Professional Documents

Culture Documents

U.S. Patent App. Ser. No. 2014/0216230, Entitled "Adjustable Zero Fret" To Gibson, Inc., Pub. Aug. 7, 2014.

Uploaded by

Anonymous a7S1qyXOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

U.S. Patent App. Ser. No. 2014/0216230, Entitled "Adjustable Zero Fret" To Gibson, Inc., Pub. Aug. 7, 2014.

Uploaded by

Anonymous a7S1qyXCopyright:

Available Formats

US 20140216230A1

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2014/0216230 A1

Johns et al.

(54)

(43) Pub. Date:

ADJUSTABLE ZERO FRET AND METHOD OF

USE ON A STRINGED INSTRUMENT

Publication Classi?cation

(51)

(71) Applicant: Gibson Brands, Inc., Nashville, TN

(US)

Aug. 7, 2014

Int. Cl.

G10D 3/06

(52) US. Cl.

(2006-01)

CPC ...................................... .. G10D 3/06 (2013.01)

(72)

Inventors: Frank Johns, Hermitage, TN (US);

USPC ...................................................... .. 84/314 R

George Mathews, Mt Juliet, TN (US);

(57)

JOhn Steve Fren?ey Lebanon TN (Us)

An apparatus and method of varying the tonal aspects of a

ABSTRACT

string instrument such as an acoustic or electric guitar which

(21)

App1_ NO; 14/092,181

(22)

Filed?

NOV- 27 2013

Related US. Application Data

is commonly provided With a body and a fret board on the

instruments neck. The apparatus includes an upper portion

and a lower portion. The lower portion is con?gured to con

nect With the fret board and to provide a base for the upper

portion, The upper portion is con?gured to engage the lower

portion. The upper portion is also con?gured to'receive and

support an 1nstrument s strings. The upper portron rs selec

(60)

Provisional application No. 61/ 73 1 ,026, ?led on Nov.

29, 2012.

tively movable relative to the lower portion by an operator to

change the tonal nature of the instrument.

Patent Application Publication

Aug. 7, 2014 Sheet 1 0f 5

US 2014/0216230 A1

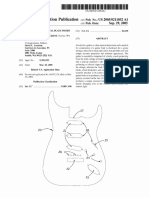

FIG.1

Patent Application Publication

Aug. 7, 2014 Sheet 2 0f 5

US 2014/0216230 A1

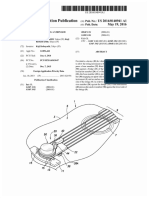

FIG.3

FIG.2

Patent Application Publication

Aug. 7, 2014 Sheet 3 0f 5

wE/

NE

m.95

\\(Q

(5

(t

wt(CN?

L?l/IEw\ lF

\\\

w

M

V

v

w.QE

US 2014/0216230 A1

Patent Application Publication

Aug. 7, 2014 Sheet 4 0f 5

US 2014/0216230 A1

/\\

S68

G

J

l\

i9

@JLL

3A6

//

Bug

/%

\

(lgg

&\

Patent Application Publication

Aug. 7, 2014 Sheet 5 0f 5

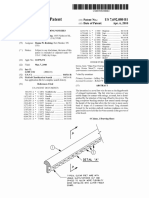

FIG.9

US 2014/0216230 A1

10FIG.

Aug. 7, 2014

US 2014/0216230 A1

ADJUSTABLE ZERO FRET AND METHOD OF

USE ON A STRINGED INSTRUMENT

CROSS-REFERENCE TO RELATED

APPLICATIONS

[0001] The present application claims the bene?t of US.

Provisional Patent Application No. 61/731,026, titled Adjust

instruments. Suitable, non limiting examples include, acous

tic guitar, electric guitar, acoustic bass guitar and electric bass

guitar, banjo, mandolin, and similar type instruments.

Although the Figures depict a six stringed instrument, the

scope of this disclosure includes instruments with more or

fewer strings.

[0017]

With speci?c reference to FIGS. 1-3, an adjustable

able Zero Fret and Method of Use on a Stringed Instrument,

?led on Nov. 29, 2012, the entire contents of which are all

fret assembly 100 is depicted. The adjustable fret assembly

herein incorporated by reference and made a part hereof.

elongated U-shaped element. The base portion 104 includes a

FIELD OF THE INVENTION

[0002] The present invention relates to an adjustable zero

fret device, and speci?cally to an adjustable zero fret device

for use with stringed instruments.

