,

TABLE I

lNERTIAL PARAMETERS OF THE STAUBU

3

4

T-

387

S l

- 82

S83

S 4

00

00 01 !l

0 001 l

0 00 !

0

00 01 0.0135l

0 001 l

0 0

-S81

C81

-S82

-C82

-S83

C83

-S84

C84

(1)

[0 0 0

00 ]

0

[ 0 0 0 -Of65

g

0 00 ]

CO,

sT - - Os -COs

CO' -S06

6T- S

6

_

82 =Atan2 [(-a3-a2C3)P z+(Clpx+S1Py)(a2S3-d4)

(a2C3- d4)pz+(a3+a2C3)(CIP x+S1Py)]- 83

-SOs

C06

83=Atan2(a3,d4)-

Atan2(a3c3 - d4S3,.Ja + d + (a3c3 - d4s3)

84=Atan2(-T13s1+T23Cl , -T13CIC23-T23S1C23+T33S23)

-1

85 = Atan2 (Ss,Cs)

86=Atan2(s6,c6)

In which C8j , S8j are representative for Cos(8j) and Sin(8j),

respectively.

The following relation specifies the end effector position

and orientation with respect to the base.

(2)

2T is a 4x4 matrix whose elements are shown in Appendix.

The position of joints through the process of transferring

into ADAMS is considered as zero state in default.

Consequently, when assembling model in CATIA, zero state

of the joints should be the same as zero state of specified

coordinates. Fig. 4 shows zero state of Stiiubli robot joints. To

adapt the direction of joint motion with the real robot, the

positive direction of rotation should be compatible with right

handed direction of Z axis.

Due to the nonlinearity of equations, their closed solution

might be difficult to attain, so the Genetic Algorithm as a

numerical method has been considered for calculating 8j ,[16].

MATLAB software aims at achieving joint space variables for

a given end effector position and orientation (EqA) based on

GA. The comparison between GA results and analytical

solution is made in Table 3. It should be stated that angular

limits are assigned to each motor that lead to unique solution

[17]. Fig. 5 illustrates the error between numerical solution of

the inverse kinematics and analytical solution that is about

ll

3.06e- mm

.

Px = -0.26 mm

cp=O.OO rad

Pz=0.22 mm

\jI=O.OO rad

Py = -0.18 mm

8=0.00 rad

(4)

TABLE III

COMPARISON OF NUMERICAL SOLUTION WITH ANALYTICAL ONE

Joint

angles

Closed

Genetic

Error

equations

Algorithm

percentage

[rad]

[rad]

[%]

91

0.7165

0.7165

0.000

92

-2.0048

-2.0052

0.019

93

0.2143

0.2145

0.093

94

0.000

95

1.7912

1.7908

0.022

96

-0.7165

-0.7165

0.000

Best:

3.060ge')11

Mean:

3.4471e-008

Best fitness

Mean 1nness

Fig. 4 Zero state of joint angles in ADAMS

0

A. Inverse Kinematics

g

The inverse kinematics problem consists of the

determination of joint variables corresponding to a given end

effector position and orientation. The solution to this problem

is of fundamental importance in order to transform the motion

specifications, assigned to the end effector in operational

space, into the corresponding joint space motions that allow

execution of desired motion.

Inverse kinematics of 6-DOF Stiiubli manipulator consists

of establishing closed analytical equations of the joint space

using algebraic and trigonometric methods and the final

results are specified in equations 3.

81=Atan2(Py,px)-Atan2(d3,

r- - - - - -p + P - d D

(3)

"

u:

.

.

500"--

10 00--

15 00--

--25

2000

00

--

3000

0"

PQuee

Generation

Fig. 5 Numerical solution error using Genetic Algorithm

As seen in Table 3, consequences of numerical solution are

highly acceptable and reliable.

388

B. MATLAB and ADAMS Co-simulation:

MATLAB is a powerful tool for applying control

commands to the robot so for having an efficient simulator

package, the co-simulation between ADAMS an MATLAB is

noticeable. In order to execute a co-simulation between

ADAMS and MATLAB, defmition of an acceptable format

for the inputs and outputs of each program is required. The

objective of co-simulation is to make a connection so that any

change in one of the programs affects the other one [18].

