Professional Documents

Culture Documents

Api 5l Test Pressrure

Uploaded by

Sıddık SarıcalarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Api 5l Test Pressrure

Uploaded by

Sıddık SarıcalarCopyright:

Available Formats

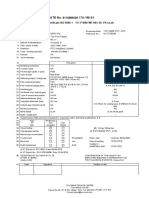

ISO 3183:2007(E)

API Specification 5L/ISO 3183

Table 25 Test pressures for heavy-wall threaded pipe

Specified outside

diameter

D

Specified wall

thickness

t

mm (in)

mm (in)

Test pressure

MPa (psi)

minimum

Grade

L175 or A25

L175P or A25P

L210 or A

L245 or B

10,3 (0.405)

2,4 (0.095)

5,9 (850)

5,9 (850)

5,9 (850)

5,9 (850)

13,7 (0.540)

3,0 (0.119)

5,9 (850)

5,9 (850)

5,9 (850)

5,9 (850)

17,1 (0.675)

3,2 (0.126)

5,9 (850)

5,9 (850)

5,9 (850)

5,9 (850)

21,3 (0.840)

3,7 (0.147)

5,9 (850)

5,9 (850)

5,9 (850)

5,9 (850)

26,7 (1.050)

3,9 (0.154)

5,9 (850)

5,9 (850)

5,9 (850)

5,9 (850)

33,4 (1.315)

4,5 (0.179)

5,9 (850)

5,9 (850)

5,9 (850)

5,9 (850)

42,2 (1.660)

4,9 (0.191)

9,0 (1 300)

9,0 (1 300)

10,3 (1 500)

11,0 (1 600)

48,3 (1.900)

5,1(0.200)

9,0 (1 300)

9,0 (1 300)

10,3 (1 500)

11,0 (1 600)

60,3 (2.375)

5,5 (0.218)

9,0 (1 300)

9,0 (1 300)

17,0 (2 470)

17,0 (2 470)

73,0 (2.875)

7,0 (0.276)

9,0 (1 300)

9,0 (1 300)

17,0 (2 470)

17,0 (2 470)

88,9 (3.500)

7,6 (0.300)

9,0 (1 300)

9,0 (1 300)

17,0 (2 470)

17,0 (2 470)

101,6 (4.000)

8,1 (0.318)

11,7 (1 700)

11,7 (1 700)

19,0 (2 760)

19,0 (2 760)

114,3 (4.500)

8,6 (0.337)

11,7 (1 700)

11,7 (1 700)

18,7 (2 700)

19,0 (2 760)

141,3 (5.563)

9,5 (0.375)

11,7 (1 700)

11,7 (1 700)

16,7 (2 430)

19,0 (2 760)

168,3 (6.625)

11,0 (0.432)

16,2 (2 350)

18,9 (2 740)

219,1 (8.625)

12,7 (0.500)

14,4 (2 090)

16,8 (2 430)

273,1 (10.750)

12,7 (0.500)

11,6 (1 670)

13,4 (1 950)

12,7 (0.500)

9,7 (1 410)

11,3 (1 650)

323,9 (12.375)

a

Not applicable.

10.2.6.5

Except as allowed by 10.2.6.6, 10.2.6.7 and the footnotes to Table 26, the hydrostatic test

pressure, P, expressed in megapascals (pounds per square inch), for plain-end pipe shall be determined

using Equation (6), with the results rounded to the nearest 0,1 MPa (10 psi):

P=

2 St

D

(6)

where

S

is the hoop stress, expressed in megapascals (pounds per square inch), equal to a percentage of the

specified minimum yield strength of the pipe, as given in Table 26;

is the specified wall thickness, expressed in millimetres (inches);

is the specified outside diameter, expressed in millimetres (inches).

