Professional Documents

Culture Documents

TDS Wabo Elastodec E

Uploaded by

aomareltayebCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS Wabo Elastodec E

Uploaded by

aomareltayebCopyright:

Available Formats

WaboElastodec E

Plain and laminated elastomeric bearings

Uses

Product Data

WABO ELASTODEC E elastomeric bearings are

used as bearings in bridges and in other civil and

industrial structures. Actually, they are capable of

taking up and transferring forces from an element

to another in the structure and placed vertical

between sections act as to absorb seismic shock.

Rubber used for manufacturing WABO ELASTODEC

E is based on synthetic elastomers complying with

UNI-CNR 10018/87 standard, featuring Shore A

hardness equal to 60 5.

Polymers making up the elastomer feature

particularly long and flexible molecular chains,

capable of being elastically deformed when

developing under the vulcanization process.

Upon request, elastomers with other properties and

bearings meeting different standards, such as

AASHTO, DIN, BS, SETRA, NBN, etc. can be

supplied. Fe 430-UNI 7070 or higher grade steel is

used for WABO ELASTODEC E bearing

reinforcements, featuring the following specifications:

Benefits

Reduced thickness

Easy installation

Maintenance-free

Cost-effectiveness

Description

WABO ELASTODEC E bearings are manufactured

making use of materials complying with all

regulations in force, in simple layers of rubber or

with several layers separated by thin sheet metal.

In reinforced bearings, vulcanized rubber sheets

are used to protect the steel from corrosion and to

convey horizontal forces from rubber to sheet

metal.

This steel sheet is smaller in size than bearing, in

order to be encapsulated by the rubber, and their

edges are finished in order to prevent cutting the

rubber.

WABO ELASTODEC E bearings consist of rubber,

which are possibly reinforced by sheet metal and

may be rectangular (fig.1) or circular (fig. 2) in

shape. In case of larger movement requirement,

the WABO ELASTODEC EM (free sliding fig.

3), ELASTODEC EL (guided longitudinal fig. 4)

and ELASTODEC ET (guided transversal)

bearings are put forward, that are very similar to

the previous models, with the option of the

addition of a PTFE layer and of a stainless steel

sliding surface.

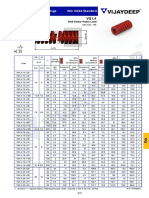

Tensile strength: R, N/ mm2

Yield strength: R, N/ mm2

Elongation at break, A, %

430

275

23

Sheet thickness is not lower than 2 mm.

Stainless steel is X5 Cr Ni Mo 17/12 UNI 6903/71,

with mirror-finished surface to UNI13963, 2 mm

thickness.

Surfaces in contact with PTFE are

polished and feature roughness Ra 0,1 mm,

according to UNI 3696.

PTFE is a virgin polytetrafluorethylene produced by

free deposition instead of thickening, 4 mm minimum

thickness, featuring the following specifications:

Density,kg/m3

217030

Tensile strength (23C), N/mm2

24

Elongation at break (23C): A, %

300

Hardness, Shore D

55

Tests and approvals

Installed on behalf of ANAS (Italian Trunk Road

Board) and other Italian Road & Highway

Management Boards.

Packaging

WABO ELASTODEC E bearings are supplied

complete with identification data indelibly engraved

into their surface.

Figure 3: Cross-section of a free sliding bearing

(WABO ELASTODEC EM)

Storage

When bearings are not directly installed upon

supply they shall be stored in an adequate place,

raised from the ground, and in such a way as to be

protected from shock, dust, humidity and direct

sunlight.

Figure 4: Cross-section of a guided longitudinal

bearing (WABO ELASTODEC EL)

Installation

Figure 1: Rectangular laminated bearing

WABO ELASTODEC E bearings must be correctly

positioned for optimum operation and long service

life. The surface of contact between concrete and

bearing shall be smooth, free from protruding parts

and clean, to afford perfect seating of bearing. This

surface shall be perfectly level and at least 5 cm

greater than the bearing's size. To bond bearings to

structures, mortars or epoxy resins suitable for the

applied rubber type must be used.

All slopes if any shall be eliminated by fitting

adequate levelling layers onto the pre-cast beams, or

by placing a resin prism between bearing and

superstructure.

Bearings shall be placed with their shorter side

parallel to the beam axis, in order to allow for a

greater possibility of rotation.

