Professional Documents

Culture Documents

A4-P 13.0 en

Uploaded by

mkpqOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A4-P 13.0 en

Uploaded by

mkpqCopyright:

Available Formats

Structural design and erection

General requirements

Approved date: 11 July 2013

Created by: OMa

Approved by: KimN

Doc. No.

749500-13.0

Structural design and erection

749500-13.0

List of contents:

Page:

0.

Revision historic ........................................................................................... 3

General ....................................................................................................... 4

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

Loads

Purpose ........................................................................................................

Standards .....................................................................................................

General Arrangement drawings .......................................................................

Sequential progression ...................................................................................

Estimated information ....................................................................................

On hold ........................................................................................................

Buyer supplied equipment ..............................................................................

Release status ...............................................................................................

Update of drawings ........................................................................................

Overlapping plant departments .......................................................................

for calculation of civil structures .............................................................

4

4

4

4

4

4

4

5

5

5

6

2.1

2.2

2.3

2.4

2.5

General information ....................................................................................... 6

Units of measure ........................................................................................... 6

Natural loads ................................................................................................ 6

Dynamic loads exerted by the equipment ......................................................... 7

Load categories ............................................................................................. 7

2.5.1

Dead load (permanent loads) .............................................................. 7

2.5.2

Live loads, normal (variable loads) ....................................................... 7

2.5.3

Live loads, extraordinary .................................................................... 8

2.5.4

Natural loads ..................................................................................... 8

2.5.5

Special loads ..................................................................................... 8

2.6

Deck and roof ............................................................................................... 9

2.7

Special load requirements for roofs without access ........................................... 10

2.8

Stairs and landings .......................................................................................10

Execution of support structure ....................................................................... 10

3.1

Settlements ................................................................................................. 10

3.2

Concrete strength ......................................................................................... 10

3.3

Surface reinforcement ................................................................................... 10

3.4

Alignment and grouting ................................................................................. 11

3.5

Bolt holes .................................................................................................... 13

3.6

Final grouting ............................................................................................... 13

Various specifications ................................................................................... 13

4.1

Water seepage ............................................................................................. 13

4.2

Covering and flashing.................................................................................... 13

4.3

Drain ..........................................................................................................14

4.4

Floors and walls............................................................................................ 14

4.5

Stairways and walkways ................................................................................ 14

4.6

Exit doors ....................................................................................................15

4.7

Steel or concrete structures ........................................................................... 15

4.8

Constructional elements (beams, columns, braces, etc.) .................................... 15

4.9

Tolerances ................................................................................................... 15

Erection corrections...................................................................................... 16

2/16

The information transmitted by this document is the proprietary and confidential property of FLSmidth

and may not be duplicated, disclosed or utilized without written consent from FLSmidth.

Structural design and erection

749500-13.0

0 Revision historic

Version 12.0

5-Mar-08

Section 0 Revision historic added

Section 1.2 Standards added

Section 1.7 Buyer supplied equipment added

Section 1.8 Release status. Editorial changes

Section 1.9 Update of drawings. Editorial changes

Section 2.8 Stairs and landing added

General: the equipment supplier and the supplier have been substituted by Seller

Version 13.0

11-Jul-13

General: Seller changed to Supplier

General: Loads changed with equipment loads

Section 2.3 Natural loads. Editorial changes

Section 4.4 Floors and walls. Misfit phrases included

The information transmitted by this document is the proprietary and confidential property of FLSmidth

and may not be duplicated, disclosed or utilized without written consent from FLSmidth.

3/16

Structural design and erection

749500-13.0

General

1.1

Purpose

This instruction manual is to provide the civil designer, the civil contractor and the

erection contractor with general requirements regarding civil design and erection of

the equipment. Specific requirements are stated in plant layout documentation and

instruction manuals.

1.2

Standards

Reference by Supplier to any international or national Standard does not incur

an obligation on Supplier to provide any recipient, reader or user of the

documentation with samples or copies of the said Standard(s).

Hence, any recipient, reader or user of the documentation is expected at his

own cost to obtain necessary knowledge of the contents of any of the

Standards referred to.

1.3

General Arrangement drawings

General Arrangement drawings (GA drawings) serve to show the project

arrangements with an indication of installation dimensions, conditions of space,

access and loadings, etc. Loads and detailed dimensions are specified on GA

drawings or Outline and Load drawings (OL drawings).

1.4

Sequential progression

The GA drawings are developed through sequential progression and are issued in

different stages of completion.

1.5

Estimated information

On GA drawings some equipment measurements and loads may be estimated. This is

indicated by a cloud marked with E. The cloud may cover the equipment or

localised areas, where the detailed information is not available. Such drawings may

still be used for the ongoing civil design work.

1.6

On hold

Some information in the drawings may be on hold, which is indicated by a cloud

marked with H. The cloud may cover some items of equipment or localised areas,

where the detailed information is not available or needs verification by the Buyer or

other parties. Such drawings may still be used for the ongoing civil design work with

exception of the on hold areas.

1.7

Buyer supplied equipment

Buyer supplied equipment (BSS), e.g. screw conveyors, secondary filters etc,

is estimated in size, if the equipment is a natural part of the arrangement.

Detailed information regarding hole sizes, platform sizes, loads, reference to

Outline and Load Drawing etc., are not given by Supplier.

If water pipes, compressed air pipes, cables, etc. are Buyer supply, trenches

and holes in floors are not shown by Supplier.

Buyer supplied equipment is usually shown as being Supplier supply i.e.

