Professional Documents

Culture Documents

PL 3900 Battery Room Ventilation System

Uploaded by

candratrikusumaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PL 3900 Battery Room Ventilation System

Uploaded by

candratrikusumaCopyright:

Available Formats

BHS1.

com

Battery Room Ventilation System

Lead-acid batteries release hydrogen gas during the charging process. Proper ventilation in the battery room

is necessary to ensure potentially dangerous gases are diffused. The BHS Battery Room Ventilation System

(BRVS) is designed to detect hydrogen gas at low levels and dissipate the gas to prevent accumulation.

Components

Functionality

Hydrogen Gas Detector (HGD)

Hydrogen Exhaust Fan (HEF)

The Battery Room Ventilation System (BRVS) incorporates the Ventilation Stands, Hydrogen Gas

Detector (HGD), Hydrogen Exhaust Fan (HEF), and exhaust duct work into one complete system.

Ventilation Stands

Ventilation Ducts

The HGD monitors hydrogen gas levels and provides warning of increasing levels before they

become dangerous. The HGD controls the HEF; therefore, the powered exhaust fans will run when

the concentration of hydrogen gas has reached 1% or greater. This feature will help a facility save

money by both reducing the run time of the fans and by preventing the unnecessary escape of

climate-controlled air.

The Ventilation Stands and connected exhaust duct network are designed to capture hydrogen gas

with or without forced ventilation. As gas exits the batteries, it flows through a network of ducts to

safely exit the building with the aid of the HEF.

When the BRVS is used in conjunction with the Electrical Distribution System (EDS), the optional

Charger Shutdown disables the chargers when an excessive amount of hydrogen (more than 2%)

is detected in the area. By disabling the chargers, the production of hydrogen gas is stopped.

Reference literature PL-3800 Electrical Distribution System for more information on the EDS.

Features & Benefits

Increases battery room safety by monitoring hydrogen levels

Improves battery room air quality by exhausting gases

produced during battery charge

Product Specifications

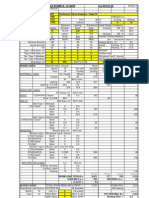

Hydrogen Gas Detector

Dimensions

2.5 x 4.75 x 7 (63.5 mm x 120.7 mm x 178 mm)

Mounting

(4) 3/16 (4.8 mm) screws

Positive airflow shutoff

Remote firefighters shutdown capability (recommended per

NEC 501)

Exhaust damper on each stand ensures even airflow

throughout the entire system

Spiral steel exhaust pipe for added durability (PVC or other

material available upon request)

Dimensions

Pipes are mounted to the stands, eliminating both the need to

attach to rafters and issues caused by high ceilings

Mounting

Custom designs available to fit all your battery changing

requirements

Input

Positive shutoff control, Normally open dry contacts

A complete BRVS aids in compliance with the following

standards: NEC 480.9 Ventilation of Battery Rooms, NEC

501.125. (B), 501.105 (1-3), NFPA 2 Hydrogen Technology

Code

Air Flow

(4) fans, each rated at 850 ft3/min, total 3,400 ft3/min

N+1 (redundancy), (3) fans at 850 ft3/min,

total 2,550 ft3/min for 2,550 ft3 (72 m3) area

Visit http://na.bhs1.com/battery-room/ventilation/ for a free, online

calculator to estimate the possible level of hydrogen in a facility

and determine the necessary precautions that should be taken.

Power Requirements

85 V ac to 265 V ac 50/60 Hz, or 17 V dc to 60 V dc

Relay

At 2% SPDT, At 1% SPDT

Operating Temperature

14F to 104F (-10C to 40C)

Hydrogen Exhaust Fan

Weight

18 x 24 x 24 (457 mm x 610 mm x 610 mm)

Fan: 51 lb (24 kg), Rain shield and damper: 24 lb (11 kg)

(4) 1.5 (38 mm) Wings, Standard 24 (610 mm) Duct

Power Requirements

115 V ac, Grounded

Positive Shutoff

Dry contact activated, manually reset

Ventilation Stand*

6 (152 mm) diameter pipe from rear of each stand feeds

into single 16 (406 mm) diameter pipe

Exhaust Duct Network

Center of 16 (406 mm) diameter pipe feeds into single

24 (610 mm) diameter pipe adjoining to HEF and exiting

the building

* The dimensions of Ventilation Stands vary slightly from standard System Stands.

Reference PL-2000 Battery Roller Stands literature for System Stands specifications.

Designs can be customized to meet the needs of each facility.

