Professional Documents

Culture Documents

Assignment 2016

Uploaded by

Rama KrishnaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assignment 2016

Uploaded by

Rama KrishnaCopyright:

Available Formats

UNIVERSITI TUNKU ABDUL RAHMAN

FACULTY OF ENGINEERING AND SCIENCE

ASSIGNMENT

Unit Code and title

UEMK 3313 Chemical Process Control and Instrumentation

Course

Bachelor of Engineering (Hons) Chemical Engineering

Semester

January 2016

Lecturer

Ir Dr Lee Tin Sin

Due Date

24th March 2016 (Reminder: 1 mark reduction for each day delay)

Group Assignment (4 to 5 persons group)

Supreme Solution Inc is a consultancy film on chemical process development. Recently, they are awarded by a giant petrochemical

company to conduct a preliminary study on the vinyl acetate production process. Your team is so fortunate to be assigned by the

project director to handle the process control and instrumentation setup of the vinyl acetate production plant. Vinyl acetate is an

organic compound with the formula CH3COOCH=CH2, a colorless liquid with a pungent odor, it is the precursor to polyvinyl acetate,

an important polymer in industry. Your team is required to design the most appropriate process control strategies and the related

instrumentations for the vinyl acetate production as shown in the process flow diagram of Figure 1. The control system is preferred to

be as simple and economical as possible but sufficiently and efficiently to cater for the control purpose according the process

description and contraints. The final report which submitting to director should include the following:

Page 1 of 7

UNIVERSITI TUNKU ABDUL RAHMAN

FACULTY OF ENGINEERING AND SCIENCE

1) Provide an overall description of vinyl acetate production technology.

2) Describe your control functions/strategies and justify the instruments selection.

3) Explain the function(s) of each instrument applied to the control system.

Some basic control requirements are provided by the manager as follows for the reaction process of vinyl acetate:

PROCESS REQUIREMENTS

1. Basic Control Requirement

The reactions take place in the reactor::

Main reaction: C2H4 + CH3COOH + O2

Side reaction: C2H4 + 3O2

CH2=CHOCOCH3 + H2O (exothermic = 176.2 kJ/mol)

2CO2 + 2H2O (highly exothermic = 1323 kJ/mol)

Process constraints

1. O2 concentration must not exceed 8 mol% anywhere in the gas recycle loop to remain outside the explosivity envelope of

ethylene.

2. The pressure in the gas recycle loop and distillation column cannot exceed 965 kPa because of the mechanical construction

limit of the vessels.

3. The peak reactor temperature along the length of the tube must remain below 200 oC to prevent mechanical damage to the

catalyst.

Page 2 of 7

UNIVERSITI TUNKU ABDUL RAHMAN

FACULTY OF ENGINEERING AND SCIENCE

4. Reactor inlet temperature and the hot side exit temperature from the feed-effluent heat exchanger (FEHE) must remain above

130 oC to avoid condensation of liquid.

5. In the distillation column, the acetic acid in the decanter organic phase must not exceed 600 ppm as a product specification.

6. The VAc composition in the bottoms stream must remain below 100 ppm to prevent polymerization and fouling in the reboiler

and vaporizer.

7. Inert ethane (C2H6) is fed together with fresh ethylene stream as impurity.

2. Safety Control Requirement

Since this system involves corrosive and highly flammable chemical. Please indicate the additional instrumentations required to

ensure safe operation during some unexpected circumstances such as malfunction of control system.

3. Relevant information to task

Important aspects to consider:

1) Efficiency of the process controls.

2) Moment of power interruption/emergency shutdown

3) Minimizing instruments cost by minimizing usage of controller and mechanical-elctromagnetic converter (MEC) or MEC

containing equipment.

Page 3 of 7

UNIVERSITI TUNKU ABDUL RAHMAN

FACULTY OF ENGINEERING AND SCIENCE

List of applicable instruments:

Measuring device

1) Level sensor/switch (high level- HL & low level- LL), level sensor/transmitter (point type- LS or continuous type- CLT)

2) Flow meter (FM), flow sensor/indicator (FS/FI).

3) Resistance Temperature Detectors (RTD), thermocouple wires (T), temperature gauge (TG), temperature indicator (TI).

4) Pressure sensor/transmitter (PT), pressure indicator (PI), pressure gauge (PG)

5) Composition analyzer/transmitter (AT).