--`,,,```,,,,,````````,,```,``-`-`,,`,,`,

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

64

64

Licensee=FMC Technologies /5914950002

Not for Resale, 04/07/2009 18:01:58 MDT

ISO 2007 All rights reserved

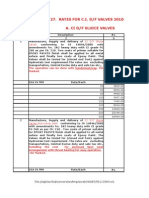

ISO 3183:2007(E)

API Specification 5L/ISO 3183

Table 26 Percentage of specified minimum yield strength for determination of S

Percentage of specified minimum yield strength

for determination of S

Specified outside diameter

Pipe grade

D

mm (in)

Standard test pressure

Alternative test pressure

L175 or A25

u 141,3 (5.563)

60 a

75 a

L175P or A25P

u 141,3 (5.563)

60 a

75 a

L210 or A

any

60 a

75 a

L245 or B

any

60 a

75 a

u 141,3 (5.563)

60 b

75 c

> 141,3 (5.563) to u 219,1 (8.625)

75 b

75 c

> 219,1 (8.625) to < 508 (20.000)

85 b

85 c

W 508 (20.000)

90 b

90 c

L290 or X42 to

L830 or X120

a

For D u 88,9 mm (3.500 in), it is not necessary that the test pressure exceed 17,0 MPa (2 470 psi); for D > 88,9 mm (3.500 in), it is

not necessary that the test pressure exceed 19,0 MPa (2 760 psi).

b

It is not necessary that the test pressure exceed 20,5 MPa (2 970 psi).

For D u 406,4 mm (16.000 in), it is not necessary that the test pressure exceed 50,0 MPa (7 260 psi); for D > 406,4 mm

(16.000 in), it is not necessary that the test pressure exceed 25,0 MPa (3 630 psi).

10.2.6.6

If pressure testing involves an end-sealing ram that produces a compressive longitudinal stress,

the hydrostatic test pressure, P, expressed in megapascals (pounds per square inch), may be determined

using Equation (7), with the result rounded to the nearest 0,1 MPa (10 psi), provided that the required test

pressure produces a hoop stress in excess of 90 % of the specified minimum yield strength:

P A

R

S R

Ap

P=

D AI

2t Ap

(7)

where

S

is the hoop stress, expressed in megapascals (pounds per square inch), equal to a percentage of the

specified minimum yield strength of the pipe (see Table 26);

PR is the internal pressure on end-sealing ram, expressed in megapascals (pounds per square inch);

AR is the cross-sectional area of end-sealing ram, expressed in square millimetres (square inches);

Ap is the cross-sectional area of pipe wall, expressed in square millimetres (square inches);

AI

is the internal cross-sectional area of pipe, expressed in square millimetres (square inches);

is the specified outside diameter, expressed in millimetres (inches);

is the specified wall thickness, expressed in millimetres (inches).

10.2.6.7

If agreed, the minimum permissible wall thickness, tmin, may be used in place of the specified wall

thickness, t, for the determination of the required test pressure (see 10.2.6.5 or 10.2.6.6, whichever is

applicable), provided that a hoop stress of at least 95 % of the specified minimum yield strength of the pipe is

used.

--`,,,```,,,,,````````,,```,``-`-`,,`,,`,`,,`---

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

ISO 2007 All rights reserved

65

Licensee=FMC Technologies /5914950002

Not for Resale, 04/07/2009 18:01:58 MDT

65

You might also like

- Astm A106 Ts EnglDocument4 pagesAstm A106 Ts EnglxaviereduardoNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless PipeashokkahirwarNo ratings yet

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocument3 pagesTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanNo ratings yet

- Tigweldarc Alloys: Certification of TestsDocument1 pageTigweldarc Alloys: Certification of TestsArunNo ratings yet

- C43Document1 pageC43rudramansingh123No ratings yet

- SB 241Document24 pagesSB 241JolettitoNo ratings yet

- Welder Certificate ISO 9606-1 QualificationDocument1 pageWelder Certificate ISO 9606-1 QualificationDeepak Das100% (1)

- Data Sheet Material 2.4819Document3 pagesData Sheet Material 2.4819BoberNo ratings yet

