Professional Documents

Culture Documents

Envirocare Wte Msds

Uploaded by

dpfrzCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Envirocare Wte Msds

Uploaded by

dpfrzCopyright:

Available Formats

ENVIROCARE WTE

Drew Marine

Chemwatch Hazard Alert Code: 2

Chemwatch: 23-9028

Version No: 2.1.1.1

Safety Data Sheet according to OSHA HazCom Standard (2012) requirements

Issue Date: 01/01/2013

Print Date: 12/10/2014

Initial Date: Not Available

S.GHS.USA.EN

SECTION 1 IDENTIFICATION OF THE SUBSTANCE / MIXTURE AND OF THE COMPANY / UNDERTAKING

Product Identifier

Product name

ENVIROCARE WTE

Chemical Name

Not Applicable

Proper shipping name

Not Applicable

Chemical formula

Not Applicable

Other means of

identification

CAS number

Not Available

Not Applicable

Relevant identified uses of the substance or mixture and uses advised against

Relevant identified uses

Use according to manufacturer's directions.

Details of the manufacturer/importer

Registered company name

Address

Telephone

Drew Marine

100 South Jefferson Road Whippany 07981 NJ United States

973 526-5700.

Fax

Not Available

Website

Not Available

Not Available

Emergency telephone number

Association / Organisation

Emergency telephone

numbers

Other emergency telephone

numbers

Not Available

The numbers below are for EMERGENCY USE ONLY. Use the corporate number above for all other calls.

CHEMWATCH: From within the US and CANADA: 1 877-715-9305 OR call + 613 9573 3112. From outside the US and Canada: + 800 2436 2255 ( +800

CHEMCALL) or +613 9573 3112

CHEMWATCH EMERGENCY RESPONSE

Primary Number

Alternative Number 1

Alternative Number 2

877 715 9305

+612 9186 1132

Not Available

Once connected and if the message is not in your prefered language then please dial 01

Una vez conectado y si el mensaje no est en su idioma preferido, por favor marque 02

SECTION 2 HAZARDS IDENTIFICATION

Classification of the substance or mixture

GHS Classification

Skin Corrosion/Irritation Category 2, Eye Irritation Category 2A, STOT - SE (Resp. Irr.) Category 3

Label elements

GHS label elements

SIGNAL WORD

WARNING

Hazard statement(s)

H315

Causes skin irritation

H319

Causes serious eye irritation

H335

May cause respiratory irritation

Continued...

Chemwatch: 23-9028

Page 2 of 7

Version No: 2.1.1.1

ENVIROCARE WTE

Issue Date: 01/01/2013

Print Date: 12/10/2014

Supplementary statement(s)

Not Applicable

Precautionary statement(s): Prevention

P271

Use only outdoors or in a well-ventilated area.

P261

Avoid breathing dust/fume/gas/mist/vapours/spray.

P280

Wear protective gloves/protective clothing/eye protection/face protection.

Precautionary statement(s): Response

P305+P351+P338

P312

IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing.

Call a POISON CENTER/doctor/physician/first aider/if you feel unwell.

P337+P313

If eye irritation persists: Get medical advice/attention.

P302+P352

IF ON SKIN: Wash with plenty of water and soap

P304+P340

IF INHALED: Remove person to fresh air and keep comfortable for breathing.

P332+P313

If skin irritation occurs: Get medical advice/attention.

P362+P364

Take off contaminated clothing and wash it before reuse.

Precautionary statement(s): Storage

P405

P403+P233

Store locked up.

Store in a well-ventilated place. Keep container tightly closed.

Precautionary statement(s): Disposal

P501

Dispose of contents/container to authorised chemical landfill or if organic to high temperature incineration

SECTION 3 COMPOSITION / INFORMATION ON INGREDIENTS

Substances

See section below for composition of Mixtures

Mixtures

CAS No

%[weight]

Name

7647-14-5

>60

sodium chloride

Note: Manufacturer has supplied full ingredient

information to allow CHEMWATCH assessment.

Note: Manufacturer has supplied full ingredient information to allow CHEMWATCH assessment.

SECTION 4 FIRST AID MEASURES

Description of first aid measures

Eye Contact

Skin Contact

If this product comes in contact with eyes:

Wash out immediately with water.

If irritation continues, seek medical attention.

Removal of contact lenses after an eye injury should only be undertaken by skilled personnel.

If skin or hair contact occurs:

Flush skin and hair with running water (and soap if available).

Seek medical attention in event of irritation.

Inhalation

If fumes, aerosols or combustion products are inhaled remove from contaminated area.

Other measures are usually unnecessary.

Ingestion

Immediately give a glass of water.

First aid is not generally required. If in doubt, contact a Poisons Information Centre or a doctor.

Indication of any immediate medical attention and special treatment needed

Treat symptomatically.

SECTION 5 FIREFIGHTING MEASURES

Extinguishing media

There is no restriction on the type of extinguisher which may be used.

Use extinguishing media suitable for surrounding area.

Special hazards arising from the substrate or mixture

Fire Incompatibility

None known.