Supplier equipment.

In case the documentation shows equipment, lining, etc. supplied by Buyer

the measurements and loads have to be informed by the Buyer.

4/16

The information transmitted by this document is the proprietary and confidential property of FLSmidth

and may not be duplicated, disclosed or utilized without written consent from FLSmidth.

Structural design and erection

749500-13.0

In case equipment or the operational conditions at a later stage is changed

by Buyer the impact on the structure has to be considered by a civil

designer.

1.8

Release status

The release status of the GA drawings (e.g. Basic, Main, Detail) is not written on the

drawing. The release status is only described in the release note.

1.9

Update of drawings

Every time a GA drawing is updated, the revisions are shown encircled with clouds,

and the drawing is given a new version number for example 2.0. Minor version

numbers, for example 2.1, may be used for communication internally in Suppliers

organisation. These minor versions numbers are not forwarded to the Buyer

1.10 Overlapping plant departments

The department numbering follows the equipment rather than the physical

boundaries of the buildings. Therefore some GA drawings may show parts of other

departments where the equipment overlaps. In such cases, the GA drawing will show

the outline of the overlapping department(s) together with a reference to the

relevant department(s). In such cases the civil designer must cross-reference

between departments to find the required information and the civil designer must

take due consideration of these loads and other influences and restrictions.

The information transmitted by this document is the proprietary and confidential property of FLSmidth

and may not be duplicated, disclosed or utilized without written consent from FLSmidth.

5/16

Structural design and erection

749500-13.0

Loads for calculation of civil structures

2.1

General information

The drawings state loads originating from the equipment as well as live loads on

decks, platforms, walkways, etc. For load categories, see sub-section 2.5.

In some cases the actual load data may not be available in due time. A higher

general floor replacement load might then be given for the area concerned (for

example for electrical panels or minor equipment).

Design the individual decks to withstand all the loads specified, i.e. loads from the

equipment as well as the uniformly distributed loads.

Apply load factors, safety system and partial coefficient according to applicable

codes and design norms.

The civil designer assumes full responsibility for compliance with all local regulations

and codes of practice.

2.2

Units of measure

The units applied are SI-units.

Elevations are in m, whereas other dimensions are in mm.

Loads are in N (Newton) or kN (kilo Newton).

2.3

Natural loads

Loads originating from external forces, e.g. wind load, snow load and seismic loads,

are not indicated on the drawings, but must be determined by the civil designer in

accordance with local regulations codes of practice and conditions.

When calculating natural loads assume, that expansion joints on machines and

ducts cannot transfer loads.

When calculating seismic loads, the assumption is to safeguard against major

structural failure and loss of life, but not to prevent damage nor to maintain function

of the equipment.

The civil designer is also required to evaluate and determine loads caused by

settlement, temperature stresses, etc.

Consult Supplier, if deflections or settlements of the civil structure are greater than

specified.

Fixtures (Foundation bolts, anchor plates) for the equipment fixed to the ground or

floors are designed for loads caused by wind, snow and seismic loads.

Supports and foundations must be designed in accordance with local regulations

codes of practice and conditions.

6/16

The information transmitted by this document is the proprietary and confidential property of FLSmidth

and may not be duplicated, disclosed or utilized without written consent from FLSmidth.

Structural design and erection

749500-13.0

2.4

Dynamic loads exerted by the equipment

a) For equipment subject to comparatively small dynamic loads, the dynamic loads

are specified as an equivalent additional static load (See sub-section 2.5).

b) For equipment subject to considerable dynamic loads (e.g. heavy-duty fans) the

individual load rates of the equipment are specified (dead load, live load and

dynamic loads).

c) The load rate applying to certain equipment will be specified as the total load (P)

of the equipment multiplied by factor (k). The specified factor (k) incorporates

dynamic loads and load variations.

Unless otherwise specified on the drawing, the load can be divided into a dead

load (permanent load) of 1 x P and a normal live load (variable load) of (k - 1) x

P.

Attention is drawn to the fact that in each individual case the civil designer assumes

full responsibility in respect of ensuring that the individual constructions are so

designed that vibrations and noise nuisances from the building structures are

eliminated in accordance with the local codes and regulations.

A minimum 20 % deviation from the dynamic frequency of the equipment and the

natural frequency of the load-carrying structures (incl. the mass of the equipment

and its foundation) is required.

2.5

Load categories

2.5.1 Dead load (permanent loads)

Dead load of equipment, lining and other well-defined installations (in terms of

both load and location).

The dead load is sub-divided as follows:

DL1 Dead load from equipment, etc.

DL2 Dead load from lining or insulation.

2.5.2 Live loads, normal (variable loads)

Normally occurring loads from e.g. plant operators, furniture and equipment,

traffic, material (stored, transported, occasional accumulations, dust, fillings,

etc.).

When a dynamic load is approximated to an additional static load, this additional

load, which stems from normally occurring conditions of impacts and vibrations, is

included in this load category. (See sub-section 2.4.a).

Normal live loads are sub-divided as follows:

LL1

Live load (per m, per m2 or as a point load) from plant operators,

furniture and equipment, stored or transported goods and materials.

(Normal operating conditions).

LL2

Material accumulations and similar conditions.

LL3

Traffic load. (As e.g. loads originating from trucks operating in stores,

loads from rolling materials handling devices, etc.).

LL4

Static additional load equivalent to a dynamic vibration or impact

load.

LL5

Dynamic vibration or impact load.