Controller & transducer

1) Level controller (LC)

2) Flow controller (FC)

3) Temperature controller (TC)

4) Pressure controller (PC), pressure switch (PS)

5) I/P transducer (IP)

6) Composition controller (CC)

7) Composition analyzer controller (AC)

8) Ratio controller (RC)

9) Solenoid valve/switch (SV/SS)

*Electrical motors can be interlocked with other instruments directly via switching contactor (CS).

Page 4 of 7

UNIVERSITI TUNKU ABDUL RAHMAN

FACULTY OF ENGINEERING AND SCIENCE

Final Control Element

1) Actuated valve (AV), control valve (CV), pressure relief valve (PV).

NOTICE: Please refer to recommended references for a more precise/common symbol & abbreviation.

Contents of the report

1) Brief explanation on the overall vinyl acetate production process for about 1000 words with 2 Figures and 2 Tables are allowed

only. All references must be cited according to UTAR Thesis/FYP standard. At least 5 papers/book chapters must be referred.

NO INTERNET REFERENCES ARE ALLOWED- i.e. WIKIPEDIA. Recommend to search from ScienceDirect, Wiley

Interscience and Springerlink database.

2) The report should introduce the type of control strategies and its advantages. The basic functions of each control system

component & how they related to control objectives need to be explained. The Process Flow Diagram must be REDRAWN

using the STANDARD SYMBOLS for each type of instruments (process & instrumentation diagram- P & ID). Recommended

tool; Microsoft Visio Technical drawing software.

REMINDER: This assignment contributes 15% out of the 40% of the total coursework marks.

Page 5 of 7

UNIVERSITI TUNKU ABDUL RAHMAN

FACULTY OF ENGINEERING AND SCIENCE

RECOMMENDED REFERENCES:

1) Perrys Chemical Engineers Handbook 7th Ed. (1997). McGraw-Hill.

2) Turton, R., Bailie, R. C., Whiting, W. B. and Shaeiwitz, J. A. (2009). Analysis, Synthesis and Design of Chemical Processes.

Prentice Hall.

3) McAvinew, T. and Mulley, R. (2004). Control System Documentation- Applying Symbols and Identification 2 edition. The

Instrumentation, System, and Automation Society.

Page 6 of 7

UNIVERSITI TUNKU ABDUL RAHMAN

FACULTY OF ENGINEERING AND SCIENCE

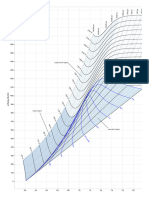

Figure 1 Process flow diagram of the vinyl acetate monomer production plant

Page 7 of 7

You might also like

- HAZOP STUDY Report (Kutch Chemical Industries Limited)Document82 pagesHAZOP STUDY Report (Kutch Chemical Industries Limited)kanakarao173% (11)

- EPRI 2011 Boiler & Turbine Steam & Cycle Chemistry - Program 64Document13 pagesEPRI 2011 Boiler & Turbine Steam & Cycle Chemistry - Program 64pipedown45650% (2)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Risk Assessment & AnalysisDocument9 pagesRisk Assessment & AnalysisbobyNo ratings yet

- Process Safety Management (PSM) : General Awareness TrainingDocument18 pagesProcess Safety Management (PSM) : General Awareness Trainingrpercy01No ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- ABAP Training PlanDocument4 pagesABAP Training PlanAhmed HamadNo ratings yet

- TIGERAS-NPC2018 - HPC Commissioning Paper-DEFDocument16 pagesTIGERAS-NPC2018 - HPC Commissioning Paper-DEFTigerasNo ratings yet

- Prior To The Purchase of Control Equipment,.Experience Has T" 1"Ffi:Triffit :ffi :T:Ii, :L 'Il:':Xi :T"H"LDocument11 pagesPrior To The Purchase of Control Equipment,.Experience Has T" 1"Ffi:Triffit :ffi :T:Ii, :L 'Il:':Xi :T"H"LPhoebe Sam Siow YiNo ratings yet

- D C, P, C M E U E T, L (N C) : Important Instructions For StudentsDocument3 pagesD C, P, C M E U E T, L (N C) : Important Instructions For Studentsumair saleemNo ratings yet

- Assignment Saponification of Ethyl Acetate: Universiti Tunku Abdul RahmanDocument3 pagesAssignment Saponification of Ethyl Acetate: Universiti Tunku Abdul RahmanAllan ChongNo ratings yet

- ch32b Midterm1 2005Document8 pagesch32b Midterm1 2005Nguyễn Tiến DũngNo ratings yet

- Solution Manual For Introduction To Process Technology 4th Edition Thomas 9781305251472Document17 pagesSolution Manual For Introduction To Process Technology 4th Edition Thomas 9781305251472gregory100% (1)

