Professional Documents

Culture Documents

WD946-EZ300-00009 Procedure For Painting Rev 0

Uploaded by

Manuel BurdilesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WD946-EZ300-00009 Procedure For Painting Rev 0

Uploaded by

Manuel BurdilesCopyright:

Available Formats

TOTAL 21 PAGES

(Including Cover)

Procedure for Painting

PROJECT CODE

PROJECT NAME : SISTEMA DESULFURIZACION DE GASES DE

Purpose

ESCAPE PARA LA UNIDAD 1 CENTRAL BOCAMINA

For Review

PACKAGE NAME: SEMI DRY FGD SYSTEM

For Approval

DOCUMENT No. : WD946-EZ300-00009

For Construction

TITLE

: Procedure for Painting

For Bid

OWNER

: ENDESA S.A.

For Information

2013-02-15

Rev.

No.

DATE

H.J Cho

PREP

Owner:

Contractor:

J.W Kim D.M. Choi

REVIEW

For Construction

APPR

REVIEW

REVIEW

DESCRIPTION

STX Heavy Industries

ENDESA S.A.

APPR

PROJECT

Procedure for Painting

REV No.

PAGE

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

1 of 20

Contents

1.

2.

3.

3.1.

3.2.

4.

4.1.

4.2.

4.3.

4.4.

4.5.

4.6.

4.7.

5.

6.

7.

8.

8.1.

8.2.

8.3.

8.4.

8.5.

SCOPE ..................................................................................................................................... 2

GENERALS ............................................................................................................................. 2

CODES AND STANDARDS .................................................................................................... 2

Steel Structure Painting Council (SSPC) ................................................................................. 2

ISO 12944 ................................................................................................................................ 2

APPLICATION ......................................................................................................................... 2

Surface to be painted. .............................................................................................................. 2

Surface not to be painted ......................................................................................................... 3

Surface Preparation ................................................................................................................. 3

Painting..................................................................................................................................... 4

Protection of Stainless Steel .................................................................................................... 6

Galvanizing ............................................................................................................................... 6

Touch-up Painting ..................................................................................................................... 7

TESTING & INSPECTION ....................................................................................................... 8

STORAGE OF PAINTS .......................................................................................................... 10

SAFETY ................................................................................................................................. 10

COATING SYSTEM ................................................................................................................11

Application of Materials ...........................................................................................................11

Painting System ......................................................................................................................11

Safety Color Code .................................................................................................................. 15

Final Painting .......................................................................................................................... 15

Piping Color Code .................................................................................................................. 17

PROJECT

Procedure for Painting

1.

REV No.

PAGE

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

2 of 20

SCOPE

This procedure covers the surfaces preparation and application of protective coating for

SISTEMA DESULFURIZACION DE GASES DE ESCAPE PARA LA UNIDAD 1 CENTRAL

BOCAMINA.

2.

3.

GENERALS

1)

All regulations including storage of paint, handling, surface preparation, painting work,

safety, etc, shall be in compliance with KS, SSPC and paint manufacturers specifications.

2)

All painting procedures shall be in compliance with the requirements of SSPC-PA1, this

technical specification and the manufacturers recommendations.

CODES AND STANDARDS

Codes and standards not specified hereafter shall be in compliance with Korean industrial

Standard. The others shall comply with following SSPC standard.

3.1.

Steel Structure Painting Council (SSPC)

1)

SSPC-PA1

: Shop, field and Maintenance Painting

2)

SSPC-PA2

: Measurement of Dry Film Thickness with Magnetic Gages

3)

SSPC-PA Guide 3

: A Guide to Safety in Paint Application

4)

SSPC-SP1

: Sol vent Cleaning

5)

SSPC-SP2

: Hand Tool Cleaning

6)

SSPC-SP3

: Power Tool Cleaning

7)

SSPC-SP5

: White Metal Blast Cleaning

8)

SSPC-SP6

: Commercial Blast Cleaning

9)

SSPC-SP8

: Pickling

10) SSPC-SP10

3.2.

: Near-White Blast Cleaning

ISO 12944

Paints and varnishes - Corrosion protection of steel structures by protective paint systems

4.

APPLICATION

4.1.

Surface to be painted.

1)

General

a) For the selection of painting system, the supplier shall take into account each material

to be painted, insulation, service temperature, etc. If necessary, the constructor who is

carrying out field coating shall execute touch-up painting for shop coating and field

application in accordance with painting standard.

b) All equipment for field weld surface, in case of not using a good weld ability paint,

shall be protected with masking tape or adhesive material within 75mm of field weld.

c) Machined surfaces, bolts, valve stems, gasket surfaces shall be protected with anticorrosive petroleum solvents in accordance with the manufacturers instruction.

2)

Paint of fitting and flanges shall match that of piping.

a) Field fabricated brackets, clips, nozzles, manways, attachments, flanged connections

PROJECT

Procedure for Painting

REV No.

PAGE

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

3 of 20

paint shall match the surfaces of main parts of the equipment.

4.2.

Surface not to be painted

The surfaces of the following products shall not be painted and shall be protected during

painting work.

4.3.

1)

Galvanized, stainless steel, nickel, brass, bronze, copper, lead and aluminum

2)

Non-metallic surfaces : rubber, plastic, glass, gaskets

3)

Metal jacketing over insulation

4)

Concrete foundation surfaces

5)

Machined surfaces, threads and contact surfaces

6)

Valve stems, gland and bonnet bolts, packing and exposed bonnet gasket surfaces

7)

Nameplates and identification tags

8)

Surfaces of field welding parts

Surface Preparation

1)

All surface of carbon steel & Alloy steel shall be blasted, unless otherwise specified,

using dry blasting abrasive only. Blast cleaning shall be carried out in accordance with

surface preparation of coating system in this procedure.

2)

The surface of the component shall be blasted within 2hours prior to coating the

component. If the relative humidity is greater than 80%, blast immediately prior to coating.

Blast cleaning shall not be conducted when the temperature of the surface is less than 3

above dew point of the surrounding air.

3)

Primed areas which suffer damage must be spot blasted or wire brushed, according to

the damage, on site to a degree of cleanliness P Sa 2 1/2, St3 before touching up.

4)

Weld slag and residue, dust or other residue shall be removed completely before painting.

5)

Second coating shall not be applied until the first coating is completely dry in accordance

with the paint manufacturers instructions.

6)

Surface preparation for field coating shall include removal of all mill scale, rust and

foreign matters by compressed air or soft brush, or by water cleaning. Oil or grease shall

be removed by adequate solvent with does not detrimentally effect the surface of first

coat. Zinc dust shall be removed completely on the parts coated with inorganic zinc rich

primer before application of the following coatings.

7)

Oil, grease, and other rust on the surface to be painted shall be cleaned with solvent or

water washed before blast cleaning in accordance with SSPC-SP1.

8)

The surface preparation of masking taped parts shall be in accordance with SSPC-SP3.

9)

The Supplier shall submit surface preparation procedure recommended by Supplier prior

to use.

10) All surfaces shall be blast cleaned whenever possible. When that is not possible (Thin

metal sheet) alternative cleaning shall be done. Such as Pickling, or Power Tool Cleaning.

