Professional Documents

Culture Documents

(UV Specs) Emens Auditorium A New Lobby (Addition)

Uploaded by

Tej Vir SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(UV Specs) Emens Auditorium A New Lobby (Addition)

Uploaded by

Tej Vir SinghCopyright:

Available Formats

C.

Drain pan on cooling coil to extend 4 upstream and 24 past face of cooling coil.

D.

Downcomer drains from stacked coils to be minimum 1dia.

E.

Air Coils: Certify capacities, pressure drops, and selection procedures in accordance with ARI

410. Refer to Section 23 8216.

2.7

ULTRA-VIOLET LIGHT SECTION (Alternate Bid)

A.

General Requirements for UV-Light Sections:

1.

2.

3.

4.

5.

B.

Protection of Polymeric Materials

1.

C.

UV-C light fixtures and lamps shall be provided by the air handler manufacturer. The

UV-C fixtures shall be factory-assembled and tested in the air handler. Field-installed

fixtures shall not be allowed.

UV Fixtures to meet UL Standards 153, 1598 & 1995.

The UV-C fixtures and lamps shall be coupled end-to-end and mounted on a slide-out

rack to enable complete replacement and/or maintenance of the bulbs from the unit

exterior.

Voltage for lamps / transformers: 120V.

MC to provide unit mounted control panel housing: fuses, contactors, relays and wiring.

All polymeric materials that come into direct or indirect (reflected) contact with UV-C

light shall be tested and certified as UV-C tolerant. Any polymeric material in direct or

indirect contact with UV-C light not certified as UV-C tolerant shall be completely

shielded from the UV-C light using a certified UV-C tolerant material such as metal. UVC tolerance is defined as being capable of performing its intended duty for a minimum of

20 years.

Safety

1.

2.

3.

4.

Access doors shall be provided at the location of each UV-C light as indicated on the

plans and schedule. All sections of the air handler with access doors where the UV-C

lights may pose a risk for direct exposure shall have a mechanical interlock switch that

disconnectspower to the lights when the door is opened.

In addition to the mechanical interlock switch, each unit shall be equipped with an

externally mounted on-off/disconnect/shut off switch that disconnects power to the UV-C

lights. The switch shall be equipped with a lock-out/tag-out to prevent unwanted

operation of the UVC lights.

A view port with cover shall be provided in each UV section to allow viewing of the UVC light array confirming operation. The view port and other AHU windows shall be

treated to assure the UV-C energy emitted through it is below the threshold limits

specified by NIOSH and ACGIH.

Units shall have a safety warning label applied to the exterior of each section containing

UVC lights.

Ball State University

A New Lobby Addition for Emens Auditorium

BSU Project No. 2016-025.01 AU

Applied Engineering No. 15-159

CUSTOM INDOOR CENTRAL STATION AHU

237313 - 9

5.

2.8

Complete safety, maintenance and servicing instructions for the UV-C lights and fixtures

shall be incorporated into the air handler manufacturers standard installation, operating

and maintenance manuals.

FILTERS

A.

Filter Box: Section with filter guides, access doors from both sides, for side loading with

gaskets and blank-off plates.

B.

All filter housings shall have a factory supplied 0.0 to 2.0 magnehelic differential pressure

gauge, which may be shipped separately for field installation. All filters shall be 12 x 24 or

24 x 24. Pre-filter and final filter MERV ratings shall be as called out in the schedules. Refer

to Section 234000.

C.

Provide factory applied label on outside of filter sections with Type, Sizes, and Quantities of

each filter size.

D.

FILTERS

1. Disposable Panel Filters:

Factory-fabricated, viscous-coated, flat-panel type.

Thickness: 2 inches.

Initial Resistance: 0.025.

Recommended Final Resistance: 0.5.

Arrestance (ASHRAE 52.1): 80%.

MERV (ASHRAE 52.2): 8.

Media: Interlaced glass fibers sprayed with nonflammable adhesive.

Frame: Nonflammable cardboard.

2. Extended-Surface, Disposable Panel Filters:

Factory-fabricated, dry, extended-surface type.

Thickness: 4 inches.

Initial Resistance: 0.25.

Recommended Final Resistance: 0.75.

Arrestance (ASHRAE 52.1): 90%.