- (Marko Zlokarnik) Scale-Up in Chemical EngineeringDocument9 pages(Marko Zlokarnik) Scale-Up in Chemical EngineeringakilaprabuNo ratings yet

- Design of A New Chemical Injection Pump System For Gas Hydrate InhibitionDocument4 pagesDesign of A New Chemical Injection Pump System For Gas Hydrate InhibitionJohnNo ratings yet

- How To Write A Plant Operating ManualDocument3 pagesHow To Write A Plant Operating Manualsj_scribd100% (1)

- PH ControlDocument10 pagesPH Controllux0008No ratings yet

- Course Code: 4360504Document9 pagesCourse Code: 4360504Abhishek ThummarNo ratings yet

- AstroUV Turbo - HACH New ProductDocument4 pagesAstroUV Turbo - HACH New ProductprannoyNo ratings yet

- Rojas 2021Document158 pagesRojas 2021angelospNo ratings yet

- Automation of Cleaning-In-Place For Food and Beverage Industry Using PLC and SCADADocument7 pagesAutomation of Cleaning-In-Place For Food and Beverage Industry Using PLC and SCADAmhafizanNo ratings yet

- The Structure of Control System of GLP Animal LaboratoryDocument6 pagesThe Structure of Control System of GLP Animal Laboratoryviet_ha04No ratings yet

- Journal of Loss Prevention in The Process Industries Volume 17 Issue 3 2004 (Doi 10.1016/j.jlp.2003.11.003)Document7 pagesJournal of Loss Prevention in The Process Industries Volume 17 Issue 3 2004 (Doi 10.1016/j.jlp.2003.11.003)Dori BarreirosNo ratings yet

- Evaluating The Condition & Remaining Life of Older Power PlantsDocument12 pagesEvaluating The Condition & Remaining Life of Older Power PlantsDanie-ElsNo ratings yet

- Units Description (Petroleum)Document6 pagesUnits Description (Petroleum)Amar BenAmarNo ratings yet

- Hach APA-6000 High Range Hardness AnalyzerDocument28 pagesHach APA-6000 High Range Hardness Analyzermcschuster6879No ratings yet

- PDC PedagogyDocument125 pagesPDC PedagogyPawan ChaudhariNo ratings yet

- Control and Automation of An Industrial Food DryerDocument9 pagesControl and Automation of An Industrial Food DryerNEFTALI VAZQUEZ ESPINOSANo ratings yet

- An Introduction To Boiler Control Systems R1Document35 pagesAn Introduction To Boiler Control Systems R1Smiss KarlNo ratings yet

- PIP PCEIA001 (2016) - Instrument Air Systems GuidelinesDocument12 pagesPIP PCEIA001 (2016) - Instrument Air Systems Guidelinesjoana ramirezNo ratings yet

- Material On Process DigramsDocument47 pagesMaterial On Process Digramsram uoNo ratings yet

- Measurement Task (4) (D2)Document7 pagesMeasurement Task (4) (D2)Medo ElzaeemNo ratings yet

- Ethanol Plant Commissioning Startup and ShutdownDocument5 pagesEthanol Plant Commissioning Startup and Shutdowntsrinivasan5083No ratings yet

- Indoor Air Quality Assessment in An Office BuildinDocument9 pagesIndoor Air Quality Assessment in An Office BuildinDeva RajNo ratings yet

- Industrial Control: (A B.Sc. Course)Document20 pagesIndustrial Control: (A B.Sc. Course)ShannonDaiiannaDalgoNo ratings yet

- Temperature Optimization of A Naphtha Splitter UnitDocument10 pagesTemperature Optimization of A Naphtha Splitter UnitSalma TajNo ratings yet

- Mechanical Practice ExamDocument20 pagesMechanical Practice ExamRazif Rasheed78% (9)

- Pics Verificaci N de Instalaciones PDFDocument11 pagesPics Verificaci N de Instalaciones PDFMario Vazquez BNo ratings yet

- A770 A790 Ce Emi ReportDocument56 pagesA770 A790 Ce Emi ReportthanatitosNo ratings yet

- Development of PLC Program For Multi-Process ParamDocument11 pagesDevelopment of PLC Program For Multi-Process Paramrullyhimawan.tmmjNo ratings yet

- Process Control PCT301T ProjectDocument29 pagesProcess Control PCT301T ProjecterickamitzNo ratings yet

- Nonlinear Model Predictive Control of PH in Rolling Mill Wastewater TreatmentDocument5 pagesNonlinear Model Predictive Control of PH in Rolling Mill Wastewater TreatmentHammad JoufarNo ratings yet

