Professional Documents

Culture Documents

4925-w2 Standard For Purchase of Induction Pipe Bends

Uploaded by

LorenaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4925-w2 Standard For Purchase of Induction Pipe Bends

Uploaded by

LorenaCopyright:

Available Formats

Engineering Standards

Standard

4925

Page

1 of 6

STANDARD FOR PURCHASE OF

INDUCTION PIPE BENDS

Issue Date

Rev. No.

Date

1.

03/88

2

08/93

SCOPE

This standard covers the requirements for the procedure qualification and induction bending of steel pipe for use in

natural gas pipelines. Pipe to be bent may be supplied by either the Company or the Manufacturer as specified in

the purchase documents or specification sheet herein.

2.

CODES AND STANDARDS

2.1

The pipe used for bending shall meet the requirements of API 5L, as modified by Company Engineering

Standard 4905 or an applicable ASTM standard referenced by 49 CFR Part 192 and mutually agreed to by

the Company and the Manufacturer. In addition, for grades X60 and higher, the pipe shall contain a

minimum of 0.020% niobium and shall have a minimum carbon equivalent (CE) of 0.34%. Maximum

CE shall be 0.42%.

2.2

Pipe bends shall meet the requirements of International Pipe Association Voluntary Induction Bending

Standard (IPA-VIBS-86) and this standard.

3.

PRE-PRODUCTION REQUIREMENTS

Manufacturer shall submit, or have on file with the Company, the following for approval prior to making

production bends.

4.

3.1

A procedure qualified for making pipe bends meeting the requirements of this standard using pipe from

the same heat and of the same size, wall thickness and grade specified herein. The manufacturing

procedure shall be either qualified by testing in accordance with Section 4 of this standard or one

previously qualified by the Manufacturer.

3.2

Details of the manufacturing procedure qualification testing, including the results of the non-destructive

inspection and mechanical testing of the trial bend.

3.3

Details on dimensional changes caused by the bending process.

3.4

Proposed shipping and handling procedures and shipping schedule for finished bends.

PROCEDURE QUALIFICATION TESTING

4.1

General

4.1.1

The Manufacturer shall perform procedure qualification testing of each bend size, wall

thickness and grade combination to be produced.

4.1.2

One pipe selected from the same heat from which pipes for bending were manufactured shall

be bent using the bending procedure and thermal and mechanical treatments that will be

applied to the production bends.

4.1.3

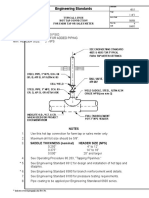

The finished test bend must meet the mechanical test requirements below and the nondestructive inspection requirements in Section 6 of this standard. See illustration below of

required mechanical test samples and locations.

* Indicates revised paragraph, this Rev. No.

Standard

Engineering Standards

4925

Page

2 of 6

STANDARD FOR PURCHASE OF

INDUCTION PIPE BENDS

Issue Date

03/88

2

08/93

Rev. No.

Date

No. & Type Specimens Each Location

(1) 2 tensile

1 set of 3 Charpy

2 DWTT (if specified)

1 hardness

(2) 2 tensile

1 set of 3 Charpy

2 DWTT (if specified)

1 hardness

(3) 4 tensile (2 top & 2 bottom)

2 sets of 3 Charpy on weld seam

1 set of 3 Charpy on body (top or bottom)

4 DWTT (if specified, 2 top & 2 bottom)

1 hardness

(4) 2 tensile

1 set of 3 Charpy

(5) 2 sets of 3 Charpy on weld seam

4.3

*

Outside

Radius

(1)

(4)

(3) Neutral

Axis

(2) Inside

Radius

(5)

Longitudinal Weld Seam

4.2.1

The actual yield strength shall not exceed the yield strength as reported on the pipe mill test

by more than 15 ksi and shall not be less than the specified minimum yield strength.

4.2.2

The ratio of yield to tensile strength shall not exceed 0.90.

4.2.3

Transverse weld tensile test requirements shall apply to all longitudinal, spiral and

circumferential welds and shall meet the yield and ultimate strength requirements and 75% of

the elongation requirements of API 5L as modified by Engineering Standard 4905.