MERV (ASHRAE 52.2): 12/13.

Media: Fibrous material formed into deep-V-shaped pleats and held by self-supporting wire

grid.

Media-Grid Frame: Nonflammable cardboard

Ball State University

A New Lobby Addition for Emens Auditorium

BSU Project No. 2016-025.01 AU

Applied Engineering No. 15-159

CUSTOM INDOOR CENTRAL STATION AHU

237313 - 10

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Donaldson Process Chiller Manual MiniDocument31 pagesDonaldson Process Chiller Manual MiniTasos Mythbuster50% (6)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Piaggio Liberty 100 Indonesia MY 2011 (EN)Document179 pagesPiaggio Liberty 100 Indonesia MY 2011 (EN)Manualles67% (3)

- Thermo Safety Cabinets MSC-Advantage - Service ManualDocument73 pagesThermo Safety Cabinets MSC-Advantage - Service Manualaartb10182% (11)

- 1 - 118 TOP Current Electricity - Electrical Engineering Multiple Choice Questions and Answers - MCQs Preparation For Engineering Competitive ExamsDocument12 pages1 - 118 TOP Current Electricity - Electrical Engineering Multiple Choice Questions and Answers - MCQs Preparation For Engineering Competitive ExamsHussam GujjarNo ratings yet

- 100 Home Design IdeasDocument110 pages100 Home Design IdeasMilan Markovic100% (10)

- Hino 3241 Series700 8x4Document6 pagesHino 3241 Series700 8x4C.H. WEE100% (1)

- VRF SpecsDocument6 pagesVRF SpecsAshar HassanNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Surefire 2002 IllDocument100 pagesSurefire 2002 Illbenchiew100% (2)

- 60A0088 19 Radiance EnglishDocument24 pages60A0088 19 Radiance EnglishOscar GomezNo ratings yet

- ASHRAE 15 Mechanical Room SpecDocument6 pagesASHRAE 15 Mechanical Room SpecwillchamNo ratings yet

- 11kv SWGR SpecsDocument87 pages11kv SWGR SpecsstalinNo ratings yet

- Kittler - A Short History of The SearchlightDocument7 pagesKittler - A Short History of The Searchlightanton.de.rotaNo ratings yet

- Fire Alarm Installation MethodDocument7 pagesFire Alarm Installation MethodAleen Gamal Al-Dinji100% (1)

- FM-200 Clean Agent Fire Suppression System: Engineering SpecificationsDocument17 pagesFM-200 Clean Agent Fire Suppression System: Engineering SpecificationsPanner2009No ratings yet

- 00 - MS - Fire Alarm System InstallationDocument10 pages00 - MS - Fire Alarm System Installationkikokiko KarimNo ratings yet

- Fire Detection/Total Flooding Carbon Dioxide Suppression System Engineering Specifications Part 1 - General 1.01 Description of WorkDocument17 pagesFire Detection/Total Flooding Carbon Dioxide Suppression System Engineering Specifications Part 1 - General 1.01 Description of Work張哲僑No ratings yet

- Emergency Light Fitting Data SheetDocument4 pagesEmergency Light Fitting Data SheetSriram SubramanianNo ratings yet

- 11kv SWGR SpecsDocument87 pages11kv SWGR SpecsMekonnen Shewarega100% (1)

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Fike Fm-200 With SHP ProDocument8 pagesFike Fm-200 With SHP ProGovinda GopinathNo ratings yet

- SVC MNL Rp-29fc40pDocument34 pagesSVC MNL Rp-29fc40pjotajota2562No ratings yet

- RP-21FD10 TV Flatron LG 21 PDFDocument18 pagesRP-21FD10 TV Flatron LG 21 PDFAdriano AurélioNo ratings yet

- Patient Wall Systems ConfigurationDocument11 pagesPatient Wall Systems Configurationno nameNo ratings yet

- 3D Network Blu-Ray / Disc Player With Media Library: Service ManualDocument147 pages3D Network Blu-Ray / Disc Player With Media Library: Service ManualPaul KupasNo ratings yet

- MOTOR REQUIREMENTS FOR PLUMBING PROJECTSDocument12 pagesMOTOR REQUIREMENTS FOR PLUMBING PROJECTSsyedNo ratings yet