To provide a simulation that enables ADMAS to recognize

the exported output from MATLAB, there is a need for

activating "control" plug-in in "Plug-in Manager" of ADAMS

and defining the robot as a plant. After activation, a new

window appears for the determination of plant and its inputs

and outputs. Afterwards, ADAMS saves dynamic model of

robot motion as a complex of seven matrices that is capable of

sending to MATLAB. The first four are A,B,C,D matrices of

state-space representation. The fifth and sixth matrices are

associated with predefmed inputs and outputs. And the last

one includes information about state variables of the plant

[19,20]. Trajectory planning of each robot joint (9(t)), as

ADAMS inputs, is stated as a five-degree polynomials for

solving forward kinematics of robot, [21].

This function is suitable for each joint in the view point of

dynamic considerations, [22].

(5)

The coefficients of this function regarding to initial and

fmal position, velocity, acceleration values of each joint are

assigned based on equations in [15]. ADAMS outputs are

components of end effector position (x,y,z) with respect to the

frame attached to the base.

To call the generated plant in MATLAB, the plant name

should be entered in the "command window" so that the input

and output information will appear. By executing "Adams_sys"

command, the blocks containing information about dynamic

model of robot in SIMULINK environment, are 10aded.(Fig. 6)

S-Function

State Spa ce

generated in "Embedded MATLAB Function". Outputs of this

block represent the plant inputs of robot in ADAMS. By

starting the simulation in SIMULINK, the signals of function

coefficients for 9(t) will enter the plant and run ADAMS

simultaneously which continues to a defmite fmal state.

Generated trajectory functions for each motor yields the end

effector to track the desired position and orientation. Fig. 7

demonstrates the block diagram of forward kinematics.

ffiG

[0

G

[0

1---1'=

1::'

H---'.

8

8-

'

8

[0

.

.

ciJ8

G

ffi

..

ciJ

g;;J

8

88

8

8

8G

8

8

8G

8

8

..

I:

'-

'

-

...

1----1=

Fig. 7 block diagram of forward kinematics in SIMULINK

In this simulation initial values of position, velocity and

acceleration and also fmal velocity and acceleration of each

joint are presumed to be zero. The fmal position of each joint,

9r, in period of 5 seconds is assumed as equation 6.

8f= [0.7165 -2 0.2145 0 1.79 -0.7165]

(6)

With these 6 values of initial and fmal position, velocity,

acceleration all 6 coefficients of the equation 5 can be

determined so that trajectory function of the joints are

generated. The fmal functions are as equation 7.

9 1 (t) = 0.2654t3-O.1327t4+O.0176t5

92 (t) = -0.7427t3+0.3714t4-0.049t5

93(t) = 0.079t3_0.039t4+0.005t5

94(t) = 0

95(t) = 0.663t3_0.331t4+0.044t5

96(t) = -0.265t3+O.1327t4-O.017t5

(7)

Based on the analytical viewpoint and forward kinematics

solution, each joint approaching its given fmal position, 9r, the

end effector must track the position and orientation according

to equation 8. Note that cp, 9, 'I' are roll, pitch, yaw angles

respectively.

1-------lD

Px = -0.26 mm

cp=O.OO rad

adams.:-.,sub

Fig. 6 model plant and state space blocks

By having "Adams-sub" block in SIMULINK environment,

the robot model is suitable for control and motion simulation

as a defmed system in MATLAB.

Regarding the forward kinematics of robot, the fmal

transformation matrix and trajectory planning block are

py= -0.18 mm

9=0.00 rad

pz = 0 .22 mm

'1'=0.00 rad

(8)

By the end of the simulation, the end effector position in

work space is depicted in scope of MATLAB/SIMULINK Fig.

8. By comparing the results with the forward kinematics

solution, it can be inferred that the simulation satisfies our

desired accuracy.

389

r . ...

02 ..........,

';" 0.1

.

c

D ...........:............

o

.. ........... . . . ....... 1. ,

...

.1

<.

.. ..

.

............ ..

.... I

..... ....................................

05

.. .

....... .

.. . . ...

--

. ......

. .... . .

15

--

--

--

....'__ .

35

Analysis for forward kinematics

--

--

..... I ......... I .. . .....l . ......

.....

-0.1

. ...

. ... ..

,

,

. ....... . . .... . . . . .. . .... . , . .

. .

..... .. ......... ...

.

. .. . .

="-' ...... . ....... '

OA ....

OJ ..

g, Oli

O

. ..

. . .. . ... . \.. . .

,

.

. . ..

......... ........ 1 . . .

.. .

. : ........

.

..

... . ,1 . ....

. .

. .

. . .. . . ... . . ..... .. . . ........

,

,

,

.

.. 1.... . ......

Determination of inputs, outputs and

.. .

'" Oli ....

... .

. . j .

. ....

--

. . . .. . .. ..!.. . .........