11) The abrasive employed in blasting shall be such that it will produce a surface roughness

in compliance with specifications. The abrasive shall be dry, clean and free from soluble

contaminants and shall not be reused. Abrasive contaminated with sea salt shall not be

used.

PROJECT

Procedure for Painting

REV No.

PAGE

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

4 of 20

12) The abrasives used for blast-cleaning shall be graded flint, grit, shot or silica sand and

shall be such that they will produce and average keying profile on the blast-cleaned

surface of not more than 120 microns.

13) Saddles or other structure supporting equipment to be rotated during the paint process

shall be a minimum of 1meter in height.

14) No blast cleaning shall be performed during the rainy season. The blasted surface shall

be maintained free of frost or moisture.

15) The blast cleaning compressor shall provide moisture free air with adequate capacity. Oil

and moisture must be purged from compressor system prior to commencing blasting

after any compressor shutdown. Contaminant level is to be checked using a white-clean

cloth.

16) A power-operated wire brush which provides surface gloss shall not be used for cleaning.

17) Shop painted surface shall be protected during surface preparation.

18) All machined surfaces, including flange faces, shall be suitable covered to prevent

damage during surface preparation.

19) Masking tape from shop painting or other adhesive materials shall be removed

completely.

20) Steelwork protected by shop primer after arrival on site must be cleaned of salt, sand, oil,

etc. before the first coat of paint is applied on site. Shop primer damaged during

transport must be rectified by blast or brush cleaning, depending on the damage, and

coating before application of the site coats as bellows

Impurity

Removal

Dust, loose deposits

Vacuum-cleaning, brushing

Adhesive deposits

Power brushing

Oils, greasy impurities

Use of detergent additives by agreement

Salt deposits

Rinsing

Damages,

Burns,

Weld Disc sanding to St 3 according to ISO 8501-1:1988 or

Smoke, Marking, Corroded abrasive sweeping to Sa 2 1/2 According to ISO 8501areas

2:1994.

White Rust

Fresh water hosing and scrubbing with stiff brushes.

a) Surfaces to be coated must be dry and free of all dirt, mildew, chalk, spent abrasive

and any other contaminant of foreign material that could inhibit adhesion.

b) Shop coated surfaces shall be thoroughly cleaned before the application of the prime

coat

21) Should any phase not meet the standard required during inspection, Supplier shall carry

out necessary rectification in accordance with this specification

4.4.

Painting

1)

Painting work shall be performed when the substrate surface is in dry condition. All the

rust, sand, shot ball, grit, oil, grease shall be removed completely.

2)

Where practical, outdoor exposed steel (except stainless steel) bolts, nuts and washers,

including general grade high tensile friction-grip bolts (referred to in B.S. 3139 and S.B.

4395, Part 1) shall be dichromated and subsequently centrifuged.

3)

All carbon steel shall be treated in accordance with this specification.

4)

No paint area such as machined surface (metal to metal contacted surface), bolt threads,

PROJECT

Procedure for Painting

REV No.

PAGE

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

5 of 20

etc shall be coated with rust preventive oil. (Tectyl 506 or equivalent)

5)

Painting shall be commenced within 4 hours after surface preparation. If some sign of

rust might occur even within 4 hours, surfaces shall be prepared again in accordance

with the specification.

6)

Painting shall be proceeded within the temperature limits specified by the manufacturers

recommendation. The general conditions are as follows:

a) Atmospheric temperature

-

The optimum temperature range will be 15~32. In general, painting shall not

be proceeded below 10 or above 38.

Painting shall not be carried out when the steel surface temperature is less than 3

above the dew point.

b) Humidity

-

As the humidity during the painting give much effect on the dry time, the optimum

humidity for painting will be the range of 40-80%. Painting shall be done within the

humidity range of paint manufacturers recommendations.

c) Others

-

Painting shall not be executed outdoors when weather conditions are unsuitable

(i.e. foggy, rainy and windy day). Indoor painting shall only be carried out with

supervisors permission.

If chemical contamination occurs between coats, then water or solvent cleaning

shall be applied before re-coating.

7)

Use of paint thinner shall be in strict accordance with paint manufacturers data sheets.

The thinners shall conform to the paint manufacturers recommendations.

8)

Field welds on items which have been shop coated with inorganic zinc primer shall be

properly prepared before field touch up primer and finishing coats. Slag occurred in

welding work and slag residue shall be removed completely. Grinding or power tool

cleaning shall be executed to comply with SSPC_SP3.

9)

Faying surface of bolted connection (high tension bolted areas) shall be masked to

prevent application of all but the qualified inorganic zinc rich primer. After bolting (high

tension bolted areas), these area shall be coated in accordance with the qualified coating

system.

10) Painting shall be carefully performed at all edges, corners, crevices, rivets, bolts and nuts,

welds and other complex shapes that may be sensitive to rusting. (stripe coating)

11) Dry film thickness (D.F.T)

a) To the maximum extent practical, the coats shall be applied as a continuous film of

uniform thickness and free of pores. Overspray, skips, runs, sags and drips shall be

avoided.

b) The different coats shall not be of the same colour.

c) The minimum total dry film thickness of the paint system shall be as recommended in

the following Coating system below. The D.F.T is given in microns (millionths of a

meter).

12) All parts shall be shop-painted including finishing coats as far as possible. Field painting

will be limited to touch-up repairs to shop finish coats damaged during erection, and field

preparation and painting of field weld areas.

PROJECT

Procedure for Painting

REV No.

PAGE

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

6 of 20

13) Insulated equipment and piping shall be painted with primary coat only on the equipment

surface subject to addressing Contractors comments on the Suppliers painting

specification.

4.5.

Protection of Stainless Steel

1)

The sand blasting and coating shall not be applied on the surface of austenitic stainless

steel and high alloy steel.

2)

Paint, dust, soil(mud clay) and foreign matter on the surfaces of austenitic stainless and

high alloy steel shall be removed with water first. Contaminant not removed by water

shall be cleaned by stainless steel brush. The surfaces of carbon steel shall not be

applied with the brush. Oil and grease shall be removed not by aliphatic or chlorinated

solvent but by clean rags and pure(unstained) aromatic solvent.

3)

Before surface painting, the welding areas of austenitic stainless, high alloy steel and

carbon steel shall be protected as follows.

a)

Large C.S attachment parts (C.S skirt welded to S.S vessel)

-

Where the service temperature is lower than 149, epoxy type paint shall be

coated on each side of 300mm coverage at S.S and C.S welding parts.

Where the service temperature is higher than 150, the modified silicone shall be

coated on each side 300mm coverage at S.S and C.S welding parts.

b) Small C.S attachment part (clips, brackets, flange welding etc.)

-

Where the service temperature is lower than 149, two coats of epoxy type paint

shall be applied to cover the C.S completely.

If the service temperature is higher than 150, two coats of modified silicone shall

be applied. Coating shall be over lapped at least 25mm on the surface of S.S

4.6.

Galvanizing

1)

Galvanizing works shall conform in all respect to ASTM A153 and B.S. 729, B.S. 3083

and B.S.C.P. 2008 and DIN 50976 and to KSD8308 whatever requires the higher quality

and shall be performed by the hot dip process, unless otherwise specified.