LL6

Explosion load and similar conditions.

LL7

Friction load originating from thermal expansions and contractions.

The information transmitted by this document is the proprietary and confidential property of FLSmidth

and may not be duplicated, disclosed or utilized without written consent from FLSmidth.

7/16

Structural design and erection

749500-13.0

2.5.3 Live loads, extraordinary

The loads only affect the construction transiently and only occur where extreme

operating conditions for the equipment or plant department are encountered.

Cases in point include explosions, falling objects or collisions.

Extraordinary live loads are sub-divided as follows:

EL1

Falling objects, shock impacts, etc.

EL2

Collision impacts, etc.

EL3

Extraordinary material accumulations, etc.

EL4

Explosion recoil loads, etc.

Additional information regarding explosion recoil load might be stated in the

drawings:

The duration of the pulse of explosion recoil loads in seconds [s].

tR

The impulse transmitted by the explosion recoil load [kNs].

IR

The assumption is that extraordinary live loads act simultaneously with the load

types DL1, DL2, LL1, LL2 and LL3, but not simultaneously with neither LL4, LL5,

LL6 nor LL7.

2.5.4 Natural loads

Reference is made to sub-section 2.3.

2.5.5 Special loads

In case of quite extraordinary load types, these will in each individual case be

specified and described on drawings.

8/16

The information transmitted by this document is the proprietary and confidential property of FLSmidth

and may not be duplicated, disclosed or utilized without written consent from FLSmidth.

Structural design and erection

749500-13.0

2.6

Deck and roof

Levels are given to top of concrete or top of steel structure. However, for secondary

platform without equipment the level is to top of grating or embossed plate

(chequered plate).

The drawings specify the uniformly distributed live load as well as any live loads

acting as line or point loads.

If specific deck areas require designing for a higher live load than the remaining part

of the deck (uniformly distributed loads or point loads), this area will be marked on

the drawing, specifying the live load applying to that area.

All concrete decks and roofs must be designed to withstand the below-mentioned

single loads (P1 and P2) which are applied to the deck at random points. The single

loads, which may be considered as normal live loads, are not assumed to act

simultaneously nor coinciding with the live loads specified on the drawings for deck

and roof constructions.

Specified uniformly

distributed live load

Single

load

Single

load

Single

load

P1

P2

P3

kN/m2

kN

kN

kN

25.0

18.0

7.0

20.0

15.0

6.0

10.0

12.0

5.0

7.5

11.0

4.5

5.0

10.0

4.0

2.5

5.0

1.5

3.0

2.0

4.0

1.5

2.5

1.5

2.0

1.0

1.0

P1 is assumed to act over an area of 0.75 m x 0.75 m

P2 is assumed to act over an area of 0.2 m x 0.2 m

P3 is assumed to act over an area of 0.1 m x 0.1 m

The information transmitted by this document is the proprietary and confidential property of FLSmidth

and may not be duplicated, disclosed or utilized without written consent from FLSmidth.

9/16

Structural design and erection

749500-13.0

2.7

Special load requirements for roofs without access

Unless otherwise specified, it must be assumed that light roofs without access are

subjected to a uniformly distributed live load LL1 (dust) of 0.75 kN/m2 (horizontal

projection), whereas concrete roofs without access are assumed to be subjected to a

uniformly distributed live load LL1 (dust) of 1.0 kN/m2 (horizontal projection).

In connection with pre-fabricated concrete roofs and light steel roofs, the purlins

must as a minimum requirement be able to absorb a single load of 1 kN, applied at

random points and act simultaneously with LL1. Rafter constructions in workshops,

etc. must likewise be capable of absorbing a single load of 10 kN, applied at random

points to the underside of rafter and simultaneously with LL1.

2.8

Stairs and landings

If not otherwise stated the connecting stairs and landings have to be

designed for the same load as the evenly distributed load for the deck or

platform, where the stairway leads to. However max 5 kN/m2.

Execution of support structure

3.1

Settlements

If the equipment is supported by several supports, the supports must be executed so

that detrimental differential settlements are avoided.

In general the GA- or OL-drawings are specifying the maximum acceptable

settlement. If settlements, deflections or bendings of the structure due to poor soil

conditions, wind, earthquake etc. exceed the given figures, the Supplier must be

contacted for his approval.

Separate supports for gear units and motors must be executed to prevent differential

settlements from occurring between the support of the machine and the support of

the drive station.

If a number of silos are erected next to one another or in connection with other

buildings, the silo foundations must be executed so that following a maximum load

condition (full silo) no settlements occur having detrimental effects on the connecting

conveyors.

3.2

Concrete strength

Concrete used for the execution of support structures must have a 28-day cube

strength T 30 MN/m2, corresponding to a 28-day cylinder strength of C 25

MN/m2.

3.3

Surface reinforcement

Concrete support structure for kilns, mills, main gear units, crushers and other heavy

machinery must be executed with an appropriate surface reinforcement, however, as

a minimum 7 kg/m2.

When determining the reinforcement, account must be taken of the influences from

the equipment, including temperature loads.

Concrete supports for small-size equipment must be executed with appropriate

surface reinforcement, however, as a minimum 3.5 kg/m2.

The lateral face reinforcement of the concrete support must be carried to level where

it covers the construction joint between the first pour and grouting which is executed

after the equipment has been mounted. See Figs. 3.4a and 3.4b and sub-sections

3.4, 3.5 and 3.6.

