Professional Documents

Culture Documents

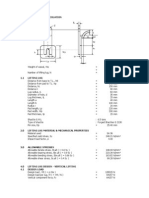

WRC-107 Calculations for Cylindrical Vessel Nozzle

Uploaded by

Sakthi VelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WRC-107 Calculations for Cylindrical Vessel Nozzle

Uploaded by

Sakthi VelCopyright:

Available Formats

REV No.

www.venveldesigners.com & mail @ sakthivel@venveldesigners.com +91 99657 64325

WRC 107 CALCULATIONS (N1) (INTERNAL)

:0

Method 2

Vessel type : Cylinderical

Attachment type : Round

INPUT DATAS FOR NOZZLES N1 : INLET

PARAMETER

Shell Diameter (OD)

Shell Inside diameter (Dv )

Shell Thickness (T)

Shell material

Design Temperature

Design pressure (Dp)

Allowable strength of Material (Hot)

Allowable strength of Material (Cold)

Corrosion allowance (Shell and Nozzle)

SI UNITS

406.4 mm

387.34 mm

9.53 mm

A 106 Gr B

170 Deg C

1.77 MPa(g)

118 MPa (g)

118 MPa (g)

3 mm

Nozzle Diameter (OD)

Nozzle thickness (Tn )

Nozzle material

Allowable strength of material ( Snh) (Hot)

Allowable strength of material ( Snc) (Cold)

114.3 mm

8.56 mm

A 106 Gr B

118 MPa (g)

118 MPa (g)

LOADINGS DATA

Radial Load (P)

4000 N

Circumferential shear load (VC)

4000 N

Longitudinal Shear load (VL)

4000 N

Circumferential Moment ( MC)

3800 Nm

Longitudinal Moment (ML)

3800 Nm

Tortional Moment (MT)

3800 Nm

CALCULATION VALUES

Attachment radius (ro)

57.15 mm

Vessel radius (Mean) (Rm) (Corroded Condition)

199.94 mm

Thickness of the vessel (T) (Corroded condition)

6.53 mm

Calculation for Gamma and Beta :

Gamma = Rm / T

Beta

= 7.871 / 0.257

DATED

= 30.626

= (0.875) x (ro /Rm) = 0.875 x ( 2.25 / 7.871) = 0.250

CUSTOMERY UNITS

16 in

15.249 in

0.375 in

A 106 Gr B

338 Deg F

256.72 PSI(g)

17114 PSI (g)

17114 PSI (g)

0.118 in

4.5 in

0.337 in

A 106 Gr B

17114 PSI (g)

17114 PSI (g)

900 Lb

900 Lb

900 Lb

2750 Lb ft

2750 Lb ft

2750 Lb ft

2.25 in

7.871 in

0.257 in

27/5/15

www.venveldesigners.com & mail @ sakthivel@venveldesigners.com +91 99657 64325

REV No.

WRC 107 CALCULATIONS (N1) (INTERNAL)

:0

DATED

27/5/15

Dimensionless loads for cylinderical shells at attachment junction :

Reference table : Table No 8

To find Stresses :

Location

A,B

C,D

A,B

C,D

A,B,C,D

A,B,C,D

A,B,C,D

A,B,C,D

Gamma

30.63

30.63

30.63

30.63

30.63

30.63

30.63

30.63

To find X Stresses :

Location

A,B

C,D

A,B

C,D

A,B,C,D

A,B,C,D

A,B,C,D

A,B,C,D

Gamma

30.63

30.63

30.63

30.63

30.63

30.63

30.63

30.63

Beta

Figure

Beta

Figure

0.25

0.25

0.25

0.25

0.25

0.25

0.25

0.25

0.25

0.25

0.25

0.25

0.25

0.25

0.25

0.25

4C

3C

2C1

1C

3A

1A

3B

1B

3C

4C

1C1

2C

4A

2A

4B

2B

N / (P /Rm)

N / (P /Rm)

