Professional Documents

Culture Documents

MeasurIT Tideflex - 37 0906

Uploaded by

cwiejkowskaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MeasurIT Tideflex - 37 0906

Uploaded by

cwiejkowskaCopyright:

Available Formats

ValvesSensorsSystems measurIT technologies

20 years

Tideflex

in Ireland

Tideflex® series 37 Check Valve

1989 009

-2

• Installs between pipe flanges, eliminating valve body.

Fastened with internal expansion clamp.

• Offers minimal face-to-face dimension - only the

thickness of the flange.

• Features unique, maintenance-free, one-piece

elastomer check sleeve design.

• Eliminates chatter—silent, non-slamming.

• Closes on entrapped solids.

MATERIALS:

Body: Pure Gum Rubber,

Neoprene, Buna-N, Hypalon,

H

EPDM, Viton,

Forward Flow Backflow Flanges: ANSI Class 125,

valve opens easily valve seals tightly DIN PN6, PN10, PN16.

Special coating available D

L

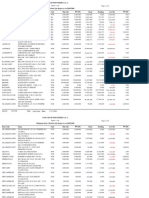

The Series 37 Flanged InLine Check Valve is a simple, Max backpressure [bar]

nominal

reliable, costeffective solution to backflow problems.

size* [mm] L [mm] H [mm] D [mm] standard with saddle

Designed to be installed between two mating flanges, the (pipe ID) Tideflex support

Series 37 eliminates the need for a valve body. 50 125 47 9 10.3 N/A

With only one moving part, the maintenance-free rubber 75 138 72 9 6.9 N/A

check sleeve, the Series 37 Check Valve is simple in 100 175 97 9 5.2 10.3

design. Sliding, rotating, swinging and spring parts are 150 275 147 9 5.2 10.3

eliminated. There are no seats to corrode or packing

to maintain. In addition, the Series 37 is a passive 200 313 197 13 4.1 8.6

design, requiring no external source of air or electricity 250 388 247 13 3.1 5.2

to operate. The result is reduced operating costs.

300 463 297 13 2.4 5.2

The Series 37 Check Valve can be ordered in a variety of 350 550 344 16 1.7 4.8

elastomers. Flanges conform to ANSI B16.1 Class 125 400 575 394 19 1.4 4.1

specifications. Special custom designs or metric flanged

models are also available. When ordering, specify line 450 600 444 25 1.0 3.1

pressure, backpressure and whether an SST is required. 500 800 494 25 0.7 2.8

The pressure drop of the Series 37 is increased because 600 925 594 25 0.7 2.8

of the smaller ID required to fit the check valve in the 750 1025 744 38 0.6 2.8

line.

900 1175 894 38 0.6 2.4

Headloss charts request - please email us with 1050 1225 1038 44 0.3 1.7

information about valve type and size. We will send you 1200 1300 1188 44 0.3 1.7

a headloss chart of the valve that meets pressure and

hydraulic requirements for your specific project. 1350 1425 1338 50 0.3

1500 1600 1488 50 0.3 for enquiry

1800 1825 1788 50 0.3

Numbers indicate maximum dimensions in millimetres.

* Larger sizes available upon request.

MeasurIT Technologies Ltd.

Craan, Craanford, email: info@measurIT.com Phone: +353 (0) 53 942 8962

Gorey, Co. Wexford, Ireland www.measurIT.com Fax: +353 (0) 53 942 8963

You might also like

- Demco Gate Valve PDFDocument56 pagesDemco Gate Valve PDFyacine3516100% (1)

- FactSheet - EcoBoostDocument2 pagesFactSheet - EcoBoostFord Motor Company100% (2)

- Demco Gate ValvesDocument52 pagesDemco Gate ValvesJuan Lorenzo100% (1)

- Butterfly Valve FundamentalDocument40 pagesButterfly Valve Fundamentaldocdia1235083No ratings yet

- 7.1. Concrete MixDocument17 pages7.1. Concrete MixKrishna SankarNo ratings yet

- 1600 Kva GTPDocument3 pages1600 Kva GTPBADRI VENKATESHNo ratings yet

- ARC 213 History of Architecture Lecture NotesDocument137 pagesARC 213 History of Architecture Lecture NotesMar Cariaga Opeña57% (7)

- Demco CatalogDocument50 pagesDemco CatalogEduardo100% (3)

- Instruction Manual Instruction Manual: Operating & Maintenance Operating & MaintenanceDocument106 pagesInstruction Manual Instruction Manual: Operating & Maintenance Operating & MaintenanceCris LozoyaNo ratings yet

