Professional Documents

Culture Documents

4915-w4 Handling, Storage and Shipping of Pipe (Contract Specification)

Uploaded by

LorenaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4915-w4 Handling, Storage and Shipping of Pipe (Contract Specification)

Uploaded by

LorenaCopyright:

Available Formats

Engineering Standards

Standard

4915

Page

1 of 4

HANDLING, STORAGE

AND SHIPPING OF PIPE

Issue Date

Rev. No.

Date

1.

07/87

4

02/96

SCOPE

This standard covers general requirements for handling, storage and shipping of steel pipe either bare or with

corrosion protective coating.

2.

CODES AND STANDARDS

API RP 5L1 Recommended Practice for Railroad Transportation of Line Pipe

API RP 5LW Recommended Practice for Transportation of Line Pipe on Barges and Marine Vessels.

3.

4.

GENERAL

3.1

"Contractor" as used herein shall mean the manufacturer of the pipe at the pipe mill or the Company's

contractor responsible for the handling, storage, loading for shipment or coating of the pipe.

3.2

For shipment by means not covered by API RP standards, the manufacturer shall load pipe for shipment in

such a way as to eliminate the possibility of critical stresses and fatigue cracks occurring due to cold

working of pipe in transit.

3.3

Pipe shall be handled at all times in a manner that will not cause dents, nicks, gouges, permanent bends,

ovality, disbondment of coating or other damage to the pipe, end bevels or pipe coating.

3.4

Contractor shall bear the cost of replacement or repair, at Company's option, of any of the pipe, end bevels

or pipe coating which is damaged due to Contractor's operations or negligence.

3.5

Company shall have the right to inspect all activities related to the handling, storage or shipping of pipe

as covered by this standard.

3.6

Pipe shall be protected during loading, transit and storage in order to prevent contamination by oil,

grease, salt water or other chemicals which could adversely affect coating adhesion. A positive reaction

with potassium ferricyanide indicating paper will be considered proof of chemical contamination and will

mandate phosphoric acid treatment of all pipe. Such treatment shall consist of preheating the pipe to at

least 120F, followed by phosphoric acid solution wash and a high pressure rinse with clean water. Where

other contamination is found, the pipe shall be inspected and segregated at the destination and all affected

pipe shall be cleaned by detergent wash.

HANDLING

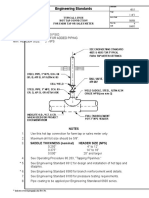

4.1

Only equipment acceptable to the Company's inspector shall be used in handling the pipe. Use of wire

slings is prohibited unless special handling techniques are used to avoid cable marks on the pipe.

4.2

The bearing surface of end hooks shall have a shape and width sufficient to prevent permanent

deformation of the pipe. The surfaces of end hooks that come in contact with the pipe shall be covered

with a protective cover such as aluminum, teflon or ultrahigh molecular weight polyethelene and shall be

changed as required to prevent wearing to base metal. Copper alloy lining shall not be permitted.

4.3

A cable spreader bar between the crane boom and end hooks will be used if necessary to prevent pipe

deformation or exceeding stress limits specified by the Company.

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4915

Page

2 of 4

HANDLING, STORAGE

AND SHIPPING OF PIPE

Issue Date

Rev. No.

Date

5.

6.

07/87

4

02/96

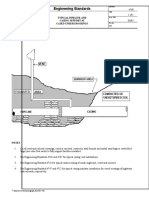

STORAGE

5.1

Pipe of each different specification (i.e., size, wall, grade, manufacturer, coating) shall be stored separately

in such a manner as to be clearly identifiable at all times.

5.2

Pipe to be stored shall be stacked either on wooden timbers or earth berms.

5.2.1

Timbers shall be a minimum of 8" wide. Three equally spaced timbers will be required for

support of a 40-foot pipe length. An additional support timber will be required for each

additional 10 feet of pipe length.

5.2.2

When earth berms are used, a polyethylene cover of not less than 20 mils thickness shall be

placed between the earth and pipe.