2)

It is essential that details of steel members and assemblies which are to be hot-dip

galvanized shall be designed in accordance with B.S. 4479.

3)

Vent-holes and drain-holes shall be provided to avoid high internal pressures and airlocks during immersion, which may cause explosions, and to ensure that molten zinc is

not retained in pockets during withdrawal.

4)

All defects of the steel surface including cracks, surface laminations, laps and folds shall

be removed in accordance with B.S. 4360. All drilling, cutting, welding, forming and final

fabrication of unit members and assemblies shall be completed, where feasible, before

the structures are galvanized. The surface of the steelwork to be galvanized shall be free

from paint, oil, grease and similar contaminants in accordance with DIN 55928, part 4

and DIN 50976. The weight of zinc coating per unit area has to be noted in the

manufacturing documents in accordance with DIN 50976.

5)

The minimum average coating weight shall be as specified in Table 1 of B.S. 729 or

Table 2, DIN 50976, whatever requires higher quality, and the minimum thickness of

galvanizing shall be 4mils(100).

PROJECT

Procedure for Painting

REV No.

PAGE

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

7 of 20

6)

Structural steel item shall be initially grit-blasted to B.S. 4232, second quality (Sa 2 1/2),

or by pickling in a bath and the minimum average coating weight on steel section 5mm

thick and over shall be 900 g/m2.

7)

Galvanized contact surfaces to be joined by high-tensile friction-grip bolts shall be

roughened before assembly so that the required slip factor (defined in B.S. 3294, Part 1

and B.S. 4604, Part 1) is achieved. Care shall be taken to ensure that the roughening is

confined to the area of the mating faces.

8)

Protected slings must be used for off-loading and erection. Galvanized work which is to

be stored at the works or on site shall be stacked so as to provide adequate ventilation to

all surfaces to avoid wet storage staining (white rust)

9)

Small areas of the galvanized coating damaged in any way shall be restored in

accordance with DIN 55928, part A and DIN 50976 by:

a) Cleaning the area of any weld slag rust and other impurities and by thorough wire

brushing to give a metallic clean surface.

b) Application of suitable number of coats of zinc rich paint containing more than 90%

w/w of zinc in dried film

c) The dry film thickness shall exceed at least as of the desired galvanization.

d) The restored area shall not to exceed 1% of the galvanized surface.

4.7.

Touch-up Painting

1)

The Supplier shall touch up before erection in jobsite all destroyed or damaged surfaces

during delivery.

2)

Touch-up painting shall be with brush or airless spray after SSPC-SP3 cleaning. If the

touch up area is wide and blasting operation is possible, spray coating method shall be

applied after re-blasting.

3)

The Supplier shall provide sufficient quantity of touch-up paint of the same types and

colors as applied for shop painting. The Supplier shall provide not less than 5% of total

paint quantity, unless otherwise specified.

a) Bare steel surface where the surface rusts

-

Areas where surface temperature is below 93, and coated with inorganic zinc

rich primer

Surface preparation

Touch-up : Finish coating in accordance with Painting System after primer

coating with epoxy mastic aluminum 100 DFT.

: SSPC- SP2 or SP3

Areas where surface temperature is between 94~399, and coated with

inorganic zinc rich primer.

Surface preparation

Touch-up : Finish coating in accordance with Painting System after primer

coating with inorganic zinc rich primer 75 DFT.

Areas where surface temperature is between 400~600, and coated with silicone.

: SSPC-SP3

Surface preparation

: SSPC-SP3

Primer and finish coats : Silicone more than 50 DFT.

Areas coated with coal tar epoxy, polyamide epoxy, amine adduct epoxy, phenolic

PROJECT

Procedure for Painting

REV No.

PAGE

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

8 of 20

epoxy.

Surface preparation

: SSPC-SP3

Primer and finish coatings shall be in accordance with Painting System. But, in

case of the paint which requires the time interval for repainting. Existing film

shall be overlapped with touch-up painting after re-blasting, sand papering, or

sand sweeping.

Areas coated with Alkid water Reducible Primer

Surface preparation : SSPC-SP2 or SSPC-SP3

Touch-up : Finish coating in accordance with Painting System after primer

coating with Alkid water Reducible primer 40 DFT.

Areas coated with modified epoxy.

Surface preparation : SSPC-SP3

5.

Primer and finish coatings shall be in accordance with Painting System. But, in

case of the paint which requires the time interval for repainting. Existing film

shall be overlapped with touch-up painting after re-blasting, sand papering, or

sand sweeping.

Damage areas of primer, intermediate, top-coats where the steel surface does not

rust.

Surface preparation

Touch-up : Finish coating in accordance with the Painting System, sufficient to

re-establish the specified dry film thickness.

: SSPC-SP1

TESTING & INSPECTION

1)

Painting materials, equipment and working conditions shall be tested and inspected

according to the Suppliers quality assurance procedures which shall be submitted for

OWNERs approval.

2)

The minimum check points for testing & inspection are as follows.

a) Paint

-

Inspection of coating and blasting materials in accordance with materials

specifications

Checking of storage conditions of materials

Before Mixing and application of coating material, Check the following information

listed;

Coating material suppliers name

Product name

Product color designation

Product batch number and manufacturing date

Product shelf life

b) Equipment for painting

-

Checking adequateness of coating, cleaning and blasting equipment

c) Surface preparation

-

Checking the condition in accordance with surface preparation specification

Checking the accuracy of surface preparation in accordance with painting

PROJECT

Procedure for Painting

REV No.

PAGE

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

9 of 20

specification

-

Confirm the blast quality by comparing the blasted surface with SSPC-Vis1 and

verify the height of the anchor pattern profile with an Elcometer roughness gauge

adjusted to profile height

Inspect blasted surfaces immediately before application of the coating as follows

Check dryness by visual inspection.

Check rusting visually. If rusting is detected, surfaces shall be re-blasted until

acceptable.

d) Painting

-

Checking the precision of mixing and screening of inorganic zinc rich primer

Checking the adequateness of environmental condition for paint application

Checking the continuous agitation of inorganic zinc rich paint container during

application

Checking the pot life time of paint

e) Film thickness

-

Checking the wet film thickness of first coat for non-zinc rich primer

Checking the dry film thickness for zinc rich primer

Checking the finish coating of organic coating for making precise film thickness

Checking the film thickness vs. specified film thickness

f) Visual Inspection

-

Check continuously the following coating defects & take immediate corrective

action

Orange peel

Thin film

Film Brush

Over Spray

Surface Contamination

Mildew

Slow Drying Time

Mud Cracking

Blisters

Rust

g) Galvanizing

-

Check appearance

The appearance status after the coating will be confirmed with the visual sight

Galvanized surfaces shall be free from uncoated areas, blisters, flux deposits,

and Lumps, projections, globules, or heavy deposits of zinc which will interfere

with the intended use of the material will not be permitted.

Check Thickness

It will be measured with the Electronic Film Thickness Measuring Device. The

thickness of the coating shall be determined by magnetic thickness gage

measurements in accordance with SSPC-PA2.

h) Adhesion of paint

-

Executing a surface inspection to check bonding between primer and finish

PROJECT

Procedure for Painting

REV No.