- Best PPT On VALVESDocument155 pagesBest PPT On VALVESPanda BoyNo ratings yet

- Demco Gate Valves BrochureDocument56 pagesDemco Gate Valves BrochureVictor100% (1)

- Architect 092016Document216 pagesArchitect 092016Anonymous IGtWHoi00% (1)

- Gate ValveDocument56 pagesGate ValveNitesh Shetty100% (2)

- Sanitary FittingsDocument58 pagesSanitary FittingsMherlieNo ratings yet

- Ingersollrand P260WIRDocument2 pagesIngersollrand P260WIROjik OnlineNo ratings yet

- Lift Slab ConstructionDocument123 pagesLift Slab Constructionarunavails100% (2)

- MeasurIT Tideflex - 37G 0905Document1 pageMeasurIT Tideflex - 37G 0905cwiejkowskaNo ratings yet

- MeasurIT Tideflex Valves Full 0912Document9 pagesMeasurIT Tideflex Valves Full 0912Lalo SepulvedaNo ratings yet

- Cilindro Posicionador Martonair NorgrenDocument7 pagesCilindro Posicionador Martonair NorgrenMikelNo ratings yet

- Demco ValvesDocument48 pagesDemco ValvesEizeldin KhalilNo ratings yet

- Victaulic Flexible Hose Connecting To Regular Reliable SprinklerDocument27 pagesVictaulic Flexible Hose Connecting To Regular Reliable SprinklerOwais AhmedNo ratings yet

- BsdcatalogDocument2 pagesBsdcatalogrickbolgerNo ratings yet

- Victaulic Flexible Hose Connecting To Dry Barrel SprinklerDocument27 pagesVictaulic Flexible Hose Connecting To Dry Barrel SprinklerOwais AhmedNo ratings yet

- B-0010 Butterfly ValveDocument11 pagesB-0010 Butterfly ValveLudi D. LunarNo ratings yet

- Outfits and RegulatorsDocument6 pagesOutfits and Regulatorsfjrank_frankNo ratings yet

- Клапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnDocument12 pagesКлапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnAli KianersiNo ratings yet

- Bermad: Quick Pressure Relief ValveDocument2 pagesBermad: Quick Pressure Relief ValveCarlos Rovello GandoNo ratings yet

- Ps 001222Document16 pagesPs 001222Lassané KINDONo ratings yet

- A Mefi MC001 E1Document16 pagesA Mefi MC001 E1aptureincNo ratings yet

- 6240 SpecDocument2 pages6240 SpecCarlos Miguel Barrena TorresNo ratings yet

- Valv Diluvio Claval Diafragma TubularDocument29 pagesValv Diluvio Claval Diafragma TubularDaniel ReyNo ratings yet

- S SE ER RI IE ES S: Rotary Screw Compressors by DevairDocument4 pagesS SE ER RI IE ES S: Rotary Screw Compressors by DevairSethuraman Kumarappan (KPCL)No ratings yet

- Seawater Fire Deluge Valve: 800 Series (Tubular Diaphragm Valve)Document2 pagesSeawater Fire Deluge Valve: 800 Series (Tubular Diaphragm Valve)dmitosNo ratings yet

- Cam Switches CA SeriesDocument26 pagesCam Switches CA SeriesEdwin SaynesNo ratings yet

- Dresser Nut Valves: 300 SeriesDocument5 pagesDresser Nut Valves: 300 SeriesDaniel PáezNo ratings yet

- Mini Vitaq - 022858Document4 pagesMini Vitaq - 022858Ahmed SalemNo ratings yet

- (2018) MN-41005 - Brochure-Gea19372a-EnDocument8 pages(2018) MN-41005 - Brochure-Gea19372a-EnAqua SamaNo ratings yet

- Application EngineeringDocument4 pagesApplication EngineeringSidali BenmiloudNo ratings yet

- CAMERON T30 Series: Fully Welded Ball ValveDocument2 pagesCAMERON T30 Series: Fully Welded Ball ValveEdgar VelandiaNo ratings yet

- Protect and Preserve The Integrity of Electronic Components: Gore Automotive Vents For Adhesive InstallationDocument4 pagesProtect and Preserve The Integrity of Electronic Components: Gore Automotive Vents For Adhesive InstallationBurak YILMAZNo ratings yet

- Series DM Gate Valves: Features and BenefitsDocument3 pagesSeries DM Gate Valves: Features and BenefitsRICHARDNo ratings yet

- Reservoir Vent FiltersDocument8 pagesReservoir Vent FiltersHesham MahdyNo ratings yet