P.O. Box 28990 St. Louis, MO 63132 USA 1.800.BHS.9500 Fax: 314.423.6444 Email: sales@bhs1.com Web: BHS1.com

Specifications are subject to change without notice. 20132015 Battery Handling Systems Inc. St. Louis, MO Data Sheet: PL-3900 03/15

You might also like

- Sample BOQ Central HVACDocument7 pagesSample BOQ Central HVACbookjaman92% (12)

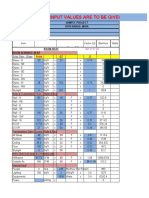

- RTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20Document1 pageRTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20alvinchuanNo ratings yet

- Underground Steam & Condensate Piping PDFDocument26 pagesUnderground Steam & Condensate Piping PDFZacky JoeNo ratings yet

- Return Air Square: Ceiling DiffuserDocument1 pageReturn Air Square: Ceiling DiffuserEnak Cenir100% (1)

- PEERLEES Fire Pump PDFDocument175 pagesPEERLEES Fire Pump PDFN. AndradeNo ratings yet

- Valvulas FC WoodwortDocument2 pagesValvulas FC WoodwortMigue MedZa100% (1)

- Moody Diagram (Plot of Colebrook's Correlation) : Fully Rough Flow - Complete Turbulence Transition ZoneDocument1 pageMoody Diagram (Plot of Colebrook's Correlation) : Fully Rough Flow - Complete Turbulence Transition ZoneJuan Chirinos MegoNo ratings yet

- ASME PTC 10 - Compressors and ExhaustersDocument191 pagesASME PTC 10 - Compressors and ExhaustersAndreea FloreaNo ratings yet

- 2K Method Excess Head Loss in Pipe FittingsDocument8 pages2K Method Excess Head Loss in Pipe Fittingsjxd3261No ratings yet

- Ventilation DesignDocument4 pagesVentilation DesignPhyu Mar Thein KyawNo ratings yet

- Sizing Duct Work SheetDocument4 pagesSizing Duct Work SheetMaulana MaftuhiNo ratings yet

- Pressur Drop Supply Air DuctDocument2 pagesPressur Drop Supply Air Ductmarsha.fsdNo ratings yet

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- Aero Ducts IDocument31 pagesAero Ducts ImanhngoducNo ratings yet

- Pumb RoomDocument2 pagesPumb RoomMohamed HamzaNo ratings yet

- Pressure Drop Calculation For Fan (Exf-Bsc-02) Typical Calculation For Fan (Exf-Bsc-02)Document10 pagesPressure Drop Calculation For Fan (Exf-Bsc-02) Typical Calculation For Fan (Exf-Bsc-02)ibnrafeeqNo ratings yet

- Project: FT Catcher Fpso Feed: Hvac - Heater Load CalculationDocument7 pagesProject: FT Catcher Fpso Feed: Hvac - Heater Load CalculationinstrengNo ratings yet

- Cooling Load Calculation SheetDocument5 pagesCooling Load Calculation SheetingridNo ratings yet

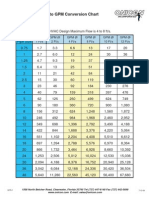

- Flow Velocity (FT/S) To GPM Conversion ChartDocument1 pageFlow Velocity (FT/S) To GPM Conversion Chartmonaco59No ratings yet

- Static Pressure Calculation in The Air DuctsDocument2 pagesStatic Pressure Calculation in The Air Ductsmeeng2014No ratings yet

- Sewer Pumpstation Design Calculations For AlqiDocument7 pagesSewer Pumpstation Design Calculations For AlqiTahirJabbarNo ratings yet

- 2.4 Static Pressure Spreadsheet 1Document4 pages2.4 Static Pressure Spreadsheet 1Jitendra KadamNo ratings yet

- Pressure DropDocument4 pagesPressure DropNyandoro E-max MaxmoreNo ratings yet

- Copper Pipes (Based On Silver Book) : Purpose AssumptionsDocument3 pagesCopper Pipes (Based On Silver Book) : Purpose AssumptionscesNo ratings yet

- Heatload Calculation - Kirloskar Ferrous - UPS RoomDocument6 pagesHeatload Calculation - Kirloskar Ferrous - UPS Roomsenthil kumarNo ratings yet

- Hazen Williams EquationDocument1 pageHazen Williams EquationNur IzzaidahNo ratings yet

- Steam Pipe SizingDocument16 pagesSteam Pipe SizingsamvendanNo ratings yet

- Summer AHU Load CalculationsDocument3 pagesSummer AHU Load CalculationsMd Arbaz PoonawalaNo ratings yet

- Nicotra (Backward Curve)Document95 pagesNicotra (Backward Curve)Archityrema Surya100% (1)