Charpy Impact Tests for Pipe Body Bends

4.3.1

Three (3) Charpy V-notch transverse specimens shall be cut from each of the following three

(4) locations: the areas of maximum bending on the inside and outside radius areas, from the

top or bottom neutral axis and one tangent end.

4.3.2

The specimens shall be tested in accordance with ASTM A370 at the specified temperature

and shall meet the specified notch toughness properties.

4.4

Charpy Impact Tests for Longitudinal Welds

4.4.1

Samples shall consist of two (2) sets of three (3) transverse specimens from the longitudinal

seam taken from each of the following two (2) locations: the top or bottom neutral axis in the

bend and in one tangent end.

4.4.2

One set of samples shall be prepared with through-wall oriented notches in the center of the

weld; the other set shall be prepared with through-wall oriented notches lying as much as

possible in the heat affected zone.

4.4.3

The specimens shall be tested in accordance with ASTM A370 at the specified temperature

and shall meet the specified notch toughness properties.

4.5

Drop Weight Tear Tests

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4925

Page

3 of 6

STANDARD FOR PURCHASE OF

INDUCTION PIPE BENDS

Issue Date

Rev. No.

Date

4.6

5.

03/88

2

08/93

4.5.1

When specified, drop-weight-tear tests shall be conducted in accordance with API 5L. For

pipe having nominal wall thickness greater than 0.75 inch, the test procedure shall be subject

to approval by the Company.

4.5.2

Two (2) specimens shall be cut from each of following four (4) locations: the area of

maximum bending on the inside and outside radius areas and the top and bottom neutral axis.

4.5.3

The specimens shall be tested at the specified temperature and, unless specified otherwise, the

average shear area of two (2) specimens from any sample location shall not be less than 60%.

4.5.4

Energy absorbed by each specimen during drop-weight-tear tests shall be reported.

Hardness Tests

4.6.1

Micro hardness traverses shall be performed using a 500g load on one (1) specimen from each

of the following four (4) locations: the area of maximum bending in the inside and outside

radius areas and the top and bottom neutral axis.

4.6.2

For all welds, the macro and micro hardness of the weld metal and heat affected zone shall not

exceed a maximum Vickers hardness of 280 Hv10 or equivalent.

BENDING PROCEDURE

5.1

All production bends shall be made in accordance with qualified and approved procedures.

5.2

The seam weld of longitudinally welded pipe shall be located at the neutral axis of the finished bend. If

seamless pipe is used, it shall be inspected for wall thickness variations and the thickest part of the pipe

wall shall be oriented to the outside of the bend.

5.3

Unless specified otherwise, all pipe shall be grit blasted prior to bending.

6.

INSPECTION

6.1

Bends shall be free of loose mill scale, foreign matter, oil or grease and shall be clean and dry for final

inspection.

6.2

Defects and Defect Repair

Each pipe bend shall be inspected for injurious defects. Definition and allowable repair of injurious

defects shall be in accordance with API 5L as modified by Engineering Standard 4905. All repaired areas

shall be inspected using liquid penetrant or magnetic particle inspection.

6.3

Liquid Penetrant or Magnetic Particle Inspection

Each production bend shall be examined using liquid penetrant or magnetic particle techniques for surface

defects on the inside and outside radius areas. The finished bend shall contain no surface cracks.

6.4

Ultrasonic Inspection

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4925

Page

4 of 6

STANDARD FOR PURCHASE OF

INDUCTION PIPE BENDS

Issue Date

Rev. No.

Date

03/88

2

08/93

All welds shall be 100% inspected after bending using an ultrasonic tech nique. Equipment, reference

standards and acceptance criteria shall be in accordance with API 5L.

7.

6.5

Hardness Tests

Each production bend shall be hardness tested. Surface hardness readings shall be taken after final heat

treatment in each circumferential quadrant at the beginning of the heat zone, at the end of the heat zone

and in the center of the sweep (12 hardness readings per bend). The inside and outside radius areas of the

pipe bend and any start-stop areas shall be visually examined to detect irregularities in the pipe bend

curvature which may indicate hard spots. The hardness of the pipe body shall not exceed 280 H v10 or

equivalent.

6.6

Dimensional Tolerances

6.6.1

The outside diameter of the pipe bend shall not be reduced in any circumferential plane by

more than 2.5% of the nominal pipe diameter and shall meet the requirements of API 5L for a

distance of 4 inches from each end.

