Professional Documents

Culture Documents

Water Pipelines Crossing

Uploaded by

lsatchithananthanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Pipelines Crossing

Uploaded by

lsatchithananthanCopyright:

Available Formats

Regional Engineering

Engineering Services

4 Welding Way

off Administration Road

P.O. Box 1000

Concord, Ontario, L4K 1B9

Water Pipeline

Crossing Application

Applicants shall submit three (3) copies of an acceptable plan. Plans shall conform to Transport Canada (TC) Standards

Respecting Pipeline Crossings Under Railways, and Part 5 of the AREMA Manual for overhead pipeline crossings.

The application fee, in the amount of $950.00 (+HST), to cover the cost of reviewing the application and plans, will be invoiced.

The Applicant will be charged an additional fee of $159.00 (HST included) for each review after the initial application due to

inadequate or missing information. For more complex installations, separate purchase order authority will be requested in lieu

of standard review fees.

The Applicant shall indicate the duration of construction on / above / below the CN right-of-way, provide an

estimated construction schedule and provide a field contact name and phone number.

The following information is required on the application drawing:

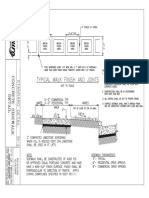

Drawings must be to scale or have all dimensions shown.

A site plan showing the location of crossing in relation to a legal description or road allowance or Railway mileage and

subdivision.

Dimension width of CN right-of-way, the number of tracks and the angle of crossing.

Indicate direction of flow and location of nearest shut off valves.

Provide a profile showing the depth of burial from the base of rail (minimum 5.5 ft. or below frost line) and ditch

bottom to top of pipe (minimum 3.0 ft. or below frost line).

Note type, wall thickness and pressures (operating and maximum test) of carrier and casing pipes. Ensure wall

thickness of carrier and casing pipes conform to TC requirements (CN requires carrier & casing to be designed for

cooper E-90 loading).

Pipelines carrying steam, water, sewer and other non-flammable or non-hazardous substances under the railway shall

be encased in a casing pipe. Casing pipe may be omitted under the following circumstances:

o

o

Under secondary or industrial tracks approved by the Engineer, provided maximum operating pressure in the

carrier pipe does not exceed 700 kPa;

For non-pressure sewer crossings where the strength of the pipe and its joints are capable of withstanding railway

loading, as approved by the Engineer.

Show the cross-section of the pipe, or note that the carrier pipe will be held clear of the casing pipe by supports.

NOTE: Every carrier pipe with a diameter of 3 inches or greater shall be held clear of the casing pipe by properly

designed supports, insulators or centering devices, installed so that no external loads will be transmitted to the carrier

pipe. Grouting of the space between the carrier and casing will not be permitted. The casing pipe shall be so

constructed as to prevent leakage of any substance from the casing throughout its length except at the ends where free

flow must be maintained. The casing shall be installed so as to prevent the formation of a waterway under the

Railway, with an even bearing throughout its length, and shall slope to one end (except for longitudinal occupancy).

The ends of the casing pipe shall not be sealed by any load transferring material.

Note intention to install warning markers at each edge of the CN right-of-way.

Indicate type of cathodic protection (if used). Where the casing and/or carrier pipe is cathodically protected, suitable

tests shall be undertaken to ensure that other railway structures and facilities are adequately protected from the

cathodic current.

When casing is used, it must extend the full width of CNs right-of-way or a minimum of fifty (50) feet on each side of

the outermost track.

Note method of installation (i.e. boring / augering).

Indicate location of proposed jacking and receiving pits in relation to the gauge side (inside) of nearest rail.

Revised Sept 2007

Page 1 of 2

Include a caption stating Construction and maintenance to be in accordance with Transport Canada Standards

Respecting Pipeline Crossings Under Railways.

Professional Engineers stamp, date and signature required.

Contact name, address and phone number of Utility Owner on plan or cover letter.

Revised drawings shall be marked as revised and state reason for revision.

NOTE: The nearest point at which excavation can be undertaken, is as follows:

Starting ten (10) feet from the gauge side (inside) of the nearest rail, measured perpendicular to the rail, calculate a slope to

the bottom of the proposed pipe at a 1.5:1 slope. If a 1.5:1 slope cannot be maintained or more restrictive conditions

occur, approved shoring will be required.

Additional requirements for underground crossing application drawings:

Supply cables must be protected for the full width of CNs right-of-way.

Indicate type and details of cable and mechanical protection.

If cables are to be encased, the casing shall extend the full width of CNs right-of-way.

Include a profile showing depth of burial from base of rail and ditch bottoms to cable.

Minimum depth of burial below base of rail is 1.68 m Main Tracks.

Minimum depth of burial below base of rail is 1.37 m Industrial Tracks.

Minimum depth of burial below road surface is 1.0 m.

Minimum depth of burial below ditch bottom is 1.52 m.

Note intention to install warning markers at each edge of CN right-of-way.

