Professional Documents

Culture Documents

On Hill's Stress Rate in The Continuum Mechanics of Polycrystals

Uploaded by

Chandra ClarkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

On Hill's Stress Rate in The Continuum Mechanics of Polycrystals

Uploaded by

Chandra ClarkCopyright:

Available Formats

Acta Mechanica 14, 183--187 (i972)

@ by Springer-Verlag 1972

On Hill's Stress Rate in the Continuum Mechanics of Polyerystals*

By

K. S. Havner, Raleigh, N o r t h Carolina

With 1 Figure

(Received December 11, 1970, revised April 12, 1971)

Summary-

Zusammenfassung

On Hill's Stress Rate in the Continuum Mechanics of Polyerystals. The lattice corotational stress rate, suggested by HILL [i], is contrasted with the "material" co-rotational

(Jaumann-Zaremba)

stress rate and shown to be preferred in phenomenological continuum

models of crystal behavior. A simple application to a crystal deforming via quasi-static

single slip is included.

Zur Hillsehen Spannungsgeschwindigkeit in der Kontinuumsmechanik yon Vielkristallen. Die yon HILL [1] vorgeschlagene, mit dem Gitter mitrotierende Spannungsgeschwindigkeit wird d e r m i t der Materie mitrotierenden (Jaumann-Z~remba) gegeniibergestellt. Es wird gezeigt, daft erstere in einem ph~nomenologischen Kontinuumsmodell des

Kristallverhaltens vorzuziehen ist. Eine einfache Anwendung auf den durch quasistatisches

Gleiten sich verformenden Kristall wird angegeben.

1. Introduction

HILL [1], in an i m p o r t a n t paper devoted to the consequences of a general

hardening law in crystal plasticity, mentions in passing t h a t "within attainable

limits of a c c u r a c y " a suitable choice of stress-rate is the time derivative of Cauchy

stress on "coordinates rotating b u t n o t deforming with the lattice". I t is our

purpose herein to elaborate u p o n Hill's definition, showing t h a t in the c o n t i n u u m

physics of crystals and polycrystals it is to be preferred over the well k n o w n

J a u m a n n - Z a r e m b a stress-rate. Indeed, t h e adoptio n of the latter within c o n stitutive equations, as advocated b y TltO~AS [2] in a paper addressed to this

same topic, is clearly inappropriate.

2. Physical Preliminaries and Deformation Mechanisms

We

within

smooth

Hence,

consider the deformation of a crystal grain, whose typical dimension

a moderately fine-grained aggregate i s 10-1 ram, say, to be relatively

as viewed b y an observer who can resolve distances down to 10 -8 ram.

a material " p o i n t " in the c o n t i n u u m model has dimensions of order

* This work was supported by the Office of Naval Research and by the Advanced Research Projects Agency of the Department of Defense under Contract No. N00014-68-A-0187.

184

K.S. H~V~Ea:

10-4_10 3 mm. Dislocated geometries of the underlying lattice (with atomic

distances in the range 10- v - 10 -6 mm) are not considered. The mechanical behavior

of the grain is thus taken to be representable via phenomenological laws referred to

tile undislocated lattice structure (in the tradition of the classic single crystal

studies of the 1920's [3, 4]). The mechanisms of deformation are two: (a) elastic

(recoverable) infinitesimal strain of the lattice and (b) simple glide, on welldefined crystallographic slip systems, which translates material "lines" of points

relative to one another but leaves the crystal structure unchanged.

Let X represent a material point whose coordinates in the undeformed crystal

are Xi relative to a Cartesian reference frame. The position of X in a deformed

configuration at time t is expressed by

x = Z ( x , t).

(1)

We denote unit vectors in the normal and glide directions of the/cth crystallographic slip system by n ~, b ~, respectively, and define N ~, ~(2k as the symmetric

and antisymmetric parts of the tensor (dyadic) product 5 k @ n 1r Referred to a

rigid rectangular coordinate system ~j rotating with the lattice at X, these

vectors are expressed

n~L ) = b ~ h z,

b~L) = m j ~ h J.