- A106 Pipe Spec SheetDocument7 pagesA106 Pipe Spec SheetyanurarzaqaNo ratings yet

- Impact AR500 PlateDocument2 pagesImpact AR500 PlateMario Diez100% (1)

- En ASME ComparisonDocument18 pagesEn ASME ComparisonPeterWay100% (1)

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- Ferrite Testing ProcedureDocument6 pagesFerrite Testing ProcedureReadersmo0% (1)

- ST 35.8 (Germany / DIN) : Material PropertiesDocument3 pagesST 35.8 (Germany / DIN) : Material Propertiesmohammad zareiNo ratings yet

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- Material Data Sheet en Aw 6082 Almgsi1Document1 pageMaterial Data Sheet en Aw 6082 Almgsi1pankajrs.mechengineer4502No ratings yet

- Comparison of Flange Face Finish As Per B16-5Document1 pageComparison of Flange Face Finish As Per B16-5Vivi OktaviantiNo ratings yet

- Material Information Sheet For Plates: Erndtebrücker EisenwerkDocument2 pagesMaterial Information Sheet For Plates: Erndtebrücker EisenwerkAhmad KamilNo ratings yet

- WPS for FCAW Welding of SteelDocument2 pagesWPS for FCAW Welding of SteelHamid MansouriNo ratings yet

- Method Statement For In-Situ Metallography Test: DCSM Project 2019Document5 pagesMethod Statement For In-Situ Metallography Test: DCSM Project 2019Thinh NguyenNo ratings yet

- 1 7335Document5 pages1 7335stamatsNo ratings yet

- ISO 15510 - Part 1Document5 pagesISO 15510 - Part 1Zdenko MahacekNo ratings yet

- MTC Er70s 2Document1 pageMTC Er70s 2Mirza BaigNo ratings yet

- WPQR TIG Fillet Welding ProcedureDocument3 pagesWPQR TIG Fillet Welding ProcedureDimitris NikouNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Material Datea 2.4602Document3 pagesMaterial Datea 2.4602Charwin XiaoNo ratings yet

- Drop Weight Tear Testing of High Toughness Pipeline MaterialDocument8 pagesDrop Weight Tear Testing of High Toughness Pipeline MaterialKK SinghNo ratings yet

- NDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023Document16 pagesNDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023SANJEEV YADAVNo ratings yet

- Hardness Test Report: Test Details Machine DetailsDocument1 pageHardness Test Report: Test Details Machine DetailsESHWAR CHARYNo ratings yet

- Aisi 4130Document2 pagesAisi 4130Marcos CarreroNo ratings yet

- Indt QCP RT HJ 05NDocument14 pagesIndt QCP RT HJ 05NAsad Bin Ala QatariNo ratings yet

- A106 Seamless Carbon Steel Pipe: Hydrostatic TestingDocument7 pagesA106 Seamless Carbon Steel Pipe: Hydrostatic TestingTan Chee MingNo ratings yet

- Inspection and Test Plan Sheet: Pt. Pertamina Geothermal Energy Pt. Bina Rasano EngineeringDocument2 pagesInspection and Test Plan Sheet: Pt. Pertamina Geothermal Energy Pt. Bina Rasano EngineeringHerruSetiawan100% (1)

- Iso14341 ADocument2 pagesIso14341 AAluculesei Ciprian100% (1)

- A572 50 TY1 KrakatauposcoplateASTMproductDocument1 pageA572 50 TY1 KrakatauposcoplateASTMproductSteel BridgeNo ratings yet

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentDocument2 pagesSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- Nikopol Steel Pipe Plant Yutist Seamless Steel TubesDocument2 pagesNikopol Steel Pipe Plant Yutist Seamless Steel Tubesvishal.nitham100% (1)

- Astm A335 p91 PipeDocument1 pageAstm A335 p91 PipeBhagwati SteelageNo ratings yet