15

..... ...'.......... I ......_ _ . I . __.... . l ......

. . . . ..., ..

..

... ..

--

I . .

.... ..

------

.....

15

0 2 r---r-

]0.1

:.:.:.:..

,..

. . .I. . .

.)..

plant in ADAMS

:...... . .. .. : ............ .

,

.

,

.

1 ..

,

I ...

,

.

Creating M-File of end effector

......

transformation matrices

..

.... . . . ....

t

.

..

..

...

Jj

lOL-----:O-':-j-----'----1:-:cj------:-------:':

1 :----'----'':---L-----:':----Ij

-:'

-....,(s)

Fig. 8 The end effector position showing in scope

IV. CONCLUSIONS

Fig. 9 The flow-chart showing the procedure of co-simulation

In this paper modeling and simulation of 6-DOF Stiiubli

robot have been performed using CATIA, ADAMS,

MATLAB programs. The Denavit-Hartenberg and inertia

parameters and also kinematic analysis of robot were

exploited. Then the procedure of establishing a co-simulation

between ADAMS and MATLAB has been clearly expressed

and the flowchart in Fig. 9 shows the whole process.

Consequences of this simulation clarify the correct guidance

of robot in the software modeling. With the help of created

model, design and simulation of closed loop control systems

and applying optimized design parameters are simply

executable.

REFERENCES

[I]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

K. T. Park, Y. J. Shin and C. H. Park Y. S. Mo, D. C. Jeong,Y. S.

Shin,"Robot Application for Assembly Process of Engine Part",

International Conference on Control, Automation and Systems in

CDE}{, Korea, pp. 1-4, 2008

DD Ray, M. Singh, "Development of a Force Reflecting Tele-robot for

Remote Handling in Nuclear Installations", 1st International

Conference on Applied Robotics for the Power Industry Delta Centre

Ville Montreal, Canada, p.p 1-6, 2010

F. Cheraghpour., S.A.A Moosavian, and A. Nahvi, "Multiple Aspect

Grasp performance index for cooperative object manipulation tasks",

IEEE/ASME Int. Conf. on Advanced Intelligent Mechatronics, pp 386391, 2009

M. Eslamy, S.A.A Moosavian, "Dynamics and Cooperative object

Manipulation Control of Suspended Mobile Manipulators", J Intell

Robot Syst Springer Science+Business Media B.V, pp. 1-19, 2010

K. Harada, K. Kaneko, F. Kanehiro, "Fast Grasp Planning for

Hand/Arms Systems Based on Convex Model", IEEE International

Conference onRobotics and Automation, pp. 1-7, 2008

F. Cheraghpour., S.A.A Moosavian, and A. Nahvi, "Robotic grasp

planning by multiple aspects grasp index for object manipulation tasks",

18th Iranian Conf. on Electrical Engineering (ICEE), pp 635-640, 2010

A. Agovic, N. Papanikolopoulos, "Grasp Planning by Alignment of

Pairwise Shape Descriptorss", IEEEIRSJ International Conference on

Intelligent Robots and Systems, pp. 1-8, 2009

M. Strandberg, B. Wahlberg, "A Method for Grasp Evaluation Based

on Disturbance Force Rejection", IEEE transactions on robotics, pp. 19, 2006

M. Karimi, S.A.A. Moosavian, "Modified Transpose Effective

Jacobian Law for Control of Underactuated Manipulators",

Koninklijke Brill

, Leiden and The Robotics Society of Japan, pp.

605-626, 2009

G. Zeng, A. Hemami, "An overview of robot force control", Robotica,

Cambridge University Press, volume 15 , pp. 473 - 482, 1997

S.A.A. Moosavian, and E. Papadopoulos, "Cooperative Object

Manipulation with Contact Impact Using Multiple Impedance Control,"

NY

[10]

[11]

390

[12)

[13)

[14)

[15)

[16)

[17)

[18)

[19)

[20)

[21)

[22)

International Journal of Control, Automation, and Systems, pp 314327., 2010

S. Dehghani, H.D. Taghirad, M Darainy, "Self-tuning Dynamic

Impedance Control for Human Arm Motion", Biomedical Engineering

(ICBME), 17th Iranian Conference, pp. 1-6, 2010

B. Armstrong, O. Khatib And J. Burdick, "The Explicit Dynamic

Model and Inertial Parameters of the PUMA 560 Arm, " Robotics And

Automation IEEE International Conf. pp 510-518 , 1986

Staub Ii

TX40 product leaflet, 2002, AT http://www.staubli.com.