BACKGROUND

100 includes a base portion 104 which is substantially an

locator channel 106 de?ned by opposedparallel lowerportion

?rst support 124 and second lower second support 126. (best

seen in FIGS. 3 and 7-8). The base portion 104 is generally

con?gured to form a base element for the adjustable zero fret

assembly 100. In use, the base portion 104 rest on the fret

board or neck of a stringed instrument at a desired location

best seen in FIGS. 9 and 10. In an embodiment, the base

portion 104 includes at least one fastener bore 132 extending

[0003] A zero fret is typically a fret-like device placed at the

headstock end of the neck of a stringed instrument, such as,

there through to enable the lower portion to be ?xedly

without limitation, a banjo, guitar, mandolin, or bass guitar. A

fasteners include, without limitation, screws (not shown) or

function of the zero fret is that it holds the strings a desired

distance above the other frets on the instruments fret board.

Typical zero frets are either static and therefore cant be

the like. Similarly, adhesives or other known fastening means

attached to the fret board or next of an instrument. Suitable

may also be incorporated without exceeding the spirit and

ment or overly complex in their construction and use.

scope of this disclosure. In an alternative embodiment, the

base portion does not include a fastener bore 132. In such

instances the adjustable zero fret assembly 100 is held in

[0004]

place by the instruments strings. In this manner, the adjust

adjusted to selectively modify the tonal quality of the instru

An adjustable zero fret that is effective in modifying

tonal quality and easy to use is desired.

able zero fret assembly 100 may be removed easily and with

out harm to the instrument fret board or neck.

BRIEF DESCRIPTION OF THE DRAWINGS

[0005] FIG. 1 is an exploded isometric view of the adjust

able zero fret assembly;

[0006] FIG. 2 is an isometric view of an upper portion of the

adjustable zero fret assembly;

[0007]

FIG. 3 is an isometric view ofa lower portion ofthe

adjustable zero fret assembly;

[0008] FIG. 4 is a top plan view ofthe upper portion ofthe

adjustable zero fret assembly;

[0009] FIG. 5 is a frontal plan view of the upper portion of

the adjustable zero fret assembly;

[0010] FIG. 6 is an end plan view of the upper portion of the

adjustable zero fret assembly;

[0011] FIG. 7 is a top plan view ofthe lower portion ofthe

adjustable zero fret assembly;

[0012] FIG. 8 is an end plan view ofthe lower portion ofthe

adjustable zero fret assembly;

[0013] FIG. 9 is a top view of the adjustable zero fret

assembly of FIG. 1 in use with a guitar; and,

[0014] FIG. 10 is a side view of the adjustable zero fret

assembly of FIG. 1 in use with a guitar.

DETAILED DESCRIPTION

[0015]

The device will now be described with reference to

[0018] The adjustable zero fret assembly 100 also includes

an adjustable portion 102. The adjustable portion 102 is a

substantially elongated T-shaped element. The adjustable

portion 102 includes a locator post 108 and opposed ?rst

?ange portion 110 and second ?ange portion 112. The locator

post 108 is con?gured to engage and, when in use, be posi

tioned within the locator channel 106. It will be appreciated

that the tolerance between the locator post 108 and the locator

channel 106 will be such that the locator post 108 may be

inserted and removed into the locator channel 106 as needed.

However, once inserted, the tolerance between the two pieces

will be such that any non user activated relative movement

between the pieces is minimized or otherwise prevented.

[0019] As best seen in FIGS. 2 and 4-6, the adjustable

portion 102 includes opposed ?rst ?ange portion 110 and

second ?ange portion 112. The ?rst ?ange portion 110 is

con?gured with a number of seats 114. Each seat 114 is

con?gured to receive one string of the instrument. As shown,

the seats 114 are all the same size, however, the size and shape

of the seats is variable. In an embodiment, the size, shape,

spacing and general location of the seats 114 is based on the

diameter of the instrument string and type of instrument. By

way of non limiting example, the Figures depict a con?gura

tion as one might ?nd used with a six string guitar.