PAGE

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

10 of 20

coating.

-

Checking the drying condition of primer before finish coating

i) Repairs

-

Checking all the repair complete.

j) Drying

3)

Checking the drying condition in accordance with transportation, handling and recoating interval instructions (specifications) of paint manufacturer

The list of equipment for checking the painting procedure is as follows;

a) Surface profile roughness gauge

b) Air temperature gauge

c) Steel surface temperature gauge

d) Hygrometer & dew point calculator

e) Wet film thickness gauge

f) Dry film thickness gauge

g) Other related instruments

4)

The surface preparation shall be checked properly in accordance with SSPC and this

specification

5)

Wet film thickness of non-zinc rich paint shall be checked to make sure dry film thickness

during each application (first, second, third coating).

6)

Dry film thickness of painted area shall be checked in accordance with SSPC-PA2.

7)

Periodic checking shall be carried out for the area which might have adhesion problems

between each coatings.

8)

Tester (elcometer adhesion) or higher qualified method shall be used to check the

adhesion condition for doubtful area.

9)

Finished painting shall be checked by Contractors visual inspections.

a) RE-coating or touch-up which did not follow this specification shall be performed

under the responsibility od the Suppliers expense.

10) The Supplier shall submit an inspection report.

6.

STORAGE OF PAINTS

1)

2)

7.

Paint materials shall be stored in a well-ventilated area, free from spark, flame, heat and

direct rays of the sun. Containers for paint shall be turned regularly in accordance with

paint manufacturers recommendation.

Storage of paint shall be in compliance with the paint manufacturers recommendation.

SAFETY

1)

Painting materials to be used for primer and intermediate, finish coating shall be the

product of the same manufacture. In special cases, other paint can be used after

Owners approval through testing.

2)

All painting materials shall be delivered to the field in sealed containers with testing

reports. All paint containers shall be labeled to show product name and mark of

manufacturer.

3)

Surface preparation, painting working conditions and painting materials shall be in

PROJECT

Procedure for Painting

REV No.

PAGE

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

11 of 20

accordance with the latest product data sheet published by the paint manufacturer in

addition to the requirements in this specification.

4)

Painting shall be performed with the application of safe working methods considering the

health and safety workers and other personnel.

5)

As painting materials include solvent and other chemical constituents, all prudent

precautions shall be taken to ensure the safety of personnel during storage, handling,

painting and drying.

6)

Most paints contain flammable liquids and are thus a fire hazard. Equipment, lighters,

etc., eating a park or flame shall be kept away from working area. No smoking will be

allowed in working areas. All electric equipment shall be spark free.

7)

Food preparation and eating place shall be separate from painting area.

8)

When indoor coating is required, ventilation shall be provided to prevent workers from

inhaling vapors of solvent, dust and paints. Fan(s) shall be set up at lower section of

work area and ventilator shall be set up at upper section of work area.

9)

Worker shall wear safety mask and face protector.

10) The foothold (or scaffold) shall be set up to insure worker safety and shall be checked

regularly. Safety net shall be provided protect worker.

11) Worker must wear face goggles during painting.

12) When handing painting materials for a long time, worker shall wear gloves, protection

cloth, face protector, food mask and goggles to prevent toxic effects. Protective creams

and lotions are often used on hands, arms and face. If workers skin is stained with paint,

clean the skin with adequate solvent and soap.

13) Adequate fire-fighting equipment shall be installed to protect against a fire in paint

storage place.

8.

COATING SYSTEM

8.1.

Application of Materials

1)

Painting system for complete vendor product

a) The type and number of protective coating for complete vendor items which requires

corrosion protection shall be in accordance with the technical specification of maker

standard.

b) Final color of complete vendor product shall be applied in accordance with Customer

requirements. If final color is not requirement with Customer requirements, it shall be

applied in accordance with manufacturers Standard Color.

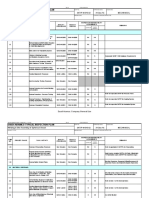

8.2.

Painting System

Application

No

Surface

Preparation

Description

No

of

coat

Min.

Paint Type

DFT

()

Remark

Work

Scope

Surface Temp

()

Shop

75~134

Spray Dryer

Absorber(SDA)

Out

side

SP 10

1st

Inorganic

zinc

silicate primer

75

Insulated

-Sherwin

Williams

PROJECT

Procedure for Painting

In

side

SP 10

Out

side

In

side

Inorganic

zinc

silicate primer

30

Shop

SP 10

1st

Inorganic

zinc

silicate primer

75

Shop

SP 10

1st

Inorganic

zinc

silicate primer

30

Shop

1st

Inorganic Zinc

Silicate primer

H.B Polyamide

Epoxy

75

Shop

75

Shop

75

Shop

st

Out

side

SP 10

2nd

3rd

In

side

SP 10

Atomizer

Tank

Feed

Out

side

SP 10

2nd

3rd

In

side

SP 10

12 of 20

75(continuous.)

134(rarely)

Storage Tank

-Recycle

slurry

storage tank

-Lime

slurry

storage tank

Out

side

SP 10

2nd

3rd

In

side

SP 10

SP 10

Tank

-SDA

make-up

water tank

In

side

SP 10

2nd

FGD Duct

Shell

Hopper

(cone)

SP 10

Polyurethane

Inorganic Zinc

Silicate primer

H.B Polyamide

Epoxy

Polyurethane

1st

Inorganic Zinc

Silicate primer

H.B Polyamide

Epoxy

H.B Polyamide

Epoxy

Inorganic Zinc

Silicate primer

H.B Polyamide

Epoxy

2nd

1st

Silo

Recycle

ash silo

-Lime

storage

silo

Inorganic Zinc

Silicate primer

H.B Polyamide

Epoxy

3rd

3rd

Out

side

Inorganic Zinc

Silicate primer

H.B Polyamide

Epoxy

Polyurethane

-Sherwin

Williams

Shop

75

Shop

75

Shop

75

Shop

75

Shop

75

Shop

75

Shop

40~50

-Sherwin

Williams

40~50

-Sherwin

Williams

After Erection

Site

Glass Flake Lining

1st

Out

side

Polyurethane

40~50

Only for

Transportation

-Sherwin

Williams

Insulated

-Sherwin

Williams

Only for

transportation

-Sherwin

Williams

Glass Flake Lining

1st

Glass Flake Lining

1st

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

Fabric Filter

Recycle mix tank

REV No.