- Stair Case-01 Pressurisation Calculation: 3.3 7.255 2.56 64.78 2.2 1.1 - 6.6 Walls (Tight) Door Frame (Single Leaf)Document7 pagesStair Case-01 Pressurisation Calculation: 3.3 7.255 2.56 64.78 2.2 1.1 - 6.6 Walls (Tight) Door Frame (Single Leaf)Shabeer HamzaNo ratings yet

- Cooling Coil 03Document18 pagesCooling Coil 03Sam Wang Chern Peng100% (3)

- Sizing calculations for BFW pumps, FD, SA and ID fans for 50,000 kg/hr boilerDocument5 pagesSizing calculations for BFW pumps, FD, SA and ID fans for 50,000 kg/hr boilerMati Dalam Penantian CintamuNo ratings yet

- World Highest Building (Burj Kalifa) Air DisruptionDocument40 pagesWorld Highest Building (Burj Kalifa) Air DisruptionPrabu RajaNo ratings yet

- Pipe Size For Cooling Water SystemDocument5 pagesPipe Size For Cooling Water Systemnagu108No ratings yet

- Steam Properties Paper2Document9 pagesSteam Properties Paper2Gary JonesNo ratings yet

- Rosemount 1495 Orifice Plate, 1496 Flange Union, 1497 Meter SectionDocument24 pagesRosemount 1495 Orifice Plate, 1496 Flange Union, 1497 Meter SectionJames ThomasNo ratings yet

- TES Storage Tank All CalculationDocument45 pagesTES Storage Tank All CalculationmitulNo ratings yet

- Ductwork Sizing Calculation StudyDocument2 pagesDuctwork Sizing Calculation StudyNghia Huynh NgocNo ratings yet

- 35-Duct Weight Calculation SheetDocument11 pages35-Duct Weight Calculation SheetAnanth Ganesan100% (1)

- Static Pressure FansDocument35 pagesStatic Pressure FansarifkhadeerNo ratings yet

- Granite Panel Installation Project DesignDocument10 pagesGranite Panel Installation Project DesignKilaru HareeshNo ratings yet

- Psychrometry. Heat Recovery Air Handling Unit (Ahu) - by Ömer Faruk DDocument13 pagesPsychrometry. Heat Recovery Air Handling Unit (Ahu) - by Ömer Faruk DKarl WeierstrassNo ratings yet

- ELECTROLINE EMT, IMC, RSC Conduit Fittings Catalog 2015-2016Document88 pagesELECTROLINE EMT, IMC, RSC Conduit Fittings Catalog 2015-2016Hayrettin Çakmak50% (2)

- Shell and Tube Heat Exchanger Design: Fig. 4 Fig. 2Document42 pagesShell and Tube Heat Exchanger Design: Fig. 4 Fig. 2songjihyo16111994No ratings yet

- Pan Humidifier CalculaitonDocument1 pagePan Humidifier CalculaitonAshok KrishnamurthyNo ratings yet

- Coil Selection For 38 TR Ahu r0 18.12.2006Document2 pagesCoil Selection For 38 TR Ahu r0 18.12.2006Mohsin ShaikhNo ratings yet

- Area ΔT U: Project Sample Project Location Hyderabad, India Client ConsultantDocument4 pagesArea ΔT U: Project Sample Project Location Hyderabad, India Client ConsultantUTKARSH GADVE100% (1)

- System Duct Pressure Loss CalculationDocument6 pagesSystem Duct Pressure Loss Calculationthanh_79No ratings yet

- DESIGN DATA FOR COOLING AND HEATING LOAD ESTIMATIONDocument5 pagesDESIGN DATA FOR COOLING AND HEATING LOAD ESTIMATIONFarzin ShahabNo ratings yet

- Pressure Loss - SwitchyardDocument1 pagePressure Loss - Switchyardkarthikraja21No ratings yet

- Design Note For Air Reciever TankDocument6 pagesDesign Note For Air Reciever TankJoshua Balaram RaoNo ratings yet

- Pressure Drop Calculation Combined Steel and Mesonery Duct PDFDocument3 pagesPressure Drop Calculation Combined Steel and Mesonery Duct PDFsmcsamindaNo ratings yet

- Room ventilation options comparisonDocument9 pagesRoom ventilation options comparisonSamved PatelNo ratings yet

- SP SP VP V PR) : Velocity Pressure Method Calculation SheetDocument6 pagesSP SP VP V PR) : Velocity Pressure Method Calculation SheetAnkit LonareNo ratings yet