M /P

M /P

N / (Mc / Rm2 )

M / (Mc / Rm )

N / (ML / Rm2 )

M / (ML / Rm )

NX / (P /Rm)

Nx / (P /Rm)

Mx /P

Mx /P

Nx / (Mc / Rm2 )

Mx / (Mc / Rm )

Nx / (ML / Rm2 )

Mx / (ML / Rm )

Read data

Read data

3.900

3.000

0.050

0.060

1.400

0.068

2.800

0.018

3.000

3.900

0.080

0.032

2.500

0.026

1.300

0.032

Value

Value

www.venveldesigners.com & mail @ sakthivel@venveldesigners.com +91 99657 64325

REV No.

WRC 107 CALCULATIONS (N1) (INTERNAL)

:0

DATED

27/5/15

Stress concentration factor : From Fig B-2

Fillet Radius = 0.394 in

Kn

= 1.55 (From Tension curve), Kb = 1.3 (From Bending curve)

Type of

Stress

Circ.

Membrance

Circ.Bending

Circ.

Membrance

Circ.Bending

Circ.

Membrance

Circ.Bending

Total Circ

Stress

Type of

Stress

Circ.

Membrance

Circ.Bending

Circ.

Membrance

Circ.Bending

Circ.

Membrance

Circ.Bending

Total Circ

Stress

Shear Stress

Load

Au

Al

-2690

-2690

P

Mc

-5314

0

Mc

Ml

0

-2998

Ml

O

-2971

-13973

Load

P

Tortion,MT

Du

Dl

-2069

-2069

-2069

-2069

5314

0

-5314

0

5314

0

-6377

-1499

6377

-1499

-6377

1499

6377

1499

0

-2998

0

2998

0

2998

-11223

0

11223

0

-11223

0

11223

0

Cu

Cl

Du

Dl

-2690

-2690

-2690

-2690

-4291

0

4291

0

2971

2597

2971

-2035

-2971

2651

Stress value at (psi)

Bu

Bl

-2069

-2069

0

-1392

0

-1392

Ml

Ox

Cl

-2690

Al

-8503

0

Cu

-2690

Au

P

Mc

Mc

Ml

Stress value at (psi)

Bu

Bl

-2069

-2069

0

1392

0

1392

8503

0

-8503

0

-5281

-17245

5281

10323

757

757

0

-21168

0

14032

0

-18170

0

17030

8503

0

-3401

-2677

3401

-2677

-3401

2677

5281

-3899

-5281

2545

0

-13059

0

2325

0

-7705

0

7679

757

757

757

757

757

757

-4291

0

4291

0

3401

2677

www.venveldesigners.com & mail @ sakthivel@venveldesigners.com +91 99657 64325

Shear Stress Load,Vc

Shear Stress Load,Vl

Total Shear Stress

REV No.

496

0

1253

496

0

1253

-496

0

-261

-496

0

-261

0

-496

-261

0

-496

-261

WRC 107 CALCULATIONS (N1) (INTERNAL)

:0

0

496

1253

DATED

Here 0

So, Combined stress intensity is Largest absolute magnitude of S1 and S2

S1 = [Ox + O +/- (Sq.rt ((Ox O)2 + 42 ))] or S2 = Sq.rt ((Ox O)2 + 42 )

Type of

Stress

O

Ox

S2

S1

Max of S1

and S2

-

Au

Al

Bu

Bl

Cu

Cl

Du

-13973

2597

-2035

2651

-21168

14032

-18170

1253

1253

-261

-261

-261

-261

1253

-17245

4121

10323

8122

-3899

1935

2545

532

-13059

8125

2325

11718

-7705

10760

Dl

17030

7679

1253

9680

-13548

10521

-1999

2864

-13050

14037

-7557

17090

-13893

10357

-1999

2864

-13050

14037

10760

17090

Sign indicates Compressional stress

sign indicates tensional stress

Conclusion :

All the stresses in the both of the nozzles less then the allowable stress of 17,114 psi (g)

So, The nozzles can be used for the above mentioned loading conditions.