The WBA Representative shall be pleased to provide

additional detailed information.

Figure 2: Circular laminated bearing

Health & Safety

Appropriate health and safety advice can be found

in the Material Safety Data Sheets.

Users are advised to wear gloves and eye

protection when installing Elastodec E bearings.

LIMITED WARRANTY:

Watson Bowman Acme Corp. warrants that this product conforms to its current applicable specifications. Watson Bowman Acme Corp. makes no other warranty, express or

implied, including any WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE. The sole and exclusive remedy of Purchaser for

any claim concerning this product, including, but not limited to, claims alleging breach of warranty, negligence, strict liability or otherwise, is the replacement of product or refund of

the purchase price, at the sole option of Watson Bowman Acme Corp. Any claims concerning this product shall be submitted in writing within one year of the delivery date of this

product to Purchaser and any claims not presented within that period are waived by Purchaser. In no event shall Watson Bowman Acme Corp. be liable for any special, incidental,

consequential (includes loss of profits) or punitive damages.

The data expressed herein is true and accurate to the best of our knowledge at the time published; it is, however, subject to change without notice.

Contact:

Watson Bowman Acme Europe

MAC Spa Via F.lli Gracchi, 27 20092 Cinisello Balsamo (MI) Italy

Phone +39 02 617941 Fax +39 02 61794438

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Bearing Pad - 2007Document4 pagesBearing Pad - 2007Kumar JbsNo ratings yet

- WeboflexDocument17 pagesWeboflexfretts08No ratings yet

- Bridge Bearings & Expansion JointsDocument16 pagesBridge Bearings & Expansion Jointsjacob_arun100% (3)

- Lap Lengths For Reinforcing Steel Mesh Fabric 3091Document2 pagesLap Lengths For Reinforcing Steel Mesh Fabric 3091Adji SetiaNo ratings yet

- WaboElastoFlex Park 0408Document4 pagesWaboElastoFlex Park 0408Cristhian Alfonso Mandujano PérezNo ratings yet

- PIMOT 68 WITTEK AngDocument14 pagesPIMOT 68 WITTEK AngAshu SharmaNo ratings yet

- VSL - The Fricvtion Damper PresentationDocument34 pagesVSL - The Fricvtion Damper PresentationDang LuongNo ratings yet

- Anchorage of Wood Shear Walls To Concrete For Tension and Shear PDFDocument6 pagesAnchorage of Wood Shear Walls To Concrete For Tension and Shear PDFIonFlorentaNo ratings yet

- TDS - Masterflex J SealDocument3 pagesTDS - Masterflex J SealVenkata RaoNo ratings yet

- ElbDocument5 pagesElbjcunha4740No ratings yet

- AN603 - Thruster MountingDocument6 pagesAN603 - Thruster MountingAhmad NazriNo ratings yet

- Wavistrong Installation ManualDocument63 pagesWavistrong Installation ManualRenganathan Prabunath0% (1)

- NMDOT Bridge ProceduresDocument11 pagesNMDOT Bridge Proceduressiva_civil4051No ratings yet

- Construction of BLT Rheda - 2000 in Tunne PDFDocument17 pagesConstruction of BLT Rheda - 2000 in Tunne PDFAnkit GuptaNo ratings yet

- ATS5650 Bonded Metal Elastomer Expansion JointsDocument10 pagesATS5650 Bonded Metal Elastomer Expansion JointshighwayNo ratings yet

- Single Seal Expansion JointsDocument8 pagesSingle Seal Expansion JointsbosskojNo ratings yet

- ATS5630 Elastomeric Strip Seal Expansion JointsDocument11 pagesATS5630 Elastomeric Strip Seal Expansion JointshighwayNo ratings yet

- ABC2017 065 17 Jessey Lee Design Guidelines For Post Installed and Cast in Anchors in Australia For Safety Critical ApplicationsDocument11 pagesABC2017 065 17 Jessey Lee Design Guidelines For Post Installed and Cast in Anchors in Australia For Safety Critical ApplicationsDuncanNo ratings yet

- Rotabolt Tension Control James WalkerDocument12 pagesRotabolt Tension Control James Walkercvishwas1159No ratings yet

- Elastomeric Bearnings Assembly SOWDocument5 pagesElastomeric Bearnings Assembly SOWneelcorNo ratings yet