Advice for firefighters

Fire Fighting

Alert Fire Brigade and tell them location and nature of hazard.

Wear breathing apparatus plus protective gloves in the event of a fire.

Prevent, by any means available, spillage from entering drains or water courses.

Use fire fighting procedures suitable for surrounding area.

DO NOT approach containers suspected to be hot.

Continued...

Chemwatch: 23-9028

Page 3 of 7

Version No: 2.1.1.1

Issue Date: 01/01/2013

Print Date: 12/10/2014

ENVIROCARE WTE

Cool fire exposed containers with water spray from a protected location.

If safe to do so, remove containers from path of fire.

Equipment should be thoroughly decontaminated after use.

Fire/Explosion Hazard

Non combustible.

Not considered a significant fire risk, however containers may burn.

Decomposition may produce toxic fumes of:, hydrogen chloride

SECTION 6 ACCIDENTAL RELEASE MEASURES

Personal precautions, protective equipment and emergency procedures

Clean up all spills immediately.

Avoid contact with skin and eyes.

Wear impervious gloves and safety glasses.

Use dry clean up procedures and avoid generating dust.

Vacuum up (consider explosion-proof machines designed to be grounded during storage and use).

Do NOT use air hoses for cleaning

Place spilled material in clean, dry, sealable, labelled container.

Minor Spills

Clear area of personnel and move upwind.

Alert Fire Brigade and tell them location and nature of hazard.

Control personal contact with the substance, by using protective equipment and dust respirator.

Prevent spillage from entering drains, sewers or water courses.

Avoid generating dust.

Sweep, shovel up. Recover product wherever possible.

Put residues in labelled plastic bags or other containers for disposal.

If contamination of drains or waterways occurs, advise emergency services.

Major Spills

Personal Protective Equipment advice is contained in Section 8 of the MSDS.

SECTION 7 HANDLING AND STORAGE

Precautions for safe handling

Safe handling

Other information

Limit all unnecessary personal contact.

Wear protective clothing when risk of exposure occurs.

Use in a well-ventilated area.

Avoid contact with incompatible materials.

When handling, DO NOT eat, drink or smoke.

Keep containers securely sealed when not in use.

Avoid physical damage to containers.

Always wash hands with soap and water after handling.

Work clothes should be laundered separately.

Use good occupational work practice.

Observe manufacturer's storage and handling recommendations contained within this MSDS.

Atmosphere should be regularly checked against established exposure standards to ensure safe working conditions are maintained.

Store in original containers.

Keep containers securely sealed.

Store in a cool, dry area protected from environmental extremes.

Store away from incompatible materials and foodstuff containers.

Protect containers against physical damage and check regularly for leaks.

Observe manufacturer's storage and handling recommendations contained within this MSDS.

For major quantities:

Consider storage in bunded areas - ensure storage areas are isolated from sources of community water (including stormwater, ground water, lakes and

streams}.

Ensure that accidental discharge to air or water is the subject of a contingency disaster management plan; this may require consultation with local

authorities.

Conditions for safe storage, including any incompatibilities

Suitable container

Storage incompatibility

Lined metal can, lined metal pail/ can.

Plastic pail.

Polyliner drum.

Packing as recommended by manufacturer.

Check all containers are clearly labelled and free from leaks.

Avoid contamination of water, foodstuffs, feed or seed.

None known

PACKAGE MATERIAL INCOMPATIBILITIES

Not Available

SECTION 8 EXPOSURE CONTROLS / PERSONAL PROTECTION

Control parameters

OCCUPATIONAL EXPOSURE LIMITS (OEL)

INGREDIENT DATA

Not Available

EMERGENCY LIMITS

Ingredient

TEEL-0

TEEL-1

TEEL-2

TEEL-3

Continued...

Chemwatch: 23-9028

Page 4 of 7

Version No: 2.1.1.1

Issue Date: 01/01/2013

Print Date: 12/10/2014

ENVIROCARE WTE

ENVIROCARE WTE

Not Available

Not Available

Not Available

Ingredient

Original IDLH

Revised IDLH

sodium chloride

Not Available

Not Available

Not Available

Exposure controls

Engineering controls are used to remove a hazard or place a barrier between the worker and the hazard. Well-designed engineering controls can be highly

effective in protecting workers and will typically be independent of worker interactions to provide this high level of protection.

The basic types of engineering controls are:

Process controls which involve changing the way a job activity or process is done to reduce the risk.

Enclosure and/or isolation of emission source which keeps a selected hazard "physically" away from the worker and ventilation that strategically "adds" and

"removes" air in the work environment. Ventilation can remove or dilute an air contaminant if designed properly. The design of a ventilation system must match

the particular process and chemical or contaminant in use.

Employers may need to use multiple types of controls to prevent employee overexposure.

Local exhaust ventilation is required where solids are handled as powders or crystals; even when particulates are relatively large, a certain proportion will be

powdered by mutual friction.

If in spite of local exhaust an adverse concentration of the substance in air could occur, respiratory protection should be considered.

Such protection might consist of:

(a): particle dust respirators, if necessary, combined with an absorption cartridge;

(b): filter respirators with absorption cartridge or canister of the right type;

(c): fresh-air hoods or masks.