10/16

The information transmitted by this document is the proprietary and confidential property of FLSmidth

and may not be duplicated, disclosed or utilized without written consent from FLSmidth.

Structural design and erection

749500-13.0

3.4

Alignment and grouting

The support heights are stated on the drawings with a level corresponding to the

underside of the equipment supporting surface.

Normal mounting means that the equipment must be aligned. Unless otherwise

specified, the equipment must be supported on the entire supporting face.

When equipment has small supporting faces, alignment plates must be used, if

required directly on to steel or concrete bases.

Gear unit and motor must always be supported by minimum 10 mm alignment irons,

taking account possible future replacement of gear unit and motor, which may have

minor dimensional deviations when supplied. Place the alignment irons between the

foundation blocks or the rails, if any, according to the instruction manuals.

When aligning equipment having large supporting faces, subsequently involving

grouting with concrete or mortar, the support must not be carried to the full height

during the initial pouring operation.

To ensure proper grouting under the entire supporting face, usually 100 mm are

required for large supporting faces, whereas small supporting faces require 50 mm.

In special cases is required non-shrinking mortar. The use of non-shrinking mortar is

specified in the applicable instruction manuals.

The grout thickness must be determined by the consulting civil engineering

company.

The contractor must consider to use templates in order to keep the tolerances

between multiple bolt for fixing the bolts during grouting.

The construction joint between first pour and the grout must be executed so that an

effective connection is established.

The information transmitted by this document is the proprietary and confidential property of FLSmidth

and may not be duplicated, disclosed or utilized without written consent from FLSmidth.

11/16

Structural design and erection

749500-13.0

Figs. 3.4a and 3.4b.

1.

Grout the holding down bolts here after coarse alignment of the equipment.

2.

Do not forget wedges or shims on either side of the bolt.

3.

Bend down the side face reinforcement.

4.

Spot welding, if required.

5.

Support height specified on drawings.

6.

Grout (50-100 mm) after fine alignment of the equipment.

7.

Support height without grout.

8.

In some cases it is required to embed the support frames. See specifications on

drawings.

When the equipment is attached to embedded plates, the plates must be inserted in

the formwork and support must be carried up to full height.

Supports for equipment requiring fastening with expansion bolts, stud anchors or

similar must be carried to the full height.

Some heavy equipment, e.g. preheater cyclones, is supported directly on the first

concrete pour. Grouting below the supporting surface can not be used due to friction

loads from heat expansions and extractions from the equipment. Tolerances of the

first pour are stated on the GA- or OL-drawings.

12/16

The information transmitted by this document is the proprietary and confidential property of FLSmidth

and may not be duplicated, disclosed or utilized without written consent from FLSmidth.

Structural design and erection

749500-13.0

3.5

Bolt holes

After the equipment has been mounted and aligned, grout the holding down bolts

freely suspended from the equipment. Use mortar or concrete having a minimum

strength as specified in sub-section 3.2.

Holding down bolt holes indicated on drawings by e.g. 100/M24 may be made round

having a diameter of 100 mm, or square with a side of 100 mm. M24 indicates that a

24 mm bolt must be grouted.

The hole must be made using corrugated steel or plastic moulds ensuring an

effective connection with the grout.

When the holding down bolts are to be grouted, the bolts must be degreased and be

absolutely free from oil. Remove water and impurities at the bottom of the holding

down bolt holes before grouting.

3.6

Final grouting

Having finally aligned the equipment and tightened up the holding down bolts, grout

or embed the equipment.

Use mortar or concrete having strength as specified in sub-section 3.2.

When proportioning mortar and concrete, use correctly graduated additives having

an adequate maximum stone size to ensure good placement properties. It may be

required to use special grouting mortars for particular applications.

For heavy equipment the sequence and number of groutings as well as the use of

non-shrinking mortar are described in the mechanical instruction manuals. These

manuals must be handed over to the contractor before the work commence.

Prior to grouting or embedment of the equipment, the parts to be grouted and

embedded must be degreased and cleaned.

Remove (chip off) any oil spillage, grease stains and impurities on the concrete in

the construction joint.

Embed the support flange only if it is shown on the drawings or required in the

instruction manuals.

Various specifications

4.1

Water seepage

Roofs must be constructed so as to avoid water accumulations and water seepage.

Holes in roofs for lead-in of machines and pipes to be made with a raised edge of

minimum 100 mm in order to prevent rainwater seepage. On completion of

mounting, the equipment must be provided with a cap, which is extended beyond the

raised edge.

Storey partitions, which also are roofs in a closed room, must be constructed so that

no water seeps into the room.

4.2

Covering and flashing

Coverings and flashings must be made to the extent shown on the GA drawings.

Coverings and flashings must be constructed to avoid water ingress and water

seepage. Openings in building fronts for ventilation or pressure relief from explosion

flaps must likewise be made as shown on the GA drawings.

Any deviations will be accepted only subject to prior arrangement with Supplier.

The information transmitted by this document is the proprietary and confidential property of FLSmidth

and may not be duplicated, disclosed or utilized without written consent from FLSmidth.

13/16

Structural design and erection

749500-13.0

4.3

Drain

Pits, basements, inspection trenches, etc. placed below ground level must be made

watertight and must be provided with pump sumps or water drainpipes discharging

into a permanent drainage system.

When carrying out the design and execution of drainpipes and drainage systems,

spillage of raw meal, clinker, cement, oil, petrol, etc. entering the drainage system

must be avoided.

Drains are required at water drain-off points.

Where equipment is placed at ground level, it must be inclined to ensure that

surface water is diverted.