(2)

wherein the subscript (L) refers to the lattice and the h z are unit base vectors of

the Cartesian system ~j. To the order of approximation of infinitesimal lattice

strains, lz~ and m j ~ m a y be taken as constant and equal to the normalized Miller

indices of the k t h slip system, ttence, the physical mechanisms of deformation are

l~inematically independent at X, and the rate of deformation and rate of rotation

tensors can be written

D=y

1 (L @ L T) = ~ @ ~)k N k ,

1

W = 2" (L -- L ~') = m )>e~ ~.

(3)

(4)

L=O_~_

0x~ is the velocity gradient, ~ is the lattice infinitesimal strain rate (velocity

strain), (9 is the spin tensor of the lattice (relative to the x i reference frame) and

~)e is the plastic shear rate in the k t h slip system, as traditionally defined. Alternatively, referred to the ~j lattice frame,

D(L) = e(z) na PkN~L),

in which the tensors N~L) and ~-(L)

oe

W(z) = ~e$2-fL)

(5)

are constant.

3. An Objective Stress Rate

Consider an observer in a Cartesian reference frame xi* undergoing an objectively equivalent motion (see [5], for example) given b y

x* = x*(X, t) = ~(t) ) ( X , t) -1- c(t)

(6)

On Hill's Stress Rate in the Continuum Mechanics of Polycrystals

185

where Q is an orthogonal transformation. Denoting the Cauchy (true) stress

tensor referred to the xi-eoordinates by T, we have

T * = ~ o T 0 ~.

(7)

Taking the material time derivatives of (6) and (7) and utilizing (4) and the

transformation ,o,** = Q ~ k Off,

a_o _ 0 = " * 0

dt - (~'* - - ~ * T *

+ T*(a*) = Q(T

O~

-- oT

(s)

+ T e ) ) Q T,

(9)

and we may define the objective stress rate

= ~v _ ~ T + T ~ .

00)

In terms of the "material" co-rotational (Jaumann-Zaremba) stress rate T [5],

~v = ~v + p k . C ~ T -

pkT.O.~.

(11)

Choosing the x~* frame to coincide with the ~j coordinate system, to*-=--0

and T* = T(z), as strated by HILL [1]. The elastic stress-strain rate equations

relative to the arbitrary x i reference frame are properly expressed (to the same

order of approximation of infinitesimal lattice strains)

i~ = C T

-- CtoT

-t- C T e )

(12)

wherein C is the fourth order elastic compliance tensor and e is the infinitesimal

elastic strain tensor (e = @). Equivalently, @(z) = C(~)T(L)- This is in contrast

to the elastic constitutive equation given in [2] which, in the present notation,

9

0

~

C(~) (T(~) -- Yk

~-(L)

T(z) -~ 7k T(~),O-~L)).

would be @(~)

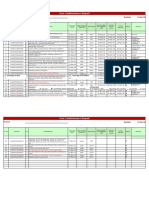

4. An Application to Single Crystal Plastic Deformation

As a simple example of the importance of choosing the Hill (or lattice corotational) stress rate of equation (10) over the Jaumann-Zaremba stress rate,

consider a single crystal specimen deforming via quasi-static single slip, as

illustrated in Fig. 1. We assume a specimen orientation such that the tension axis

(nominal stress a), the glide plane normal, and the slip direction all lie in the plane

of the diagram. For convenience, initial and subsequent positions of the deforming

crystal are depicted as viewed from the lattice (i.e., from the ~j coordinate system)

rather than from a reference frame fixed relative to the loading axis @1, say).