Air contaminants generated in the workplace possess varying "escape" velocities which, in turn, determine the "capture velocities" of fresh circulating air

required to effectively remove the contaminant.

Appropriate engineering

controls

Type of Contaminant:

Air Speed:

direct spray, spray painting in shallow booths, drum filling, conveyer loading, crusher dusts, gas discharge (active generation

into zone of rapid air motion)

1-2.5 m/s (200-500

f/min.)

grinding, abrasive blasting, tumbling, high speed wheel generated dusts (released at high initial velocity into zone of very high

rapid air motion).

2.5-10 m/s (500-2000

f/min.)

Within each range the appropriate value depends on:

Lower end of the range

Upper end of the range

1: Room air currents minimal or favourable to capture

1: Disturbing room air currents

2: Contaminants of low toxicity or of nuisance value only.

2: Contaminants of high toxicity

3: Intermittent, low production.

3: High production, heavy use

4: Large hood or large air mass in motion

4: Small hood-local control only

Simple theory shows that air velocity falls rapidly with distance away from the opening of a simple extraction pipe. Velocity generally decreases with the square

of distance from the extraction point (in simple cases). Therefore the air speed at the extraction point should be adjusted, accordingly, after reference to

distance from the contaminating source. The air velocity at the extraction fan, for example, should be a minimum of 4-10 m/s (800-2000 f/min) for extraction of

crusher dusts generated 2 metres distant from the extraction point. Other mechanical considerations, producing performance deficits within the extraction

apparatus, make it essential that theoretical air velocities are multiplied by factors of 10 or more when extraction systems are installed or used.

Personal protection

Eye and face protection

Skin protection

Hands/feet protection

Safety glasses with side shields

Chemical goggles.

Contact lenses may pose a special hazard; soft contact lenses may absorb and concentrate irritants. A written policy document, describing the wearing of

lenses or restrictions on use, should be created for each workplace or task. This should include a review of lens absorption and adsorption for the class of

chemicals in use and an account of injury experience. Medical and first-aid personnel should be trained in their removal and suitable equipment should be

readily available. In the event of chemical exposure, begin eye irrigation immediately and remove contact lens as soon as practicable. Lens should be removed

at the first signs of eye redness or irritation - lens should be removed in a clean environment only after workers have washed hands thoroughly. [CDC NIOSH

Current Intelligence Bulletin 59], [AS/NZS 1336 or national equivalent]

See Hand protection below

The selection of suitable gloves does not only depend on the material, but also on further marks of quality which vary from manufacturer to manufacturer. Where

the chemical is a preparation of several substances, the resistance of the glove material can not be calculated in advance and has therefore to be checked prior

to the application.

The exact break through time for substances has to be obtained from the manufacturer of the protective gloves and.has to be observed when making a final

choice.

Suitability and durability of glove type is dependent on usage. Important factors in the selection of gloves include:

frequency and duration of contact,

chemical resistance of glove material,

glove thickness and

dexterity

Select gloves tested to a relevant standard (e.g. Europe EN 374, US F739, AS/NZS 2161.1 or national equivalent).

When prolonged or frequently repeated contact may occur, a glove with a protection class of 5 or higher (breakthrough time greater than 240 minutes

according to EN 374, AS/NZS 2161.10.1 or national equivalent) is recommended.

When only brief contact is expected, a glove with a protection class of 3 or higher (breakthrough time greater than 60 minutes according to EN 374, AS/NZS

2161.10.1 or national equivalent) is recommended.

Some glove polymer types are less affected by movement and this should be taken into account when considering gloves for long-term use.

Contaminated gloves should be replaced.

Gloves must only be worn on clean hands. After using gloves, hands should be washed and dried thoroughly. Application of a non-perfumed moisturiser is

recommended.

Experience indicates that the following polymers are suitable as glove materials for protection against undissolved, dry solids, where abrasive particles are not

present.

polychloroprene.

nitrile rubber.

butyl rubber.

Continued...

Chemwatch: 23-9028

Page 5 of 7

Version No: 2.1.1.1

Issue Date: 01/01/2013

Print Date: 12/10/2014

ENVIROCARE WTE

fluorocaoutchouc.

polyvinyl chloride.

Gloves should be examined for wear and/ or degradation constantly.

Body protection

See Other protection below

Other protection

No special equipment needed when handling small quantities.

OTHERWISE:

Overalls.

Barrier cream.

Eyewash unit.

Thermal hazards

Not Available

Recommended material(s)

Respiratory protection

GLOVE SELECTION INDEX

Glove selection is based on a modified presentation of the:

"Forsberg Clothing Performance Index".

The effect(s) of the following substance(s) are taken into account in the computergenerated selection:

ENVIROCARE WTE

Material

CPI

NATURAL RUBBER

NATURAL+NEOPRENE

NITRILE

* CPI - Chemwatch Performance Index

A: Best Selection

B: Satisfactory; may degrade after 4 hours continuous immersion

C: Poor to Dangerous Choice for other than short term immersion

NOTE: As a series of factors will influence the actual performance of the glove, a final

selection must be based on detailed observation. * Where the glove is to be used on a short term, casual or infrequent basis, factors such as

"feel" or convenience (e.g. disposability), may dictate a choice of gloves which might otherwise

be unsuitable following long-term or frequent use. A qualified practitioner should be consulted.