0

496

1253

27/5/15

You might also like

- Local Stresses WRC107Document19 pagesLocal Stresses WRC107naeand67% (3)

- WRC 107 Stress Analysis of A Nozzle in A CylinderDocument4 pagesWRC 107 Stress Analysis of A Nozzle in A CylinderaruatscribdNo ratings yet

- WRC 107, WRC 297 Co MP PDFDocument11 pagesWRC 107, WRC 297 Co MP PDFkarthickmectr100% (2)

- Lifting LugDocument8 pagesLifting LugAzwan ShahNo ratings yet

- Bolted Flanged Connections For Non-Circular Pressure VesselsDocument8 pagesBolted Flanged Connections For Non-Circular Pressure VesselsKenneth BeerNo ratings yet

- WRC Load AnalysisDocument5 pagesWRC Load Analysisyogacruise100% (1)

- WRC Bulletin-297 Searchable PDFDocument89 pagesWRC Bulletin-297 Searchable PDFandrés morantes0% (1)

- Mechanical Calculations for Air Receiver Pressure VesselDocument32 pagesMechanical Calculations for Air Receiver Pressure VesselAndiWSutomoNo ratings yet

- 107Document79 pages107FelipeAndrésArriagadaMartínezNo ratings yet

- Asme B16.47 PDFDocument25 pagesAsme B16.47 PDFkta_87No ratings yet

- Trunnion AnalysisDocument45 pagesTrunnion AnalysisChiragJansariNo ratings yet

- Allowable External Forces on Vessel NozzlesDocument3 pagesAllowable External Forces on Vessel Nozzlesvenkatrangan2003No ratings yet

- PV EliteDocument558 pagesPV EliteJavier Orna100% (1)

- Flange Pad CalcsDocument4 pagesFlange Pad CalcstomNo ratings yet

- Cylindrical & Spherical Shell CalculationsDocument24 pagesCylindrical & Spherical Shell CalculationsTinBáoNo ratings yet

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Document35 pagesDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainNo ratings yet

- WRC 297Document94 pagesWRC 297joshuamaagNo ratings yet

- WRC 107 & 297Document10 pagesWRC 107 & 297Anonymous KpVxNXsNo ratings yet

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringFrom EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillRating: 3.5 out of 5 stars3.5/5 (3)

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDocument5 pagesTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelNo ratings yet

- Rectangular Tank Design - RoarksDocument3 pagesRectangular Tank Design - RoarksSakthi Vel100% (1)

- 212.nozzle Load Stress Analysis Using WRC 107 and WRC 297Document4 pages212.nozzle Load Stress Analysis Using WRC 107 and WRC 297jeronimo113No ratings yet

- Data Structures and AlgorithmsDocument45 pagesData Structures and AlgorithmsKeith Tanaka MagakaNo ratings yet

- Nozzle Loads WRC 107 Ver 1.1Document5 pagesNozzle Loads WRC 107 Ver 1.1Honey Tiwari75% (4)

- Calcu Nozzle NeckDocument15 pagesCalcu Nozzle Necksachmaya0% (1)

- Cover Pages For PV Elite VenvelDocument14 pagesCover Pages For PV Elite VenvelSakthi VelNo ratings yet

- Shell and Tube HE CalculationDocument16 pagesShell and Tube HE CalculationPradip ShindeNo ratings yet

- On The Design of The Tubesheet and Tubesheet-To-Shell Junction of A Fixed Tubesheet Heat ExchangerDocument7 pagesOn The Design of The Tubesheet and Tubesheet-To-Shell Junction of A Fixed Tubesheet Heat ExchangerEdgardo Chavez BelloNo ratings yet

- Step-by-step guide to WRC 107 and 297 nozzle stress checks in Caesar IIDocument7 pagesStep-by-step guide to WRC 107 and 297 nozzle stress checks in Caesar IIaap1No ratings yet

