Professional Documents

Culture Documents

Foreign Technology

Uploaded by

Sinhroo0 ratings0% found this document useful (0 votes)

7 views1 pageThis paper investigates the phase composition of high-manganese steels containing 12% Mn and 0.04-1.2% C. Samples were heated and quenched, with some undergoing plastic deformation. Phase diagrams were drawn showing the phase ratios as a function of carbon content for steels in both the quenched and deformed states. The structure of steel containing 0.5% C and 12% Mn is purely austenitic. At lower carbon concentrations, the steel contains α- and ε-phases in addition to the γ-phase. Plastic deformation leads to the formation of α-martensite in alloys with at least 0.7% C and a small amount of

Original Description:

.

Original Title

415

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis paper investigates the phase composition of high-manganese steels containing 12% Mn and 0.04-1.2% C. Samples were heated and quenched, with some undergoing plastic deformation. Phase diagrams were drawn showing the phase ratios as a function of carbon content for steels in both the quenched and deformed states. The structure of steel containing 0.5% C and 12% Mn is purely austenitic. At lower carbon concentrations, the steel contains α- and ε-phases in addition to the γ-phase. Plastic deformation leads to the formation of α-martensite in alloys with at least 0.7% C and a small amount of

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageForeign Technology

Uploaded by

SinhrooThis paper investigates the phase composition of high-manganese steels containing 12% Mn and 0.04-1.2% C. Samples were heated and quenched, with some undergoing plastic deformation. Phase diagrams were drawn showing the phase ratios as a function of carbon content for steels in both the quenched and deformed states. The structure of steel containing 0.5% C and 12% Mn is purely austenitic. At lower carbon concentrations, the steel contains α- and ε-phases in addition to the γ-phase. Plastic deformation leads to the formation of α-martensite in alloys with at least 0.7% C and a small amount of

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

FOREIGN

TECHNOLOGY

E F F E C T OF C A R B O N ON T H E P H A S E C O M P O S I T I O N

OF H I G H - M A N G A N E S E

STEELS*

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7,

p. 43, July, 1963

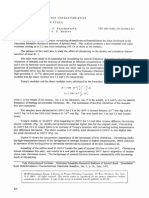

This paper concerns an investigation of the phase composition

of high-manganese steels containing 12% Mn and 0.04-1.2% C.

0

80

The samples were heated at 1100~ for 30 rain and quenched

in water; some of the samples were then subjected to slight plastic

deformation.

60

The phase composition was studied by the change in hardness, by dilatometric analysis (transformations occurring as the result of heating recorded with a dilatometer), and by changes in magnetic properties and the microstructure.

gO

I

3

0

--

00

ca.

b)

20

T-

Phase diagrams were drawn. These diagrams show the phase

ratios as a function of the carbon content in steels with 12%

Mn: a) in the quenched state; b) in the deformed state.

The structure of the quenched steel containing 0.5% C and

12% Mn is purely austenitic. At lower carbon concentrations the

steel contains not only the g-phase but also the a - and s-phases.

The lower the carbon content the larger the amount of c~-phase of

martensitic origin; its amount reaches ahout 70% when the carbon

concentration is 0.04%. The s-phase, of martensitic origin, aswell

as the intermediate phase, is formed as the result of the ), ~ a transformation; the s-phase has a close-packed hexagonal lattice.

The amount of s - p h a s e depends on the carbon content.

Quenched steel containing 12% Mn and 0.2% C contains the greatest amount of s-phase, plastic deformation'leads

to the formation of c~-phase in alloys in which the carbon content is at least 0.7%.

In alloys containing 0-0.05%C plastic deformation increases the amount of c~-phase; in alloys containing 0.50.7% C plastic deformation leads to the formation of a small amount of c~-martensite, which is formed from austenire. In steels containing over 0.7%C (Hadfield steel) plastic deformation does not result in the formation of c~-martensite (see phase diagrams a, b). In steels containing 0.7-1.0% C plastic deformation leads to the formation of a

small amount of s-martensite. In steels with a lower carbon concentration plastic deformation leads to the formation of a small amount of c~-martensite. In quenched steels with lower carbon concentrations, which contain s - and

c~-martensite, plastic deformation decreases the amount of the s-phase.