Note method of installation (i.e. boring / augering).

Indicate location of nearest excavation from nearest rail.

Additional requirements for 250 mm diameter (10 inches) or greater:

Submit a complete copy of the Geotechnical Report, including comments and recommendations with respect to

construction methodology.

Submit a detailed proposal for in-ground settlement monitoring, developed by a Geotechnical Engineer with experience

in large diameter pipe installation.

Provide, in writing, the name and phone number of the qualified site inspector(s) who will be on the job site on a full

time basis for the duration of construction, as specified by NTA General Orders.

Revised Sept 2007

Page 2 of 2

You might also like

- Casting Adjustment (S-28) - 1Document1 pageCasting Adjustment (S-28) - 1lsatchithananthanNo ratings yet

- Concrete Sidewalk Detail (S-3) - 1Document1 pageConcrete Sidewalk Detail (S-3) - 1lsatchithananthanNo ratings yet

- Fire Safety in ConstructionDocument3 pagesFire Safety in ConstructionlsatchithananthanNo ratings yet

- kwik-ZIP HD Installation GuideDocument2 pageskwik-ZIP HD Installation GuidelsatchithananthanNo ratings yet

- Pengurusan Air Selangor Sdn. Bhd. KA 1/2 (Rev - 2019) : Part ADocument10 pagesPengurusan Air Selangor Sdn. Bhd. KA 1/2 (Rev - 2019) : Part AlsatchithananthanNo ratings yet

- Lifting OperationsDocument1 pageLifting OperationslsatchithananthanNo ratings yet

- Construction Management StatementDocument1 pageConstruction Management StatementlsatchithananthanNo ratings yet

- Kwikzip Info Sheets 380Document2 pagesKwikzip Info Sheets 380lsatchithananthanNo ratings yet

- Construction HazardsDocument2 pagesConstruction HazardslsatchithananthanNo ratings yet

- Method Statement For ConstructionDocument2 pagesMethod Statement For ConstructionlsatchithananthanNo ratings yet

- Rebar Drill & Fix MethodDocument3 pagesRebar Drill & Fix Methodlsatchithananthan100% (1)

- Centralizer & Spacer Systems: For The Drilling & Civil Construction IndustriesDocument3 pagesCentralizer & Spacer Systems: For The Drilling & Civil Construction IndustrieslsatchithananthanNo ratings yet

- Calculation of Pile Base SettlementDocument3 pagesCalculation of Pile Base SettlementlsatchithananthanNo ratings yet

- Plem Design and Analysis - OilfieldWikiDocument4 pagesPlem Design and Analysis - OilfieldWikilsatchithananthanNo ratings yet

- Water Reticulation Handover FormDocument4 pagesWater Reticulation Handover FormlsatchithananthanNo ratings yet

- Design For Bending For Rectangular Sections (Beams - BS 8110)Document2 pagesDesign For Bending For Rectangular Sections (Beams - BS 8110)lsatchithananthanNo ratings yet

- PLEM Design Methodology - OilfieldWikiDocument4 pagesPLEM Design Methodology - OilfieldWikilsatchithananthanNo ratings yet

- Q235 Steel Q235A Q235B Q235C Q235D Equivalent, Properties, Specification, Composition - The World MaterialDocument6 pagesQ235 Steel Q235A Q235B Q235C Q235D Equivalent, Properties, Specification, Composition - The World MateriallsatchithananthanNo ratings yet

- Prestress Presentation SAB4323 OCW Topic 1Document50 pagesPrestress Presentation SAB4323 OCW Topic 1dasdhjhkjNo ratings yet

- Graphs To Calculate Settlement - Calculation of Pile Base Settlement - GEO5 - Online HelpDocument4 pagesGraphs To Calculate Settlement - Calculation of Pile Base Settlement - GEO5 - Online HelplsatchithananthanNo ratings yet

- Calculation of Pile Base SettlementDocument3 pagesCalculation of Pile Base SettlementlsatchithananthanNo ratings yet

- Steel GradesDocument8 pagesSteel GradesSanket Arun MoreNo ratings yet

- 2020 ESAH Complete v3.1Document130 pages2020 ESAH Complete v3.1lsatchithananthanNo ratings yet

- TNB Door - Vicmeta SDN BHDDocument5 pagesTNB Door - Vicmeta SDN BHDlsatchithananthanNo ratings yet

- Plastering RequirementDocument4 pagesPlastering RequirementlsatchithananthanNo ratings yet

- Static Analysis Laterally Loaded Pile Design PPTX CaliendoDocument55 pagesStatic Analysis Laterally Loaded Pile Design PPTX CaliendoAshishNo ratings yet

- Typical Reinforcement Details of A Cantilever SlabDocument1 pageTypical Reinforcement Details of A Cantilever SlablsatchithananthanNo ratings yet

- Tolerances of Errors in Pile Foundation ConstructionDocument3 pagesTolerances of Errors in Pile Foundation ConstructionlsatchithananthanNo ratings yet