PAGE

nd

75

Shop

75

Shop

75

Shop

100

Shop

100

Shop

100

Shop

75

Shop

75

Shop

3rd

Polyurethane

75

Shop

Out

side

SP 10

1st

Inorganic Zinc

Silicate primer

75

Shop

In

side

SP 10

1st

Inorganic Zinc

Silicate primer

30

Shop

Out

side

SP 10

1st

Inorganic Zinc

Silicate primer

75

Shop

40~50

-Sherwin

Williams

40~50

-Sherwin

Williams

AMB

AMB

75~134

Not

Insulated

-Sherwin

Williams

Insulated

-Sherwin

Williams

Only for

transportation

-Sherwin

Williams

Insulated

-Sherwin

Williams

PROJECT

Procedure for Painting

In

side

Outdoor and Off shore

Located

Non

metallic

surface

-Galvanized Steel

-Stainless Steel

-Copper, Bronze

-Aluminum, Nickel

SP 10

st

Structural Steel

- Handrail, Ladder

- Checked Plate

- Piping support

Out

side

2nd

Structural Steel

- Grating,

- Stair Thread

Out

side

Piping

-slurry piping

Out

side

SP 10

SP 10

SP 10

13 of 20

Only for

transportation

-Sherwin

Williams

AMB

Inorganic Zinc

Silicate primer

H.B Polyamide

Epoxy

75

Shop

75

Shop

Polyurethane

75

Shop

1st

Inorganic Zinc

Silicate primer

75

Shop

2nd

H.B Polyamide

Epoxy

100

Shop

3rd

Polyurethane

75

Shop

1st

Inorganic Zinc

Silicate primer

H.B Polyamide

Epoxy

75

Shop

75

Shop

75

Shop

2nd

Polyurethane

AMB

-Sherwin

Williams

AMB

-Sherwin

Williams

Galvanizing will be performed in accordance with ASTM A153,

BS 729, BS3083, DIN 50976, BS 4479, KSD8308 (Refer to

para 4.6)

1st

Inorganic Zinc

Silicate primer

75

2nd

H.B Polyamide

Epoxy

75

Shop

3rd

Polyurethane

75

Shop

Shop

Up to 60

Not

Insulated

-Sherwin

Williams

Maker Standard (Shop Finish Painting)

-Fly ash (Pneumatic)

Piping

-Service Air piping

-closed

cooling

water piping

- Maker up water

piping

- Portable water

piping

SP 10

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

Shop

3rd

3rd

Piping

10

SP 10

Structural Steel

In

door

30

No painting is needed

1st

Out

door

Inorganic Zinc

Silicate primer

REV No.

PAGE

Out

side

SP 10

Galvanizing will be performed in accordance with ASTM A153,

BS 729, BS3083, DIN 50976, BS 4479, KSD8308 (Refer to

para 4.6)

Agitator

Maker Standard (Shop Finish Painting)

AMB

Lime Slaker

Maker Standard (Shop Finish Painting)

60~90

Maker Standard (Shop Finish Painting)

81~134

Atomizer Cooling Air Fan

Maker Standard (Shop Finish Painting)

AMB

Water Pump

Maker Standard (Shop Finish Painting)

AMB

Atomizer

All motors are

applied.

Stainless

or

Galvanized

steel is not

needed

to

paint

PROJECT

Procedure for Painting

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

14 of 20

Slurry Pump

Maker Standard (Shop Finish Painting)

AMB

Air compressor

Maker Standard (Shop Finish Painting)

AMB

Maker Standard (Shop Finish Painting)

AMB

Maker Standard (Shop Finish Painting)

AMB

Maker Standard (Shop Finish Painting)

AMB

Maker Standard (Shop Finish Painting)

0~90

Maker Standard (Shop Finish Painting)

0~90

Jaw crusher

Maker Standard (Shop Finish Painting)

0~77

Reversible conveyor

Maker Standard (Shop Finish Painting)

0~77

Lump breaker

Maker Standard (Shop Finish Painting)

0~77

Air dryer

Maker Standard (Shop Finish Painting)

AMB

Motor

Maker Standard (Shop Finish Painting)

Weighing hopper feeder

(Lime)

Feed hopper

(Recycle ash)

Bin activator

Vibrating screen

(Lime slurry)

Vibrating screen

(Recycle ash slurry)

1st

11

REV No.

PAGE

Air Receiver Tank

Out

side

In

side

SP 10

SP 10

2nd

Inorganic Zinc

Silicate primer

H.B Polyamide

Epoxy

75

Shop

75

Shop

3rd

Polyurethane

75

Shop

1st

Inorganic Zinc

Silicate primer

30

Shop

Up to 130

-Sherwin

Williams

-Sherwin

Williams

12

Ash handling Vessel

Maker Standard (Shop Finish Painting)

20

13

Steam Heater

Maker Standard (Shop Finish Painting)

150

Out

side

Maker Standard (Shop Finish Painting)

Up to 400

Insulated

14

Valve

-steam piping

Valve

-slurry piping

-Service Air piping

-closed

cooling

water piping

-Make up water

piping

-Portable

water

piping

Out

side

Maker Standard (Shop Finish Painting)

Up to 60

Not

Insulated

Out

door

15

Panel

In

door

Electric Powder Coating (Min.80)

50

Out

door

16

Junction Box

17

Anchor Bolts &

Embedded

Materials

In

door

Out

door

In

door

N/A

Galvanizing will be performed in accordance with ASTM

A153, BS 729, BS3083, DIN 50976, BS 4479, KSD8308

(Refer to para 4.6)

60

AMB

Stainless

Galvanized

steel is

needed

paint

Stainless

Galvanized

steel is

needed

paint

Stainless

Galvanized

steel is

needed

paint

or

not

to

or

not

to

or

not

to

PROJECT

Procedure for Painting

18

Bolts & Embedded

Materials for Steel

Structure

1)

8.3.

REV No.

PAGE

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

15 of 20

Out

door

Dacrotized

In

door

Stainless

or

Galvanized

steel is not

needed

to

paint

AMB

Note:1. Final color shall be applied in accordance with Customer requirements.(5.4, 5.5)

If it is not required, it shall be applied in accordance with manufacturers Standard Color.

Safety Color Code

The safety color code is based on ANSI Z535.1 and shall be as follows for the proposal.

The supplier shall be noted that these colors are subject to change in accordance with

employer/engineers approval.

Safety Color

Application

Red

Fire protection and emergency; shall be used for hydrants and associated piping, fire

fighting equipment and facilities, including emergency shutdown controls.

Green

Safety; shall be used for first aid and protective equipment and facilities, sealing

devices, valves, including safety bulletin boards, gas mask boxes, and first aid kits.

Yellow

Caution; shall be used to designate location of physical hazards which might cause

stumbling, falling, tripping.

Orange

Alert; shall be used inside of removable guards for pull-up, shafts, chains, etc., inside

enclosed doors for electrical equipment, etc. Stop valves associated with relief

valves, any valves which for safety reasons are locked open.

Black and Yellow Stripe

Danger; shall be used for dangerous curbs, bottom risers, lap landings of stairways,

exposed and unguarded edges of platforms and walks, lower pulley blocks of cranes,

bumpers of fork lift trucks and cranes, pillar posts and columns in areas hazardous to

personnel (painted up to 2 meters above deck), and dead end passage ways.

Blue

Information; shall be used for informational signs and bulletin boards.

8.4.

Final Painting

This specification states final painting colors, which are based on the RAL numbers as a

Contractors standard, for equipment provided by Seller.

8.4.1.

Standard Colors of Equipment Painting

Item

No.

Description

Color

RAL Code

1.

General indoor equipment, such as STG,

condenser, pumps, etc

Signal White

2.

General outdoor equipment, such as boiler,

pumps, vessels, etc

Signal White

RAL 9003

Desulfurization System Structure

Saphire Blue

RAL 5003

4.