6.6.2

The maximum difference between any two outside diameter measurements in any

circumferential plane shall not exceed 5% of the specified diameter and shall not exceed 1%

of the specified diameter within 4 inches of the pipe end.

6.6.3

Completed bends shall have a wall thickness that is not less than the minimum permitted by

API 5L for the wall thickness specified for the bend.

PLANT ACCESS

7.1

Company may specify and perform additional tests to be performed by the Company, the Manufacturer or

a third party agency to verify compliance with this standard.

7.2

Manufacturer shall provide Company representatives reasonable access to pipe, inspection instruments or

machinery pertinent to the work covered by this standard.

7.3

Inspection by the Company or its agents shall not relieve the Manufacturer of responsibility for meeting

the requirements of this standard.

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4925

Page

5 of 6

STANDARD FOR PURCHASE OF

INDUCTION PIPE BENDS

Issue Date

Rev. No.

Date

8.

03/88

2

08/93

HYDROSTATIC TESTING

When specified, the manufacturer shall test each finished pipe bend to a pressure that will result in a

circumferential stress equivalent to 90% of the specified minimum yield strength without leakage or impairment to

serviceability of the pipe bend. The test pressure shall be maintained and recorded for a period of five (5) minutes.

The ends of the pipe bend shall be restrained in a manner to prevent deformation of the bend during hydrostatic

testing.

9.

MARKING

The following information shall be painted on the inside surface of each bend.

a.

b.

c.

d.

e.

f.

g.

h.

i.

j.

10.

Company Purchase Order No.

Manufacturer's name or mark

Outside diameter in inches

Wall thickness in inches

Pipe grade in ksi

Pipe mfr. and heat number

Bend radius in feet

Bend angle in degrees

If applicable, stress relief (SR) and stress relief temp. (e.g. SR 1150)

Test pressure, if hydrostatic test specified

DAMAGES

Manufacturer shall reimburse Company for fair value of the pipe as documented by pipe purchase order, including

applicable transportation, for bends fabricated by the manufacturer not meeting the requirements of this standard

and for pipe damaged while under the control and care of the Manufacturer.

11.

DOCUMENTATION

11.1

Records of the results of all non-destructive testing and the pipe mill test report for any pipe supplied by

the Manufacturer shall be supplied to the Company.

11.2

Manufacturer shall certify in writing to the Company, upon completion of the order, that the pipe bends

furnished were manufactured in accordance with the applicable qualified and approved procedures and

meet all applicable specifications.

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4925

Page

6 of 6

STANDARD FOR PURCHASE OF

INDUCTION PIPE BENDS

Issue Date

Rev. No.

Date

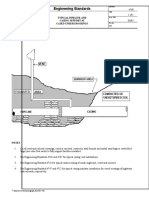

SPECIFICATION SHEET

Location:

Project:

Prepared By:

Date:

Purchase Order No.

Revision:

Requisition No.

Project No.

Approved By:

Revised Date:

P.O. Date:

SERVICE REQUIREMENTS

Item Number

Tag Number

Service Fluid

Pipe

Quantity Delivered (ft)

Size (inches O.D.)

Wall Thickness (inches)

Grade

Manufacturing Process

Pipe Bends

Quantity Required (No.)

Bend Radius (feet)

Bend Angle (degrees)

Wall Thickness

End Finish

SUPPLEMENTAL REQUIREMENTS

Test Temperature (F)

DWTT Required (yes/no)

Avg. Shear Area (%)

Charpy V-Notch Energy

Specimen (1/2, 2/3, Full)

Specimen Min. (ft-lbs)

3-Specimen Avg. (ft-lbs)

OPTIONAL REQUIREMENTS

Test Temperature (F)

DWTT Required (yes/no)

NOTES

1. Pipe purchase specification (ES 4905) and mill test report to be provided by Company.

2.

3.

* Indicates revised paragraph, this Rev. No.