5.3

The timbers or berms shall have sufficient height to prevent ground surface water or mud from

contaminating the pipe and shall be constructed in a manner to allow drainage of water from each piece of

stacked pipe.

5.4

The area in which the pipe is stored shall have sufficient drainage to prevent water standing under the

pipe.

5.5

The number or tiers of pipe to be stacked shall be limited to prevent deformation or other damage to the

pipe or its coating due to the weight of the pipe.

5.6

Pipe having a fusion bond epoxy coating shall be stacked in a manner and with materials of a type,

thickness and width necessary to maintain a minimum spacing of 3/4" between each pipe and all adjacent

pipes without damage to the coating. Pipe coated with other materials may be nested unless specified

otherwise by the Company.

SHIPPING

6.1

6.2

General

6.1.1

Dunnage shall be hardwood or dense fir.

countersunk to avoid transit damage to pipe.

Nailheads on dunnage shall be adequately

6.1.2

Pipe interiors at unloading shall be free of debris, e.g., cables, dunnage pads, etc.

6.1.3

Discovery of any transit fatigue cracking shall be grounds for rejection of the entire load until

absence of cracking of the balance of the load is proven.

6.1.4

Where steel-to-steel contact has fretted the pipe surface, magnetic particle inspection shall be

performed to ensure absence of cracking.

Railroad

6.2.1

Pipe shall be loaded on or in rail cars in accordance with all provisions of API RP 5L1, latest

edition, regardless of D/t ratio. End gates lined with wood to a minimum nominal thickness

of one (1) inch shall be provided in gondola cars and bulkhead flat cars.

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4915

Page

3 of 4

HANDLING, STORAGE

AND SHIPPING OF PIPE

Issue Date

Rev. No.

Date

6.3

6.4

07/87

4

02/96

6.2.2

The static load stress used in computing the number of bearing strips required in API RP 5L1

shall not exceed 17,000 psi.

6.2.3

Rail cars shall be clean and inspected by the Company's Inspector prior to loading. The

Inspector shall be given reasonable prior to loading and shipping so that each rail car can be

inspected prior to loading and again before it is released to the railroad.

6.2.4

Skids shall be placed directly on car bottom, not on residual debris. Skid height shall be at

least one (1) inch higher than any foreign material or integral projections on the car bottom.

Skids shall not be stacked and skid height shall not exceed skid width.

Truck

6.3.1

The type of truck or trailer Contractor proposes to use to transport the pipe will be approved

by the Company.

6.3.2

Metallic uprights on trucks/trailers shall be completely padded with a minimum of 1/8-inch

thickness of PVC or equivalent.

6.3.3

Dunnage shall be arranged to avoid contact between pipe and nails and/or staples. Skids shall

not be stacked and skid height shall not exceed skid width.

6.3.4

Nonmetallic hold-down straps shall be used. Use of chains is prohibited. Steel strapping may

be used for belly banding provided they are free of burrs.

Barge, Inland Waterway

Pipe shall be loaded on barges in accordance with API RP 5LW with mandatory wood dunnage. Barges

and loading are subject to inspection by the Company's Inspector who will be given adequate advance

notice for such inspection.

6.5

Seagoing Vessels

6.5.1

Pipe shall be loaded in accordance with API RP 5LW with mandatory wood bearing strips and

side wood bearing strips. All API requirements shall apply to all pipe regardless of actual D/t

ratio.

6.5.2

The Company's Inspector shall have free access to the vessel during loading, hatch opening

and unloading.

6.5.3

Bevel protectors shall cover all pipe ends unless stipulated otherwise in the purchase order.

6.5.4

Pipe shall not be shipped on deck.

6.5.5

No pipe end shall overhang any underlying pipe end by more than 3.3 feet.

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4915

Page

4 of 4

HANDLING, STORAGE

AND SHIPPING OF PIPE

Issue Date

Rev. No.

Date

07/87

4

02/96

6.5.6

No overstowage is permitted.