Crane bridges, monorail, trolleys, hoist, etc.,

and other mobile equipment

Signal Yellow

RAL 1003

Remarks

RAL 9003

Except Atomizer

5.

Tanks/Silos

Signal White

RAL 9003

6.

Chimney (Stack)

Traffic Red /

Pure White

RAL 3020 /

RAL 9010

Band (RAL)

- Lime : 1021/4001

- Recycle Ash :

1021/3001

PROJECT

Procedure for Painting

Item

No.

Description

REV No.

PAGE

Color

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

16 of 20

RAL Code

Remarks

7.

Grating and tread of platforms and stairways

Galvanized

8.

Checkered plates (steel floor), Galleries,

stairways, kick steps, ladder etc.

Signal White

RAL 9003

9.

Railings for floor, plate, stair

Signal Yellow

RAL 1003

10.

Fire-fighting equipment namely, piping &

fittings, and valves

Signal Red

RAL 3001

11.

Local control panel for mech. equipment

(indoor)

Pebble Grey

RAL 7032

12.

Local control panel for mech. equipment

(outdoor)

Pebble Grey

RAL 7032

13.

Electrical equipment (indoor)

Pebble Grey

RAL 7032

14.

Electrical equipment (outdoor)

Pebble Grey

RAL 7032

15.

Power transformer (external)

Pebble Grey

RAL 7032

16.

Isolated phase busduct

Pebble Grey

RAL 7032

17.

Segregated phase busduct

Pebble Grey

RAL 7032

18.

Control panel (indoor)

Pebble Grey

RAL 7032

note

19.

Control panel (outdoor)

Pebble Grey

RAL 7032

note

20.

Instrument cabinet/rack/terminal box

Pebble Grey

RAL 7032

21.

Control Valve & Manual Valve

Pebble Grey

RAL 7032

22.

Penthouse(SDA, Fabric filter)

Signal White

or Light Ivory

RAL 9003

or RAL 1015

23.

All safety purposes

As per safety

color code

24

Vessel (Ash handling)

Signal blue

RAL 5005

25

Jaw crusher (Ash handling)

Maker

Standard

Maker

Standard

26

Reversible conveyor (Ash handling)

Maker

Standard

Maker

Standard

27

Lump breaker (Ash handling)

Maker

Standard

Maker

Standard

28

Lime Slaker

Maker

Standard

Maker

Standard

Checked plate

for SDA, Duct,

Silo, Tank Item

Except

Atomizer

Cooling Air Fan

PROJECT

Procedure for Painting

Item

No.

Description

REV No.

PAGE

Color

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

17 of 20

RAL Code

Remarks

29

Vibrating screen

(Lime slurry)

Maker

Standard

Maker

Standard

30

Vibrating screen

(Recycle ash slurry)

Maker

Standard

Maker

Standard

31

Air Compressor

Maker

Standard

Maker

Standard

32

Air Receiver Tank

Signal blue

RAL 5005

33

Air Dryer

Maker

Standard

Maker

Standard

34

Agitator

Maker

Standard

Maker

Standard

35

Weighing hopper feeder

(Lime)

Maker

Standard

Maker

Standard

36

Feed hopper

(Recycle ash)

Maker

Standard

Maker

Standard

37

Bin activator

Maker

Standard

Maker

Standard

38

Truck Scale

Maker

Standard

Maker

Standard

39

Slurry Pump

Maker

Standard

Maker

Standard

40

Water Pump

Emerald green

RAL 6001

RAL 4001/2003

Band

41

Vent filter

(Fly Ash Silo)

Maker

Standard

Maker

Standard

Maker Standard

42

Vent filter

(Recycle Ash Silo)

Maker

Standard

Maker

Standard

Maker Standard

43

Pug Mill

Maker

Standard

Maker

Standard

Maker Standard

1)

Note : The color code of the control panels shall be determined at the owners review of

the packaged control system.

8.5.

Piping Color Code

8.5.1.

General

1)

8.5.2.

RAL

3001/5005/3001

Band

Piping materials shall be identified and color coded in accordance with ANSI A13.1. All

electrical conduits shall be identified using acceptable industry practice.

The product color code system shall consist of the following;

1)

A colored band around pipe to indicate classification of product

2)

Black lettering and black directional arrow to indicate flow direction between colored

PROJECT

Procedure for Painting

REV No.

PAGE

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

18 of 20

bands to identify the specific product within the general classification

8.5.3.

Color code

1)

Final colors shall be as given below. In case of galvanized, stainless steel and heat

isolated pipe, only color band shall be applied instead of painting. The color band shall

be painted around pipe..The banding color code shall be in accordance with the following:

Pipe

Material

Service/Fluid

Color

RAL Code

Closed cooling water

Carbon Steel

Base Emerald green

Band - Beige

Water Supply

Carbon Steel

Base Emerald green

Band

Red lilac/Pastel orange

Potable Water

Carbon Steel

Base Emerald green

Band - Emerald green

Lime Powder

Carbon Steel

Lime Slurry

Carbon Steel

Recycle Ash Powder

Carbon Steel

Recycle Ash Slurry

Carbon Steel

Service Air

Carbon Steel

Instrument Air

Legend

RAL 6001

RAL 1001

-

Base Signal blue

Band - Rape Yellow/

Red lilac

Base - Emerald green

Band - Rape Yellow/

Red lilac

Base Signal blue

Band

Signal

red/Silver grey

Base - Emerald green

Band - Rape Yellow/ Signal

red

CW

RW

Galv.

RAL 6001

RAL 6001

PW

Galv.

RAL 5005

RAL 1021/4001

LS

RAL 5005

RAL 3001/7001

RA

RAL 6001

RAL 1021/3001

RS

Base Signal blue

Band - Signal red

RAL 5005

RAL 3001

SA

Stainless Steel

Base - Signal blue

Band - Signal red /Signal

blue/ Signal red

RAL 5005

RAL

3001/5005/3001

IA

Air to Ashes

Carbon Steel

Base Signal blue

Band - Signal red

RAL 5005

RAL 3001

SA

Fly ash (Pneumatic)

Carbon Steel

Maker Standard

Maker Standard

Pipe Support

SS400

Base - Signal White

RAL 9003

8.5.5.

Directional Arrow

1)

The flow direction shall be indicated by black paint.

The arrow thickness at its widest point shall be equal to the letter height..

Legend

1)

Legend shall be brief, informative, pointed, and simple in full or abbreviated form.

Language shall be sued in English.

Letter height shall be in accordance with the following

Outside diameter (pipe, jacket, insulation)

<40mm

>40mm to 60mm

>60mm to 170mm

>170mm to 270mm

Galv.

RAL 6001

RAL 4001/2003

RAL 6001

RAL 1021/4001

8.5.4.

Remarks

Letter height

mm

12

20

45

65

Galv.

Galv.

PROJECT

Procedure for Painting

Outside diameter (pipe, jacket, insulation)

>270mm to

8.5.6.

REV No.