Required Minimum

Protection Factor

Half-Face

Respirator

Full-Face

Respirator

Powered Air

Respirator

up to 10 x ES

P1

Air-line*

PAPR-P1

-

up to 50 x ES

Air-line**

P2

PAPR-P2

up to 100 x ES

P3

100+ x ES

Air-line*

Air-line**

PAPR-P3

* - Negative pressure demand ** - Continuous flow

A(All classes) = Organic vapours, B AUS or B1 = Acid gasses, B2 = Acid gas or hydrogen

cyanide(HCN), B3 = Acid gas or hydrogen cyanide(HCN), E = Sulfur dioxide(SO2), G =

Agricultural chemicals, K = Ammonia(NH3), Hg = Mercury, NO = Oxides of nitrogen, MB =

Methyl bromide, AX = Low boiling point organic compounds(below 65 degC)

SECTION 9 PHYSICAL AND CHEMICAL PROPERTIES

Information on basic physical and chemical properties

Appearance

Physical state

Tan granular solid; mixes with water.

Solid

Relative density (Water = 1)

Not Available

Odour

Not Available

Partition coefficient

n-octanol / water

Not Available

Odour threshold

Not Available

Auto-ignition temperature

(C)

Not Available

pH (as supplied)

Not Available

Decomposition

temperature

Not Available

Melting point / freezing

point (C)

Not Available

Viscosity (cSt)

Not Available

Initial boiling point and

boiling range (C)

Not Available

Molecular weight (g/mol)

Not Applicable

Flash point (C)

Not Available

Taste

Not Available

Evaporation rate

Not Available

Explosive properties

Not Available

Flammability

Not Available

Oxidising properties

Not Available

Upper Explosive Limit (%)

Not Available

Surface Tension (dyn/cm or

mN/m)

Not Applicable

Lower Explosive Limit (%)

Not Available

Volatile Component (%vol)

Not Available

Vapour pressure (kPa)

Not Available

Solubility in water (g/L)

Miscible

Vapour density (Air = 1)

Not Available

Gas group

Not Available

pH as a solution(1%)

Not Available

VOC g/L

Not Available

SECTION 10 STABILITY AND REACTIVITY

Reactivity

Chemical stability

See section 7

Product is considered stable and hazardous polymerisation will not occur.

Possibility of hazardous

reactions

See section 7

Conditions to avoid

See section 7

Incompatible materials

See section 7

Hazardous decomposition

products

See section 5

SECTION 11 TOXICOLOGICAL INFORMATION

Continued...

Chemwatch: 23-9028

Page 6 of 7

Version No: 2.1.1.1

Issue Date: 01/01/2013

Print Date: 12/10/2014

ENVIROCARE WTE

Information on toxicological effects

Inhaled

Ingestion

Skin Contact

Eye

Chronic

The material is not thought to produce adverse health effects or irritation of the respiratory tract (as classified by EC Directives using animal models).

Nevertheless, good hygiene practice requires that exposure be kept to a minimum and that suitable control measures be used in an occupational setting.

Not normally a hazard due to non-volatile nature of product

The material has NOT been classified by EC Directives or other classification systems as "harmful by ingestion". This is because of the lack of corroborating

animal or human evidence. The material may still be damaging to the health of the individual, following ingestion, especially where pre-existing organ (e.g liver,

kidney) damage is evident. Present definitions of harmful or toxic substances are generally based on doses producing mortality rather than those producing

morbidity (disease, ill-health). Gastrointestinal tract discomfort may produce nausea and vomiting. In an occupational setting however, ingestion of insignificant

quantities is not thought to be cause for concern.

The material is not thought to produce adverse health effects or skin irritation following contact (as classified by EC Directives using animal models).

Nevertheless, good hygiene practice requires that exposure be kept to a minimum and that suitable gloves be used in an occupational setting.

Open cuts, abraded or irritated skin should not be exposed to this material

Contact with cuts, abraded skin is painful, but this is transient

Entry into the blood-stream through, for example, cuts, abrasions, puncture wounds or lesions, may produce systemic injury with harmful effects. Examine the

skin prior to the use of the material and ensure that any external damage is suitably protected.

Although the material is not thought to be an irritant (as classified by EC Directives), direct contact with the eye may cause transient discomfort characterised

by tearing or conjunctival redness (as with windburn). Slight abrasive damage may also result. The material may produce foreign body irritation in certain

individuals.

Long-term exposure to the product is not thought to produce chronic effects adverse to health (as classified by EC Directives using animal models);

nevertheless exposure by all routes should be minimised as a matter of course.