In other words, plastic deformation induces the ~ ~ r

c~ transformation. If the steel contains the s - and c~phases then the second step of the transformation develops and the amount of the s-phase decreases. If the initial

structure of the steel consists of ),-phase alone then plastic deformation leads only to the first step of the transformation, and the s-phase is formed.

* Imai Iunoshin, Toshio Sato, Journal Japan Institute of Metals, No. 5 (1962).

This section is taken from the publication ~Express-Information.-

415

You might also like

- FinkelShtein1963 Article HeatTreatmentOfLowCarbonSteelsDocument2 pagesFinkelShtein1963 Article HeatTreatmentOfLowCarbonSteelsSaleh SulimanNo ratings yet

- The Influence of Hot-Working Conditions On A Structure of High-Manganese SteelDocument10 pagesThe Influence of Hot-Working Conditions On A Structure of High-Manganese SteelPiranha TourniquetNo ratings yet

- Calliare 2020Document18 pagesCalliare 2020Alejandra HernandezNo ratings yet

- High Manganese Austenitic Steels: Part Two: Total Materia ArticleDocument7 pagesHigh Manganese Austenitic Steels: Part Two: Total Materia ArticleCarlos Ediver Arias RestrepoNo ratings yet

- 382 385 PDFDocument4 pages382 385 PDFSinhrooNo ratings yet

- Weldab 13%CRDocument7 pagesWeldab 13%CRcawid100% (1)

- 374 376 PDFDocument3 pages374 376 PDFSinhrooNo ratings yet

- Tool and Structural Steels: Special Features of Microstructure of W - Mo High-Speed Steel Modified With Titanium DiborideDocument6 pagesTool and Structural Steels: Special Features of Microstructure of W - Mo High-Speed Steel Modified With Titanium DiborideSinhrooNo ratings yet

- Wire Rod of Boron-Bearing Low-Carbon Steel For Direct Deep DrawingDocument9 pagesWire Rod of Boron-Bearing Low-Carbon Steel For Direct Deep DrawingNicolas ValleNo ratings yet

- Full 15633Document8 pagesFull 15633Amarjeet SinghNo ratings yet

- Phase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yuDocument2 pagesPhase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yuSinhrooNo ratings yet

- Hardening From The Liquid StateDocument5 pagesHardening From The Liquid StateSinhrooNo ratings yet

- Weldability of Metals - NPTELDocument18 pagesWeldability of Metals - NPTELKaushal Gandhi0% (1)

- 01.improving The Casting Process of Peritectic Steel Grades Ferrite Potential CalculationDocument3 pages01.improving The Casting Process of Peritectic Steel Grades Ferrite Potential CalculationsankhadipNo ratings yet

- Influence of Tungsten and Carbon Addition On Electrochemical Behaviour of 9 % CR Creep-Resistant SteelDocument6 pagesInfluence of Tungsten and Carbon Addition On Electrochemical Behaviour of 9 % CR Creep-Resistant SteelElMacheteDelHuesoNo ratings yet

- Effect of Copper Content On The Hot Ductility Loss of Low Carbon SteelsDocument5 pagesEffect of Copper Content On The Hot Ductility Loss of Low Carbon SteelsBalakrishna G SettyNo ratings yet

- Bainite in SteelDocument12 pagesBainite in Steelsathyadevi konnurNo ratings yet

- Chapter 5 Quantitative Prediction of C-MN Steel Weld Metal MicrostructureDocument18 pagesChapter 5 Quantitative Prediction of C-MN Steel Weld Metal MicrostructureXimena Mercedez Palacios PortalNo ratings yet

- Effect of Alloying, Heat Treatment, and Deformation On The Structure and Properties of Damping Z N - A I AlloysDocument4 pagesEffect of Alloying, Heat Treatment, and Deformation On The Structure and Properties of Damping Z N - A I AlloysSinhrooNo ratings yet