03/88

2

08/93

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Nso User Guide-5.3 PDFDocument178 pagesNso User Guide-5.3 PDFAla JebnounNo ratings yet

- What's New - CADWorx 2016Document5 pagesWhat's New - CADWorx 2016LorenaNo ratings yet

- 4910-w1 Engineering Guideline For Flexible Metal HoseDocument1 page4910-w1 Engineering Guideline For Flexible Metal HoseLorenaNo ratings yet

- Trusting JesusDocument1 pageTrusting JesusLorenaNo ratings yet

- Tower of BabelDocument5 pagesTower of BabelLorenaNo ratings yet

- 4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)Document3 pages4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)LorenaNo ratings yet

- Series 1500 Cooling Tower SpecificationDocument9 pagesSeries 1500 Cooling Tower SpecificationLorenaNo ratings yet

- Fluidos Termicos y Circuitos de CalentamientoDocument38 pagesFluidos Termicos y Circuitos de CalentamientoClaudio Antonio Figueroa PulgarNo ratings yet

- 2813 HXGN Live 2813 MccombDocument19 pages2813 HXGN Live 2813 MccombLorenaNo ratings yet

- 4940-w3 Standard For Purchase of Valves For Critical Gas ServiceDocument8 pages4940-w3 Standard For Purchase of Valves For Critical Gas ServiceLorena DávilaNo ratings yet

- Good Cooling Tower PractiseDocument59 pagesGood Cooling Tower Practiseamahmoud3No ratings yet

- Fire protection system philosophy for Collie Urea PlantDocument60 pagesFire protection system philosophy for Collie Urea PlantLorena Dávila100% (1)

- 4895-w2 Standard For Purchase of Forged Flanges and FittingsDocument3 pages4895-w2 Standard For Purchase of Forged Flanges and FittingsLorenaNo ratings yet

- Report DesignerDocument255 pagesReport Designerdgrant775No ratings yet

- Good Cooling Tower PractiseDocument59 pagesGood Cooling Tower Practiseamahmoud3No ratings yet

- Onshore and Offshore: Echnical PresentationDocument66 pagesOnshore and Offshore: Echnical PresentationAnonymous 4MwmDaNbNo ratings yet

- Demonstration of Hydrogen Air-Assisted FlaDocument18 pagesDemonstration of Hydrogen Air-Assisted Flahk168No ratings yet

- Selecting and Designing Branch ConnectionsDocument8 pagesSelecting and Designing Branch ConnectionsLorenaNo ratings yet

- Flare System PDFDocument41 pagesFlare System PDFAzar Deen100% (1)

- Enron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsDocument2 pagesEnron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsLorenaNo ratings yet

- 4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineDocument1 page4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineLorenaNo ratings yet

- 4815 Typical 1 Hot Tap Connection For Farm Tap or Sales MeterDocument1 page4815 Typical 1 Hot Tap Connection For Farm Tap or Sales MeterLorenaNo ratings yet

- 4890 Guide Bar Installation For Weld TeesDocument2 pages4890 Guide Bar Installation For Weld TeesLorena DávilaNo ratings yet

- 4802-w2 Concrete Anchor Block - Installation DetailsDocument2 pages4802-w2 Concrete Anchor Block - Installation DetailsLorenaNo ratings yet

- 4763-w2 Yard Applied Concrete Pipe CoatingDocument7 pages4763-w2 Yard Applied Concrete Pipe CoatingLorena DávilaNo ratings yet

- 4760-w0 Typical Stream or Ditch Pipeline UndercrossingDocument1 page4760-w0 Typical Stream or Ditch Pipeline UndercrossingLorena100% (1)

- 4762-w0 Typical Canal Undercrossing, Lined or UnlinedDocument1 page4762-w0 Typical Canal Undercrossing, Lined or UnlinedLorenaNo ratings yet

- 4758-w0 Restoration of TerracesDocument1 page4758-w0 Restoration of TerracesLorenaNo ratings yet

- 4748-w0 Typical Pipeline and Casing Support at Cased UndercrossingsDocument1 page4748-w0 Typical Pipeline and Casing Support at Cased UndercrossingsLorenaNo ratings yet

- 4752-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Railroad UndercrossingDocument1 page4752-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Railroad UndercrossingLorenaNo ratings yet

- 4747-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Cased Highway UndercrossingDocument1 page4747-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Cased Highway UndercrossingLorenaNo ratings yet

- Erc111 DKRCC - Es.rl0.e3.02 520H8596Document24 pagesErc111 DKRCC - Es.rl0.e3.02 520H8596Miguel BascunanNo ratings yet