TOXICITY

IRRITATION

Not Available

Not Available

ENVIROCARE WTE

sodium chloride

TOXICITY

IRRITATION

Intraperitoneal (Mouse) LD50: 2602

mg/kg

Eye (rabbit): 10 mg - moderate

Intraperitoneal (Rat) LD50: 2600

mg/kg

Eye (rabbit):100 mg/24h - moderate

Intravenous (Mouse) LD50: 645

mg/kg

Skin (rabbit): 500 mg/24h - mild

Oral (rat) LD50: 3000 mg/kg

Not Available

Not Available

Not available. Refer to individual constituents.

SODIUM CHLORIDE

Asthma-like symptoms may continue for months or even years after exposure to the material ceases. This may be due to a non-allergenic condition known

as reactive airways dysfunction syndrome (RADS) which can occur following exposure to high levels of highly irritating compound. Key criteria for the

diagnosis of RADS include the absence of preceding respiratory disease, in a non-atopic individual, with abrupt onset of persistent asthma-like symptoms

within minutes to hours of a documented exposure to the irritant. A reversible airflow pattern, on spirometry, with the presence of moderate to severe

bronchial hyperreactivity on methacholine challenge testing and the lack of minimal lymphocytic inflammation, without eosinophilia, have also been included

in the criteria for diagnosis of RADS. RADS (or asthma) following an irritating inhalation is an infrequent disorder with rates related to the concentration

of and duration of exposure to the irritating substance. Industrial bronchitis, on the other hand, is a disorder that occurs as result of exposure due to high

concentrations of irritating substance (often particulate in nature) and is completely reversible after exposure ceases. The disorder is characterised by

dyspnea, cough and mucus production.

The material may produce moderate eye irritation leading to inflammation. Repeated or prolonged exposure to irritants may produce conjunctivitis.

The material may cause skin irritation after prolonged or repeated exposure and may produce a contact dermatitis (nonallergic). This form of dermatitis is

often characterised by skin redness (erythema) and swelling epidermis. Histologically there may be intercellular oedema of the spongy layer (spongiosis)

and intracellular oedema of the epidermis.

Acute Toxicity

Carcinogenicity

Skin Irritation/Corrosion

Reproductivity

Serious Eye

Damage/Irritation

STOT - Single Exposure

Respiratory or Skin

sensitisation

STOT - Repeated Exposure

Mutagenicity

Aspiration Hazard

Legend:

Data required to make classification available

Data available but does not fill the criteria for classification

Data Not Available to make classification

CMR STATUS

Not Applicable

SECTION 12 ECOLOGICAL INFORMATION

Toxicity

Although inorganic chloride ions are not normally considered toxic they can exist in effluents at acutely toxic levels (chloride >3000 mg/l). The resulting salinity can exceed the tolerances of most

freshwater organisms.

Inorganic chlorine eventually finds its way into the aqueous compartment and as such is bioavailable. Incidental exposure to inorganic chloride may occur in occupational settings where chemicals

management policies are improperly applied. The toxicity of chloride salts depends on the counter-ion (cation) present; that of chloride itself is unknown. Chloride toxicity has not been observed in

humans except in the special case of impaired sodium chloride metabolism, e.g. in congestive heart failure. Healthy individuals can tolerate the intake of large quantities of chloride provided that

there is a concomitant intake of fresh water.

Continued...

Chemwatch: 23-9028

Page 7 of 7

Version No: 2.1.1.1

Issue Date: 01/01/2013

Print Date: 12/10/2014

ENVIROCARE WTE

Although excessive intake of drinking-water containing sodium chloride at concentrations above 2.5 g/litre has been reported to produce hypertension, this effect is believed to be related to the

sodium ion concentration.

Chloride concentrations in excess of about 250 mg/litre can give rise to detectable taste in water, but the threshold depends upon the associated cations. Consumers can, however, become

accustomed to concentrations in excess of 250 mg/litre. No health-based guideline value is proposed for chloride in drinking-water.

In humans, 88% of chloride is extracellular and contributes to the osmotic activity of body fluids. The electrolyte balance in the body is maintained by adjusting total dietary intake and by excretion via

the kidneys and gastrointestinal tract. Chloride is almost completely absorbed in normal individuals, mostly from the proximal half of the small intestine. Normal fluid loss amounts to about 1.5-2

liters/day, together with about 4 g of chloride per day. Most (90 - 95%) is excreted in the urine, with minor amounts in faeces (4-8%) and sweat (2%).

Chloride increases the electrical conductivity of water and thus increases its corrosivity. In metal pipes, chloride reacts with metal ions to form soluble salts thus increasing levels of metals in

drinking-water. In lead pipes, a protective oxide layer is built up, but chloride enhances galvanic corrosion. It can also increase the rate of pitting corrosion of metal pipes.

Persistence and degradability

Ingredient

Persistence: Water/Soil

Persistence: Air

sodium chloride

high

high

Bioaccumulative potential

Ingredient

Bioaccumulation

sodium chloride

low (BCF = 3.162)

Mobility in soil

Ingredient

Mobility

sodium chloride

low (KOC = 14.3)

SECTION 13 DISPOSAL CONSIDERATIONS

Waste treatment methods

DO NOT allow wash water from cleaning or process equipment to enter drains.

It may be necessary to collect all wash water for treatment before disposal.