- Medium MN SteelDocument8 pagesMedium MN Steeldzb2022No ratings yet

- The Effects of Alloying Elements On SteelsDocument36 pagesThe Effects of Alloying Elements On SteelsRahul PandeyNo ratings yet

- Comparison Between Traditional and Innovative SteelsDocument10 pagesComparison Between Traditional and Innovative SteelsIonut AdrianNo ratings yet

- High-Mn Steel Weldment Mechanical Properties at 4.2 KDocument9 pagesHigh-Mn Steel Weldment Mechanical Properties at 4.2 K3834saldNo ratings yet

- The Iron-Iron Carbide Equilibrium DiagramDocument15 pagesThe Iron-Iron Carbide Equilibrium DiagramjhangeerNo ratings yet

- Effects of MN and NB On The Macro-And Microsegregation in High-Mn High-Al Content TRIP SteelsDocument10 pagesEffects of MN and NB On The Macro-And Microsegregation in High-Mn High-Al Content TRIP SteelsKhairul MuzafarNo ratings yet

- InTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsDocument19 pagesInTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsSiap SiapNo ratings yet

- MEM Project DiplomaDocument13 pagesMEM Project DiplomaJoshua KondkarNo ratings yet

- Influence of Saw Fluxes On Low-Carbon Steel Weld MicrostructureDocument11 pagesInfluence of Saw Fluxes On Low-Carbon Steel Weld MicrostructureRaviTeja BhamidiNo ratings yet

- Effect of Mo On CCT BainiteDocument5 pagesEffect of Mo On CCT BainiteHICHAM SBAITINo ratings yet

- Thermomechanical Processing of Pipeline Steels With A With A Reduced MN ContentDocument9 pagesThermomechanical Processing of Pipeline Steels With A With A Reduced MN ContentBuchan65No ratings yet

- Iron-Carbon Phase Diagram Explained BrieflyDocument4 pagesIron-Carbon Phase Diagram Explained BrieflyZicoNo ratings yet

- Creep-Resistant Austenitic Cast SteelDocument6 pagesCreep-Resistant Austenitic Cast SteelKarna2504No ratings yet

- Martensite and Retained AusteniteDocument4 pagesMartensite and Retained Austenitemp87_ing100% (1)

- Iron Carbon Equillibrium Diagram GandhidhamDocument22 pagesIron Carbon Equillibrium Diagram Gandhidhamcal2_uniNo ratings yet

- RM Question 2Document9 pagesRM Question 2G SamhithaNo ratings yet

- Nanostructures by Severe Plastic Deformation of Steels: Advantages and ProblemsDocument9 pagesNanostructures by Severe Plastic Deformation of Steels: Advantages and Problemsramonguit9105No ratings yet

- The Effect of Alloying and of The Structure On Active-Passive Transition Potential Range of 17% Chromium Ferritic Stainless SteelsDocument6 pagesThe Effect of Alloying and of The Structure On Active-Passive Transition Potential Range of 17% Chromium Ferritic Stainless SteelsBANUNo ratings yet

- Capili Jefferson 10Document5 pagesCapili Jefferson 10Christian Al EncarnacionNo ratings yet

- Art:10.1007/s11665 008 9336 Z PDFDocument7 pagesArt:10.1007/s11665 008 9336 Z PDFJosé AntonioNo ratings yet

- Strain Ageing of Steel - Part Two - KEY To METALS ArticleDocument4 pagesStrain Ageing of Steel - Part Two - KEY To METALS Articlekumarpankaj030No ratings yet

- NRCC 48162Document20 pagesNRCC 48162Ante KovacicNo ratings yet

- TRIP SteelDocument6 pagesTRIP Steeldzb2022No ratings yet

- SteelDocument1 pageSteelSinhro018No ratings yet

- Galvanizing AHSSDocument3 pagesGalvanizing AHSSTrial_TNo ratings yet

- Ajp jp4199303C720Document4 pagesAjp jp4199303C720Satyendra SinghNo ratings yet

- Effect of Austenitizing Temperature and Time On THDocument9 pagesEffect of Austenitizing Temperature and Time On THJarek PlaszczycaNo ratings yet