- SPAN Calc.Document48 pagesSPAN Calc.yoi_123No ratings yet

- N-318-5 Lug Local StressDocument3 pagesN-318-5 Lug Local StresscohenfuNo ratings yet

- Agitator Nozzle Load Data SheetDocument1 pageAgitator Nozzle Load Data SheetAnonymous MB5YbaLrBENo ratings yet

- Condensate Tank - For 250Document3 pagesCondensate Tank - For 250Sakthi VelNo ratings yet

- Mechanical Design Calculations of Pressure Vessel - SampleDocument27 pagesMechanical Design Calculations of Pressure Vessel - SampleSakthi Vel100% (1)

- Allowable Nozzle Load Calculation PDFDocument5 pagesAllowable Nozzle Load Calculation PDFSAGARNo ratings yet

- WRC Data-ModifiedDocument40 pagesWRC Data-ModifiedGovindan KrishnamoorthybashyamNo ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- PVElite ManualDocument691 pagesPVElite Manuals.mladin75% (4)

- WRC-107 Nozzles (PVElite)Document5 pagesWRC-107 Nozzles (PVElite)Alvin SmithNo ratings yet

- Three Saddle Supports For Horizontal VesselDocument7 pagesThree Saddle Supports For Horizontal VesselhuangjlNo ratings yet

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Plate Fabricated Pipe Calculation Sample PDFDocument4 pagesPlate Fabricated Pipe Calculation Sample PDFSakthi VelNo ratings yet

- Plate Fabricated Pipe Calculation Sample PDFDocument4 pagesPlate Fabricated Pipe Calculation Sample PDFSakthi VelNo ratings yet

- 4000 m3 Storage Tank - Data SheetDocument3 pages4000 m3 Storage Tank - Data SheetSakthi Vel100% (1)

- Horizontal Vessel Stress AnalysisDocument12 pagesHorizontal Vessel Stress AnalysissridharNo ratings yet

- 100m3 Butane Tank CalculationsDocument23 pages100m3 Butane Tank CalculationsgulmstfNo ratings yet

- Xenomai 3 DocumentationDocument673 pagesXenomai 3 DocumentationGuile BonafiniNo ratings yet

- Design of Flat Head For HydrotestDocument12 pagesDesign of Flat Head For HydrotestSAGARNo ratings yet

- Is 803 Code CalcDocument5 pagesIs 803 Code CalcSakthi Vel50% (2)

- WRC107 297Document4 pagesWRC107 297MasoodMiyanNo ratings yet

- Load Cases and How They Are Handled by PV EliteDocument7 pagesLoad Cases and How They Are Handled by PV Elitearmvasi100% (1)

- Round Attachment Cylindrical Shell AnalysisDocument9 pagesRound Attachment Cylindrical Shell AnalysisakisdassasNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- PV Elite WebinarDocument24 pagesPV Elite WebinarAndrea Hank LattanzioNo ratings yet

- Step-by-step guide to WRC 107 and 297 nozzle stress checks in Caesar IIDocument7 pagesStep-by-step guide to WRC 107 and 297 nozzle stress checks in Caesar IIaap1No ratings yet

- Data Sheet For Allowable Nozzle Load - SP1-110-9850-00-PI-DTDocument8 pagesData Sheet For Allowable Nozzle Load - SP1-110-9850-00-PI-DTbabak mirNo ratings yet

- Lug SupportDocument2 pagesLug SupportSachin5586No ratings yet

- Sulfuric Acid Tank - APIDocument4 pagesSulfuric Acid Tank - APISakthi VelNo ratings yet

- Delphi 9322a000Document5 pagesDelphi 9322a000BaytolgaNo ratings yet

- Iso 10042Document5 pagesIso 10042Nur Diana100% (3)

- REGULATIONS UPDATEDDocument74 pagesREGULATIONS UPDATEDSakthi VelNo ratings yet

- Methods For Assessing The Stability of Slopes During Earthquakes-A Retrospective 1Document3 pagesMethods For Assessing The Stability of Slopes During Earthquakes-A Retrospective 1ilijarskNo ratings yet