6.5.7

Steel-to-steel contact is prohibited except for full length pipe-to-pipe contact. Welds shall be

positioned or the pipe padded to preclude contact of welds with other pipe, dunnage or

bulkheads.

6.5.8

Lashing shall be padded to preclude metal-to-metal contact with the pipe.

* Indicates revised paragraph, this Rev. No.

You might also like

- Bondstrand Series 7000 M Installation ManualDocument84 pagesBondstrand Series 7000 M Installation ManualPavel Vicentiu0% (1)

- Module 17 Section 3.4Document2 pagesModule 17 Section 3.4Manu VNo ratings yet

- HCL Fuel Tank SpecsDocument62 pagesHCL Fuel Tank SpecsM.Sreeram SanjayNo ratings yet

- Duct For Corrosive Fumes ExhaustDocument8 pagesDuct For Corrosive Fumes ExhaustTS WongNo ratings yet

- Project Standards and Specifications Pig Catcher Package Rev01Document9 pagesProject Standards and Specifications Pig Catcher Package Rev01hiyeonNo ratings yet

- Guide For Installing RTR Pipe Courtesy Bondstrand For InfoDocument4 pagesGuide For Installing RTR Pipe Courtesy Bondstrand For InfoHafiz Ali Alvi100% (1)

- Detailed Specification of PlumbingDocument7 pagesDetailed Specification of PlumbingNava PavanNo ratings yet

- Instalación de Tuberías EnterradasDocument4 pagesInstalación de Tuberías EnterradasYana ParravanoNo ratings yet

- PIPE LINE Presentation PART 1Document33 pagesPIPE LINE Presentation PART 1kannan100% (1)

- QCS 2010 Part 14 Road DrainageDocument8 pagesQCS 2010 Part 14 Road DrainageRotsapNayrb100% (4)

- Method Statement for Fire Fighting System InstallationDocument3 pagesMethod Statement for Fire Fighting System InstallationHamada ELarabyNo ratings yet

- Tubing Storage, Handling and TransportDocument5 pagesTubing Storage, Handling and TransportYougchu Luan100% (2)

- Specs For Pipeline LayingDocument38 pagesSpecs For Pipeline LayingRanjan Kumar100% (2)

- Ductile Iron CastingsDocument6 pagesDuctile Iron CastingsSusan Sue Berrospi MerinoNo ratings yet

- C 1541 - 04 Qze1ndeDocument5 pagesC 1541 - 04 Qze1ndecarlosNo ratings yet

- Section 2 15 Hydrant PitDocument2 pagesSection 2 15 Hydrant PitCassy AbulenciaNo ratings yet

- MEP Specification for Raceways and FittingsDocument8 pagesMEP Specification for Raceways and FittingsBala Krishna GallaNo ratings yet

- Ductwork Material SpecificationsDocument16 pagesDuctwork Material Specificationsvhin84No ratings yet

- QCS 2010 Section 22 Part 5Document15 pagesQCS 2010 Section 22 Part 5Abdelazim Mohamed0% (1)

- Cold Water SpecDocument17 pagesCold Water Specmunim87No ratings yet

- Inspection Check List 3Document22 pagesInspection Check List 3r.devendranNo ratings yet

- Installation Instructions For High Pressure GRE Line PipeDocument27 pagesInstallation Instructions For High Pressure GRE Line PipeSajir Thiyam100% (1)

- DPWH Waterstop SpecificationDocument6 pagesDPWH Waterstop SpecificationFrancis DomingoNo ratings yet

- Techinical Specifications Welcome To NescoDocument54 pagesTechinical Specifications Welcome To NescotejzabNo ratings yet

- Installation Instructions: Plastic Pipe Industry AssociationDocument27 pagesInstallation Instructions: Plastic Pipe Industry Associationahmedmohamed2014No ratings yet

- Special Conditions of Contract For Supply Installation and Commissioning of Temporary and Permanent Cathodic Protection SystemDocument12 pagesSpecial Conditions of Contract For Supply Installation and Commissioning of Temporary and Permanent Cathodic Protection SystemsudeepjosephNo ratings yet