- San Unit-Wise QuestionsDocument6 pagesSan Unit-Wise QuestionsSushmitha KodupakaNo ratings yet

- VCTDS 00543 enDocument62 pagesVCTDS 00543 enguido algaranazNo ratings yet

- Product Presentation Nova Blood Gas AnalyzerDocument38 pagesProduct Presentation Nova Blood Gas Analyzerlaboratorium rsdmadani100% (1)

- Color Order SystemsDocument30 pagesColor Order SystemsBeyene DumechaNo ratings yet

- CH 07Document27 pagesCH 07Jessica Ibarreta100% (1)

- Centrifugal Compressor Operation and MaintenanceDocument16 pagesCentrifugal Compressor Operation and MaintenanceNEMSNo ratings yet

- CobolDocument224 pagesCobolrahulravi007No ratings yet

- Sec 2 French ImmersionDocument1 pageSec 2 French Immersionapi-506328259No ratings yet

- Delphi 9322a000Document5 pagesDelphi 9322a000BaytolgaNo ratings yet

- ICSE Mathematics X PapersDocument22 pagesICSE Mathematics X PapersImmortal TechNo ratings yet

- Haidarali-MR-2011-PhD-Thesis 01 PDFDocument378 pagesHaidarali-MR-2011-PhD-Thesis 01 PDFIbrahim KhanNo ratings yet

- Displaymax JR 1500 SpecsDocument1 pageDisplaymax JR 1500 SpecsFRANCISCONo ratings yet

- DC Machines Chapter SummaryDocument14 pagesDC Machines Chapter SummaryMajad RazakNo ratings yet

- Superconductivity in RH S and PD Se: A Comparative StudyDocument5 pagesSuperconductivity in RH S and PD Se: A Comparative StudyChithra ArulmozhiNo ratings yet

- ISO 8243 2013 Cigarettes - SamplingDocument18 pagesISO 8243 2013 Cigarettes - SamplingEko YuliantoNo ratings yet

- GAS-INSULATED SWITCHGEAR MODELS 72kV ADVANCED ENVIRONMENTALLY FRIENDLYDocument6 pagesGAS-INSULATED SWITCHGEAR MODELS 72kV ADVANCED ENVIRONMENTALLY FRIENDLYBudi SantonyNo ratings yet

- Control Lights with SOU-1 Twilight SwitchDocument1 pageControl Lights with SOU-1 Twilight SwitchjsblNo ratings yet

- Operational Guidelines For VlsfoDocument2 pagesOperational Guidelines For VlsfoИгорьNo ratings yet

- 02-OceanStor Dorado 3 Highlights and 9 Must-Know Points 1.0Document5 pages02-OceanStor Dorado 3 Highlights and 9 Must-Know Points 1.0QQNo ratings yet

- 01-Jul-21 03:32 PMDocument6 pages01-Jul-21 03:32 PMramNo ratings yet

- Material Balance of Naphtha Hydrotreater and Reformer ReactorsDocument22 pagesMaterial Balance of Naphtha Hydrotreater and Reformer ReactorsSukirtha GaneshanNo ratings yet

- Physical parameters shaping of Farwa Lagoon - LibyaDocument7 pagesPhysical parameters shaping of Farwa Lagoon - LibyaAsadeg ZaidNo ratings yet

- Geotehnical Engg. - AEE - CRPQsDocument48 pagesGeotehnical Engg. - AEE - CRPQsSureshKonamNo ratings yet

- Data AnalysisDocument7 pagesData AnalysisAndrea MejiaNo ratings yet

- MongoDB Replication Guide PDFDocument106 pagesMongoDB Replication Guide PDFDante LlimpeNo ratings yet

- Propeller forces and typesDocument2 pagesPropeller forces and typesEdison Gutierrez CapunoNo ratings yet

- Inferential Statistics: Estimation and Confidence IntervalsDocument19 pagesInferential Statistics: Estimation and Confidence IntervalsHasan HubailNo ratings yet

- Design & Fabrication of a Cost-Effective Agricultural DroneDocument57 pagesDesign & Fabrication of a Cost-Effective Agricultural DroneFatima Nasir R:29No ratings yet