J.J.Craig, Introduction to Robotics, Addison-Wesley, pp 81-86 , 2005

P. shi, y. cui,"Dynamic path planning for mobile robot based on

genetic algorithm in unknown environment", control and decision

conference (CCDC), china, p.p 4325 - 4329, 2010

G. pengfei w. xuezhi, h. yingshi, "The enhanced genetic algorithms

for the optimization design", Biomedical Engineering and Informatics

(BMEI), 2010 3rd International Conference on, p.p 2990-2994, 2010.

Z. Yi, X. Min-min, Q. Jin-yi , Z. Hu , "Research on co-simulation

using ADAMS and MATLAB for automobile active suspension

system" , Computer Application and System Modeling (ICCASM),

International Conference, p.p V14-366 - VI4-370 , 2010.

Z. Affi, L. Romdhane, "ADAMS/SlMULINK interface for Dynamic

Modeling and Control of Closed Loop Mechanisms", Proceedings of

the 7th WSEAS International Conference on automatic control,

modeling and simulation, Prague, Czech Republic,pp. 353-356,2006

Z.Z. Naing, M.P. AI-Mamun, "Integrated ADAMS+MATLAB

environment for design of an autonomous single wheel robot, "

Industrial Electronics,.IECON 35th Annual Conference of IEEE, p.p

2253-2258, 2009

T. Fraichard , INRIA Rhone Alpes, Grenoble ,"Dynamic trajectory

planning with dynamic constraints: A 'state-time space' approach",

Intelligent Robots and Systems '93, IROS '93. Proceedings of the 1993

IEEEIRSJ International Conference , p.p 1393 - 1400 vo1.2, 2002.

Y. Guan, K. Yokoi, , O. Stasse, , A. Kheddar, ,"On robotic trajectory

planning using polynomial interpolations", Robotics and Biomimetics

(ROBIO). IEEE International Conference , p.p 111 - 116, 2006.

APPENDIX

81 = tl

84 =t4

CI =Cos81

82 =t2

85 = t5

Sl =Sin 81

Px = (9*cos(tl)*cos(t2))/40-(7*sin(tl))/200(13*sin(t5)*(sin(tl)*sin(t4)+ cos(t4)*(cos(tl)*sin(t2)*sin(t3)

cos(t1)*cos(t2)*cos(t3))))/200+

(13*cos(t5)*(cos(tl)*cos(t2)*sin(t3)+

cos(tl)*cos(t3)*sin(t2)))/200+ (9*cos(tl)*cos(t2)*sin(t3))/40+

(9*cos(t1)*cos(t3)*sin(t2))/40+(0.26);

'[21 = sin(t6)*(cos(tl)*cos(t4)+

sin(t4)*(sin(tl)*sin(t2)*sin(t3)-cos(t2)*cos(t3)*sin(tl)))+

cos(t6)*(cos(t5)*(cos(tl)*sin(t4)cos(t4)*(sin(t1)*sin(t2)*sin(t3)-cos(t2)*cos(t3)*sin(t1)))

sin(t5)*(cos(t2)*sin(tl)*sin(t3)+cos(t3)*sin(tl)*sin(t2)));

'[22 = cos(t6)*(cos(tl)*cos(t4)+

sin(t4)*(sin(tl)*sin(t2)*sin(t3)-cos(t2)*cos(t3)*sin(tl)))

sin(t6)*(cos(t5)*(cos(tl)*sin(t4)cos(t4)*(sin(tl)*sin(t2)*sin(t3)-cos(t2)*cos(t3)*sin(tl))) sin(t5)*(cos(t2)*sin(t1)*sin(t3)+cos(t3)*sin(tl)*sin(t2)))-(1);

'[23 = sin(t5)*(cos(t1)*sin(t4)- cos(t4)*(sin(tl)*sin(t2)*sin(t3)

cos(t2)*cos(t3)*sin(t1)))+

cos(t5)*(cos(t2)*sin(tl)*sin(t3)+cos(t3)*sin(tl)*sin(t2));

Py

= (7*cos(tl))/200 + (9*cos(t2)*sin(tl))/40+

(13*sin(t5)*(cos(tl)*sin(t4)- cos(t4)*(sin(tl)*sin(t2)*sin(t3)

cos(t2)*cos(t3)*sin(t1))))/200+

(13*cos(t5)*(cos(t2)*sin(tl)*sin(t3)+

cos(t3)*sin(tl)*sin(t2)))/200+(9*cos(t2)*sin(tl)*sin(t3))/40 +

(9*cos(t3)*sin(tl)*sin(t2))/40+(0.18);