- Mostuf CatalogDocument10 pagesMostuf CatalogHamed MemarianNo ratings yet

- Rawl Bolts and CapacityDocument2 pagesRawl Bolts and Capacitykevinisonline0% (1)

- BARTEC Engineers ManualDocument12 pagesBARTEC Engineers ManualMd Nazir HussainNo ratings yet

- Bearing Pad A Ash ToDocument1 pageBearing Pad A Ash ToAditya Perdana PerkasaNo ratings yet

- Chapter 2 - Post-Tensioning.Document13 pagesChapter 2 - Post-Tensioning.SaiMinMinNo ratings yet

- General Rubber 1100 Rej Specs PDFDocument6 pagesGeneral Rubber 1100 Rej Specs PDFRyan FisherNo ratings yet

- Fix 3Document12 pagesFix 3Eng TrNo ratings yet

- Ancon Tapered Thread Couplers International VersionDocument16 pagesAncon Tapered Thread Couplers International VersionRanjan SinghNo ratings yet

- MAURER Girder Grid JointsDocument12 pagesMAURER Girder Grid JointsbriankimbjNo ratings yet

- A New Model For Static Load Ratings of Surface Induction Hardened BearingsDocument3 pagesA New Model For Static Load Ratings of Surface Induction Hardened Bearingsmans2014No ratings yet

- SteelDocument19 pagesSteelJohneey DeepNo ratings yet

- Technical Specifications For The Successful Fabrication of Laminated Seismic Isolation BearingsDocument11 pagesTechnical Specifications For The Successful Fabrication of Laminated Seismic Isolation BearingsTommy HeydemansNo ratings yet

- MB - The Revision of AS5100.4 Bearings and Deck JointsDocument9 pagesMB - The Revision of AS5100.4 Bearings and Deck JointsThong NguyenNo ratings yet

- DEMU 4010 Rebar Coupler System DEMUDocument24 pagesDEMU 4010 Rebar Coupler System DEMUTonni KurniawanNo ratings yet

- VSL Thread Bar Systems BrochureDocument16 pagesVSL Thread Bar Systems BrochureFida GNo ratings yet

- Pt. Magdatama - Wabo Modular JointDocument8 pagesPt. Magdatama - Wabo Modular JointMangisi Haryanto ParapatNo ratings yet

- Ijsam 3 2 1Document8 pagesIjsam 3 2 1STATPERSON PUBLISHING CORPORATIONNo ratings yet

- Korfund Elastomeric Mounts PDFDocument66 pagesKorfund Elastomeric Mounts PDFMarko PetkovicNo ratings yet

- Concrete AccessoriesDocument9 pagesConcrete AccessoriesIm ChinithNo ratings yet

- Freyssibar: The Prestressing Bar For Civil WorksDocument12 pagesFreyssibar: The Prestressing Bar For Civil WorksJustin CorbettNo ratings yet

- 4514 Power FastDocument11 pages4514 Power Fastgreg_mercurio_1No ratings yet

- Rubber Design Vibration and Noise ControlDocument14 pagesRubber Design Vibration and Noise Controlcvishwas1159No ratings yet

- Ancon CouplersDocument32 pagesAncon CouplersNuno Telmo LopesNo ratings yet

- Design of BeamsDocument28 pagesDesign of BeamsNayan Fatania100% (2)

- Bridge Technical Note 1999002V21Document5 pagesBridge Technical Note 1999002V21er_surajrpNo ratings yet

- CSP-M MountDocument3 pagesCSP-M MountEong Huat Corporation Sdn BhdNo ratings yet

- 5 - VasoflonDocument16 pages5 - Vasoflonstavros_stergNo ratings yet

- Ancon Kwika StripDocument12 pagesAncon Kwika StripplatanospanosNo ratings yet

- Insulated BearingsDocument3 pagesInsulated Bearingsuuur35No ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- Advanced Seat Suspension Control System Design for Heavy Duty VehiclesFrom EverandAdvanced Seat Suspension Control System Design for Heavy Duty VehiclesNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- 0510 S 15 Ms 43Document16 pages0510 S 15 Ms 43aomareltayebNo ratings yet

- PT EconomicsDocument53 pagesPT EconomicsaomareltayebNo ratings yet

- PLN V000000 06 00004 PDFDocument114 pagesPLN V000000 06 00004 PDFaomareltayebNo ratings yet