Rain water must be drained away from the foundations and supports.

4.4

Floors and walls

Due consideration must be taken to the finish of surfaces of floors and walls in rooms

for oil, water, electrical equipment, etc. Tiles and painting to be considered due to

house keeping and resistance for water and oil.

Holes in floors for equipment passing through must be provided with a 100 mm high

surrounding edge and closed with a max remaining opening of 50 mm. For larger

openings hand railing may be provided.

Examples of "misfit":

Examples of holes that must be closed or otherwise ensured against personal

injures:

Mentioned "misfit" examples can be corrected by closure, surrounding edges and/or

hand railing:

4.5

Stairways and walkways

Safety guards to stairways, walkway, platforms, etc. to be made in compliance with

local safety and health regulations.

Openings in floors to be provided with toe plates or raised edges with a minimum up

stand of 100 mm and placed maximum 10 mm from the finished floor level.

The locations given for main stairways and stair flights are for guidance only.

However, the location of stairways and ladders for access platforms and equipment

is final and binding.

14/16

The information transmitted by this document is the proprietary and confidential property of FLSmidth

and may not be duplicated, disclosed or utilized without written consent from FLSmidth.

Structural design and erection

749500-13.0

If not otherwise stated in the contract permanent stairs and guardrails have to

conform to EN ISO 14122-3.

Example: The minimum headroom (vertical distance) for working platforms and

walkway, etc. is 2100 mm. The minimum headroom for stairs is 2300 mm. The

minimum clearance (perpendicular distance) is 1900 mm.

Guardrails must be provided if the vertical distance between two levels exceeds 500

mm.

4.6

Exit doors

Exit doors must be equipped with anti-panic bar opening system.

4.7

Steel or concrete structures

Indications of building construction for steel or concrete are for guidance only.

4.8

Constructional elements (beams, columns, braces, etc.)

The dimensions of constructional elements (beams, columns, etc.) are approximate.

It is the obligation of the civil designer to assess the indicated location of columns

and beams, choice of materials and enclosures, and in consultation with Supplier to

establish the most suitable structural system from a material optimisation point of

view but still ensuring a robust and flexible structural system which is easy to

manufacture and construct and which can be adjusted to the possible changes which

may be introduced by the Buyer and/or the authorities during the approval process.

Consult Supplier, if the final dimensions result in reduced space around the

equipment.

GA drawings do not specify stiffening braces in steel constructions. These must be

determined taking account of equipment, pipes, access conditions, maintenance and

service, etc.

Special requirements apply for buildings where inflammable dust can occur.

4.9

Tolerances

If GA or OL drawings does not specify any special tolerance requirements, the civil

contractor must ensure that the geometry of the finished buildings meets the

following requirements concerning maximum permissible tolerances:

General:

Plotting of main axes relative to

established superior plotting system

25 mm

Concrete constructions:

Position of construction elements relative

to plotted line system

15 mm

Cross sectional dimensions of

construction elements

+ 15 mm

Dimensions and position of holes and

recesses

10 mm

Position of grouted components

10 mm

Straightness of decks measured with 3metre straight edge

- 5 mm

+ 5 mm

The information transmitted by this document is the proprietary and confidential property of FLSmidth

and may not be duplicated, disclosed or utilized without written consent from FLSmidth.

15/16

Structural design and erection

749500-13.0

Steel constructions:

Distance between columns

3 mm

Deck elevations

5 mm

Dimensions and location of holes, etc.

5 mm

5 Erection corrections

Normal erection operations include the correction of minor misfits by moderate

amounts of straightening, shimming, reaming, chipping, cutting or grinding and the

drawing of elements into line using drift pins. Misfits which cannot be corrected by

the foregoing means or which require major changes in equipment configuration are

to be reported immediately to Supplier by the erection contractor, to enable Supplier

either to correct the misfit or to approve the most efficient and economic method of

correction to be implemented.

---o0o---

16/16

The information transmitted by this document is the proprietary and confidential property of FLSmidth

and may not be duplicated, disclosed or utilized without written consent from FLSmidth.

You might also like

- Structural Health MonitoringFrom EverandStructural Health MonitoringDaniel BalageasNo ratings yet

- A4-P - 8 0 - enDocument6 pagesA4-P - 8 0 - enmkpqNo ratings yet

- Girth Gear & PinionDocument4 pagesGirth Gear & Pinionprashant mishraNo ratings yet

- A4-P 3.1 enDocument47 pagesA4-P 3.1 enmkpqNo ratings yet

- Ball Mill GrindingDocument78 pagesBall Mill GrindingFran jimenezNo ratings yet

- 06Document8 pages06rat12345No ratings yet

- A4-P 1.0 enDocument53 pagesA4-P 1.0 enmkpq100% (1)

- 01-01-PODFA-Equipment OverviewDocument31 pages01-01-PODFA-Equipment OverviewДен СтаднікNo ratings yet

- Influence of Quartz Particles On Wear in Vertical Roller Mills.Document9 pagesInfluence of Quartz Particles On Wear in Vertical Roller Mills.chienhamthepNo ratings yet

- FL Smidth - Mill BearingDocument16 pagesFL Smidth - Mill Bearingzementhead100% (1)

- Screen Media FL SmithDocument24 pagesScreen Media FL SmithDAVID VENEGASNo ratings yet

- Roll Crusher For REPOL® POLYTRACK®Document54 pagesRoll Crusher For REPOL® POLYTRACK®Rahmat Hidayat100% (1)