'[31 = sin(t4)*sin(t6)*(cos(t2)*sin(t3)+cos(t3)*sin(t2))

cos(t6)*(sin(t5)*(cos(t2)*cos(t3)-sin(t2)*sin(t3)) +

cos(t4)*cos(t5)*(cos(t2)*sin(t3)+cos(t3)*sin(t2)));

'[32 = sin(t6)*(sin(t5)*(cos(t2)*cos(t3)-sin(t2)*sin(t3))+

cos(t4)*cos(t5)*(cos(t2)*sin(t3)+cos(t3)*sin(t2)))+

cos(t6)*sin(t4)*(cos(t2)*sin(t3)+cos(t3)*sin(t2));

'[33 = cos(t5)*(cos(t2)*cos(t3)-sin(t2)*sin(t3))

cos(t4)*sin(t5)*(cos(t2)*sin(t3)+cos(t3)*sin(t2))-(1);

'[11 = - sin(t6)*(cos(t4)*sin(tl)sin(t4)*(cos(tl)*sin(t2)*sin(t3)-cos(tl)*cos(t2)*cos(t3)))

cos(t6)*(cos(t5)*(sin(tl)*sin(t4)+

cos(t4)*(cos(tl)*sin(t2)*sin(t3)-cos(t1)*cos(t2)*cos(t3))) +

sin(t5)*(cos(t1)*cos(t2)*sin(t3)+ cos(tl)*cos(t3)*sin(t2)))-(l);

Pz = (9*cos(t2)*cos(t3))/40-(9*sin(t2))/40(9*sin(t2)*sin(t3))/40+(13*cos(t5)*(cos(t2)*cos(t3)

sin(t2)*sin(t3)))/200-(13*cos(t4)*sin(t5)*(cos(t2)*sin(t3)+

cos(t3)*sin(t2)))/200-(0.22);

'[12=Sin(t6)*(cos(t5)*(sin(tl)*sin(t4)+

cos(t4)*(cos(t1)*sin(t2)*sin(t3)-cos(tl)*cos(t2)*cos(t3))) +

sin(t5)*(cos(tl)*cos(t2)*sin(t3)+ cos(tl)*cos(t3)*sin(t2))) cos(t6)*(cos(t4)*sin(tl)- sin(t4)*(cos(tl)*sin(t2)*sin(t3)

cos(tl)*cos(t2)*cos(t3)));

'[13=cos(t5)*(cos(tl)*cos(t2)*sin(t3)+

cos(t1)*cos(t3)*sin(t2))-sin(t5)*(sin(tl)*sin(t4)+

cos(t4)*(cos(tl)*sin(t2)*sin(t3)- cos(tl)*cos(t2)*cos(t3)));

391

You might also like

- DC Servo Paper - Cse007Document4 pagesDC Servo Paper - Cse007DrPrashant M. MenghalNo ratings yet

- Engine Modeling A KeromnesDocument42 pagesEngine Modeling A KeromnesIvan GrujicNo ratings yet

- Ch2 Modeling in Frequency DomainDocument66 pagesCh2 Modeling in Frequency DomainWei-Hsin CheinNo ratings yet

- Airfoil Investigation Database - Showing Naca-2412Document1 pageAirfoil Investigation Database - Showing Naca-2412sudharshanreddymNo ratings yet

- HP-16C Quick Reference: General Calculator ControlDocument5 pagesHP-16C Quick Reference: General Calculator ControlhowardcarterNo ratings yet

- N.a.C.a. Aircraft Circular No.18 - 1926-10 - The de Havilland MothDocument8 pagesN.a.C.a. Aircraft Circular No.18 - 1926-10 - The de Havilland MothPiero CaprettiNo ratings yet

- Modeling A Two Wheeled Inverted Pendulum RobotDocument59 pagesModeling A Two Wheeled Inverted Pendulum Robotcdsiegert100% (2)

- HP 15C Quick ReferenceDocument16 pagesHP 15C Quick Referencejeff_56No ratings yet

- Sinusoidal Synthesis of Speech Using MATLABDocument35 pagesSinusoidal Synthesis of Speech Using MATLABAkshay JainNo ratings yet

- 15c HPDocument288 pages15c HPJose Antonio MercadoNo ratings yet

- Introduction To Matlab - 1Document190 pagesIntroduction To Matlab - 1Omer UctuNo ratings yet

- Final Cruise ControlDocument26 pagesFinal Cruise ControlKusum LataNo ratings yet