In all cases disposal to sewer may be subject to local laws and regulations and these should be considered first.

Where in doubt contact the responsible authority.

Recycle wherever possible or consult manufacturer for recycling options.

Consult State Land Waste Management Authority for disposal.

Bury residue in an authorised landfill.

Recycle containers if possible, or dispose of in an authorised landfill.

Product / Packaging

disposal

SECTION 14 TRANSPORT INFORMATION

Labels Required

Marine Pollutant

NO

Land transport (DOT): NOT REGULATED FOR TRANSPORT OF DANGEROUS GOODS

Air transport (ICAO-IATA / DGR): NOT REGULATED FOR TRANSPORT OF DANGEROUS GOODS

Sea transport (IMDG-Code / GGVSee): NOT REGULATED FOR TRANSPORT OF DANGEROUS GOODS

SECTION 15 REGULATORY INFORMATION

Safety, health and environmental regulations / legislation specific for the substance or mixture

sodium chloride(7647-14-5)

is found on the following

regulatory lists

"US Toxic Substances Control Act (TSCA) - Chemical Substance Inventory"

SECTION 16 OTHER INFORMATION

Other information

Classification of the preparation and its individual components has drawn on official and authoritative sources as well as independent review by the Chemwatch Classification committee using

available literature references.

A list of reference resources used to assist the committee may be found at:

www.chemwatch.net/references

The (M)SDS is a Hazard Communication tool and should be used to assist in the Risk Assessment. Many factors determine whether the reported Hazards are Risks in the workplace or other

settings. Risks may be determined by reference to Exposures Scenarios. Scale of use, frequency of use and current or available engineering controls must be considered.

end of SDS

You might also like

- E-00331 Vigon SDS US EnglishDocument9 pagesE-00331 Vigon SDS US EnglishDHe Vic'zNo ratings yet

- Dettol Antiseptic Wound Spray SDS Safety Data SheetDocument6 pagesDettol Antiseptic Wound Spray SDS Safety Data SheetHana AlghamdiNo ratings yet

- Aquatower 100Document7 pagesAquatower 100Diego y MagelaNo ratings yet

- SDS Graffiti EzyWipesDocument8 pagesSDS Graffiti EzyWipesadminNo ratings yet

- Vigon SDS US EnglishDocument14 pagesVigon SDS US EnglishFahad MaqsoodNo ratings yet

- Safety Data Sheet W&N Brush and Pro Markers (Article)Document9 pagesSafety Data Sheet W&N Brush and Pro Markers (Article)Chris MitrevskiNo ratings yet

- Safety Data Sheet for Lubricating Grease No. 105Document11 pagesSafety Data Sheet for Lubricating Grease No. 105Fabián Andrés Pérez ColomaNo ratings yet

- Dithane Rainshield Neo Tec SDSDocument13 pagesDithane Rainshield Neo Tec SDSpepeb febriantoNo ratings yet

- Gallant Ultra Herbicide SDS NZ Oct 2021Document13 pagesGallant Ultra Herbicide SDS NZ Oct 2021Gita Kurniawan SuciNo ratings yet

- USA001117 CloroxPro Pine Sol Multi Surface Cleaner - 1Document13 pagesUSA001117 CloroxPro Pine Sol Multi Surface Cleaner - 1Manuel Rodriguez OrtizNo ratings yet

- E - Finish ClassicDocument7 pagesE - Finish ClassicLuei NaccarNo ratings yet

- MSDS Colour Ball ToiletDocument12 pagesMSDS Colour Ball ToiletKang RaisNo ratings yet

- Material Safety Data Sheet: Product Name MS-69Document7 pagesMaterial Safety Data Sheet: Product Name MS-69QuanNo ratings yet

- E - Finish All in OneDocument7 pagesE - Finish All in OneLuei NaccarNo ratings yet

- 10 Tenths Race Coolant Inhibitor SDSDocument9 pages10 Tenths Race Coolant Inhibitor SDSᮛᮥᮞ᮪ᮓᮤ ᮎᮦᮎᮦᮕ᮪No ratings yet

- HDS Coolant Endurance Premezclado 50 50Document8 pagesHDS Coolant Endurance Premezclado 50 50Gregorio Antonio Valero VerdeNo ratings yet

- Safety Procedures for Handling TNTDocument4 pagesSafety Procedures for Handling TNTyayax_619No ratings yet

- DOALL-MSDS US English - BRIGHT EDGE 240 - US - DOALLDocument7 pagesDOALL-MSDS US English - BRIGHT EDGE 240 - US - DOALLJAY CORTEZ MAMABICHONo ratings yet

- MSDS Norlube 3030 Release AgentDocument5 pagesMSDS Norlube 3030 Release AgentrenebbNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument12 pagesSafety Data Sheet: 1. IdentificationeadriesNo ratings yet

- Castrol Optileb GT 320Document9 pagesCastrol Optileb GT 320Andreas PradanaNo ratings yet

- VM 032 - VM 068 - VM 100 - VM 150 - AuDocument9 pagesVM 032 - VM 068 - VM 100 - VM 150 - AuMariana CardosoNo ratings yet