- Water Treatment Catalogue GuideDocument12 pagesWater Treatment Catalogue GuideJim TsikasNo ratings yet

- Calculation Sheet For Make - Up Water Tank: #Value!Document4 pagesCalculation Sheet For Make - Up Water Tank: #Value!thanh_79No ratings yet

- System Duct Pressure Loss CalculationDocument6 pagesSystem Duct Pressure Loss CalculationijkendrickNo ratings yet

- PL-3900 Battery Room Ventilation SystemDocument2 pagesPL-3900 Battery Room Ventilation SystemismailayarNo ratings yet

- DeaeratorDocument8 pagesDeaeratorfjoesandiNo ratings yet

- Fisher SUB 250Document6 pagesFisher SUB 250shuyuanz6595No ratings yet

- Baxi Solo 2 40rs Gcno.41-077-77Document42 pagesBaxi Solo 2 40rs Gcno.41-077-77sjallandNo ratings yet

- Emco Wheaton - Marine Loading Arm - 30696-13744Document8 pagesEmco Wheaton - Marine Loading Arm - 30696-13744candratrikusumaNo ratings yet

- Union Pump BrochureDocument7 pagesUnion Pump Brochureahad_shiraziNo ratings yet

- Pumping Solutions for Steam Assisted Gravity Drainage (SAGDDocument16 pagesPumping Solutions for Steam Assisted Gravity Drainage (SAGDcandratrikusumaNo ratings yet

- Mtu4r0113ds100 100kw StandbyDocument4 pagesMtu4r0113ds100 100kw StandbycandratrikusumaNo ratings yet

- Catalog Loading SystemsDocument40 pagesCatalog Loading SystemsNafaka1703No ratings yet

- Vaporizer AlgasSDI Zimmer Broch LRDocument4 pagesVaporizer AlgasSDI Zimmer Broch LRcandratrikusumaNo ratings yet

- Compressor Technique Catalog 2013 Tcm113-3539053Document184 pagesCompressor Technique Catalog 2013 Tcm113-3539053steve@air-innovations.co.zaNo ratings yet

- EMCO WHEATON - Marine Loading Arm - 30696-13744 PDFDocument8 pagesEMCO WHEATON - Marine Loading Arm - 30696-13744 PDFcandratrikusumaNo ratings yet

- Pneumatic & Electric Actuator - Brochure - English - Imperial PDFDocument20 pagesPneumatic & Electric Actuator - Brochure - English - Imperial PDFcandratrikusumaNo ratings yet

- 347Document49 pages347Anonymous qOBFvINo ratings yet

- Bulletin N2 KDocument24 pagesBulletin N2 KcandratrikusumaNo ratings yet

- LIT - ES6 - LS01EN (3.7 - 7.4 KW) PDFDocument8 pagesLIT - ES6 - LS01EN (3.7 - 7.4 KW) PDFcandratrikusumaNo ratings yet

- Vaporizer AlgasSDI Zimmer Broch LRDocument4 pagesVaporizer AlgasSDI Zimmer Broch LRcandratrikusumaNo ratings yet

- LIT Desiccant Dryers AT02ENDocument12 pagesLIT Desiccant Dryers AT02ENcandratrikusumaNo ratings yet

- Catalogue K35 enDocument72 pagesCatalogue K35 enemil_burdetiuNo ratings yet

- DH Series: 15 kW-110 KW Oil-Less Rotary Screw CompressorsDocument16 pagesDH Series: 15 kW-110 KW Oil-Less Rotary Screw CompressorsVijay KumarNo ratings yet

- NEC - NFPA 496 Three Types of Purge (X-Y-Z)Document1 pageNEC - NFPA 496 Three Types of Purge (X-Y-Z)채원종No ratings yet

- No. 45 Corrosion Inhibitor (No45inhib) PDFDocument7 pagesNo. 45 Corrosion Inhibitor (No45inhib) PDFcandratrikusumaNo ratings yet

- Yalesystems Katalog Jib PDFDocument12 pagesYalesystems Katalog Jib PDFcandratrikusumaNo ratings yet

- US8172549 - Self Venting at PumpDocument8 pagesUS8172549 - Self Venting at PumpcandratrikusumaNo ratings yet

- Norsok ST 2001Document131 pagesNorsok ST 2001mamounsdNo ratings yet

- Deep Well Pump - Monarch 30, 50, 85gpm Submerssible Pump Tech SheetsDocument6 pagesDeep Well Pump - Monarch 30, 50, 85gpm Submerssible Pump Tech SheetscandratrikusumaNo ratings yet

- Foam Testing Fire Fighting Foams BrochureDocument24 pagesFoam Testing Fire Fighting Foams BrochureFaizan0% (1)