- Concrete Expansion JointsDocument80 pagesConcrete Expansion JointsDiana Sekar Sari100% (1)

- Chapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.18 Page 9-I June 2018Document40 pagesChapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.18 Page 9-I June 2018aomareltayebNo ratings yet

- Optimum Design of Resilient Sliding Isolation SystemDocument12 pagesOptimum Design of Resilient Sliding Isolation SystemaomareltayebNo ratings yet

- Who Invented Youngs ModulusDocument6 pagesWho Invented Youngs ModulusaomareltayebNo ratings yet

- Technology Paper Report CSI 31-03-09Document98 pagesTechnology Paper Report CSI 31-03-09aomareltayebNo ratings yet

- Who Invented Youngs ModulusDocument6 pagesWho Invented Youngs ModulusaomareltayebNo ratings yet

- Vibration Analysis ReportDocument13 pagesVibration Analysis ReportaomareltayebNo ratings yet

- JORDAHL Catalogue Jda PDFDocument6 pagesJORDAHL Catalogue Jda PDFIoan SosaNo ratings yet

- Design of Shear Walls Using ETABS PDFDocument97 pagesDesign of Shear Walls Using ETABS PDFEmanuelRodriguezElera100% (1)

- Hollowblockandribbedslabs 130702183359 Phpapp01Document38 pagesHollowblockandribbedslabs 130702183359 Phpapp01aomareltayebNo ratings yet

- Power Virtual Collaboration in Project Management FinalDocument38 pagesPower Virtual Collaboration in Project Management FinalTerrence GargiuloNo ratings yet

- Sika FRP Design Program ManualDocument10 pagesSika FRP Design Program ManualYoshua Yang100% (1)

- Soil Structure InteractionDocument16 pagesSoil Structure InteractionEmad Ahmed Khan67% (3)

- Control of Crack WidthsDocument55 pagesControl of Crack WidthsMahmood Mufti100% (1)

- Damping and Energy DissipationDocument14 pagesDamping and Energy DissipationAlex da SilvaNo ratings yet

- المرشد في الإسعافات الأولية PDFDocument75 pagesالمرشد في الإسعافات الأولية PDFbentaharNo ratings yet

- Diaphragm Walls SpecsDocument8 pagesDiaphragm Walls SpecsaomareltayebNo ratings yet

- Diaphragm Wall Specifications R 0Document10 pagesDiaphragm Wall Specifications R 0aomareltayebNo ratings yet

- Example Buildings KL Aug 2002Document25 pagesExample Buildings KL Aug 2002aomareltayebNo ratings yet

- Damping and Energy DissipationDocument14 pagesDamping and Energy DissipationAlex da SilvaNo ratings yet

- Diaphragm Walls SpecsDocument8 pagesDiaphragm Walls SpecsaomareltayebNo ratings yet

- AbuDhabi LowDocument1 pageAbuDhabi LowaomareltayebNo ratings yet

- BurjDocument39 pagesBurjarjunmurali1993No ratings yet

- Risk Register TemplateDocument1 pageRisk Register TemplateaomareltayebNo ratings yet

- Structure Modelling ChecklistDocument4 pagesStructure Modelling ChecklistaomareltayebNo ratings yet

- 4608 - 160214 - Structural Design Data SheetDocument9 pages4608 - 160214 - Structural Design Data SheetaomareltayebNo ratings yet

- Abacus FoundationsDocument9 pagesAbacus FoundationsNath GunasekeraNo ratings yet

- Caselet - LC: The Journey of The LCDocument5 pagesCaselet - LC: The Journey of The LCAbhi JainNo ratings yet

- Valery 1178Document22 pagesValery 1178valerybikobo588No ratings yet

- Digirig Mobile 1 - 9 SchematicDocument1 pageDigirig Mobile 1 - 9 SchematicKiki SolihinNo ratings yet

- People V NiellesDocument2 pagesPeople V NiellesRobielyn Kate NerpioNo ratings yet

- Compose Testing CheatsheetDocument1 pageCompose Testing CheatsheetEstampados SIn ApellidoNo ratings yet