- Tratamento de Aço FerramentaDocument5 pagesTratamento de Aço FerramentaclebertasparNo ratings yet

- KLP 8Document8 pagesKLP 8Ahmad HafizNo ratings yet

- Determination of The Surface Tension of Liquid Stainless SteelDocument5 pagesDetermination of The Surface Tension of Liquid Stainless SteelĐào ThườngNo ratings yet

- L Baugh Stage 1 PT 2 - ElectrolyticDocument54 pagesL Baugh Stage 1 PT 2 - ElectrolyticjeremypearceNo ratings yet

- Steel DeoxidationDocument12 pagesSteel DeoxidationUlises Quintana CarhuanchoNo ratings yet

- Callister7E - pp290 301 (The Iron Carbon System)Document12 pagesCallister7E - pp290 301 (The Iron Carbon System)iglumacNo ratings yet

- 05 - Characterization of X-120M Pipeline SteelDocument8 pages05 - Characterization of X-120M Pipeline SteelŞarîngă George AlexandruNo ratings yet

- Srivastav A 2008Document5 pagesSrivastav A 2008FARID MIFTAHUL ANWARNo ratings yet

- Iron Carbon Diagram (ChE Handbook)Document21 pagesIron Carbon Diagram (ChE Handbook)Mohamed Ismail100% (1)

- MST-15!31!843-Current Opinion in Medium Manganese SteelDocument15 pagesMST-15!31!843-Current Opinion in Medium Manganese Steelmaggie zhangNo ratings yet

- Maleable Cast IronsDocument0 pagesMaleable Cast IronsGilang Miky Pratama AlwianNo ratings yet

- The Effects of Alloying Elements On Steels 1Document36 pagesThe Effects of Alloying Elements On Steels 1Common ManNo ratings yet

- Effect of Various Kinds of Thermomechanical Treatment On The Structure and Properties of Steels Studied Using Acoustomicroscopic MethodsDocument5 pagesEffect of Various Kinds of Thermomechanical Treatment On The Structure and Properties of Steels Studied Using Acoustomicroscopic MethodsSinhrooNo ratings yet

- Phase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yuDocument2 pagesPhase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yuSinhrooNo ratings yet

- Heating IN AN Electrically Conducting Layer Carbon-Containing Particles OFDocument4 pagesHeating IN AN Electrically Conducting Layer Carbon-Containing Particles OFSinhrooNo ratings yet

- Hydrostatic Extrusion at 100°C and Its Effect On The Grain Size and Mechanical Properties of Magnesium AlloysDocument5 pagesHydrostatic Extrusion at 100°C and Its Effect On The Grain Size and Mechanical Properties of Magnesium AlloysSinhrooNo ratings yet

- 1006 1009Document4 pages1006 1009SinhrooNo ratings yet

- Hardness OF: CementiteDocument2 pagesHardness OF: CementiteSinhrooNo ratings yet

- 390 394 PDFDocument5 pages390 394 PDFSinhrooNo ratings yet

- Hardening From The Liquid StateDocument5 pagesHardening From The Liquid StateSinhrooNo ratings yet

- 386 389 PDFDocument4 pages386 389 PDFSinhrooNo ratings yet

- 374 376 PDFDocument3 pages374 376 PDFSinhrooNo ratings yet

- Protective Properties of A Nitrogen Atmosphere With An Admixture of Natural GasDocument4 pagesProtective Properties of A Nitrogen Atmosphere With An Admixture of Natural GasSinhrooNo ratings yet

- Technology of Heat Treatment: Volume-Surface Hardening of by A High-Speed Water Stream Railroad Transport PartsDocument5 pagesTechnology of Heat Treatment: Volume-Surface Hardening of by A High-Speed Water Stream Railroad Transport PartsSinhrooNo ratings yet