- Chapter 12: House Drains & House SewersDocument5 pagesChapter 12: House Drains & House SewersMr. DummyNo ratings yet

- Weld On Hot Tap Saddle InstallDocument20 pagesWeld On Hot Tap Saddle InstallRemmy Torres VegaNo ratings yet

- FAA APPROVED: November 15, 1988Document4 pagesFAA APPROVED: November 15, 1988Imam Arif RahmanNo ratings yet

- Underground Piping Systems ExplainedDocument9 pagesUnderground Piping Systems ExplainedMayank KumarNo ratings yet

- A 74 - 03 Qtc0lvjfraDocument5 pagesA 74 - 03 Qtc0lvjfraMarko's Brazon'No ratings yet

- CoatingDocument8 pagesCoatingAbhinav GoyalNo ratings yet

- UG Pipe CoatingDocument8 pagesUG Pipe CoatingcenthilkrNo ratings yet

- Pipeline Construction Procedure-1Document10 pagesPipeline Construction Procedure-1ABC Any Body Can Relax100% (1)

- Dutile IronDocument9 pagesDutile IronSaravanan ManiNo ratings yet

- 1 Scope: SAEP-302Document8 pages1 Scope: SAEP-302nasirNo ratings yet

- Ced22 (7571) PDFDocument24 pagesCed22 (7571) PDFskilmagNo ratings yet

- Fiberglass Gravity Sewer Pipe: Part 1: GeneralDocument2 pagesFiberglass Gravity Sewer Pipe: Part 1: GeneralDaniel MoralesNo ratings yet

- Installation of Electric CablesDocument14 pagesInstallation of Electric Cablesmn090078dNo ratings yet

- Guidelines DuctileIronPipeInstallGuide PDFDocument134 pagesGuidelines DuctileIronPipeInstallGuide PDFSIBINNo ratings yet

- Saes H 200Document9 pagesSaes H 200راجہ شہزاد انورNo ratings yet

- GRP Duct Material For Irrigation Works-ADM SpecificationDocument5 pagesGRP Duct Material For Irrigation Works-ADM Specificationbuddy1971No ratings yet

- Casing PresentationDocument33 pagesCasing PresentationJua RulerNo ratings yet

- Specification For FRP DuctDocument6 pagesSpecification For FRP DuctAli HassanNo ratings yet

- Api RP 5Lt Recommended Practice For Truck Transportation of Line PipeDocument7 pagesApi RP 5Lt Recommended Practice For Truck Transportation of Line PipeJitender RaiNo ratings yet

- DM Dsi SPEC04Document39 pagesDM Dsi SPEC04nadhabindhuNo ratings yet

- Technical Specification For Aac / Acsr ConductorsDocument8 pagesTechnical Specification For Aac / Acsr ConductorsDeepeshMaliNo ratings yet

- Asbestos Cement Pipe Repairs, Demolition and Disposal GuideDocument5 pagesAsbestos Cement Pipe Repairs, Demolition and Disposal GuideriysallNo ratings yet

- Spec - WeldingDocument6 pagesSpec - Weldingprasad_kcpNo ratings yet

- Qcs 2010 Section 20 Part 4 Drainage Pipes in Trenches PDFDocument5 pagesQcs 2010 Section 20 Part 4 Drainage Pipes in Trenches PDFbryanpastor106No ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Subsea Pipeline Design, Analysis, and InstallationFrom EverandSubsea Pipeline Design, Analysis, and InstallationRating: 3 out of 5 stars3/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Cathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesFrom EverandCathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesRating: 4.5 out of 5 stars4.5/5 (5)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Trusting JesusDocument1 pageTrusting JesusLorenaNo ratings yet

- Tower of BabelDocument5 pagesTower of BabelLorenaNo ratings yet

- What's New - CADWorx 2016Document5 pagesWhat's New - CADWorx 2016LorenaNo ratings yet