[0020] The adjustable portion 102 also includes a second

the accompanying Figures. In all Figures, like numerals Cor

?ange portion 112. The second ?ange portion 112 typically

respond to like elements. The device is directed to an appa

ratus and method for selectively modifying the tonal charac

does not have any seats 114. However, it is considered within

the scope of this disclosure to have a second ?ange portion

ter of an acoustic or electric stringed instrument using an

adjustable zero fret assembly. One suitable embodiment of an

tion typically does include a crown 116, although not neces

adjustable zero fret assembly, generally designated 100, is

illustrated in FIGS. 1-9. Speci?c details of the device and its

that includes seats 114. (Not shown). The second ?ange por

sarily. It will be appreciated that that crown 116 is con?gured

to provide support for any strings passing over it, while lim

use are disclosed more completely below.

iting the contact surface area with the string so as to not

[0016]

adversely affect the tonal quality of the string or cause undue

By way of background, the term stringed instru

ment is intended to be directed to a wide variety of stringed

wear.

Aug. 7, 2014

US 2014/0216230 A1

In operation, the base portion 104 is attached to the

choice is another unique aspect of this disclosure and is not

fret board 156 at, for example, a zero fret location. In one

intended to be a limiting factor.

[0025] With speci?c reference to FIGS. 9 and 10, one

[0021]

example, screws (not shown) are driven through the fastener

bores 132 of the base portion 104 into the neck of the instru

ment. The adjustable portion 102 is positioned such that the

locator post 108 is inserted into the locator channel 106. The

adjustable portion 102 is held relative to the base portion 104

via adjustment fasteners 120 passing through the adjustable

portion 102 and into the base portion 104. The adjustment

fasteners 120 are con?gured to allow for very controlled user

activated relative movement between the adjustable portion

102, the base portion 104, and when in use, the string 154.

One suitable non limiting example of an adjustment fastener

120 of interest is a machine screw or the like. Strings may then

be passed over the adjustable fret assembly 100 such that the

strings are positioned of the seats. From there, the instrument

may be strung as one normally would set up such an instru

ment.

[0022] The instrument may be tuned in a normal fashion if

desired. Also, one non limiting unique aspect of this disclo

sure is that the tonal quality of the instrument may be selec

tively modi?ed by engaging the adjustment fasteners 120 to

either move the adjustable portion 104 closer to the base

portion 104, or vice versa. In other words, in use, moving the

adjustable portion 102 toward or away from the string 154.

Thereby selectively modifying the length, tension, and diam

eter of the string 154 to modify tonal quality. It will be

appreciated that as the adjustable portion 102 is moved rela

tively farther away from the base portion 1 04, the length of the

string(s) is increased, and perhaps a corresponding decrease

in string diameter, yielding a corresponding change of tonal

method of using the adjustable zero fret assembly 100 is

depicted. In this particular, non limiting embodiment, the

adjustable zero fret assembly 100 is shown in use with a guitar

150. As depicted, the adjustable zero fret assembly 100 is

positioned adjacent the head stock 152. However, it will be

appreciated that the positioning of the adjustable zero fret

assembly 100 is variable dependent upon how a user prefers

to use the device. Such placement of device shall not be

limiting to the scope of this disclosure. Additionally, as dis

cussed above, this device is not limited to a guitar 150, but

rather to any stringed instrument.

[0026] In an embodiment of this disclosure, there is an

adjustable zero fret assembly 100 for a stringed instrument

The adjustable zero fret assembly 100 comprises a base por

tion 104, saidbase portion 104 de?ning a locator channel 106.

The adjustable zero fret assembly 100 also comprises a single

piece adjustable portion 104 selectively movable relative to

saidbase portion 102; said single piece adjustable portion 104

including at least one seat port on 114 for receiving a string

154 of the stringed instrument. The at least one seat portion

114 having a contact surface 148.

[0027]

In an embodiment, the adjustable zero fret assembly

100 is constructed from a material selected from at least one

of a metal, metal alloy, composite, synthetic, ceramic, bone

and polymer based material.

[0028] In an embodiment, the single piece adjustable por

tion is selectively moveable relative to the base portion via at

least one threaded mechanical device.

[0029]

In an embodiment, the threaded mechanical device

quality. In this manner, a nearly in?nite range of tonal values

may be achieved.

is a machine screw.