- VibrofeederDocument32 pagesVibrofeederNaveen LingamkuntaNo ratings yet

- Elevator Belt and Splice Installation GuideDocument17 pagesElevator Belt and Splice Installation Guide4B Braime ComponentsNo ratings yet

- A4-P 1.0 enDocument13 pagesA4-P 1.0 enmkpqNo ratings yet

- Vibrating FeederDocument7 pagesVibrating FeederRk Upadhyay100% (1)

- 70000905clinker Crusher (Peyvand)Document32 pages70000905clinker Crusher (Peyvand)hamid hoorshadNo ratings yet

- E0012 FLS L61 PM em MR01 01 - R1.0 PDFDocument4 pagesE0012 FLS L61 PM em MR01 01 - R1.0 PDFVegaGonzalezNo ratings yet

- MAMMUT Single-Shaft Hammer Crusher: HilfsvorrichtungenDocument1 pageMAMMUT Single-Shaft Hammer Crusher: HilfsvorrichtungenpeymanNo ratings yet

- Coal Mill Wear Measurement 29.09.2014Document1 pageCoal Mill Wear Measurement 29.09.2014Durga PrasadNo ratings yet

- Maintenance of POLYCOM Roll Bodies With Studs: Machine Manual en-PM - RUN.003.BDocument51 pagesMaintenance of POLYCOM Roll Bodies With Studs: Machine Manual en-PM - RUN.003.BYinder Vega OsorioNo ratings yet

- HMA-36509 - Reclaim Feeder Manual RevcDocument111 pagesHMA-36509 - Reclaim Feeder Manual RevcAbdul HamidNo ratings yet

- Parts List For Pulse-Jet Fabric Filter HatchDocument5 pagesParts List For Pulse-Jet Fabric Filter HatchIngeniero mecanico F.N.I.No ratings yet

- Bogiflex KGD20 - For PlantDocument13 pagesBogiflex KGD20 - For PlantAnonymous PVXBGg9TNo ratings yet

- Cast Central Pipe - EN - SmidthDocument4 pagesCast Central Pipe - EN - SmidthLuis Orlando Villarroel TorrezNo ratings yet

- A4-P 1.0 enDocument45 pagesA4-P 1.0 enmkpqNo ratings yet

- Installation Handbook - Multiply Conveyor Belts - Rev.4Document36 pagesInstallation Handbook - Multiply Conveyor Belts - Rev.4Guru Raja Ragavendran NagarajanNo ratings yet

- 03 RP - Maintenance Practices For RPDocument50 pages03 RP - Maintenance Practices For RPaff bearNo ratings yet

- Erection of A L Loesche Mill: LM 46 LM 46. 2 + 2S .2 2SDocument55 pagesErection of A L Loesche Mill: LM 46 LM 46. 2 + 2S .2 2SKob PuangthaisongNo ratings yet

- Atox 20 Coal Mill Critical Interlock SheetDocument6 pagesAtox 20 Coal Mill Critical Interlock SheetValipireddy NagarjunNo ratings yet

- FLS OK Cement Mill WEBDocument8 pagesFLS OK Cement Mill WEBjinendraNo ratings yet

- Ball Mill ManualDocument7 pagesBall Mill ManualAnonymous EBReO8vNo ratings yet

- Pan ConveyorsDocument24 pagesPan ConveyorswereerNo ratings yet

- BEUMER Bucket ElevatorsDocument12 pagesBEUMER Bucket ElevatorsIsmailNo ratings yet

- 01.0 - 22146.002E - Hydraulic SystemDocument126 pages01.0 - 22146.002E - Hydraulic SystemShariq Khan100% (1)

- Kiln Out LetDocument2 pagesKiln Out LetSamehibrahemNo ratings yet

- Pneumatic Conveying: Technology You Can TrustDocument16 pagesPneumatic Conveying: Technology You Can TrustSyed Rameez MohiuddinNo ratings yet

- Fons Technology PDFDocument28 pagesFons Technology PDFBulent BULUTNo ratings yet

- Chian BE InspectionDocument8 pagesChian BE InspectionGarfang RattanapunNo ratings yet

- A4-P 3.0 enDocument33 pagesA4-P 3.0 enmkpqNo ratings yet

- Type of SurfaceDocument31 pagesType of SurfaceD N SHARMANo ratings yet

- A4-P 1.0 enDocument27 pagesA4-P 1.0 enmkpqNo ratings yet

- Enexco BrochureDocument35 pagesEnexco BrochureErin CraigNo ratings yet

- Rubber Conveyor Belt SpecificationDocument4 pagesRubber Conveyor Belt SpecificationPrashant MishraNo ratings yet

- A4-P 1.0 enDocument21 pagesA4-P 1.0 enmkpqNo ratings yet

- Slurry Pump: Learner GuideDocument22 pagesSlurry Pump: Learner GuideRobson DE Freitas WerlingNo ratings yet

- Ball MillDocument10 pagesBall MillLuthfanNo ratings yet

- Impact CrusherDocument8 pagesImpact CrusherSharath MenonNo ratings yet

- Mat 3810 For Suppliers PDFDocument3 pagesMat 3810 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- A4-P 1.1 enDocument23 pagesA4-P 1.1 enmahantmtech100% (1)

- 01 - t-01 Instruction HandbookDocument15 pages01 - t-01 Instruction HandbookShariq KhanNo ratings yet