- Series 1500 Cooling Tower SpecificationDocument9 pagesSeries 1500 Cooling Tower SpecificationLorenaNo ratings yet

- Demonstration of Hydrogen Air-Assisted FlaDocument18 pagesDemonstration of Hydrogen Air-Assisted Flahk168No ratings yet

- 2813 HXGN Live 2813 MccombDocument19 pages2813 HXGN Live 2813 MccombLorenaNo ratings yet

- 4940-w3 Standard For Purchase of Valves For Critical Gas ServiceDocument8 pages4940-w3 Standard For Purchase of Valves For Critical Gas ServiceLorena DávilaNo ratings yet

- Good Cooling Tower PractiseDocument59 pagesGood Cooling Tower Practiseamahmoud3No ratings yet

- Fluidos Termicos y Circuitos de CalentamientoDocument38 pagesFluidos Termicos y Circuitos de CalentamientoClaudio Antonio Figueroa PulgarNo ratings yet

- Report DesignerDocument255 pagesReport Designerdgrant775No ratings yet

- Fire protection system philosophy for Collie Urea PlantDocument60 pagesFire protection system philosophy for Collie Urea PlantLorena Dávila100% (1)

- Good Cooling Tower PractiseDocument59 pagesGood Cooling Tower Practiseamahmoud3No ratings yet

- 4815 Typical 1 Hot Tap Connection For Farm Tap or Sales MeterDocument1 page4815 Typical 1 Hot Tap Connection For Farm Tap or Sales MeterLorenaNo ratings yet

- 4910-w1 Engineering Guideline For Flexible Metal HoseDocument1 page4910-w1 Engineering Guideline For Flexible Metal HoseLorenaNo ratings yet

- Onshore and Offshore: Echnical PresentationDocument66 pagesOnshore and Offshore: Echnical PresentationAnonymous 4MwmDaNbNo ratings yet

- 4760-w0 Typical Stream or Ditch Pipeline UndercrossingDocument1 page4760-w0 Typical Stream or Ditch Pipeline UndercrossingLorena100% (1)

- Flare System PDFDocument41 pagesFlare System PDFAzar Deen100% (1)

- 4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)Document3 pages4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)LorenaNo ratings yet

- 4763-w2 Yard Applied Concrete Pipe CoatingDocument7 pages4763-w2 Yard Applied Concrete Pipe CoatingLorena DávilaNo ratings yet

- 4890 Guide Bar Installation For Weld TeesDocument2 pages4890 Guide Bar Installation For Weld TeesLorena DávilaNo ratings yet

- 4802-w2 Concrete Anchor Block - Installation DetailsDocument2 pages4802-w2 Concrete Anchor Block - Installation DetailsLorenaNo ratings yet

- 4895-w2 Standard For Purchase of Forged Flanges and FittingsDocument3 pages4895-w2 Standard For Purchase of Forged Flanges and FittingsLorenaNo ratings yet

- Selecting and Designing Branch ConnectionsDocument8 pagesSelecting and Designing Branch ConnectionsLorenaNo ratings yet

- 4762-w0 Typical Canal Undercrossing, Lined or UnlinedDocument1 page4762-w0 Typical Canal Undercrossing, Lined or UnlinedLorenaNo ratings yet

- 4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineDocument1 page4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineLorenaNo ratings yet

- 4752-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Railroad UndercrossingDocument1 page4752-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Railroad UndercrossingLorenaNo ratings yet

- Enron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsDocument2 pagesEnron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsLorenaNo ratings yet

- 4748-w0 Typical Pipeline and Casing Support at Cased UndercrossingsDocument1 page4748-w0 Typical Pipeline and Casing Support at Cased UndercrossingsLorenaNo ratings yet

- 4758-w0 Restoration of TerracesDocument1 page4758-w0 Restoration of TerracesLorenaNo ratings yet

- 4747-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Cased Highway UndercrossingDocument1 page4747-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Cased Highway UndercrossingLorenaNo ratings yet