PAGE

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

19 of 20

Letter height

mm

90

Location of Color Bands

1)

Pipes

a) Color bands shall be applied to pipe immediately inside and outside of buildings,

adjacent to and on both sides of walls or partitions, and in other location as necessary

to further identify systems and maintain uniformity.

b) Band shall be applied as following spacing

Pipe Size(DN)

Up to 50

65 to 150

Over 200

2)

Band Spacing(m)

4

7

10

Vessels and Tanks

a) Markings shall normally be applied at the tank centerline but not more than 1.5m (5

feet) up from the base. Markings will normally face any entrance to the vessel area.

8.5.7.

Color Code Sketch for Piping System (Example)

1)

Identification band, legend and directional arrow

a) In case of galvanized and stainless steel, heat isolated;

-

Isolation cladding Base color Band color Base color Isolation cladding

Base color shall be painted upstream and downstream of a band but limited to

between isolation claddings only..

Cladding shall be located to separate painted surface from unpainted surface.

b) As indicated on each pipe at suitable position as following figure:

PROJECT

Procedure for Painting

REV No.

PAGE

SISTEMA DESULFURIZACION DE

GASES DE ESCAPE PARA LA

UNIDAD 1 CENTRAL BOCAMINA

20 of 20

FIGURE 1. Galvanized and stainless steel, heat isolated pipe

FIGURE 2. Ordinary pipe

2)

Identification Band

Outside diameter (pipe, jacket, insulation)

0 to 50 mm

+50mm to 150 mm

+150mm

Identification band

mm

50

100

200

Arrow length

mm

100

150

200

You might also like

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Painting Process Equipment and PipingDocument17 pagesPainting Process Equipment and PipingJoseph Darwin ZionNo ratings yet

- Control flow diagram for GACC's new welder qualification processDocument1 pageControl flow diagram for GACC's new welder qualification processSiddiqui Abdul KhaliqNo ratings yet

- Specification For 3 Layer Polyethylene CoatingDocument34 pagesSpecification For 3 Layer Polyethylene CoatingYogesh BaraskarNo ratings yet

- QATAR Pin Braze pdfr1Document14 pagesQATAR Pin Braze pdfr1Karunanithi NagarajanNo ratings yet

- Jotun Resist 86Document5 pagesJotun Resist 86Ansar AliNo ratings yet

- 6 Contractor QC Resume Review ChecklistDocument1 page6 Contractor QC Resume Review ChecklistMudabbir HussainNo ratings yet

- Denso Pipe Wrapping SolutionsDocument8 pagesDenso Pipe Wrapping SolutionsVinoth MechNo ratings yet

- Welding Control ProcedureDocument18 pagesWelding Control ProceduresumitNo ratings yet

- Annexure C3.23 - Quality Management PlanDocument23 pagesAnnexure C3.23 - Quality Management Planifansusanto100% (1)

- STS EDAC WELD REPAIR PROCEDUREDocument51 pagesSTS EDAC WELD REPAIR PROCEDUREmohd as shahiddin jafriNo ratings yet

- MS-M2101 (S09) - HSSE-GP-003 ERP Rev 0Document32 pagesMS-M2101 (S09) - HSSE-GP-003 ERP Rev 0Lau Poung HieNo ratings yet

- QAF5153 Rev.0 Pre-Mobilization Inspection Checklist - Guidelines - 1Document1 pageQAF5153 Rev.0 Pre-Mobilization Inspection Checklist - Guidelines - 1Mohamed El-SawahNo ratings yet

- Audit ReportDocument9 pagesAudit ReportVIVEK100% (1)

- Daily Weld Fit-Up and Production Report (Field Weld) - Pipeline-Satr-W-2007Document5 pagesDaily Weld Fit-Up and Production Report (Field Weld) - Pipeline-Satr-W-2007smdriyazbasha100% (2)

- Oil Pantriting ProcedureDocument5 pagesOil Pantriting ProcedureSERT-QA/QC- BUZNo ratings yet

- SAWAED'S LIQUID PENETRANT TEST PROCEDUREDocument7 pagesSAWAED'S LIQUID PENETRANT TEST PROCEDUREAlam MD SazidNo ratings yet

- Fit Up Report: Project Name Project No. Tank No. Report No. DateDocument1 pageFit Up Report: Project Name Project No. Tank No. Report No. DatekarthikumarnpNo ratings yet

- NCR Tracking Log AAILDocument5 pagesNCR Tracking Log AAILssenthil04No ratings yet

- Dimensional Inspektion ReportDocument6 pagesDimensional Inspektion Reportdidi sudiNo ratings yet

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel NdifonNo ratings yet

- Contractor QC Supervisor Resume Review ChecklistDocument1 pageContractor QC Supervisor Resume Review ChecklistAdnan ArshidNo ratings yet

- Daily Welding Report PLD LogoDocument1 pageDaily Welding Report PLD Logonike_y2kNo ratings yet

- WP 11 Corrosion Protection Tape Coating123Document3 pagesWP 11 Corrosion Protection Tape Coating123KarthikNo ratings yet

- Ok-Hydraulic Oil Flushing at Terminal AreaDocument4 pagesOk-Hydraulic Oil Flushing at Terminal AreaEric TingNo ratings yet

- ITP For Mild Steel Pipe WorksDocument4 pagesITP For Mild Steel Pipe WorksKumar AbhishekNo ratings yet

- Welding ProceduresDocument29 pagesWelding ProceduresLaith Salman100% (1)

- ICC-DS-1132 Erection ITP-GFRC Steel Sub FramesDocument3 pagesICC-DS-1132 Erection ITP-GFRC Steel Sub FramesAnwar MohiuddinNo ratings yet

- Procedure For WeldingDocument7 pagesProcedure For WeldingMecon Hyderabad100% (1)

- Radiation Safety Distance DiagramDocument3 pagesRadiation Safety Distance DiagramEswaranNo ratings yet

- Painting & Inspection FormatDocument1 pagePainting & Inspection FormatABEC Trombay siteNo ratings yet

- Transmittal SampleDocument1 pageTransmittal SamplekokocdfNo ratings yet

- Inspection and Test Plan For Epc Gas Pipeline Project-X70mDocument15 pagesInspection and Test Plan For Epc Gas Pipeline Project-X70mFolarin Ayodeji100% (1)

- Procédure MTDocument11 pagesProcédure MTAslaouiNo ratings yet

- Inspectable MaterialsDocument2 pagesInspectable MaterialsMohamed RedaNo ratings yet

- Dedicated Freight Corridor Corporation of India's Method Statement for Storing and Transporting Structural Steel Span MaterialsDocument8 pagesDedicated Freight Corridor Corporation of India's Method Statement for Storing and Transporting Structural Steel Span MaterialschepurthiNo ratings yet

- Non-Destructive Testing Methods & Applications TableDocument2 pagesNon-Destructive Testing Methods & Applications TableAlzaki Abdullah100% (1)

- Material Inspection Report: Project Name Date InspDocument22 pagesMaterial Inspection Report: Project Name Date InspRafiqKuNo ratings yet

- ASME Guidance Notes ComparisonDocument1 pageASME Guidance Notes ComparisonTrịnh Quốc TuyếnNo ratings yet

- Welder, Welding Operator Qualification Test ReportDocument2 pagesWelder, Welding Operator Qualification Test Reportkarthik sundaramNo ratings yet