- SAFETY DATA SHEET FOR KOMATSU HYDRAULIC OIL HO 46-HMDocument5 pagesSAFETY DATA SHEET FOR KOMATSU HYDRAULIC OIL HO 46-HMrolex21No ratings yet

- MSDS Puffin Traffico DoneDocument13 pagesMSDS Puffin Traffico DoneAngga PratamaNo ratings yet

- Safety Data Sheet: Section 1: Identification: Product Identifier and Chemical IdentityDocument12 pagesSafety Data Sheet: Section 1: Identification: Product Identifier and Chemical IdentityLahoucine GourdoNo ratings yet

- Paraxylene Safety Data Sheet CPChemDocument14 pagesParaxylene Safety Data Sheet CPChemscribd405No ratings yet

- Dangerous Weedkiller SDSDocument8 pagesDangerous Weedkiller SDSMark CasanovaNo ratings yet

- SDS Wetting Agent 2016Document8 pagesSDS Wetting Agent 2016M.MuthumanickamNo ratings yet

- REVANCHA-10-EC-BIFENTHRIN SafetyData SheetDocument8 pagesREVANCHA-10-EC-BIFENTHRIN SafetyData SheetBong Casir100% (1)

- Aquatower 170Document6 pagesAquatower 170Diego y MagelaNo ratings yet

- Hydrotite Adhesive SDS-GreenstreakDocument13 pagesHydrotite Adhesive SDS-Greenstreakrobox514No ratings yet

- Brake Parts Cleaner WES W5090 PDFDocument10 pagesBrake Parts Cleaner WES W5090 PDFYoutube For EducationNo ratings yet

- Msds +savlon Antiseptic Cream v4.2-D0069815Document9 pagesMsds +savlon Antiseptic Cream v4.2-D0069815jehaff ceftazidimeNo ratings yet

- Safety Data Sheet: JAX Poly-Plate EP-2 Section 1. IdentificationDocument5 pagesSafety Data Sheet: JAX Poly-Plate EP-2 Section 1. IdentificationMichael Herald100% (1)

- Safety Data Sheet: Section 1. IdentificationDocument10 pagesSafety Data Sheet: Section 1. IdentificationMantenimiento2 PdaNo ratings yet

- SAFETY DATA SHEET FOR CORROSIVE DIGESTION SOLUTIONDocument20 pagesSAFETY DATA SHEET FOR CORROSIVE DIGESTION SOLUTIONEmilia MerinoNo ratings yet

- Air Wick Decosphere Safety Data SheetDocument8 pagesAir Wick Decosphere Safety Data SheetLauraNo ratings yet

- Amine SDS 2021 - 1332471032Document9 pagesAmine SDS 2021 - 1332471032kathygona1980No ratings yet

- Sodium Perchlorate Monohydrate SDSDocument7 pagesSodium Perchlorate Monohydrate SDSemeka2012100% (1)

- Safety Data Sheet: 1. Identification of The Material and Supplier Sodium Aluminate SolutionDocument7 pagesSafety Data Sheet: 1. Identification of The Material and Supplier Sodium Aluminate SolutionHeinrich ManaligodNo ratings yet

- Revision Highlights Water Mixable Oil Paint Safety DataDocument9 pagesRevision Highlights Water Mixable Oil Paint Safety DataDanna CeiaNo ratings yet

- Harpic Fresh Power Liquid Lavender Meadows 3214283 D8393566 v1.0LDocument9 pagesHarpic Fresh Power Liquid Lavender Meadows 3214283 D8393566 v1.0Lhilman pramanaNo ratings yet

- Croc Bloc HD Insect RepellantDocument8 pagesCroc Bloc HD Insect RepellantPubcrawlNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument12 pagesSafety Data Sheet: 1. IdentificationFernanda ImbertNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument9 pagesSafety Data Sheet: 1. IdentificationneocearNo ratings yet

- Deltagard Sds 2017Document10 pagesDeltagard Sds 2017seenigs84No ratings yet

- SDS US English FLUOROCARBON+GEL+875L-MSDocument7 pagesSDS US English FLUOROCARBON+GEL+875L-MSLizeth MejíaNo ratings yet

- SW 945Document10 pagesSW 945sintaNo ratings yet

- 35V Prussian Blue .75ozDocument8 pages35V Prussian Blue .75ozEscobar ValderramaNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument8 pagesSafety Data Sheet: Section 1. Identificationtsandeep1310No ratings yet

- Biothane MSDS 10.2Document5 pagesBiothane MSDS 10.2teru_teru_bozo86No ratings yet

- Bayer Cropscience: Movento®Document11 pagesBayer Cropscience: Movento®EugeniaNo ratings yet

- Polymers ApS Products - SDS12371 - enDocument7 pagesPolymers ApS Products - SDS12371 - endanyel17No ratings yet

- Heavy Duty Cleaner SDS SummaryDocument5 pagesHeavy Duty Cleaner SDS SummaryaldiNo ratings yet