- 3D Model of Fuel Tank For System Simulation (En)Document78 pages3D Model of Fuel Tank For System Simulation (En)BeaNo ratings yet

- PUMA-560 Robot Manipulator Position Sliding Mode Control Methods Using MATLAB/SIMULINK and Their Integration Into Graduate/Undergraduate Nonlinear Control, Robotics and MATLAB CoursesDocument45 pagesPUMA-560 Robot Manipulator Position Sliding Mode Control Methods Using MATLAB/SIMULINK and Their Integration Into Graduate/Undergraduate Nonlinear Control, Robotics and MATLAB CoursesAI Coordinator - CSC JournalsNo ratings yet

- 00 CASIO QuickStartGuide Fx-CG50 Function Keys and IconsDocument3 pages00 CASIO QuickStartGuide Fx-CG50 Function Keys and IconsDon't Make Fun Of People Who Get RunoverNo ratings yet

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationFrom EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationNo ratings yet

- Mechanical Vibrations Week 1Document57 pagesMechanical Vibrations Week 1mrb87No ratings yet

- Universal Motor Process FlowDocument4 pagesUniversal Motor Process FlowAnurag Sharma100% (1)

- Chapter.3 Design of Commutator and BrushesDocument10 pagesChapter.3 Design of Commutator and BrushesFernando Rmz100% (1)

- 3-DOF Longitudinal Flight Simulation Modeling and Design Using MADocument54 pages3-DOF Longitudinal Flight Simulation Modeling and Design Using MAspbhavna100% (1)

- Servo Motor Modeling in SimulinkDocument10 pagesServo Motor Modeling in SimulinkRose GutierrezNo ratings yet

- ORCAD Pspice - Course MaterialDocument30 pagesORCAD Pspice - Course MaterialDRathikaNo ratings yet

- Fx-CG50 Exam Mode - UKDocument4 pagesFx-CG50 Exam Mode - UKAdam AlonNo ratings yet

- Intro PIC18 Assembly LanguageDocument15 pagesIntro PIC18 Assembly Languagevolhov100% (4)

- 3 March 2018 Ieee Ece Traning PresentationDocument94 pages3 March 2018 Ieee Ece Traning PresentationmarginalmeNo ratings yet

- Stress Intensity FactorDocument26 pagesStress Intensity Factormshebbal221250% (2)

- Commutator (Electric) : From Wikipedia, The Free EncyclopediaDocument12 pagesCommutator (Electric) : From Wikipedia, The Free EncyclopediaEdito Abrantes BalugoNo ratings yet

- TM 11-455 22may1944Document149 pagesTM 11-455 22may1944mariodoreNo ratings yet

- Advanced Aerodynamics Lab ReportDocument53 pagesAdvanced Aerodynamics Lab ReportIsaiah Hugh MarquezNo ratings yet

- ESI4523 Simulation NotesDocument23 pagesESI4523 Simulation NotesSamuel SmithNo ratings yet

- Control Tutorials For MATLAB and Simulink - PI Control of DC Motor SpeedDocument24 pagesControl Tutorials For MATLAB and Simulink - PI Control of DC Motor SpeedMohd A. IsaNo ratings yet

- Allsop Popelinsky 2Document10 pagesAllsop Popelinsky 2eventnowNo ratings yet

- M Phase MototrDocument6 pagesM Phase MototrRija AliNo ratings yet

- Lab 3c Creo 12123654Document2 pagesLab 3c Creo 12123654neeraj kumar100% (1)

- Introduction To SimulinkDocument123 pagesIntroduction To SimulinkCristhianCoyoNo ratings yet

- CD CatalogDocument3 pagesCD CatalogJulián Andrés Ortiz González100% (1)

- BbasdjknbdkjDocument1 pageBbasdjknbdkjsurya0% (1)

- Model-Based and System-Based Design: Writing S-FunctionsDocument556 pagesModel-Based and System-Based Design: Writing S-FunctionsMinhHà100% (1)

- FreeCAD Mod Dev Guide 20190912Document147 pagesFreeCAD Mod Dev Guide 20190912Xinrui WeiNo ratings yet

- Firearms Identification Vol 1 - JH Mathews 1973Document217 pagesFirearms Identification Vol 1 - JH Mathews 1973galak12001100% (2)

- Section Modulus and Bending Inertia of WingsDocument6 pagesSection Modulus and Bending Inertia of WingssupermarioprofNo ratings yet

- Stress Intensity Factors HandbookDocument26 pagesStress Intensity Factors HandbookJad Antonios Jelwan0% (1)