- Polycom High-Pressure Grinding Roll: Our New Name IsDocument7 pagesPolycom High-Pressure Grinding Roll: Our New Name Isrmano22No ratings yet

- 3-Bucket Elev. & 4-Chain ConvDocument24 pages3-Bucket Elev. & 4-Chain ConvYhaneNo ratings yet

- WobblerDocument1 pageWobblerptjpcsbyNo ratings yet

- Jaypee Cement Project ReportDocument29 pagesJaypee Cement Project ReportPurnendu MishraNo ratings yet

- Design Guide For Air Slide Conveyor PDFDocument4 pagesDesign Guide For Air Slide Conveyor PDFDaniel0010100% (2)

- MDR Manufacturers Data Report InfoDocument13 pagesMDR Manufacturers Data Report InfoSaut Maruli Tua Samosir100% (4)

- General Arrangement LegendDocument5 pagesGeneral Arrangement Legendmkpasha55mpNo ratings yet

- Juno-DRF - TXT - 20141001Document18 pagesJuno-DRF - TXT - 20141001Cain Peña100% (2)

- Manufacturers Data Report (MDR) - Plant Projects EP-08-030-37Document17 pagesManufacturers Data Report (MDR) - Plant Projects EP-08-030-37MekhmanNo ratings yet

- ISO 281-2007 Bearing Life StandardDocument9 pagesISO 281-2007 Bearing Life Standardgarron71100% (2)

- Anmol Khazaney by Hakeem Muhammad Tariq MahmoodDocument35 pagesAnmol Khazaney by Hakeem Muhammad Tariq MahmoodmkpqNo ratings yet

- 10 Sylvie Valero SealsDocument43 pages10 Sylvie Valero SealsmkpqNo ratings yet

- The Hydraulic Trainer Volume 1 (Basic Principles & Components of Fluid Technology)Document327 pagesThe Hydraulic Trainer Volume 1 (Basic Principles & Components of Fluid Technology)Guido Dorigoni100% (32)

- 132 Loesche Mills For Solid Fuels Coal Mill E 2016Document24 pages132 Loesche Mills For Solid Fuels Coal Mill E 2016Verananda Ariyanto100% (1)

- Alam e Islam Ebooks 1Document150 pagesAlam e Islam Ebooks 1mkpqNo ratings yet

- Jackup RigDocument22 pagesJackup RigmkpqNo ratings yet

- Ball Mill Inspection ProcedureDocument28 pagesBall Mill Inspection ProcedureRolando Quispe100% (6)

- Applied Sciences: Ffect of Venturi Structures On The CleaningDocument16 pagesApplied Sciences: Ffect of Venturi Structures On The CleaningmkpqNo ratings yet

- Applied Sciences: Ffect of Venturi Structures On The CleaningDocument16 pagesApplied Sciences: Ffect of Venturi Structures On The CleaningmkpqNo ratings yet

- Cement and LimeDocument127 pagesCement and LimeEhab Anwer HassanNo ratings yet

- Gear and Bearing Fatigue DamageDocument18 pagesGear and Bearing Fatigue DamagemkpqNo ratings yet

- Ball Mill Inspection ProcedureDocument28 pagesBall Mill Inspection ProcedureRolando Quispe100% (6)

- Imran Series 1 Khofnak ImaratDocument58 pagesImran Series 1 Khofnak ImaratmedowbreezeNo ratings yet

- Bucket ElevatorsDocument8 pagesBucket ElevatorsmkpqNo ratings yet

- Technical Manual Sample PagesDocument4 pagesTechnical Manual Sample PagesmkpqNo ratings yet

- 03 - Assembly Instruction SB-IVE DN40Document30 pages03 - Assembly Instruction SB-IVE DN40mkpqNo ratings yet

- 03 Operating Manual Silencer With Baffles en 01Document11 pages03 Operating Manual Silencer With Baffles en 01mkpqNo ratings yet

- 01 - Assembly Instruction SB-V BB DN100Document31 pages01 - Assembly Instruction SB-V BB DN100mkpqNo ratings yet

- 01 - Assembly Instruction SB-V BB DN100Document31 pages01 - Assembly Instruction SB-V BB DN100mkpqNo ratings yet

- 01 - Assembly Instruction SB-V BB DN100Document31 pages01 - Assembly Instruction SB-V BB DN100mkpqNo ratings yet

- Document List: The Document List Contains Links To All Files of The Manual. Click On The Green Text To Open A FileDocument4 pagesDocument List: The Document List Contains Links To All Files of The Manual. Click On The Green Text To Open A FilemkpqNo ratings yet

- Cement Dispatched 2016 SummaryDocument7 pagesCement Dispatched 2016 SummarymkpqNo ratings yet

- Bag FilterDocument27 pagesBag FiltermkpqNo ratings yet

- Asep Steel HandbookDocument422 pagesAsep Steel Handbookmkpq100% (7)

- Cement Industry StudyDocument36 pagesCement Industry Studymkpq100% (2)

- A4-P 1.0 enDocument13 pagesA4-P 1.0 enmkpqNo ratings yet

- A4-P 1.0 enDocument21 pagesA4-P 1.0 enmkpqNo ratings yet

- A4-P 1.0 enDocument27 pagesA4-P 1.0 enmkpqNo ratings yet

- A4-P 1.0 enDocument45 pagesA4-P 1.0 enmkpqNo ratings yet

- BTP Assignment Set - 2018 PDFDocument17 pagesBTP Assignment Set - 2018 PDF9510851294No ratings yet