Let T~ denote the critical shear stress (crystal shear strength) in the slip system

and i ~ denote its rate. (~k is a p h e n o m e n o l o g i c a l crystal property and a scalar.)

and 2 are the angles between the loading axis and the unit normals n ~, b ~,

respectively, with ~ v - 2

A Thus (Schmid-Taylor law)

~ = a cos ~v0 cos ~ = tn sin A cos A

(13)

and, upon differentiation,

T/r = -'~ ill sin 2A -~ tll COS 2 ~ ,

(14)

186

K.S. H~v~R:

~,~

a

Fig. 1. Deformation of crystal under uniaxial ~ension due to glide in a single slip system

in which tn is the true stress. Alternatively, from (9), (10) and (13)

(15)

(wherein t r denotes the trace of the tensor product). I t is easily shown t h a t (15)

is equivalent to (14), as follows. Since our canonical representation of the stress

tensor (i.e., tll = a c o s % / c o s g , all other components zero) corresponds to

an xl direction always coincident with the loading axis, both the lattice and the

macroscopic "material" are rotating relative to the reference frame. (The axes 0i

of the figure are convected material "lines".) The associated rate of rotation

tensors are readily found to be

~-~

(16)

0

0

1

o

W

--4-P - i

~- + 1

(17)

0

with ~ and i related through the kinematics of the deformation as

From

i = --~ sin ~4.

(18)

--tlli

(19)

(10) and (16)

0

0

On Hill's Stress l~ate in the Continuum Mechanics of Polycrystals

187

and from the figure and the definition of N ~

I

N ~~

sin 2A

--cos24

--cos2A

--sin 24

!]

.

(20)

Thus, substituting (19) and (20) into (15), the result ia (14) immediately

follows. In contrast, taking ~ ---- t r (N ~~v) would give, from (17), a quite different

and incorrect result far the rate of change of the crystal shear strength during

continued slip.

References

[1] HILL,1~.: Generalized constitutive relations for incremental deformation of metal crystals

by multislip, g. Mech. Phys. Solids 14, 95 (1966).

[2] TEo~As, T. Y. : Constitutive equations for elastic-plastic flow in cubic crystals. J. Math.

Mech. 16, 147 (1966).

[3] Sc~wrID,E. and W. BoAs: Kristallplastizit~t. Berlin: Springer 1935; Plasticity of Crystals

(translation). London: Chapman & Hall. 1968.

[4] The Scientific Papers of Sir G~orrR~Y I ~ a n ~ TxYLOR, Vol. I, Mechanics of Solids

(BATc~ELO~,G. K., ed.). Cambridge: University Press. 1958.

[5] T~VESD~.:Z~,C. and W. Nor,L: Encyclopedia of Physics, Vol. III/3 (FLi)OGE, S., ed.).

Berlin-Heidelberg-New York: Springer. 1965.

Pro]. Dr. Kerry S. Havner

Department o/Civil Engineering

North Carolina State University

Raleigh, NC 27607, U.S.A.

You might also like

- Review of MEP Textbooks FinalDocument10 pagesReview of MEP Textbooks FinalvickyNo ratings yet

- Review of MEP Textbooks FinalDocument10 pagesReview of MEP Textbooks FinalvickyNo ratings yet

- FDA Food - Code 2017 PDFDocument767 pagesFDA Food - Code 2017 PDFfitri widyaNo ratings yet

- Short Circuit Calculation GuideDocument5 pagesShort Circuit Calculation Guideashok203No ratings yet

- Duct FittingsDocument31 pagesDuct FittingsSam Jose100% (7)

- Milbank - U5300 O 75Document2 pagesMilbank - U5300 O 75Chandra ClarkNo ratings yet

- Rheem Prestige Series Package Gas Electric UnitDocument36 pagesRheem Prestige Series Package Gas Electric UnitChandra ClarkNo ratings yet

- Short Circuit Calculation GuideDocument5 pagesShort Circuit Calculation Guideashok203No ratings yet