- Hitachi 55EX15KDocument82 pagesHitachi 55EX15KElmer OrtezNo ratings yet

- Zenith H20H52DT - Service ManualDocument48 pagesZenith H20H52DT - Service ManualrolaperezNo ratings yet

- UVResource UV-C Performance Spec - Rev 2Document5 pagesUVResource UV-C Performance Spec - Rev 2Oscar SiriasNo ratings yet

- Sylvania srt2223x (ET)Document52 pagesSylvania srt2223x (ET)Roberto Jimenez RojasNo ratings yet

- WF203 - SM - (ET) SYMPHONICDocument53 pagesWF203 - SM - (ET) SYMPHONICarturo48No ratings yet

- Spec Sub-Distributions PanelsDocument11 pagesSpec Sub-Distributions PanelsDolyNo ratings yet

- Zenith LG A29A23wm A25A02DDocument119 pagesZenith LG A29A23wm A25A02DIng Gregorio Acevedo Escalante RamirezNo ratings yet

- Operating Instructions for Synchronous GeneratorDocument56 pagesOperating Instructions for Synchronous Generatorkazishah100% (1)

- Inst SpecDocument23 pagesInst SpecSrikala VenkatesanNo ratings yet

- TC 42LS24XDocument25 pagesTC 42LS24XNelbercolNo ratings yet

- Blu-Ray Disc Home Cinema System: Service ManualDocument121 pagesBlu-Ray Disc Home Cinema System: Service ManualJosip HrdanNo ratings yet

- Aesculap EndoVue - Service ManualDocument168 pagesAesculap EndoVue - Service ManualEnggar RatnaaNo ratings yet

- Hydrosense HSCP Installation ManualDocument18 pagesHydrosense HSCP Installation Manualben_splNo ratings yet

- Man-1078 SigmaCP 24Document24 pagesMan-1078 SigmaCP 24Viddhesh ManjrekarNo ratings yet

- EWF2703 TV EmersonDocument57 pagesEWF2703 TV EmersonEriksson Miguel Tapia SolisNo ratings yet

- Emerson EWT19S2Document50 pagesEmerson EWT19S2dreamyson1983100% (1)

- LG 21sa1rlDocument18 pagesLG 21sa1rlJavier EspinozaNo ratings yet

- Part 1 - General: Section 15856 - Packaged Air Handling UnitsDocument10 pagesPart 1 - General: Section 15856 - Packaged Air Handling UnitsTej Vir SinghNo ratings yet

- LG lv280 v180 (ET)Document108 pagesLG lv280 v180 (ET)Toni Martin SebéNo ratings yet

- UV Disinfection for HVAC SystemsDocument3 pagesUV Disinfection for HVAC SystemsFARIDNo ratings yet

- 50UX58BDocument88 pages50UX58Bnip27No ratings yet

- TV Haier HTX21S31 PDFDocument27 pagesTV Haier HTX21S31 PDFCarlos RamirezNo ratings yet

- Service Manual GuideDocument98 pagesService Manual Guidemiguel angel jaramilloNo ratings yet

- Air Curtain InstallationDocument5 pagesAir Curtain InstallationCongson JeffNo ratings yet

- MAC 10 LEDC - MDR, MDRE, MDRC Specification Text - 0422Document3 pagesMAC 10 LEDC - MDR, MDRE, MDRC Specification Text - 0422lsisniegasNo ratings yet

- Installation Manual For EcologyDocument11 pagesInstallation Manual For Ecologyhacker mutherpuckerNo ratings yet

- 60sx10ba PDFDocument83 pages60sx10ba PDFatvstereoNo ratings yet

- Pumps & Motors SpecsDocument25 pagesPumps & Motors Specsahmed ragabNo ratings yet

- LG Zenith C-Line Zp94 95 Projection TV Training Manual 2000 (Et)Document98 pagesLG Zenith C-Line Zp94 95 Projection TV Training Manual 2000 (Et)Jose Domingo Maltez VallecilloNo ratings yet

- Manual + Esquema TV LG 21SA1RLDocument18 pagesManual + Esquema TV LG 21SA1RLPortal da Eletrônica100% (1)

- Section 1 Fire Suppr 13967 Ression Sy Ystems (C CO2)Document7 pagesSection 1 Fire Suppr 13967 Ression Sy Ystems (C CO2)ghostz0rNo ratings yet

