Professional Documents

Culture Documents

6D E24 Addendum 1

Uploaded by

aleeimeranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6D E24 Addendum 1

Uploaded by

aleeimeranCopyright:

Available Formats

Date of Issue: March 2015

Affected Publication: API Specification 6D, Specification for Pipeline and Piping Valves, Twenty-fourth Edition,

August 2014

ADDENDUM 1

Page 4, 3.1 Terms and Definitions, replace two definitions:

3.1.1

assembler/manufacturer

An organization that performs assembly as defined in 3.1.2 and conforms to the requirements of Section

14.

NOTE The terms assembler and manufacturer are used interchangeably throughout this document and are

considered to be equivalent.

3.1.2

assembly

The association of multiple parts/components into a finished product, including as a minimum, installation

of all pressure-containing parts and pressure-controlling parts needed to ensure conformance to

applicable pressure testing requirements.

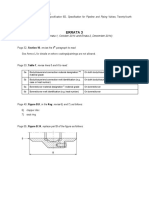

Page 16, 5.9 Drains and Table 2, revise to read:

5.9 Drains

Drain connections shall be drilled and threaded. The purchaser may specify other types of drain

connections, such as welded or flanged.

CautionThreaded connections can be susceptible to crevice corrosion.

Tapered threads shall be capable of providing a seal and comply with ASME B1.20.1.

If parallel threads are used, the connection shall have a head section for trapping and retaining a sealing

member suitable for the specified valve service. Parallel threads shall comply with ASME B1.20.1 or

ISO 228-1.

Sizes shall be in accordance with Table 2.

Table 2Pipe Thread/Pipe Sizes for Drains

Nominal Size of Valve

NPS

DN

/2 to 1-1/2

15 to 40

2 to 8

50 to 200

>8

>200

Minimum Pipe

Thread/Pipe Size

in. (mm)

1

/4 (8)

/2 (15)

1 (25)

Page 23, 6.10 Heat-treating Equipment Qualification, revise to read:

6.10 Heat-treating Equipment Qualification

Heat treating of pressure-containing and pressure-controlling parts and associated TCs shall be

performed with production-type equipment conforming to requirements specified by the manufacturer.

Production-type heat-treating equipment shall be recognized as equipment that is routinely used to

process production parts.

All heat treatment for mechanical properties shall be performed using furnaces that are calibrated in

conformance with Annex F. Post-weld heat treatment (PWHT) shall be performed with heat-treat

equipment conforming to requirements specified by the manufacturer.

Furnaces shall be calibrated and surveyed per 8.2.5.

Page 26, 8.1 NDE Requirements, revise to read:

8.1 NDE Requirements

NDE requirements shall conform to Annex G when specified by the purchaser. Additionally, final surface

(MT and PT) and ultrasonic (UT) NDE activities shall be conducted after final heat treatment or post-weld

heat treatment. Final radiography (RT) NDE activities shall be conducted after final heat treatment,

unless otherwise agreed.

(delete last paragraph)

Page 32, 11 Marking, delete the following paragraph:

The nameplate minimum letter size shall be 0.125 in. (3 mm) on valves sizes NPS 2 (DN 50) and larger.

For all valves NPS 1.5 in (DN 38) and smaller, the nameplate letter size shall be per the manufacturer's

standard.

You might also like

- Duplex and Super Duplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)Document13 pagesDuplex and Super Duplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)aleeimeran100% (1)

- Sae Arp823e-2007Document4 pagesSae Arp823e-2007aleeimeran100% (1)

- Trunnion Mounted Forged Ball Valves Model FF and GG: Reduced Bore 3"-36" Full Bore 2" - 48" ASME Class 150 - 2500Document20 pagesTrunnion Mounted Forged Ball Valves Model FF and GG: Reduced Bore 3"-36" Full Bore 2" - 48" ASME Class 150 - 2500aleeimeranNo ratings yet

- Press Release 2019 As Schneider Understanding Shells DVT Tat 072019Document5 pagesPress Release 2019 As Schneider Understanding Shells DVT Tat 072019aleeimeranNo ratings yet

- Spare Parts List and Interchangeability Record (SPIR) : Project: EquipmentDocument1 pageSpare Parts List and Interchangeability Record (SPIR) : Project: EquipmentaleeimeranNo ratings yet

- Aerospace Recommended Practice: Gas Turbine Engine Inlet Flow Distortion GuidelinesDocument24 pagesAerospace Recommended Practice: Gas Turbine Engine Inlet Flow Distortion Guidelinesaleeimeran100% (1)

- Materials For High-Temperature Conversion Process Furnace PartsDocument28 pagesMaterials For High-Temperature Conversion Process Furnace Partsaleeimeran100% (2)

- SAE ARP 4148B 2003 07 Gas TurbineDocument11 pagesSAE ARP 4148B 2003 07 Gas TurbinealeeimeranNo ratings yet

- MESC SPE 77-211 Nov 2012 PDFDocument6 pagesMESC SPE 77-211 Nov 2012 PDFaleeimeranNo ratings yet

- Global Valve & Controls: Depend On Us, We Can Handle The PressureDocument4 pagesGlobal Valve & Controls: Depend On Us, We Can Handle The PressurealeeimeranNo ratings yet

- MESC SPE 85-103 Feb 2014 PDFDocument8 pagesMESC SPE 85-103 Feb 2014 PDFaleeimeran100% (1)