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDocument15 pagesIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNo ratings yet

- 13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)Document7 pages13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)SANDEEP100% (1)

- GTAW Welding ParametersDocument1 pageGTAW Welding ParameterssahadNo ratings yet

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNo ratings yet

- Bgas Paint Faults, BittinessDocument49 pagesBgas Paint Faults, BittinessslxantoNo ratings yet

- Paint Certificate 80A45-1Document1 pagePaint Certificate 80A45-1Shyam_Nair_9667No ratings yet

- PCSB PMA Riser Maintenance Paint MatrixDocument8 pagesPCSB PMA Riser Maintenance Paint MatrixZafarul Naim JamaludinNo ratings yet

- SAIW Course Prospectus 2019 PDFDocument96 pagesSAIW Course Prospectus 2019 PDFBraamNo ratings yet

- Welding Coordinator WeldMap Weld Data Sheet PDFDocument1 pageWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadNo ratings yet

- Wps Mig PDF FreeDocument3 pagesWps Mig PDF Freehanz bermejoNo ratings yet

- 09 - Method Statement For Paint WorkDocument6 pages09 - Method Statement For Paint WorkAnsar WarraichNo ratings yet

- Contractor IOT Infrastructure & Energy Services LTDDocument38 pagesContractor IOT Infrastructure & Energy Services LTDNaveen KurupNo ratings yet

- Jurassic Production Facility (JPF) at East Raudhatain: Supplier Document Cover SheetDocument14 pagesJurassic Production Facility (JPF) at East Raudhatain: Supplier Document Cover Sheettomj9104No ratings yet

- Shaik Yousufuddin (Welding Inspector)Document3 pagesShaik Yousufuddin (Welding Inspector)Mohamed AdelNo ratings yet

- Package 2s E0001 - Jupiter DCR 30-10-2021Document96 pagesPackage 2s E0001 - Jupiter DCR 30-10-2021senthilNo ratings yet

- Saudi Aramco welding reportDocument2 pagesSaudi Aramco welding reportsmdriyazbashaNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalpravinNo ratings yet

- Shop& FLD Train GDocument64 pagesShop& FLD Train GaripramonoNo ratings yet

- Con-011 Instruction For Painting Work Rev.0Document11 pagesCon-011 Instruction For Painting Work Rev.0monchai_626No ratings yet

- Painting Scheme StructureDocument10 pagesPainting Scheme StructureVeerapandianNo ratings yet

- Unit Testing the Date Class with JUnitDocument34 pagesUnit Testing the Date Class with JUnitAbdo AZNo ratings yet

- Ebook PDF Calculus and Its Applications 11th Edition PDFDocument38 pagesEbook PDF Calculus and Its Applications 11th Edition PDFsandra.putnam416100% (37)

- Holley 1-Barrel Parts IndexDocument38 pagesHolley 1-Barrel Parts IndexBillyNo ratings yet

- Expt 8a-Study and Analysis of Hidden Terminal Problem in WLAN Using NetsimDocument5 pagesExpt 8a-Study and Analysis of Hidden Terminal Problem in WLAN Using NetsimKritika VermaNo ratings yet

- SF6 Gas Stock Balance ReportDocument4 pagesSF6 Gas Stock Balance ReportJawad AmjadNo ratings yet

- LSPS ReporteDocument5 pagesLSPS ReporteCarlosNo ratings yet

- Acid ProDocument3 pagesAcid ProoctavioluisramirezNo ratings yet

- AEP StudyGuide MediaPlanning PDF Inline DownloadDocument68 pagesAEP StudyGuide MediaPlanning PDF Inline DownloadRayan Mirza100% (1)

- PMU-Based Fast Sub-synchronous Oscillation DetectionDocument7 pagesPMU-Based Fast Sub-synchronous Oscillation DetectionDaniel Germán RomeroNo ratings yet

- PTSP Jntua Old Question PapersDocument32 pagesPTSP Jntua Old Question PapersrajuNo ratings yet

- Ujian Tengah Semester Genap TA 2020/2021 Fakultas Ekonomi dan SosialDocument4 pagesUjian Tengah Semester Genap TA 2020/2021 Fakultas Ekonomi dan SosialAchmad VidyNo ratings yet

- Final Capstone Draft ProposalDocument7 pagesFinal Capstone Draft Proposalapi-549040950No ratings yet

- OVERVIEW Materials QualityDocument14 pagesOVERVIEW Materials QualityRomeo Beding Densen Jr.No ratings yet

- Electric Machines EEE241 LAB Report#2: Name Registration Number Teacher Date of SubmissionDocument13 pagesElectric Machines EEE241 LAB Report#2: Name Registration Number Teacher Date of Submissionbilal ahmedNo ratings yet

- GOCToolKit Installation and Quick Start GuideDocument25 pagesGOCToolKit Installation and Quick Start GuideabhayuietNo ratings yet

- Cambio de Cilindro de Dirección 988KDocument4 pagesCambio de Cilindro de Dirección 988KMAQUINARIAS TRACTOR SHOPNo ratings yet

- Introduction To Networks: KVS Regional Office Jaipur - Session 2020-21 Page 14 of 19Document3 pagesIntroduction To Networks: KVS Regional Office Jaipur - Session 2020-21 Page 14 of 19adamNo ratings yet

- Lawshe CVR and CVI Calculator SpreadsheetDocument3 pagesLawshe CVR and CVI Calculator SpreadsheetGiselle Medina EstradaNo ratings yet

- Dell Latitude 5490Document8 pagesDell Latitude 5490Noemi VelasquezNo ratings yet

- Final Article Review For BRMDocument5 pagesFinal Article Review For BRMSelemon BerihunNo ratings yet

- 2.2.1.12 Lab - Windows Task ManagerDocument11 pages2.2.1.12 Lab - Windows Task ManagerKwimpal NychaNo ratings yet

- Audio SynthesisDocument80 pagesAudio Synthesiscap2010No ratings yet

- PM Debug InfoDocument156 pagesPM Debug InfoCarlos garciaNo ratings yet

- FMDS0200Document171 pagesFMDS0200Róger F. e SilvaNo ratings yet

- F12 Series Pump Service Manual Parts List and ToolsDocument4 pagesF12 Series Pump Service Manual Parts List and ToolsLuis AlapazNo ratings yet

- DBX 386 Dual Tube Mic Preamp SCHDocument21 pagesDBX 386 Dual Tube Mic Preamp SCHPablo RodriguezNo ratings yet

- Measurement: Azri Mat Saad, Khairul Nizam TaharDocument8 pagesMeasurement: Azri Mat Saad, Khairul Nizam TaharEduPeñaNo ratings yet

- Section Course OutlineDocument3 pagesSection Course OutlineAftab AhmadNo ratings yet

- Experiment No.1:: Write A LEX Program To Scan Reserved Word & Identifiers of C LanguageDocument4 pagesExperiment No.1:: Write A LEX Program To Scan Reserved Word & Identifiers of C LanguageRADHARAPU DIVYA PEC0% (1)

- Track Record Harga SahamDocument8 pagesTrack Record Harga SahamMuhammad FakhrizalNo ratings yet