- Systemair - Вентиляторы 2012Document403 pagesSystemair - Вентиляторы 2012andreys_k-g-uNo ratings yet

- Resignation LetterDocument1 pageResignation LettercandratrikusumaNo ratings yet

- Multi-function Hand Pump Generates Vacuum and PressureDocument4 pagesMulti-function Hand Pump Generates Vacuum and PressurecandratrikusumaNo ratings yet

- GGB CatalogDocument52 pagesGGB CatalogcandratrikusumaNo ratings yet

- Radial Fan Blower-RZR SeriesDocument98 pagesRadial Fan Blower-RZR SeriesAbsar MamunNo ratings yet

- fdb2 - Fire and Damper PDFDocument4 pagesfdb2 - Fire and Damper PDFcandratrikusumaNo ratings yet

- Chillers 410 A 65KW para DHLDocument122 pagesChillers 410 A 65KW para DHLDavid Ramos CarvajalNo ratings yet

- AMCA 205-10 (Rev - 2011) PDFDocument17 pagesAMCA 205-10 (Rev - 2011) PDFv2304451No ratings yet

- National Comfort Institute - Measure and Interpret Static PressuresDocument5 pagesNational Comfort Institute - Measure and Interpret Static PressurescrisNo ratings yet

- Electrical For ALLDocument51 pagesElectrical For ALLvaithy2011No ratings yet

- Motor InvntryDocument41 pagesMotor InvntryChandu ChNo ratings yet

- Light and VentilationDocument25 pagesLight and VentilationKaushal PatelNo ratings yet

- Simotics HV Overview en PDFDocument18 pagesSimotics HV Overview en PDFserkalemtNo ratings yet

- ThesisDocument124 pagesThesisRonel PagcaliwaganNo ratings yet

- Comefri - TLZ-THLZ Fan Catalogue 04-08Document46 pagesComefri - TLZ-THLZ Fan Catalogue 04-08João Guilherme Raimundo GarciaNo ratings yet

- Fan Inlet System EffectsDocument4 pagesFan Inlet System EffectsEzrizal Yusuf100% (1)

- Error Codes 7095Document70 pagesError Codes 7095Gerald Aguero PorrasNo ratings yet

- Modern Cooling System TheoryDocument4 pagesModern Cooling System TheorySporkyNo ratings yet

- H Im HGDDocument64 pagesH Im HGDMaria DazaNo ratings yet

- Pumping Station Modification PDFDocument15 pagesPumping Station Modification PDFcarlosnavalmaster100% (1)

- EEMUA Publication CatDocument36 pagesEEMUA Publication CatLamija Lamy67% (3)

- Carrier38CKC 50HzDocument20 pagesCarrier38CKC 50HzAaron LeveyNo ratings yet

- Circular Duct Attenuators: Performance Data - Open TypeDocument3 pagesCircular Duct Attenuators: Performance Data - Open TypePaul ShermanNo ratings yet

- Sub-Zero 400 Series Job Aid #3756394 (Rev D Aug 2003)Document196 pagesSub-Zero 400 Series Job Aid #3756394 (Rev D Aug 2003)nick_petrielli100% (1)

- H3C Troubleshooting Guide-HP ComwareDocument33 pagesH3C Troubleshooting Guide-HP ComwareElvis de LeónNo ratings yet

- Catalog DAIKIN 2013 SingDocument47 pagesCatalog DAIKIN 2013 SingVan Diep100% (1)

- Products Catalogue VRF PDFDocument144 pagesProducts Catalogue VRF PDFMiraNo ratings yet

- LT 999 600 227 PPH308 Integrator PackageDocument14 pagesLT 999 600 227 PPH308 Integrator Packagerokoma7No ratings yet

- 2003 Mtps Project ReportDocument48 pages2003 Mtps Project ReportSunil Giri100% (1)

- Saab900ownersmanual1992US (Ocr)Document114 pagesSaab900ownersmanual1992US (Ocr)mnbvqwertNo ratings yet

- Perkins Fans&BlowersDocument12 pagesPerkins Fans&BlowersPranay KharbeNo ratings yet

- Startup ID Fan ProcedureDocument9 pagesStartup ID Fan Proceduresprotkar100% (1)

- Cassette Fan Coil ManualDocument38 pagesCassette Fan Coil ManualLaptuca GabrielNo ratings yet

- Classifying Compressors by Type PDFDocument49 pagesClassifying Compressors by Type PDFSadashiw PatilNo ratings yet

- What Is SFPDocument1 pageWhat Is SFPMari MoNo ratings yet