- 26 00 00 - Basic Electrical Materials and MethodsDocument4 pages26 00 00 - Basic Electrical Materials and MethodsChris Benedict S. GalvezNo ratings yet

- Conventional Fire Control PanelDocument20 pagesConventional Fire Control PanelRabahNo ratings yet

- Qcs 2010 Section 10 Part 3 Primary ElementsDocument9 pagesQcs 2010 Section 10 Part 3 Primary Elementsbryanpastor106No ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

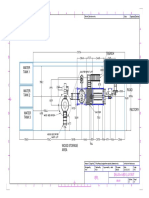

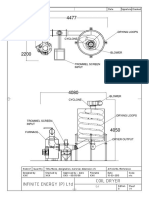

- 11-Feb-19 A30133-WA 11-Feb-19 A30133-WA: DWG. # Title DL Custom Division of 304260 Ontario LimitedDocument1 page11-Feb-19 A30133-WA 11-Feb-19 A30133-WA: DWG. # Title DL Custom Division of 304260 Ontario LimitedTej Vir SinghNo ratings yet

- A30133 Wa PDFDocument1 pageA30133 Wa PDFTej Vir SinghNo ratings yet

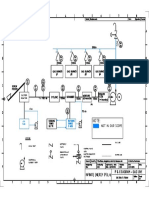

- Gasifier Melting Furnace SchematicDocument1 pageGasifier Melting Furnace SchematicTej Vir SinghNo ratings yet

- Sargroh Corp - Final INVOICEDocument1 pageSargroh Corp - Final INVOICETej Vir SinghNo ratings yet

- Fahu 1Document2 pagesFahu 1Tej Vir SinghNo ratings yet

- DG400+WBD LayoutDocument1 pageDG400+WBD LayoutTej Vir SinghNo ratings yet

- Quotation: Qty Model Number Description List Each Net Each Net TotalDocument1 pageQuotation: Qty Model Number Description List Each Net Each Net TotalTej Vir SinghNo ratings yet

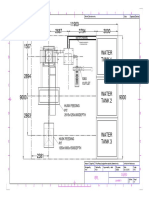

- Fahu 2Document1 pageFahu 2Tej Vir SinghNo ratings yet

- Water channel and husk feeding pits layout diagramDocument1 pageWater channel and husk feeding pits layout diagramTej Vir SinghNo ratings yet

- Yoga Day cultural activities and summer camp prize distributionDocument1 pageYoga Day cultural activities and summer camp prize distributionTej Vir SinghNo ratings yet

- PG125 LayoutDocument1 pagePG125 LayoutTej Vir SinghNo ratings yet

- DG 350-OT-750kWDocument1 pageDG 350-OT-750kWTej Vir SinghNo ratings yet

- DG400 Layout-IsO A3 Title BlockDocument1 pageDG400 Layout-IsO A3 Title BlockTej Vir SinghNo ratings yet

- Heat Exchanger ScheduleDocument1 pageHeat Exchanger ScheduleTej Vir SinghNo ratings yet

- Briquette Gasifier-IsO A3 Title BlockDocument1 pageBriquette Gasifier-IsO A3 Title BlockTej Vir SinghNo ratings yet

- North - Workshop BLDG (Chilled Water Type)Document1 pageNorth - Workshop BLDG (Chilled Water Type)Tej Vir SinghNo ratings yet

- MC125 GaDocument1 pageMC125 GaTej Vir SinghNo ratings yet

- CRAC - East - Admin BLDG (DX and Chilled Water Type)Document1 pageCRAC - East - Admin BLDG (DX and Chilled Water Type)Tej Vir SinghNo ratings yet

- Cyclone Duct ArrangementDocument1 pageCyclone Duct ArrangementTej Vir SinghNo ratings yet

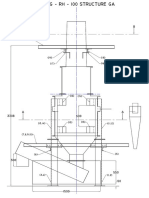

- DDG RH GA Dev DwgsDocument1 pageDDG RH GA Dev DwgsTej Vir SinghNo ratings yet

- DDG RH Structure GA2Document1 pageDDG RH Structure GA2Tej Vir SinghNo ratings yet