[0023]

[0030] In an embodiment, the at least one seat portion is

constructed from a material that is different than the remain

For example, in one embodiment, the adjustment

fasteners 120 are adjusted in the same direction equally such

that the entire adjustable portion 102 is moved equidistance

ing portions of the single piece adjustable portion.

[0031]

In an embodiment, a method of varying the tonal

from the base portion 104 across the entire length of the

adjustable portion 102. However, it is also within the scope of

this disclosure that the adjustment fasteners 120 may be

adjusted unequally, either in value or direction, such that a

variable force is applied across a string group. In this manner,

quality of a stringed instrument is provided. This method

includes providing a stringed instrument having at least two

strings 154 con?gured to produce a tonal sound. The stringed

instrument having an initial tonal quality, The method further

includes providing an adjustable zero fret assembly 100 adja

a user may match or correlate string properties (such as manu

cent the at least two strings 154, said adjustable zero fret

factured materials, size, shape, etc.) to a desired tonal quality

assembly 100 including a base portion 104 and a single piece

simply by varying the adjustment fastener 120 settings.

adjustable portion 102, the single piece adjustable portion

[0024] With regard to material choices for the adjustable

zero fret assembly 100, it will be appreciated that the bulk of

102 being selectively moveable relative to the base portion

1 04. The method also includes providing a biasing force to the

the adjustable zero fret assembly 100 can be made of any

at least two strings 154 by selectively moving the single piece

suitably durable and hard material. Any variety of known

adjustable portion 102 in a direction toward or away from the

at least two strings 154.

metals, metal alloys, composites, bone, and suitable polymer

based materials are within the scope of this disclosure pro

[0032]

vided they have adequate properties. Also, there may be

piece adjustable portion being selectively moveable relative

selective materials choices, either for the device entirely or at

to the base portion via at least one threaded mechanical

device.

[0033] In an embodiment, the method includes the threaded

mechanical device being a machine screw.

selective positions of the adjustable zero fret assembly 100.

For example, those portions of the seat 114 and/ or crown 118

that contact the strings may be made of a material that

matches or compliments the string choice while the remain

ing assembly 100 is constructed from another material. For

example, a contact surface of the seat 114 may be made of the

same or similar material as the outer surface of the string

while the remaining assembly is of another material. In this

manner, a user may achieve a desired tonal modi?cation,

while keeping such things as cost or weight within acceptable

parameters. The selection and arrangement of the material

In an embodiment, the method includes the single

[0034] While various aspects of this disclosure have been

illustrated and described, it will be appreciated that various

changes can be made therein without departing from the spirit

and scope of this disclosure. For example, without limitation,

the base portion 104 and the adjustable portion 102 do not

necessarily need to be substantially U-shaped and T-shaped,

respectively. Other geometries may be used. Additionally,

there may be more or fewer than the two adjustment fasteners

Aug. 7, 2014

US 2014/0216230 A1

120 used to control movement of the adjustable portion 102

relative to the base portion 104. Further, other variations and

modi?cations apparent to those skilled in the art may be made

within the nature of this disclosure.

What is claimed is:

1. An adjustable zero fret assembly for a stringed instru

ment, comprising:

(a) a base portion, said base portion de?ning a locator

channel; and

(b) a single piece adjustable portion selectively movable

relative to said base portion; said single piece adjustable

portion including at least one seat portion for receiving a

string of the stringed instrument, said at least one seat

portion having a contact surface.

2. A method of varying the tonal quality of a stringed

instrument, comprising:

(a) providing a stringed instrument having at least two

strings playable to produce a tonal sound, said stringed

instrument having an initial tonal quality;

(b) providing a two piece adjustable zero fret assembly

adjacent the at least two strings, said two piece adjust

able Zero fret assembly including a base portion and a

single piece adjustable portion, the single piece adjust

able portion being selectively moveable relative to the

base portion; and,

(c) providing a biasing force to the at least two strings by

selectively moving single piece adjustable portion in a

direction toward or away from the at least two strings.