- 2B. Glicerina - USP-NF-FCC Glycerin Nutritional Statement USP GlycerinDocument1 page2B. Glicerina - USP-NF-FCC Glycerin Nutritional Statement USP Glycerinchristian muñozNo ratings yet

- User Exits in Validations SubstitutionsDocument3 pagesUser Exits in Validations SubstitutionssandeepNo ratings yet

- Project of Consumer BehaviourDocument28 pagesProject of Consumer BehaviourNaveed JuttNo ratings yet

- PCIB Vs ESCOLIN (G.R. No. L-27860 & L-27896)Document61 pagesPCIB Vs ESCOLIN (G.R. No. L-27860 & L-27896)strgrlNo ratings yet

- Geotechnical Design MannulDocument828 pagesGeotechnical Design MannulJie ZhouNo ratings yet

- 5-Benefits at A GlanceDocument2 pages5-Benefits at A GlanceBlackBunny103No ratings yet

- CPA Taxation by Ampongan - Principles of TaxationDocument43 pagesCPA Taxation by Ampongan - Principles of TaxationVictor Tuco100% (1)

- Sarah Williams CVDocument2 pagesSarah Williams CVsarahcwilliamsNo ratings yet

- Operational Business Suite Contract by SSNIT Signed in 2012Document16 pagesOperational Business Suite Contract by SSNIT Signed in 2012GhanaWeb EditorialNo ratings yet

- Understanding FreeRTOS SVCDocument11 pagesUnderstanding FreeRTOS SVCshafi hasmani0% (1)

- Detroit ManualDocument435 pagesDetroit Manualvictorhernandezrega50% (2)

- Evaporator EfficiencyDocument15 pagesEvaporator EfficiencySanjaySinghAdhikariNo ratings yet

- 11 - Savulescu Et Al (2020) - Equality or Utility. Ethics and Law of Rationing VentilatorsDocument6 pages11 - Savulescu Et Al (2020) - Equality or Utility. Ethics and Law of Rationing VentilatorsCorrado BisottoNo ratings yet

- County Project Name Cycle Project Address Proj City Proj Zip Applicant/Owner Name HDGP $ Home $ FHTF $ Lihtc9 $ Help $ Oahtc $ Ghap $ HPF $ Lihtc4 $Document60 pagesCounty Project Name Cycle Project Address Proj City Proj Zip Applicant/Owner Name HDGP $ Home $ FHTF $ Lihtc9 $ Help $ Oahtc $ Ghap $ HPF $ Lihtc4 $Mamello PortiaNo ratings yet

- Too Much Time in Social Media and Its Effects On The 2nd Year BSIT Students of USTPDocument48 pagesToo Much Time in Social Media and Its Effects On The 2nd Year BSIT Students of USTPLiam FabelaNo ratings yet

- Product Information DIGSI 5 V07.50Document56 pagesProduct Information DIGSI 5 V07.50g-bearNo ratings yet

- Variable Length Subnet MasksDocument4 pagesVariable Length Subnet MaskszelalemNo ratings yet

- Procurement Systems and Tools RoundTable Notes (Europe) 13 Oct 2020 - 0Document8 pagesProcurement Systems and Tools RoundTable Notes (Europe) 13 Oct 2020 - 0SathishkumarNo ratings yet

- Universal Marine: Welcome To Our One Stop Marine ServicesDocument8 pagesUniversal Marine: Welcome To Our One Stop Marine Serviceshoangtruongson1111No ratings yet

- Performance Ratio Analysis Based On Energy Production For Large-Scale Solar PlantDocument22 pagesPerformance Ratio Analysis Based On Energy Production For Large-Scale Solar PlantPrateek MalhotraNo ratings yet

- Projek Rekabentuk Walkwaybridge 2014 - 15Document6 pagesProjek Rekabentuk Walkwaybridge 2014 - 15HambaliNo ratings yet

- Questions & Answers On CountersDocument24 pagesQuestions & Answers On Counterskibrom atsbha100% (2)

- On Fracture MechanicsDocument81 pagesOn Fracture MechanicsDEEPAK100% (1)

- Low Cost HousingDocument5 pagesLow Cost HousingReigna SantillanaNo ratings yet

- Rectangular Wire Die Springs ISO-10243 Standard: Red Colour Heavy LoadDocument3 pagesRectangular Wire Die Springs ISO-10243 Standard: Red Colour Heavy LoadbashaNo ratings yet