- Dg200 With DryerDocument1 pageDg200 With DryerTej Vir SinghNo ratings yet

- DDG RH Structure GA1Document1 pageDDG RH Structure GA1Tej Vir SinghNo ratings yet

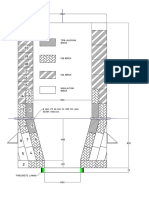

- DDG 300 RefractoryDocument1 pageDDG 300 RefractoryTej Vir SinghNo ratings yet

- Coil Dyrer Ga NormalDocument1 pageCoil Dyrer Ga NormalTej Vir SinghNo ratings yet

- DDG RH GA ElevationDocument1 pageDDG RH GA ElevationTej Vir SinghNo ratings yet

- DG200 With FilterDocument1 pageDG200 With FilterTej Vir SinghNo ratings yet

- Coil Dyrer Ga NormalDocument1 pageCoil Dyrer Ga NormalTej Vir SinghNo ratings yet

- Coil Dyrer Ga NormalDocument1 pageCoil Dyrer Ga NormalTej Vir SinghNo ratings yet

- Aislador Epoxi Catalogo 2011 ENGDocument56 pagesAislador Epoxi Catalogo 2011 ENGmk116dNo ratings yet

- UVA Prep 3Document12 pagesUVA Prep 3Serkan AkşanlıNo ratings yet

- AQUADA-DataDocument4 pagesAQUADA-DatajoseNo ratings yet

- Uniit 9 399-408 DepEd-IPDocument10 pagesUniit 9 399-408 DepEd-IPpeucogcoNo ratings yet

- Service Manual: Multimedia Projector Model NoDocument126 pagesService Manual: Multimedia Projector Model NoTrudy CoopeyNo ratings yet

- LEDL057 GE LED 14W Value Type A LED Glass Tubes Spec SheetDocument2 pagesLEDL057 GE LED 14W Value Type A LED Glass Tubes Spec SheetAldyPratamaNo ratings yet

- Latihan Diode and TransistorDocument7 pagesLatihan Diode and TransistorayydenNo ratings yet

- Megaman 43663 Lamp - Led Par16 Vivid 7,5w 10º 4000k Gu10Document5 pagesMegaman 43663 Lamp - Led Par16 Vivid 7,5w 10º 4000k Gu10VEMATELNo ratings yet

- Rate Schedules 2010: The All-Island Electric Licence 2001Document4 pagesRate Schedules 2010: The All-Island Electric Licence 2001csf571No ratings yet

- Flurocent LampDocument44 pagesFlurocent LampNagineni NareshNo ratings yet

- Sylvania Lumalux Ordering Guide 1986Document2 pagesSylvania Lumalux Ordering Guide 1986Alan MastersNo ratings yet

- Yi Smart LaMP-EnDocument3 pagesYi Smart LaMP-EnCiprian GeorgeNo ratings yet

- Kim Lighting EKG Gen. 2 Series Brochure 1985Document18 pagesKim Lighting EKG Gen. 2 Series Brochure 1985Alan MastersNo ratings yet

- Betalight Tritium Illumination DevicesDocument28 pagesBetalight Tritium Illumination DevicesGautam NatrajanNo ratings yet

- CBSE Class 7 Science Paper 1Document12 pagesCBSE Class 7 Science Paper 1Monu SharmaNo ratings yet

- 10.1201 9781351072540-34 ChapterpdfDocument20 pages10.1201 9781351072540-34 Chapterpdfjideli5825No ratings yet

- Superlight Compact FloodlightsDocument20 pagesSuperlight Compact FloodlightsOmar Adel DiabNo ratings yet

- INTERNAL ELECTRICAL WORKS SUMMARYDocument91 pagesINTERNAL ELECTRICAL WORKS SUMMARYUpendra ChariNo ratings yet

- GCSE Physics Electronic Control Answers and Mark SchemesDocument9 pagesGCSE Physics Electronic Control Answers and Mark SchemesLelon OngNo ratings yet

- Load Management: A Focused ApproachDocument26 pagesLoad Management: A Focused ApproachneyNo ratings yet

- Ohms LawDocument15 pagesOhms LawM Kumar MarimuthuNo ratings yet

- Plant Layout Factors and PrinciplesDocument7 pagesPlant Layout Factors and PrinciplesCASTRO, JHONLY ROEL C.No ratings yet