- AS 2159 & 3600 Concrete Pile Design - SkyCiv Cloud Structural Analysis SoftwareDocument10 pagesAS 2159 & 3600 Concrete Pile Design - SkyCiv Cloud Structural Analysis SoftwarelsatchithananthanNo ratings yet

- Tolerances of Errors in Pile Foundation ConstructionDocument3 pagesTolerances of Errors in Pile Foundation ConstructionlsatchithananthanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Dynamic Analysis of Steering BogiesDocument57 pagesDynamic Analysis of Steering BogiesAlfath RizkiNo ratings yet

- PRICE LIST MARCH 2018 MEDIUM DUTY TESTER KITSDocument11 pagesPRICE LIST MARCH 2018 MEDIUM DUTY TESTER KITScarlosNo ratings yet

- Enhanced Sleeper Coach Technology - Space UtilisationDocument10 pagesEnhanced Sleeper Coach Technology - Space UtilisationAkhil ShastryNo ratings yet

- RTB 1 03 Axlebox DesignsDocument32 pagesRTB 1 03 Axlebox Designsmatrix2525009No ratings yet

- Volume 5 PDFDocument288 pagesVolume 5 PDFArindam NandyNo ratings yet

- Register DIN Standards For MiningDocument45 pagesRegister DIN Standards For Miningluis martinezNo ratings yet

- Guidance Note: The Design and Construction of Freight WagonsDocument41 pagesGuidance Note: The Design and Construction of Freight WagonsamiedNo ratings yet

- Indian Railways 1234Document15 pagesIndian Railways 1234abhi0006100% (1)

- Life of Isambard Kingdom BrunelDocument312 pagesLife of Isambard Kingdom BruneltheshadowknightNo ratings yet

- T E QuestionsDocument4 pagesT E QuestionsAISWARYANo ratings yet

- HSR Investment, An Overview of The LiteratureDocument8 pagesHSR Investment, An Overview of The LiteratureHighSpeedRailNo ratings yet

- ApnaTech Profile MeasurementDocument2 pagesApnaTech Profile MeasurementDochoaa Ochoa AriasNo ratings yet

- Colonial India RailwayDocument39 pagesColonial India RailwaySara WadeNo ratings yet

- Glossary of Rail Transport Terms - Wikipedia, The Free EncyclopediaDocument45 pagesGlossary of Rail Transport Terms - Wikipedia, The Free EncyclopediasaospieNo ratings yet

- 6 Transport Infrastucture: Chapter 6 / Transport Infrastructure PAGE 6-1Document36 pages6 Transport Infrastucture: Chapter 6 / Transport Infrastructure PAGE 6-1Jeannot MpianaNo ratings yet

- Transportation and CommunicationDocument34 pagesTransportation and CommunicationMadifa Queen100% (1)

- MSRP A1Document110 pagesMSRP A1JayeshNo ratings yet

- Testing Railway Vehicles for Dynamic BehaviorDocument78 pagesTesting Railway Vehicles for Dynamic BehaviorDustin RodriguezNo ratings yet

- Rail track isolation and safety distancesDocument3 pagesRail track isolation and safety distancesAkhlesh ChoureNo ratings yet

- BS en 14363-2016Document200 pagesBS en 14363-2016Hadi Howaida100% (3)

- Multi-function track recording cars optimize railway maintenanceDocument5 pagesMulti-function track recording cars optimize railway maintenanceandrewgeorgecherianNo ratings yet

- An Overview of The Development of The Sri Lanka Railway 1. The NetworkDocument4 pagesAn Overview of The Development of The Sri Lanka Railway 1. The NetworkUvin RanaweeraNo ratings yet

- prEN 16432-1 (2015) (E) PDFDocument6 pagesprEN 16432-1 (2015) (E) PDFAntnio50% (2)

- DIN Standard For Mining PDFDocument45 pagesDIN Standard For Mining PDFriysallNo ratings yet

- RRB Exam Previous Year ModelDocument3 pagesRRB Exam Previous Year ModelShijumon XavierNo ratings yet

- Coach Rehab Workshop BhopalDocument8 pagesCoach Rehab Workshop Bhopalochrerocker100% (1)

- Emaintenance Proceedings 2012 PDFDocument260 pagesEmaintenance Proceedings 2012 PDFRABIU M RABIUNo ratings yet

- CanRail - User Guide v1.1Document51 pagesCanRail - User Guide v1.1Alex GeorgeNo ratings yet

- A Good Practice Guide For Managing The Wheel-Rail Interface of Light Rail and Tramway SystemsDocument21 pagesA Good Practice Guide For Managing The Wheel-Rail Interface of Light Rail and Tramway SystemsIbraheem Adel SheerahNo ratings yet

- Design Criteria For RailwayDocument1 pageDesign Criteria For RailwayKrischanSayloGelasanNo ratings yet