- X-Winder TriFold BrochureDocument2 pagesX-Winder TriFold BrochureSwamy RakeshNo ratings yet

- Allsop PopelinskyDocument10 pagesAllsop PopelinskyeventnowNo ratings yet

- Advanced Composite Engineering Using MSC - Patran and FibersimDocument15 pagesAdvanced Composite Engineering Using MSC - Patran and FibersimSandeep BandyopadhyayNo ratings yet

- Rubiks Cube Solver PDFDocument10 pagesRubiks Cube Solver PDFpbikerator100% (1)

- Rocket Simulation With Matlab CodeDocument12 pagesRocket Simulation With Matlab Codegaza001No ratings yet

- MBD PDFDocument53 pagesMBD PDFMina ZakariaNo ratings yet

- Conf 15288 1529303363 11.IJMPERD - ICEMSDocument6 pagesConf 15288 1529303363 11.IJMPERD - ICEMSanandharajaNo ratings yet

- AerE 351 Rocket Optimization PDFDocument8 pagesAerE 351 Rocket Optimization PDFAnonymous RJZnbDDNNo ratings yet

- Active Model Rocket Stabilization Via Cold Gas Thrusters - Danylo MalyutaDocument12 pagesActive Model Rocket Stabilization Via Cold Gas Thrusters - Danylo MalyutaTim MarvinNo ratings yet

- MScKabbabe2011 PDFDocument176 pagesMScKabbabe2011 PDFJamal AlshaweshNo ratings yet

- Torsion Spring Design InfoDocument3 pagesTorsion Spring Design Infoashish19851No ratings yet

- Fresh PerspectiveDocument96 pagesFresh PerspectiveKhanh Dam100% (1)

- Technical Data of The Zeppelin NT 07 PDFDocument8 pagesTechnical Data of The Zeppelin NT 07 PDFVishnoo PrathapNo ratings yet

- EasyChair Preprint 1619Document14 pagesEasyChair Preprint 1619paulo baptistaNo ratings yet

- ADAMS/MATLAB Co SimulationDocument6 pagesADAMS/MATLAB Co SimulationkranthiNo ratings yet

- Design, Simulation, and Analysis of A 6-Axis Robot Using Robot Visualization SoftwareDocument10 pagesDesign, Simulation, and Analysis of A 6-Axis Robot Using Robot Visualization Softwareswag bucksNo ratings yet

- HibapapierDocument12 pagesHibapapierujjainbNo ratings yet

- LicenseDocument5 pagesLicensedany_erwcomNo ratings yet

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Nina Camba PDFDocument2 pagesNina Camba PDFRicardo GuerreroNo ratings yet

- Saxo TenorDocument1 pageSaxo TenorRicardo GuerreroNo ratings yet

- Fuerza de La ManoDocument10 pagesFuerza de La ManoRicardo GuerreroNo ratings yet

- TIP31CDocument1 pageTIP31CRicardo GuerreroNo ratings yet

- AD590Document13 pagesAD590Brzata PticaNo ratings yet

- Flor Palida TBDocument1 pageFlor Palida TBRicardo GuerreroNo ratings yet

- TL084CN Amplificador OperacionalDocument31 pagesTL084CN Amplificador OperacionalJuanchoGKNo ratings yet

- Modelo UmngDocument4 pagesModelo UmngRicardo GuerreroNo ratings yet

- Flor Palida PnoDocument2 pagesFlor Palida PnoRicardo GuerreroNo ratings yet

- +5V-Powered, Multichannel RS-232 Drivers/Receivers: General Description Next-Generation Device FeaturesDocument36 pages+5V-Powered, Multichannel RS-232 Drivers/Receivers: General Description Next-Generation Device FeaturesAli AhmadNo ratings yet

- Merged Document 7Document4 pagesMerged Document 7Ricardo GuerreroNo ratings yet

- Introduction To COMSOL Multi PhysicsDocument168 pagesIntroduction To COMSOL Multi PhysicsSiddharth RSNo ratings yet

- MTC6Document8 pagesMTC6Ricardo GuerreroNo ratings yet

- Generalized PI Control of Active VehicleDocument19 pagesGeneralized PI Control of Active VehicleilublessingNo ratings yet

- Lagrage PIDDocument13 pagesLagrage PIDRicardo GuerreroNo ratings yet

- Modelagem Diagrama de BlocsoDocument12 pagesModelagem Diagrama de BlocsoAlessandro BraatzNo ratings yet