- Astm A 450Document10 pagesAstm A 450Telmo VianaNo ratings yet

- RT Standards NotesDocument4 pagesRT Standards NotesprabhuNo ratings yet

- Astm A800Document6 pagesAstm A800utreshwarmiskinNo ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- Australian Standard®Document10 pagesAustralian Standard®Syed Mahmud Habibur Rahman0% (1)

- Astm A688Document8 pagesAstm A688Aadarsh Kumar ShitalNo ratings yet

- International Comparision of Standards PDFDocument1 pageInternational Comparision of Standards PDFwitanto90No ratings yet

- S235jr Carbon SteelDocument2 pagesS235jr Carbon Steelcheligp1981No ratings yet

- 02 Samss 011Document36 pages02 Samss 011OMER ELFADILNo ratings yet

- Astm A423 A423m-95Document3 pagesAstm A423 A423m-95FeteneNo ratings yet

- WELDING PROCEDURE SPECIFICATION SHEET 2 OF 2Document2 pagesWELDING PROCEDURE SPECIFICATION SHEET 2 OF 2surya1960No ratings yet

- Welding Rod For c5 & f5 - Er 80s-b6Document1 pageWelding Rod For c5 & f5 - Er 80s-b6SatyamEngNo ratings yet

- Thickness Tolerance of API 5L ASTM A53 EN10219 StandardDocument2 pagesThickness Tolerance of API 5L ASTM A53 EN10219 StandardhungNo ratings yet

- Nema Li 1Document4 pagesNema Li 1usamafalakNo ratings yet

- Reduce Hydrogen Cracking with Proper PreheatDocument3 pagesReduce Hydrogen Cracking with Proper PreheatVJG369No ratings yet

- Astm A240-16Document14 pagesAstm A240-16VIPAN RAINo ratings yet

- WPQR SBM 029Document3 pagesWPQR SBM 029HoJienHauNo ratings yet

- Control Ferrite Content Stainless Steel WeldsDocument5 pagesControl Ferrite Content Stainless Steel Weldstedmer1No ratings yet

- Astm A31 (1995)Document4 pagesAstm A31 (1995)gsb2100% (1)

- Specification For Line Pipe (Tensile Properties)Document2 pagesSpecification For Line Pipe (Tensile Properties)jan_matej5651No ratings yet

- BS en 1555-2 (2010)Document30 pagesBS en 1555-2 (2010)Sıddık SarıcalarNo ratings yet

- 1-24 Corrugated MetalDocument1 page1-24 Corrugated MetalSıddık SarıcalarNo ratings yet

- BS en 1555-3 (2008)Document29 pagesBS en 1555-3 (2008)Sıddık SarıcalarNo ratings yet

- Manual Material Thickness Meter Pce TG 50Document6 pagesManual Material Thickness Meter Pce TG 50Sıddık SarıcalarNo ratings yet

- Y4 CFDDocument22 pagesY4 CFDSıddık SarıcalarNo ratings yet

- Ansys Fluids 1 v8p1Document23 pagesAnsys Fluids 1 v8p1api-3833671No ratings yet

- 8 Presentation - FairclothDocument41 pages8 Presentation - FairclothSıddık SarıcalarNo ratings yet

- Y4 CFDDocument22 pagesY4 CFDSıddık SarıcalarNo ratings yet

- Non-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2Document242 pagesNon-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2darqm589% (18)

- AWS D1-1 PQR-WPS Yes Pre QualifiedDocument2 pagesAWS D1-1 PQR-WPS Yes Pre QualifiedJRodengineerNo ratings yet

- Non-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2Document242 pagesNon-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2darqm589% (18)

- Facta Universitatis (Ni S) Ser. Math. Inform. Vol. 22, No. 2 (2007), Pp. 165-174Document10 pagesFacta Universitatis (Ni S) Ser. Math. Inform. Vol. 22, No. 2 (2007), Pp. 165-174Sıddık SarıcalarNo ratings yet

- 1 s2.0 S0009250905005853 MainDocument18 pages1 s2.0 S0009250905005853 MainSıddık SarıcalarNo ratings yet