*

You might also like

- U.S. Pat. App. 2012/0258051, Entitled "Multistrata Nanoparticles", Published Oct. 11, 2012.Document16 pagesU.S. Pat. App. 2012/0258051, Entitled "Multistrata Nanoparticles", Published Oct. 11, 2012.Anonymous a7S1qyXNo ratings yet

- U.S. Patent 9,462,902, Entitled "Health Pillow", Issued Oct. 11, 2016.Document14 pagesU.S. Patent 9,462,902, Entitled "Health Pillow", Issued Oct. 11, 2016.Anonymous a7S1qyXNo ratings yet

- U.S. Pat. App. 2005/0211,052, Entitled "Guitar Having A Metal Plate Insert", Pub. 2005.Document12 pagesU.S. Pat. App. 2005/0211,052, Entitled "Guitar Having A Metal Plate Insert", Pub. 2005.Duane BlakeNo ratings yet

- U.S. Patent 7,461,424, Entitled "Method and Apparatus For A Pillow Including Foam Pieces of Various Sizes", Issued 2008.Document7 pagesU.S. Patent 7,461,424, Entitled "Method and Apparatus For A Pillow Including Foam Pieces of Various Sizes", Issued 2008.Anonymous a7S1qyXNo ratings yet

- U.S. Pat. Pub. 2010/0154,620, Entitled "Optical Pickup For A Musical Instrument" Pub. 2010.Document20 pagesU.S. Pat. Pub. 2010/0154,620, Entitled "Optical Pickup For A Musical Instrument" Pub. 2010.Anonymous a7S1qyXNo ratings yet

- US Patent 1,915,858, Entitled "Method and Apparatus For The Production of Music" To Inventor, Miessner, 1933.Document9 pagesUS Patent 1,915,858, Entitled "Method and Apparatus For The Production of Music" To Inventor, Miessner, 1933.Anonymous a7S1qyXNo ratings yet

- U.S. 7,586,029, Entitled "GUITAR AND STRAP FOR PLAYING IN A STANDING CONFIGURATION", 2009.Document10 pagesU.S. 7,586,029, Entitled "GUITAR AND STRAP FOR PLAYING IN A STANDING CONFIGURATION", 2009.Anonymous a7S1qyXNo ratings yet

- Patent WO-2015/173732A1, Entitled "Preamplification System For An Acoustic Guitar", Nov. 19, 2015.Document57 pagesPatent WO-2015/173732A1, Entitled "Preamplification System For An Acoustic Guitar", Nov. 19, 2015.Anonymous a7S1qyXNo ratings yet

- U.S. Patent Pub. 2016-140941A1, Entitled, "Device For Vibrating A Stringed Instrument", To Kobayashi, May 19, 2016.Document22 pagesU.S. Patent Pub. 2016-140941A1, Entitled, "Device For Vibrating A Stringed Instrument", To Kobayashi, May 19, 2016.Anonymous a7S1qyXNo ratings yet

- U.S. Pat. App. 2005/0211,052, Entitled "Guitar Having A Metal Plate Insert", Pub. 2005.Document12 pagesU.S. Pat. App. 2005/0211,052, Entitled "Guitar Having A Metal Plate Insert", Pub. 2005.Duane BlakeNo ratings yet

- U.S. Patent 3,826,171, Entitled Guitar String, Issued 1974.Document4 pagesU.S. Patent 3,826,171, Entitled Guitar String, Issued 1974.Anonymous a7S1qyXNo ratings yet

- U.S. Patent 4,383,465, Entitled Space-Wrapped Strings For Musical Instruments, Issued 1983.Document11 pagesU.S. Patent 4,383,465, Entitled Space-Wrapped Strings For Musical Instruments, Issued 1983.Anonymous a7S1qyXNo ratings yet

- U.S. Patent 9,024,171, Entitled, Sensor Assembly For Stringed Musical Instruments, To Actodyne General, March 5, 2015 PDFDocument15 pagesU.S. Patent 9,024,171, Entitled, Sensor Assembly For Stringed Musical Instruments, To Actodyne General, March 5, 2015 PDFAnonymous a7S1qyXNo ratings yet

- Great Britain B Patent 588178A, Entitled "Electro-Magnetic Pick-Up For Stringed Musical Instruments" Dated 1946.Document4 pagesGreat Britain B Patent 588178A, Entitled "Electro-Magnetic Pick-Up For Stringed Musical Instruments" Dated 1946.Anonymous a7S1qyXNo ratings yet

- U.S. Patent 8,853,517, Entitled Musical Instrument Pickup, To George Dixon, Dated Oct. 7, 2014 PDFDocument38 pagesU.S. Patent 8,853,517, Entitled Musical Instrument Pickup, To George Dixon, Dated Oct. 7, 2014 PDFAnonymous a7S1qyXNo ratings yet