- 9 (I,, TillDocument4 pages9 (I,, TillSinhrooNo ratings yet

- E 1 - 6 3 8 8 - L o - / Y) - 7 - Zi : Corporation, StreetDocument1 pageE 1 - 6 3 8 8 - L o - / Y) - 7 - Zi : Corporation, StreetSinhrooNo ratings yet

- Effect of Alloying, Heat Treatment, and Deformation On The Structure and Properties of Damping Z N - A I AlloysDocument4 pagesEffect of Alloying, Heat Treatment, and Deformation On The Structure and Properties of Damping Z N - A I AlloysSinhrooNo ratings yet

- TA201 Lecture 3Document19 pagesTA201 Lecture 3Rhythm's PathakNo ratings yet

- Flexographic Printing Defects - Troubleshooting by SubstrateDocument14 pagesFlexographic Printing Defects - Troubleshooting by SubstrateMohamed BendoudouchNo ratings yet

- MET22A - ETG125C-Unit1 - 2-MT - Qeustion-File C MemoDocument10 pagesMET22A - ETG125C-Unit1 - 2-MT - Qeustion-File C MemoTinyiko ChaukeNo ratings yet

- SVCK - Physical OpticsDocument12 pagesSVCK - Physical OpticsHarsh DeoNo ratings yet

- BS 2561carbon Fibre Reinforced Plastics UnidirecionalDocument16 pagesBS 2561carbon Fibre Reinforced Plastics UnidirecionalDamian GilNo ratings yet

- Question Bank On Electronic ConfigurationDocument4 pagesQuestion Bank On Electronic ConfigurationRaju SinghNo ratings yet

- Yield Stress Sa 240 304Document1 pageYield Stress Sa 240 304faizalNo ratings yet

- Interview QuestionsDocument2 pagesInterview QuestionsAsad ShehzadNo ratings yet

- Clipconn Bolt Weld 13Document42 pagesClipconn Bolt Weld 13Jay GalvanNo ratings yet

- APT Catalogo 2023.6 - WMDocument62 pagesAPT Catalogo 2023.6 - WMJoel GuerreroNo ratings yet

- MD Elements 05Document100 pagesMD Elements 05Prince Jairo50% (2)

- Laboratory Experiment No. 5 Losses in Pipes, Pipe Bends and Pipe FittingsDocument11 pagesLaboratory Experiment No. 5 Losses in Pipes, Pipe Bends and Pipe FittingsKhryz AbadNo ratings yet

- Duval EarthingDocument4 pagesDuval EarthingHambali Strangers100% (1)

- Piglet ManualDocument50 pagesPiglet ManualJonathan Wardrop100% (1)

- Fibre Reinforced Polymers - Strengths, Weaknesse, Opportunities and ThreatsDocument6 pagesFibre Reinforced Polymers - Strengths, Weaknesse, Opportunities and ThreatsalexisdiakNo ratings yet

- Effect of Repeated Weld Repairs....Document12 pagesEffect of Repeated Weld Repairs....Nicolás Toro ValenzuelaNo ratings yet

- W1W2 BTD1123 Chapter 1 Intro To Mat ScienceDocument39 pagesW1W2 BTD1123 Chapter 1 Intro To Mat ScienceHakim ShahmiNo ratings yet

- A Comprehensive Review On The Molecular Dynamics Simulation of The Novel Thermal Properties of GrapheneDocument12 pagesA Comprehensive Review On The Molecular Dynamics Simulation of The Novel Thermal Properties of GrapheneHiran ChathurangaNo ratings yet

- Unclassified: Armed Services Technical Informa1Ion AgencyDocument233 pagesUnclassified: Armed Services Technical Informa1Ion AgencyHari SuthanNo ratings yet

- Nov Dec 2022Document3 pagesNov Dec 2022Asif ChandarkiNo ratings yet

- Zona PanelDocument7 pagesZona PanelrobertNo ratings yet

- Solved Problems of Laser Chapter 4 KeiserDocument35 pagesSolved Problems of Laser Chapter 4 KeiserAamir khanNo ratings yet