- BS5930-2015 187Document1 pageBS5930-2015 187Ford cellNo ratings yet

- Cube TestDocument15 pagesCube TestFAHIEMAH ZAHRA YAAKUBNo ratings yet

- James Ins Detayli KatalokDocument96 pagesJames Ins Detayli KatalokJoshua RoblesNo ratings yet

- ASTM E 139-06 Standard Test Methods For Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials1Document14 pagesASTM E 139-06 Standard Test Methods For Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials1Angel RamirezNo ratings yet

- Reverse Circulating With Coiled TubingDocument21 pagesReverse Circulating With Coiled Tubingwoodiehed9039100% (1)

- Im Mckxa McquayDocument64 pagesIm Mckxa Mcquaydom007thyNo ratings yet

- Ideal Regenerative Rankine Cycle ExplainedDocument22 pagesIdeal Regenerative Rankine Cycle ExplainedJohn Michael Go AbalosNo ratings yet

- Properties of Concrete by A M NevilleDocument2,866 pagesProperties of Concrete by A M NevilleAnthony Angeles83% (6)

- Surface & Coatings Technology: SciencedirectDocument9 pagesSurface & Coatings Technology: SciencedirectVitor JardimNo ratings yet

- Method of PlasteringDocument3 pagesMethod of PlasteringTAHER AMMAR100% (2)

- Singly Reinforced BeamsDocument15 pagesSingly Reinforced BeamsRhea Michelle Caballero100% (3)

- Technical Manual - 2000 USG Horizontal Lined Acid TankDocument20 pagesTechnical Manual - 2000 USG Horizontal Lined Acid TankGade JyNo ratings yet

- MBH Catalogue 2019Document56 pagesMBH Catalogue 2019Anonymous 1oWzM3No ratings yet

- 26 418Document6 pages26 418ari_prasNo ratings yet

- Wall Mounted PDFDocument5 pagesWall Mounted PDFAhmed AzadNo ratings yet

- 16 Duct Suspension AdsDocument46 pages16 Duct Suspension AdsdheerajdorlikarNo ratings yet

- Pengekstrakan besi dalam industriDocument5 pagesPengekstrakan besi dalam industriNajwa Ghazali100% (1)

- Bolts Torque CalculatorDocument4 pagesBolts Torque Calculatorcaod1712No ratings yet

- Valve RatesDocument34 pagesValve RatesDeepthy VasavanNo ratings yet

- Bt5 Lecture 1Document32 pagesBt5 Lecture 1Marrielle BalagotNo ratings yet

- Concrete Construction Article PDF - Evaluating Cracks in Concrete Walls PDFDocument4 pagesConcrete Construction Article PDF - Evaluating Cracks in Concrete Walls PDFhillamngNo ratings yet

- Nominal Pipe Size NPS, Nominal Bore NB, Outside Diameter ODDocument6 pagesNominal Pipe Size NPS, Nominal Bore NB, Outside Diameter ODjigneshdalwadiNo ratings yet

- BDK ValveDocument12 pagesBDK ValvevinaypNo ratings yet

- Ding 2014Document4 pagesDing 2014pranav razdanNo ratings yet

- Assignment 01 v3Document3 pagesAssignment 01 v3Ricardo AlanisNo ratings yet

- Guide to Miniature Tube Fittings & ConnectorsDocument34 pagesGuide to Miniature Tube Fittings & ConnectorsBrant AkkanNo ratings yet

- 2 - Compressibility of SoilsDocument34 pages2 - Compressibility of SoilsKatherine Shayne YeeNo ratings yet

- Detention Tank 1 Construction Rev 1Document23 pagesDetention Tank 1 Construction Rev 1johnNo ratings yet

- Fracture Mechanics - MUHAMMADABDULLAH ATIFDocument10 pagesFracture Mechanics - MUHAMMADABDULLAH ATIFSyed Hassan.911No ratings yet

- 2430 & TB2448 ComarisionDocument6 pages2430 & TB2448 ComarisionpiyushNo ratings yet