- Ece380 Notes PDFDocument171 pagesEce380 Notes PDFMohamed Aly SowNo ratings yet

- EE5103 Part1 Lecture 1Document66 pagesEE5103 Part1 Lecture 1sugarpotpieNo ratings yet

- Experimental Study of An Adaptive Base Isolation System For BuildingsDocument8 pagesExperimental Study of An Adaptive Base Isolation System For BuildingslouhibiNo ratings yet

- Control Theory I by DR Yousif Al Mashhadany 2020-2021Document188 pagesControl Theory I by DR Yousif Al Mashhadany 2020-2021Yousif Al mashhadanyNo ratings yet

- Control SystemDocument44 pagesControl SystemAishwarya Chandrasekar100% (1)

- Integrating Iot With Lqr-Pid Controller For Online Surveillance and Control of Ow and Pressure in Uid Transportation SystemDocument16 pagesIntegrating Iot With Lqr-Pid Controller For Online Surveillance and Control of Ow and Pressure in Uid Transportation SystemAlisha KshetriNo ratings yet

- Identification of Gyroplane Lateral/directional Stability and Control Characteristics From Flight TestDocument15 pagesIdentification of Gyroplane Lateral/directional Stability and Control Characteristics From Flight TestYhoanColmenaresNo ratings yet

- Jntua B.tech 2-1 Eee r15Document20 pagesJntua B.tech 2-1 Eee r15Vinodhkumar ReddyNo ratings yet

- Generalized PI Control of Active VehicleDocument19 pagesGeneralized PI Control of Active VehicleilublessingNo ratings yet

- 20-21 CS Midterm Exam QuestionsDocument2 pages20-21 CS Midterm Exam QuestionsAhmet ŞimşekNo ratings yet

- dmcs0708 PDFDocument327 pagesdmcs0708 PDFarviandyNo ratings yet

- The Use of Gaussian Processes in System IdentificationDocument13 pagesThe Use of Gaussian Processes in System IdentificationaaNo ratings yet

- Basic Control System With Matlab ExamplesDocument19 pagesBasic Control System With Matlab ExamplesMostafa8425No ratings yet

- Control System LabDocument37 pagesControl System LabSagarManjrekarNo ratings yet

- R19M.TECHEPE EPSISemDocument37 pagesR19M.TECHEPE EPSISemParameshwar TummetiNo ratings yet

- Homework 1: E1 241 - Dynamics of Linear Systems (Aug 2021) Due Date: Sept 08, 2021 Maximum Marks: 140Document2 pagesHomework 1: E1 241 - Dynamics of Linear Systems (Aug 2021) Due Date: Sept 08, 2021 Maximum Marks: 140Anand GuptaNo ratings yet

- EE Lab Manuls Fast NuDocument83 pagesEE Lab Manuls Fast NuMuhammad SaadNo ratings yet

- Michael Lewis - Influence of Loyalty Programs 2009Document13 pagesMichael Lewis - Influence of Loyalty Programs 2009Nóra AntóniaNo ratings yet

- Artificial Intelligence in EducationDocument765 pagesArtificial Intelligence in EducationNicole Stevens100% (3)

- Tutorial 2a Skee4113Document139 pagesTutorial 2a Skee4113Andres RaymondNo ratings yet

- Control Lab Report Experiment No. 04Document2 pagesControl Lab Report Experiment No. 04Nahin AminNo ratings yet

- Pendulo Invertido PDFDocument7 pagesPendulo Invertido PDFluis fernandoNo ratings yet

- Xie 2008 Multi-Objective H-Infinity Alpha-Stability Controller Synthesis of LTI SystemsDocument5 pagesXie 2008 Multi-Objective H-Infinity Alpha-Stability Controller Synthesis of LTI SystemsLucas SantosNo ratings yet

- R. W. EricksonDocument51 pagesR. W. EricksonVanshika JindalNo ratings yet

- MECH6091 - Poject1.Flight Control Systems - Qball Quadrotor HelicopterDocument28 pagesMECH6091 - Poject1.Flight Control Systems - Qball Quadrotor HelicopterOmar MalikNo ratings yet

- An RFID-based Inventory Management Framework For Emergency Relief OperationsDocument22 pagesAn RFID-based Inventory Management Framework For Emergency Relief OperationsRashidul IslamNo ratings yet

- Eigenstructure Assignment For Design of Multimode Flight Control SystemsDocument7 pagesEigenstructure Assignment For Design of Multimode Flight Control SystemsRitesh SinghNo ratings yet

- IntroMarkovChainsandApplications PDFDocument8 pagesIntroMarkovChainsandApplications PDFVishnuvardhanNo ratings yet