- French Patent 990405A, Entitled "Electric Piano" Dated 1949.Document13 pagesFrench Patent 990405A, Entitled "Electric Piano" Dated 1949.Anonymous a7S1qyXNo ratings yet

- U.S. Patent 3,624,264, Entitled "Vibration Detection" To Lazarus, Issued 1971.Document5 pagesU.S. Patent 3,624,264, Entitled "Vibration Detection" To Lazarus, Issued 1971.Anonymous a7S1qyXNo ratings yet

- U.S. Patent 2,911,871, Entitled "Magnetic Pickup Device" To Charles Schultz, Issued 1959.Document4 pagesU.S. Patent 2,911,871, Entitled "Magnetic Pickup Device" To Charles Schultz, Issued 1959.Anonymous a7S1qyXNo ratings yet

- U.S. Patent 2,683,388, Entitled "Pickup Device For Stringed Instruments" To Keller, Issued 1954.Document4 pagesU.S. Patent 2,683,388, Entitled "Pickup Device For Stringed Instruments" To Keller, Issued 1954.Anonymous a7S1qyXNo ratings yet

- US Patent 2,294,861, Entitled "Electrical Pickup For Stringed Instruments" To Inventor Fuller (Assignee Owner Gibson, Inc.), Issued 1940.Document4 pagesUS Patent 2,294,861, Entitled "Electrical Pickup For Stringed Instruments" To Inventor Fuller (Assignee Owner Gibson, Inc.), Issued 1940.Anonymous a7S1qyXNo ratings yet

- U.S. Reexam Patent 20070, Entitled "Electric Translating Device For Stringed Instruments" To Lesti, Issued 1935.Document7 pagesU.S. Reexam Patent 20070, Entitled "Electric Translating Device For Stringed Instruments" To Lesti, Issued 1935.Anonymous a7S1qyXNo ratings yet

- US7692080-Fret Wire With Bending Notches-2008Document4 pagesUS7692080-Fret Wire With Bending Notches-2008Duane BlakeNo ratings yet

- U.S. Patent 3,085,460, Entitled "Portable Electronic Musical Instruments", Issued 1963.Document3 pagesU.S. Patent 3,085,460, Entitled "Portable Electronic Musical Instruments", Issued 1963.Anonymous a7S1qyXNo ratings yet

- U.S. Patent 5,932,827, Entitled "Sustainer For Musical Instrument", To Osborne, Aug. 3, 1999.Document58 pagesU.S. Patent 5,932,827, Entitled "Sustainer For Musical Instrument", To Osborne, Aug. 3, 1999.Anonymous a7S1qyXNo ratings yet

- U.S. Patent 6,797,871, Entitled "Pick and Method", To Adkin, Dated 2004.Document14 pagesU.S. Patent 6,797,871, Entitled "Pick and Method", To Adkin, Dated 2004.Anonymous a7S1qyXNo ratings yet

- U.S. Patent 8,886,584, Recommendation of Media Content, Issued 2014.Document24 pagesU.S. Patent 8,886,584, Recommendation of Media Content, Issued 2014.Anonymous a7S1qyXNo ratings yet

- U.S. Patent 3,085,460, Entitled "Portable Electronic Musical Instruments", Issued 1963.Document3 pagesU.S. Patent 3,085,460, Entitled "Portable Electronic Musical Instruments", Issued 1963.Anonymous a7S1qyXNo ratings yet

- U.S. Patent 2,094,771, Composition of Matter, 1937.Document4 pagesU.S. Patent 2,094,771, Composition of Matter, 1937.Anonymous a7S1qyXNo ratings yet

- U.S. Patent 2,094,771, Composition of Matter, 1937.Document4 pagesU.S. Patent 2,094,771, Composition of Matter, 1937.Anonymous a7S1qyXNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hotel California Solo tab by Eagles (17 charactersDocument4 pagesHotel California Solo tab by Eagles (17 charactersWill HarrisonNo ratings yet

- Wishes (Wait For You) : Capo 1 FretDocument2 pagesWishes (Wait For You) : Capo 1 Fret김용오No ratings yet