- Carrier - Rtu - 4 8 F C Da 0 4 A 2 A 5 - 0 A 0 A 0Document158 pagesCarrier - Rtu - 4 8 F C Da 0 4 A 2 A 5 - 0 A 0 A 0Chandra ClarkNo ratings yet

- Commercial Product Specifications: Packaged Gas / ElectricDocument48 pagesCommercial Product Specifications: Packaged Gas / ElectricChandra ClarkNo ratings yet

- Electrical Symbols CS: PVC Film, On SheetDocument13 pagesElectrical Symbols CS: PVC Film, On SheetChandra ClarkNo ratings yet

- TB08104003E Tab 1Document152 pagesTB08104003E Tab 1priyanka236No ratings yet

- 50 Powerful Sales QuestionsDocument19 pages50 Powerful Sales QuestionsChandra Clark100% (2)

- Electrical CodeDocument11 pagesElectrical CodeChandra ClarkNo ratings yet

- Solid Mechanics 94 10Document89 pagesSolid Mechanics 94 10landatoNo ratings yet

- Won't Crack. - . It Just Stretches: Technical DataDocument2 pagesWon't Crack. - . It Just Stretches: Technical DataChandra ClarkNo ratings yet

- What Is A One-Pager?: - E.M. Forster "Only Connect." - E.M. ForsterDocument1 pageWhat Is A One-Pager?: - E.M. Forster "Only Connect." - E.M. ForsterChandra Clark100% (1)

- Modeling Texture, Twinning and Hardening PDFDocument12 pagesModeling Texture, Twinning and Hardening PDFChandra ClarkNo ratings yet

- IELTS Life Skills - Sample Paper A Level A1 PDFDocument4 pagesIELTS Life Skills - Sample Paper A Level A1 PDFAnonymous QRT4uuQ100% (1)

- Konsep Sistem InformasiDocument30 pagesKonsep Sistem InformasiNijar SetiadyNo ratings yet

- ANSYS Release Notes 190 PDFDocument146 pagesANSYS Release Notes 190 PDFAle100% (1)

- Biscay: Tentative Forward ScheduleDocument5 pagesBiscay: Tentative Forward ScheduleChandra ClarkNo ratings yet

- Tensor AnalysisDocument30 pagesTensor AnalysisChandra ClarkNo ratings yet

- Modeling Texture, Twinning and HardeningDocument25 pagesModeling Texture, Twinning and HardeningChandra ClarkNo ratings yet

- Foundations of Tensor Analysis For Students of Physics and Engineering With An Introduction To Theory of Relativity (Nasa)Document92 pagesFoundations of Tensor Analysis For Students of Physics and Engineering With An Introduction To Theory of Relativity (Nasa)Silver Olguín CamachoNo ratings yet

- Physics and Phenomenology of Strain Hardening The FCC Case PDFDocument103 pagesPhysics and Phenomenology of Strain Hardening The FCC Case PDFChandra ClarkNo ratings yet

- ASME & IEEE Engineering Career Fair - Information Package v11Document2 pagesASME & IEEE Engineering Career Fair - Information Package v11Chandra ClarkNo ratings yet

- Waves 2008 11 26Document20 pagesWaves 2008 11 26Chandra ClarkNo ratings yet

- Groma Bako PhysRevLet 2000Document4 pagesGroma Bako PhysRevLet 2000Chandra ClarkNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- GT2000 TurbineplansDocument27 pagesGT2000 TurbineplansSzabolcs Szalai100% (1)

- UploadedFile 130150889032970873Document175 pagesUploadedFile 130150889032970873Sorescu Radu VasileNo ratings yet

- Subject Code Theory of Metal CuttingDocument2 pagesSubject Code Theory of Metal CuttingShimada TadaNo ratings yet

- Foerster Circograph 2014 enDocument6 pagesFoerster Circograph 2014 enTiến NguyễnNo ratings yet