- Java10 PDFDocument137 pagesJava10 PDFswarup sarkarNo ratings yet

- Pressure Vessel Lifting Lug CalculationDocument2 pagesPressure Vessel Lifting Lug Calculationtekstep767% (3)

- Pressure Vessel Nozzle Calc - ASME VIII Div 1Document20 pagesPressure Vessel Nozzle Calc - ASME VIII Div 1aauppal100% (1)

- Nozzle Load AnalysisDocument2 pagesNozzle Load Analysisvm153748763No ratings yet

- WRC 107 Calculation-Circular Attachment On Cylinder (Without Repad)Document3 pagesWRC 107 Calculation-Circular Attachment On Cylinder (Without Repad)naim100% (1)

- SDH TechnologyDocument26 pagesSDH TechnologyJayesh SinghalNo ratings yet

- Fundamentals of Neural Networks by Laurene FausettDocument476 pagesFundamentals of Neural Networks by Laurene Fausettsivakumar89% (18)

- WRC Input InstructionDocument2 pagesWRC Input InstructionpandiangvNo ratings yet

- Condenser BasicsDocument4 pagesCondenser Basicsjimbzthegr8100% (2)

- Allowable Nozzle Loading for Carbon Steel and Stainless Steel PipesDocument1 pageAllowable Nozzle Loading for Carbon Steel and Stainless Steel PipesoberaiNo ratings yet

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyNo ratings yet

- TCB TCB HD Brief Catalogue 2011Document15 pagesTCB TCB HD Brief Catalogue 2011Anonymous xrBCp9Ej100% (1)

- WRC 107 For Vertical Internal ClipDocument22 pagesWRC 107 For Vertical Internal ClipAlvin SmithNo ratings yet

- WellheadNodalGas SonicFlowDocument7 pagesWellheadNodalGas SonicFlowthe_soldier_15_1No ratings yet

- Analysis of Base Plate: Bp1/2/5 (Loadingtype - I) (WSM Per Is800-2007)Document23 pagesAnalysis of Base Plate: Bp1/2/5 (Loadingtype - I) (WSM Per Is800-2007)satyakamNo ratings yet

- API Calcs Rev1 Version 2Document107 pagesAPI Calcs Rev1 Version 2JithuJohnNo ratings yet

- Practice EXAM: Chemistry 605 (Reich)Document10 pagesPractice EXAM: Chemistry 605 (Reich)Dua SinjlawiNo ratings yet

- Nozzle Calculation Summary and Checks for ASME-DCN-2018Document2 pagesNozzle Calculation Summary and Checks for ASME-DCN-2018Sakthi VelNo ratings yet

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelNo ratings yet

- Sheet 1 of 4 Technical Data Sheet for Shell and Tube Heat ExchangerDocument4 pagesSheet 1 of 4 Technical Data Sheet for Shell and Tube Heat ExchangerSakthi VelNo ratings yet

- Mechanical Design - Cooler PDFDocument13 pagesMechanical Design - Cooler PDFSakthi VelNo ratings yet

- Design Calculations - I Beam SelectionDocument14 pagesDesign Calculations - I Beam SelectionSakthi VelNo ratings yet

- Design Calculations - I Beam SelectionDocument14 pagesDesign Calculations - I Beam SelectionSakthi VelNo ratings yet

- Skirt Design - For Small VesselsDocument7 pagesSkirt Design - For Small VesselsSakthi VelNo ratings yet

- Cata - Flange ANSI - pdf1299758077 PDFDocument48 pagesCata - Flange ANSI - pdf1299758077 PDFNikhil PanchalNo ratings yet

- FLS Specific Heat Capacities of GasesDocument1 pageFLS Specific Heat Capacities of GasesHüsamettin Deniz ÖzerenNo ratings yet