- Testing A Metalenclosed Bus PDFDocument10 pagesTesting A Metalenclosed Bus PDFTunoNegro1No ratings yet

- 1.reply To Consultant CommentsDocument1 page1.reply To Consultant Commentsjayaprakaash100% (1)

- Necessity For Ethics in Social EngineeringDocument14 pagesNecessity For Ethics in Social EngineeringMatt BaileyNo ratings yet

- Easy Hydraulic MachinesDocument11 pagesEasy Hydraulic MachinesMaridjan WiwahaNo ratings yet

- Mastip Technology IntroductionDocument12 pagesMastip Technology IntroductionQuang PhamNo ratings yet

- Preamble About The Subject: Subject Name: Branch Semester/Year Date of SubmissionDocument1 pagePreamble About The Subject: Subject Name: Branch Semester/Year Date of SubmissionSweetlineSoniaNo ratings yet

- CV - Aqeel Ahmed Qazi Updated - Rev - CompressedDocument4 pagesCV - Aqeel Ahmed Qazi Updated - Rev - Compressedsidiq7No ratings yet

- 2paa105801r0201 BDMDocument46 pages2paa105801r0201 BDMmostafa_60No ratings yet

- Channel Court Shopping CentreDocument2 pagesChannel Court Shopping CentrePi SopiNo ratings yet

- Handbook - Chairman's Message & PrefaceDocument8 pagesHandbook - Chairman's Message & PrefacemakrsnakminesNo ratings yet

- Rein F Detail Footing ColDocument25 pagesRein F Detail Footing Colshailesh goralNo ratings yet

- Linear Analysis of Guyed MastDocument6 pagesLinear Analysis of Guyed MastPankaj_Taneja_9684No ratings yet

- Report On Industrial Visit ScribdDocument11 pagesReport On Industrial Visit ScribdJakeer CJNo ratings yet

- Central Luzon State University: Republic of The Philippines Science City of Muñoz, Nueva EcijaDocument2 pagesCentral Luzon State University: Republic of The Philippines Science City of Muñoz, Nueva EcijaGLENN BRYAN FELIXNo ratings yet

- DDRCS Project IS Codes-1Document3 pagesDDRCS Project IS Codes-1Devendra SharmaNo ratings yet

- Bmitted To: Submitted By:: "DTMF Controlled Robot Without Microcontroller"Document9 pagesBmitted To: Submitted By:: "DTMF Controlled Robot Without Microcontroller"XtremeInfosoftAlwarNo ratings yet

- Abhishek IITB ResumeDocument1 pageAbhishek IITB ResumeAbhishek ChaurasiyaNo ratings yet

- LNG and Condensate Loading Jetty Projectsheet DMCDocument2 pagesLNG and Condensate Loading Jetty Projectsheet DMCRaymond Jackson100% (1)

- Revised Minimum Performance Standards/ Specifications (By Technical Committee) I. Governing Codes and SpecificationsDocument6 pagesRevised Minimum Performance Standards/ Specifications (By Technical Committee) I. Governing Codes and SpecificationsBendaña KHayeNo ratings yet

- Final Year Building Project PresentationDocument48 pagesFinal Year Building Project PresentationSudeen ShresthaNo ratings yet

- External Pressure CalculationsDocument40 pagesExternal Pressure Calculationsmisterdavi50% (2)

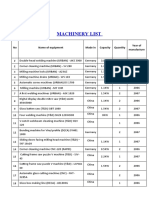

- Machinery List-1Document2 pagesMachinery List-1Hồng HạnhNo ratings yet

- USACE Contractor Database As of 23 MAY 22 For PostingDocument45 pagesUSACE Contractor Database As of 23 MAY 22 For Postingdora tavarezNo ratings yet

- An Introduction To BS 7910 2006Document15 pagesAn Introduction To BS 7910 2006api-3855165100% (4)

- SBO Achievement Week 5 January-1Document1 pageSBO Achievement Week 5 January-1sultan bintangNo ratings yet

- BIBLIOGRAFIE Design de ProdusDocument3 pagesBIBLIOGRAFIE Design de ProdusAna Izabela MunteanuNo ratings yet

- CV. Muhammad Bin SurpadiDocument6 pagesCV. Muhammad Bin SurpadiShaiful Annuar50% (2)

- About DasDocument2 pagesAbout DasnmurugesanNo ratings yet

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsFrom EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsRating: 5 out of 5 stars5/5 (1)

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)From EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Rating: 5 out of 5 stars5/5 (2)

- Beginning AutoCAD® 2020 Exercise WorkbookFrom EverandBeginning AutoCAD® 2020 Exercise WorkbookRating: 2.5 out of 5 stars2.5/5 (3)

- SketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyFrom EverandSketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyRating: 1.5 out of 5 stars1.5/5 (2)

- Autodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersFrom EverandAutodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersNo ratings yet

- Certified Solidworks Professional Advanced Surface Modeling Exam PreparationFrom EverandCertified Solidworks Professional Advanced Surface Modeling Exam PreparationRating: 5 out of 5 stars5/5 (1)

- Product Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesFrom EverandProduct Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesRating: 4 out of 5 stars4/5 (4)

- Contactless Vital Signs MonitoringFrom EverandContactless Vital Signs MonitoringWenjin WangNo ratings yet

- FreeCAD | Design Projects: Design advanced CAD models step by stepFrom EverandFreeCAD | Design Projects: Design advanced CAD models step by stepRating: 5 out of 5 stars5/5 (1)