- Organic Fine ChemicalsDocument456 pagesOrganic Fine ChemicalsWellfroNo ratings yet

- Module 1 Pneumatics LectureDocument6 pagesModule 1 Pneumatics LectureABDULLA MOHAMED AHMED JASIM ASHOORNo ratings yet

- TIGER Knowledge Based Gas Turbine Condition Monito PDFDocument15 pagesTIGER Knowledge Based Gas Turbine Condition Monito PDFchdiNo ratings yet

- AME6015 AssignmentDocument5 pagesAME6015 AssignmentRasogya PubudumaliNo ratings yet

- PDFDocument49 pagesPDFTITANIUM ALFREDONo ratings yet

- PH SystemsDocument12 pagesPH Systemslux0008No ratings yet

- Headspace Oxygen Measurement in Vials and AmpoulesDocument4 pagesHeadspace Oxygen Measurement in Vials and AmpoulesGhanta Ranjith KumarNo ratings yet

- Legendair: Service ManualDocument169 pagesLegendair: Service ManualagustinldgNo ratings yet

- Method Statement For Chemical Protection ProgramDocument10 pagesMethod Statement For Chemical Protection Programgökhan oğuzNo ratings yet

- Split Air Conditioner TrainerDocument2 pagesSplit Air Conditioner TrainerAhmed AzadNo ratings yet

- High-Integrity Pressure Protection System: Traditional SystemsDocument4 pagesHigh-Integrity Pressure Protection System: Traditional SystemsgowtemdmNo ratings yet

- Inductive Logic Programming ForDocument13 pagesInductive Logic Programming ForCS & ITNo ratings yet

- Hipps - Azade To CeoDocument48 pagesHipps - Azade To Ceoazade_qasemi100% (2)

- Process Safety ManagementDocument41 pagesProcess Safety ManagementJohn Lasswell100% (2)

- Practical Control of Electric Machines: Model-Based Design and SimulationFrom EverandPractical Control of Electric Machines: Model-Based Design and SimulationNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Chapter 13 Law of AgencyDocument6 pagesChapter 13 Law of AgencyRama Krishna100% (1)

- 7 Ponggal Vizha: AcknowledgementDocument2 pages7 Ponggal Vizha: AcknowledgementRama KrishnaNo ratings yet

- Etbe 3Document33 pagesEtbe 3Rama KrishnaNo ratings yet

- Chapter 7 - Criminal LawDocument12 pagesChapter 7 - Criminal LawRama KrishnaNo ratings yet

- Becoming Jane-Selbourne Wood-SheetMusicDownload PDFDocument2 pagesBecoming Jane-Selbourne Wood-SheetMusicDownload PDFRama KrishnaNo ratings yet

- Chapter 4 Nominal and Effective Interest RateDocument42 pagesChapter 4 Nominal and Effective Interest RateRama Krishna100% (1)

- Ch10 DepreciationDocument18 pagesCh10 DepreciationRama KrishnaNo ratings yet

- Example of QuestionDocument5 pagesExample of QuestionRama KrishnaNo ratings yet

- Lecture 1-Additional NotesDocument7 pagesLecture 1-Additional NotesRama KrishnaNo ratings yet

- UEME2133 Engineering Materials IntroductionDocument12 pagesUEME2133 Engineering Materials IntroductionRama KrishnaNo ratings yet

- Molar Fraction Vs Temperature: Temperatue (°C)Document3 pagesMolar Fraction Vs Temperature: Temperatue (°C)Rama KrishnaNo ratings yet

- CLDocument12 pagesCLRama Krishna100% (1)

- L10 Nonelementary RxnsDocument34 pagesL10 Nonelementary RxnsRama KrishnaNo ratings yet

- Tutorial 1 Answer Q3 Q4Document1 pageTutorial 1 Answer Q3 Q4Rama KrishnaNo ratings yet

- Semi-Gauss Elimination: R1 R2 R3 R4 R5Document4 pagesSemi-Gauss Elimination: R1 R2 R3 R4 R5Rama KrishnaNo ratings yet

- Simplex Method: Leather Limited Manufactures Two Types of BeltsDocument8 pagesSimplex Method: Leather Limited Manufactures Two Types of BeltsRama KrishnaNo ratings yet

- Discussion 3A (Mid-Term Preparation)Document1 pageDiscussion 3A (Mid-Term Preparation)Rama KrishnaNo ratings yet