- Poor Man's Mass Spectrometer: 158.42.28.33 On: Thu, 18 Dec 2014 10:44:15Document7 pagesPoor Man's Mass Spectrometer: 158.42.28.33 On: Thu, 18 Dec 2014 10:44:15gregorbanalt1No ratings yet

- UB254 To UB457Document7 pagesUB254 To UB457ihpeterNo ratings yet

- Thermodynamics: An Engineering Approach, Third Edition (New Media Version)Document1 pageThermodynamics: An Engineering Approach, Third Edition (New Media Version)Raghib ShakeelNo ratings yet

- STPM Physics Sem 1 ThermodynamicsDocument8 pagesSTPM Physics Sem 1 ThermodynamicsChong Yin Ping0% (1)

- Sma 6512H 2017Document9 pagesSma 6512H 2017jieNo ratings yet

- BTME-18301 BTME-18302 BTME-18303 BTME-18304 BTME-18305 BTME-18306 BTME-18307 BTME-18308 Memc-IDocument31 pagesBTME-18301 BTME-18302 BTME-18303 BTME-18304 BTME-18305 BTME-18306 BTME-18307 BTME-18308 Memc-IRohit NathNo ratings yet

- This Study Resource Was: MEEN 360 Quiz: Chapter 16Document1 pageThis Study Resource Was: MEEN 360 Quiz: Chapter 16daniel valderramaNo ratings yet

- Fire Season: Field Notes from a Wilderness LookoutFrom EverandFire Season: Field Notes from a Wilderness LookoutRating: 4 out of 5 stars4/5 (142)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessFrom EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo ratings yet

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldFrom EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldRating: 4 out of 5 stars4/5 (598)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (812)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsFrom EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsRating: 3.5 out of 5 stars3.5/5 (13)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorFrom EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorRating: 4.5 out of 5 stars4.5/5 (139)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsFrom EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsRating: 4 out of 5 stars4/5 (223)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (35)

- Come Back, Como: Winning the Heart of a Reluctant DogFrom EverandCome Back, Como: Winning the Heart of a Reluctant DogRating: 3.5 out of 5 stars3.5/5 (10)

- Braiding Sweetgrass: Indigenous Wisdom, Scientific Knowledge and the Teachings of PlantsFrom EverandBraiding Sweetgrass: Indigenous Wisdom, Scientific Knowledge and the Teachings of PlantsRating: 4.5 out of 5 stars4.5/5 (1425)

- Remnants of Ancient Life: The New Science of Old FossilsFrom EverandRemnants of Ancient Life: The New Science of Old FossilsRating: 3 out of 5 stars3/5 (3)

- Spoiled Rotten America: Outrages of Everyday LifeFrom EverandSpoiled Rotten America: Outrages of Everyday LifeRating: 3 out of 5 stars3/5 (19)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildFrom EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildRating: 4.5 out of 5 stars4.5/5 (44)

- The Soul of an Octopus: A Surprising Exploration into the Wonder of ConsciousnessFrom EverandThe Soul of an Octopus: A Surprising Exploration into the Wonder of ConsciousnessRating: 4.5 out of 5 stars4.5/5 (254)

- The Other End of the Leash: Why We Do What We Do Around DogsFrom EverandThe Other End of the Leash: Why We Do What We Do Around DogsRating: 5 out of 5 stars5/5 (65)

- Fen, Bog and Swamp: A Short History of Peatland Destruction and Its Role in the Climate CrisisFrom EverandFen, Bog and Swamp: A Short History of Peatland Destruction and Its Role in the Climate CrisisRating: 4 out of 5 stars4/5 (24)

- The Mind of Plants: Narratives of Vegetal IntelligenceFrom EverandThe Mind of Plants: Narratives of Vegetal IntelligenceRating: 4.5 out of 5 stars4.5/5 (12)

- Darwin's Doubt: The Explosive Origin of Animal Life and the Case for Intelligent DesignFrom EverandDarwin's Doubt: The Explosive Origin of Animal Life and the Case for Intelligent DesignRating: 4 out of 5 stars4/5 (19)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeFrom EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeRating: 4.5 out of 5 stars4.5/5 (700)