- Bluegrass Style FlatpickingDocument3 pagesBluegrass Style FlatpickingPoss HumNo ratings yet

- Africa by Andy McKeeDocument9 pagesAfrica by Andy McKeerafaelkiNo ratings yet

- Ironic Tragedy - Guitar SoloDocument3 pagesIronic Tragedy - Guitar SoloJohn BoutzetisNo ratings yet

- Tea Time For PunksDocument9 pagesTea Time For Punksjulianus51No ratings yet

- 1 Octave Arpeggios Alternate Finger Patterns PDFDocument2 pages1 Octave Arpeggios Alternate Finger Patterns PDFErnestGermanovičNo ratings yet

- MEMORIES CHORDS by Maroon 5 @Document4 pagesMEMORIES CHORDS by Maroon 5 @Miss_AccountantNo ratings yet

- You Are The Apple of My Eye Yuki MatsuiDocument7 pagesYou Are The Apple of My Eye Yuki MatsuiichsanwiNo ratings yet

- Blackmores Night-Possum Goes To PragueDocument4 pagesBlackmores Night-Possum Goes To PragueGabeNo ratings yet

- What A Wonderful World - Fingerstyle: Drue JamesDocument3 pagesWhat A Wonderful World - Fingerstyle: Drue Jamesnitish nairNo ratings yet

- In My Darkest Hour - Megadeth Full TabDocument14 pagesIn My Darkest Hour - Megadeth Full TabErnesto GonzalezNo ratings yet

- To Aru Kagaku No Railgun ED 1 - Dear My Friend Mada Minu Mirai e Guitar CoverDocument2 pagesTo Aru Kagaku No Railgun ED 1 - Dear My Friend Mada Minu Mirai e Guitar CoverPeluka Cesar Mejia LlontopNo ratings yet

- Guitar PartsDocument15 pagesGuitar Partsaftersound bandNo ratings yet

- The Endless Knot: Guitar Solo HakenDocument2 pagesThe Endless Knot: Guitar Solo Hakendinho santosNo ratings yet

- Uchiage Hanabi / DAOKO: Standard TuningDocument2 pagesUchiage Hanabi / DAOKO: Standard TuningStanciu MariusNo ratings yet

- FreightTrain 1MM1 Acoustic PDFDocument2 pagesFreightTrain 1MM1 Acoustic PDFmiromarkoNo ratings yet

- One Last Cry by Bryan Mcknight (TABS)Document6 pagesOne Last Cry by Bryan Mcknight (TABS)jerwin gamboaNo ratings yet

- Intro To Fingerstyle PDFDocument4 pagesIntro To Fingerstyle PDFPoss Hum100% (1)

- Guitar Tab MOPDocument13 pagesGuitar Tab MOPombrimz owner ke2No ratings yet

- Aurora en PekinDocument4 pagesAurora en PekinmorbidpaleNo ratings yet

- Christopher Larkin - Hollow Knight - Main Theme PDFDocument2 pagesChristopher Larkin - Hollow Knight - Main Theme PDFSergio Ivan Granados TorresNo ratings yet

- 2 3year 8 Music Practical Lesson Plan 1 WK 6Document4 pages2 3year 8 Music Practical Lesson Plan 1 WK 6api-229273655No ratings yet

- Viva La Vida / Love Story (Boomwhackers) : VoiceDocument32 pagesViva La Vida / Love Story (Boomwhackers) : VoiceJoaan FooNo ratings yet

- Carlevaro Abel - Guitar Masterclass, Vol 1 - Sor, 10 Studies (1985)Document3 pagesCarlevaro Abel - Guitar Masterclass, Vol 1 - Sor, 10 Studies (1985)JoeNo ratings yet

- Your Guitar: Steel-StringDocument4 pagesYour Guitar: Steel-Stringkhan47pkNo ratings yet

- Interstellar Theme - TABSDocument2 pagesInterstellar Theme - TABSDavid Samuel Maya Cabrera75% (4)

- Guitar Accessory EssentialsDocument3 pagesGuitar Accessory EssentialsPrashant BhujelNo ratings yet

- Round Midnight - Uke Chord MelodyDocument2 pagesRound Midnight - Uke Chord Melodyrichroberge100% (1)

- Guitar TuningsDocument18 pagesGuitar TuningsSean Sherman100% (2)