- Centralized Suply of Gas SystemDocument43 pagesCentralized Suply of Gas SystemAmir ChakaNo ratings yet

- Parts IR5000-IR6000Document256 pagesParts IR5000-IR6000Watcharapong KesornsombutNo ratings yet

- Steam Trap LossDocument12 pagesSteam Trap LossVikas SinglaNo ratings yet

- Technical Bulletin: Three Bond 2217HDocument3 pagesTechnical Bulletin: Three Bond 2217HbehzadNo ratings yet

- Maintenance ProblemDocument19 pagesMaintenance Problembgs_ndrtNo ratings yet

- Shell & Tube Gas Heater Data SheetDocument3 pagesShell & Tube Gas Heater Data SheetRobles DreschNo ratings yet

- Chapter 9 - Electron Beam WeldingDocument14 pagesChapter 9 - Electron Beam WeldingrafikdmeNo ratings yet

- Operating Mannua2Document96 pagesOperating Mannua2Ajay Kumar0% (1)

- OPW Fil-Master 600 Series Fast-Fill/Fleet-Fill Noz (CC600)Document5 pagesOPW Fil-Master 600 Series Fast-Fill/Fleet-Fill Noz (CC600)Maung OoNo ratings yet

- Lab ReportDocument16 pagesLab Reportabe97No ratings yet

- Bulk BOQUpload TemplateDocument12 pagesBulk BOQUpload TemplatemargamvivekkumarNo ratings yet

- 9 Catalogo Accesorios de Perforacion para PV 275Document12 pages9 Catalogo Accesorios de Perforacion para PV 275Anonymous kjJfuvMMNo ratings yet

- What is a Foam Pig and how is it usedDocument4 pagesWhat is a Foam Pig and how is it usedyogacruiseNo ratings yet

- Ground Fault Protection GuideDocument56 pagesGround Fault Protection Guidewilliamb285No ratings yet

- Generator TestingDocument2 pagesGenerator Testingraghavendran raghu100% (1)

- SSP 522 - The 2.0-Liter 162 KW 169 KW TSI EngineDocument56 pagesSSP 522 - The 2.0-Liter 162 KW 169 KW TSI Engineotandreto100% (4)

- Tle-Eim Supplies and MaterialsDocument32 pagesTle-Eim Supplies and Materialssheryl victorio100% (1)

- ADP962Document17 pagesADP962thefikeNo ratings yet

- ECODAN AtW Split WWW - ZubadanDocument2 pagesECODAN AtW Split WWW - ZubadanFlorentin GheorghitaNo ratings yet

- Maxlyzer Service Manual PDFDocument37 pagesMaxlyzer Service Manual PDFFidaa JaafrahNo ratings yet

- Thermal Properties of Jute Fiber Reinforced Chemically Functionalized High Density Polyethylene (JF/CF-HDPE) Composites Developed by Palsule ProcessDocument12 pagesThermal Properties of Jute Fiber Reinforced Chemically Functionalized High Density Polyethylene (JF/CF-HDPE) Composites Developed by Palsule ProcessManju ANNo ratings yet

- Vibration Lectures Part 1Document71 pagesVibration Lectures Part 1AshokNo ratings yet

- Why Soft Starts Reduce Motor Stress and Improve ControlDocument5 pagesWhy Soft Starts Reduce Motor Stress and Improve ControlSohJiaJieNo ratings yet

- Mobil Delvac Hydraulic 10w Delvac Hydraulic 10w Delivers Excellent PerformanceDocument2 pagesMobil Delvac Hydraulic 10w Delvac Hydraulic 10w Delivers Excellent PerformanceYordan YupanquiNo ratings yet

- External NCR MonitoringDocument7 pagesExternal NCR MonitoringGhayas JawedNo ratings yet

- Teknokroma Capillary Columns: Trb-WaxDocument1 pageTeknokroma Capillary Columns: Trb-WaxchiralicNo ratings yet