- 287 English SDS USDocument7 pages287 English SDS USpiradeepancNo ratings yet

- MSDS Wash PackDocument11 pagesMSDS Wash PackSn DayanidhiNo ratings yet

- Rotair Food Grade SafetyDocument7 pagesRotair Food Grade SafetyAristideNo ratings yet

- Dowtherm SR-1 (Ingles)Document13 pagesDowtherm SR-1 (Ingles)Jana DmitrievaNo ratings yet

- 2 - How To Create Business ValueDocument16 pages2 - How To Create Business ValueSorin GabrielNo ratings yet

- Equity Inv HW 2 BHDocument3 pagesEquity Inv HW 2 BHBen HolthusNo ratings yet

- Chapter 12 The Incredible Story of How The Great Controversy Was Copied by White From Others, and Then She Claimed It To Be Inspired.Document6 pagesChapter 12 The Incredible Story of How The Great Controversy Was Copied by White From Others, and Then She Claimed It To Be Inspired.Barry Lutz Sr.No ratings yet

- Mayflower Compact - WikipediaDocument4 pagesMayflower Compact - WikipediaHeaven2012No ratings yet

- Module 6: 4M'S of Production and Business ModelDocument43 pagesModule 6: 4M'S of Production and Business ModelSou MeiNo ratings yet

- RA 4196 University Charter of PLMDocument4 pagesRA 4196 University Charter of PLMJoan PabloNo ratings yet

- BICON Prysmian Cable Cleats Selection ChartDocument1 pageBICON Prysmian Cable Cleats Selection ChartMacobNo ratings yet

- EAPP Q2 Module 2Document24 pagesEAPP Q2 Module 2archiviansfilesNo ratings yet

- Topic 1 in 21st CneturyDocument8 pagesTopic 1 in 21st CneturyLuwisa RamosNo ratings yet

- Equity Valuation Concepts and Basic Tools (CFA) CH 10Document28 pagesEquity Valuation Concepts and Basic Tools (CFA) CH 10nadeem.aftab1177No ratings yet

- Poetry Recitation Competition ReportDocument7 pagesPoetry Recitation Competition ReportmohammadNo ratings yet

- Jesus' Death on the Cross Explored Through Theological ModelsDocument13 pagesJesus' Death on the Cross Explored Through Theological ModelsKhristian Joshua G. JuradoNo ratings yet

- Otto F. Kernberg - Transtornos Graves de PersonalidadeDocument58 pagesOtto F. Kernberg - Transtornos Graves de PersonalidadePaulo F. F. Alves0% (2)

- CH 19Document56 pagesCH 19Ahmed El KhateebNo ratings yet

- Megha Rakheja Project ReportDocument40 pagesMegha Rakheja Project ReportMehak SharmaNo ratings yet

- ModalsDocument13 pagesModalsJose CesistaNo ratings yet

- The Serpents Tail A Brief History of KHMDocument294 pagesThe Serpents Tail A Brief History of KHMWill ConquerNo ratings yet

- Skin Yale University Protein: Where Does Collagen Come From?Document2 pagesSkin Yale University Protein: Where Does Collagen Come From?Ellaine Pearl AlmillaNo ratings yet

- Note-Taking StrategiesDocument16 pagesNote-Taking Strategiesapi-548854218No ratings yet

- BI - Cover Letter Template For EC Submission - Sent 09 Sept 2014Document1 pageBI - Cover Letter Template For EC Submission - Sent 09 Sept 2014scribdNo ratings yet

- Important TemperatefruitsDocument33 pagesImportant TemperatefruitsjosephinNo ratings yet

- Compound SentenceDocument31 pagesCompound Sentencerosemarie ricoNo ratings yet

- Examination of InvitationDocument3 pagesExamination of InvitationChoi Rinna62% (13)

- Get 1. Verb Gets, Getting Past Got Past Participle Got, GottenDocument2 pagesGet 1. Verb Gets, Getting Past Got Past Participle Got, GottenOlga KardashNo ratings yet

- An Analysis of Students Pronounciation Errors Made by Ninth Grade of Junior High School 1 TengaranDocument22 pagesAn Analysis of Students Pronounciation Errors Made by Ninth Grade of Junior High School 1 TengaranOcta WibawaNo ratings yet

- Notes Socialism in Europe and RussianDocument11 pagesNotes Socialism in Europe and RussianAyaan ImamNo ratings yet

- Lost Temple of Forgotten Evil - Adventure v3 PDFDocument36 pagesLost Temple of Forgotten Evil - Adventure v3 PDFВячеслав100% (2)

- Virtue Ethics: Aristotle and St. Thomas Aquinas: DiscussionDocument16 pagesVirtue Ethics: Aristotle and St. Thomas Aquinas: DiscussionCarlisle ParkerNo ratings yet

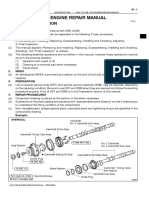

- How To Use This Engine Repair Manual: General InformationDocument3 pagesHow To Use This Engine Repair Manual: General InformationHenry SilvaNo ratings yet

- Clinical Eval Brittany RivasDocument8 pagesClinical Eval Brittany Rivasapi-613460741No ratings yet