- 8 XXX SizesDocument9 pages8 XXX SizesInsubordinadoNo ratings yet

- PTS 12.32.07 Jun 2017 - Product Acceptance Test (PAT) For ValvesDocument55 pagesPTS 12.32.07 Jun 2017 - Product Acceptance Test (PAT) For Valvesaleeimeran67% (3)

- FailureofmaterialsDocument29 pagesFailureofmaterialsaleeimeranNo ratings yet

- MESC SPE 77-310 Aug 2011Document10 pagesMESC SPE 77-310 Aug 2011aleeimeran50% (2)

- List Shell Dep Amp Mesc Spe PDFDocument9 pagesList Shell Dep Amp Mesc Spe PDFAzhar Ahmad100% (1)

- 6D E24 Errata 1 & 2Document2 pages6D E24 Errata 1 & 2aleeimeranNo ratings yet

- 6D E24 Errata 3Document2 pages6D E24 Errata 3aleeimeranNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tutorial 5 SolvedDocument3 pagesTutorial 5 SolvedAshutoshKumarNo ratings yet

- Aleutia Solar Container ClassroomDocument67 pagesAleutia Solar Container ClassroomaleutiaNo ratings yet

- Enochian Dragon Ritual PDFDocument4 pagesEnochian Dragon Ritual PDFDenis NantelNo ratings yet

- Drug Addiction Final (Term Paper)Document15 pagesDrug Addiction Final (Term Paper)Dessa Patiga IINo ratings yet

- Lieh TzuDocument203 pagesLieh TzuBrent Cullen100% (2)

- Out PDFDocument211 pagesOut PDFAbraham RojasNo ratings yet

- Delonghi Esam Series Service Info ItalyDocument10 pagesDelonghi Esam Series Service Info ItalyBrko BrkoskiNo ratings yet

- Economic Review English 17-18Document239 pagesEconomic Review English 17-18Shashank SinghNo ratings yet

- Design of Penstock: Reference Code:IS 11639 (Part 2)Document4 pagesDesign of Penstock: Reference Code:IS 11639 (Part 2)sunchitk100% (3)

- Rom 2 - 0-11 (En)Document132 pagesRom 2 - 0-11 (En)Mara HerreraNo ratings yet

- PC Model Answer Paper Winter 2016Document27 pagesPC Model Answer Paper Winter 2016Deepak VermaNo ratings yet

- Activity On Noli Me TangereDocument5 pagesActivity On Noli Me TangereKKKNo ratings yet

- Listen and Arrange The Sentences Based On What You Have Heard!Document3 pagesListen and Arrange The Sentences Based On What You Have Heard!Dewi Hauri Naura HaufanhazzaNo ratings yet

- DLP - Light Science 7Document6 pagesDLP - Light Science 7Samara M. SalacayanNo ratings yet

- How To Configure PowerMACS 4000 As A PROFINET IO Slave With Siemens S7Document20 pagesHow To Configure PowerMACS 4000 As A PROFINET IO Slave With Siemens S7kukaNo ratings yet

- Advanced Chemical Engineering Thermodynamics (Cheg6121) : Review of Basic ThermodynamicsDocument74 pagesAdvanced Chemical Engineering Thermodynamics (Cheg6121) : Review of Basic ThermodynamicsetayhailuNo ratings yet

- 2016 Closing The Gap ReportDocument64 pages2016 Closing The Gap ReportAllan ClarkeNo ratings yet

- Umwd 06516 XD PDFDocument3 pagesUmwd 06516 XD PDFceca89No ratings yet

- Man and Historical ActionDocument4 pagesMan and Historical Actionmama.sb415No ratings yet

- My Mother at 66Document6 pagesMy Mother at 66AnjanaNo ratings yet

- 20-Admission of PatientDocument3 pages20-Admission of Patientakositabon100% (1)

- Standard Answers For The MSC ProgrammeDocument17 pagesStandard Answers For The MSC ProgrammeTiwiNo ratings yet

- QuexBook TutorialDocument14 pagesQuexBook TutorialJeffrey FarillasNo ratings yet

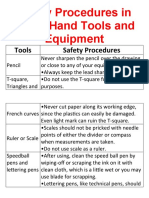

- Safety Procedures in Using Hand Tools and EquipmentDocument12 pagesSafety Procedures in Using Hand Tools and EquipmentJan IcejimenezNo ratings yet

- Anatomy of the pulp cavity กย 2562-1Document84 pagesAnatomy of the pulp cavity กย 2562-1IlincaVasilescuNo ratings yet

- Cable To Metal Surface, Cathodic - CAHAAW3Document2 pagesCable To Metal Surface, Cathodic - CAHAAW3lhanx2No ratings yet

- Microsmart GEODTU Eng 7Document335 pagesMicrosmart GEODTU Eng 7Jim JonesjrNo ratings yet

- Summary of Bill of Quantities ChurchDocument52 pagesSummary of Bill of Quantities ChurchBiniamNo ratings yet

- Bolt Grade Markings and Strength ChartDocument2 pagesBolt Grade Markings and Strength ChartGregory GaschteffNo ratings yet

- Configuring BGP On Cisco Routers Lab Guide 3.2Document106 pagesConfiguring BGP On Cisco Routers Lab Guide 3.2skuzurov67% (3)