- UEMK3313 Chemical Process Control and Instrumentation: G S Ke G S G G G G G G C W KDocument3 pagesUEMK3313 Chemical Process Control and Instrumentation: G S Ke G S G G G G G G C W KRama KrishnaNo ratings yet

- UEMK3313 Chemical Process Control and InstrumentationDocument4 pagesUEMK3313 Chemical Process Control and InstrumentationRama KrishnaNo ratings yet

- PPT5. SeptIITK - Crystal - Imperfections - DislocationsDocument92 pagesPPT5. SeptIITK - Crystal - Imperfections - DislocationsKartik Shankar KumbhareNo ratings yet

- LCS21 - 35 - Polar PlotsDocument14 pagesLCS21 - 35 - Polar Plotsgosek16375No ratings yet

- Research FinalDocument29 pagesResearch FinalLaw VesperaNo ratings yet

- PR100 BrochureDocument28 pagesPR100 Brochuregus289No ratings yet

- Lexium 23 Plus - BCH0802O12A1CDocument4 pagesLexium 23 Plus - BCH0802O12A1Cagungch100% (1)

- Mohamad Fakhari Mehrjardi - 1Document18 pagesMohamad Fakhari Mehrjardi - 1Hilmi SanusiNo ratings yet

- Prosper & Sucker RodDocument20 pagesProsper & Sucker RodOmar AbdoNo ratings yet

- ElectrolysisDocument3 pagesElectrolysisRaymond ChanNo ratings yet

- TR 94 13Document25 pagesTR 94 13Christian Norambuena VallejosNo ratings yet

- Mollier Enthalpy Entropy Chart For Steam - US UnitsDocument1 pageMollier Enthalpy Entropy Chart For Steam - US Unitslin tongNo ratings yet

- Artikel Ilmiah Aulia Sekar Pramesti 181100006Document13 pagesArtikel Ilmiah Aulia Sekar Pramesti 181100006auliaNo ratings yet

- Gauss Method - Nisan 15Document1 pageGauss Method - Nisan 15Otis ArmsNo ratings yet

- Experimental Techniques For Low Temperature Measurements PDFDocument2 pagesExperimental Techniques For Low Temperature Measurements PDFVanessaNo ratings yet

- Honda IDSI SM - 5 PDFDocument14 pagesHonda IDSI SM - 5 PDFauto projectNo ratings yet

- Processing of Synthetic Aperture Radar Images - H. Maitre (Wiley, 2008) WWDocument411 pagesProcessing of Synthetic Aperture Radar Images - H. Maitre (Wiley, 2008) WWbehzad100% (4)

- Python Unit 1Document18 pagesPython Unit 1Rtr. Venkata chetan Joint secretaryNo ratings yet

- Rr410209 High Voltage EngineeringDocument7 pagesRr410209 High Voltage EngineeringSrinivasa Rao GNo ratings yet

- AWK - WikipediaDocument1 pageAWK - WikipediachassisdNo ratings yet

- Solved Worksheet-Cell and Specialized Cells 3Document3 pagesSolved Worksheet-Cell and Specialized Cells 3Everything Everything100% (1)

- BCIT COMP 8505 Final Project Covert Channel Exfiltration by Wesley Kenzie, June 2011Document39 pagesBCIT COMP 8505 Final Project Covert Channel Exfiltration by Wesley Kenzie, June 2011Wesley KenzieNo ratings yet

- 2D Pipeline Bottom Roughness - Mochammad ImronDocument6 pages2D Pipeline Bottom Roughness - Mochammad ImronLK AnhDungNo ratings yet

- Brazil (1997) The Communicative Value BW PDFDocument200 pagesBrazil (1997) The Communicative Value BW PDFJuan LopezNo ratings yet

- 3 Perform Industry CalculationsDocument90 pages3 Perform Industry CalculationsRobinson ConcordiaNo ratings yet

- OODBMSDocument19 pagesOODBMSashimsarkar2006No ratings yet

- Mit BBM (Ib), Ipm-Session 2.4Document32 pagesMit BBM (Ib), Ipm-Session 2.4Yogesh AdhateNo ratings yet

- Ugc Model Curriculum Statistics: Submitted To The University Grants Commission in April 2001Document101 pagesUgc Model Curriculum Statistics: Submitted To The University Grants Commission in April 2001Alok ThakkarNo ratings yet

- Script Track IP TermuxDocument5 pagesScript Track IP TermuxAsepNo ratings yet

- Robot Sensors and TransducersDocument176 pagesRobot Sensors and TransducerssakthivelNo ratings yet

- Valence Bond Theory VBTDocument32 pagesValence Bond Theory VBTAsif AhnafNo ratings yet