- SEU-LAB4: Determining Heat Transfer CoefficientsDocument14 pagesSEU-LAB4: Determining Heat Transfer CoefficientsSakthi VelNo ratings yet

- 5 MW Condenser PDFDocument133 pages5 MW Condenser PDFSakthi Vel100% (1)

- India's Neighbourhood PDFDocument257 pagesIndia's Neighbourhood PDFMohit GautamNo ratings yet

- Finned Tube Heat Exchanger - DetailsDocument7 pagesFinned Tube Heat Exchanger - DetailsSakthi VelNo ratings yet

- Low-Complexity Iterative Detection For Large-Scale Multiuser MIMO-OFDM Systems Using Approximate Message PassingDocument14 pagesLow-Complexity Iterative Detection For Large-Scale Multiuser MIMO-OFDM Systems Using Approximate Message PassingNitin KumarNo ratings yet

- Data Warehousing: Modern Database ManagementDocument49 pagesData Warehousing: Modern Database ManagementNgọc TrâmNo ratings yet

- BetaDocument16 pagesBetaAkshita Saxena100% (2)

- PF-CIS-Fall 2022 LABDocument4 pagesPF-CIS-Fall 2022 LABMuhammad FaisalNo ratings yet

- Bobcat Technical Information Bulletin - CompressDocument2 pagesBobcat Technical Information Bulletin - Compressgerman orejarenaNo ratings yet

- Indian Standards List As On Jan2009Document216 pagesIndian Standards List As On Jan2009Vasudeva Pavan VemuriNo ratings yet

- Public Key Cryptography: S. Erfani, ECE Dept., University of Windsor 0688-558-01 Network SecurityDocument7 pagesPublic Key Cryptography: S. Erfani, ECE Dept., University of Windsor 0688-558-01 Network SecurityAbrasaxEimi370No ratings yet

- Mathematics of Finance: Simple and Compound Interest FormulasDocument11 pagesMathematics of Finance: Simple and Compound Interest FormulasAshekin MahadiNo ratings yet

- Submittal Chiller COP 6.02Document3 pagesSubmittal Chiller COP 6.02juan yenqueNo ratings yet

- Sequelize GuideDocument5 pagesSequelize Guidemathur1995No ratings yet

- View DsilDocument16 pagesView DsilneepolionNo ratings yet

- Logic CHPT71Document27 pagesLogic CHPT71Eronjosh FontanozaNo ratings yet

- Nso User Guide-5.3 PDFDocument178 pagesNso User Guide-5.3 PDFAla JebnounNo ratings yet

- Physical parameters shaping of Farwa Lagoon - LibyaDocument7 pagesPhysical parameters shaping of Farwa Lagoon - LibyaAsadeg ZaidNo ratings yet

- 10th Term Exams Computer Science PaperDocument2 pages10th Term Exams Computer Science PaperMohammad Tariq JavaidNo ratings yet

- R8557B KCGGDocument178 pagesR8557B KCGGRinda_RaynaNo ratings yet

- e-GP System User Manual - Tender Evaluation Committee UserDocument82 pagese-GP System User Manual - Tender Evaluation Committee UserMd. Jakaria ApuNo ratings yet

- Lecture 1: Encoding Language: LING 1330/2330: Introduction To Computational Linguistics Na-Rae HanDocument18 pagesLecture 1: Encoding Language: LING 1330/2330: Introduction To Computational Linguistics Na-Rae HanLaura AmwayiNo ratings yet

- Efficiency Evaluation of The Ejector Cooling Cycle PDFDocument18 pagesEfficiency Evaluation of The Ejector Cooling Cycle PDFzoom_999No ratings yet

- Lesson 1Document24 pagesLesson 1Jayzelle100% (1)

- Ce010 601 Design of Steel Structures Ce PDFDocument5 pagesCe010 601 Design of Steel Structures Ce PDFPrakash rubanNo ratings yet

- Potenciometro 15KDocument8 pagesPotenciometro 15Kra101208No ratings yet