- Product Bulletin Fisher Ez Sliding Stem Control Valve en 124666Document24 pagesProduct Bulletin Fisher Ez Sliding Stem Control Valve en 124666jestin1947No ratings yet

- Feroli Radijatori Club N PDFDocument2 pagesFeroli Radijatori Club N PDFDejan DrincicNo ratings yet

- MVE Eterne Series: - 190°C Vapor StorageDocument2 pagesMVE Eterne Series: - 190°C Vapor StorageraviNo ratings yet

- Honeywell EA79 SpecsDocument6 pagesHoneywell EA79 SpecsNestor PerezNo ratings yet

- Drawing 80AQ15-60 Non CodedDocument2 pagesDrawing 80AQ15-60 Non Codeddaus nasNo ratings yet

- 1 C221 D 01Document4 pages1 C221 D 01Azka AiraNo ratings yet

- 2020 Style 600 CatDocument8 pages2020 Style 600 CatdiamsamNo ratings yet

- Demco DM DTDocument30 pagesDemco DM DTNelsonParedesNo ratings yet

- pdf140 PDFDocument8 pagespdf140 PDFRobson Custódio de SouzaNo ratings yet

- Gas Control: VAREC 7100B SeriesDocument8 pagesGas Control: VAREC 7100B SeriesWilson Ramirez ZuniniNo ratings yet

- Control Valves Two PortDocument16 pagesControl Valves Two Portwendelreis19746883100% (1)

- A11 High Performance Butterfly Valve BulletinDocument28 pagesA11 High Performance Butterfly Valve BulletinRizalfariz HasbiNo ratings yet

- 05 Tyco TJRDocument6 pages05 Tyco TJRsamNo ratings yet

- 39G - Carrier AHUDocument20 pages39G - Carrier AHUnomi1873No ratings yet

- Reflux 819: Pressure RegulatorDocument20 pagesReflux 819: Pressure RegulatorRafael Jose Tasco ZabaletaNo ratings yet

- Pentair Mecair Threaded Pulse Jet ValvesDocument5 pagesPentair Mecair Threaded Pulse Jet ValvesYing Kei ChanNo ratings yet

- Pressure Relief ValveDocument1 pagePressure Relief ValvebuddhikasatNo ratings yet

- Pentair Goyen Manifold Mount Pulse Jet ValvesDocument11 pagesPentair Goyen Manifold Mount Pulse Jet ValvesAbhishek PatelNo ratings yet

- Series 2200 Butterfly Valve Product BrochureDocument18 pagesSeries 2200 Butterfly Valve Product BrochureSandesh KambleNo ratings yet

- Rainwater CalculationDocument2 pagesRainwater Calculationhtinlin09No ratings yet

- V260 Control ValveDocument12 pagesV260 Control ValvenwabukingzNo ratings yet

- Manual Paquete 5 TonDocument4 pagesManual Paquete 5 TonOscar MorenoNo ratings yet

- A6V10387805 - 2-Port Shutoff Valves and 3-Port Changeover Ball V - enDocument16 pagesA6V10387805 - 2-Port Shutoff Valves and 3-Port Changeover Ball V - enhugoNo ratings yet

- Fisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyDocument20 pagesFisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyAlberto GuillenNo ratings yet

- MeasurIT Flexim HPI Project Enterprise Products Pipeline USA 1007Document1 pageMeasurIT Flexim HPI Project Enterprise Products Pipeline USA 1007cwiejkowskaNo ratings yet

- MeasurIT OilSpy Extended Brochure 1003Document5 pagesMeasurIT OilSpy Extended Brochure 1003cwiejkowskaNo ratings yet

- MeasurIT Flexim HPI Project Enterprise Products Pipeline USA 1007Document1 pageMeasurIT Flexim HPI Project Enterprise Products Pipeline USA 1007cwiejkowskaNo ratings yet

- MeasurIT Red Valve Pressure Sensors Series 42 0806Document1 pageMeasurIT Red Valve Pressure Sensors Series 42 0806cwiejkowskaNo ratings yet

- RFQ 0014 1a Level Application At, Km26, MT5000, UltrasonicDocument2 pagesRFQ 0014 1a Level Application At, Km26, MT5000, UltrasoniccwiejkowskaNo ratings yet

- MeasurIT-Tideflex Mixing Systems-White Paper-Preserving Water Quality-1002Document2 pagesMeasurIT-Tideflex Mixing Systems-White Paper-Preserving Water Quality-1002cwiejkowskaNo ratings yet

- MeasurIT Tideflex Project TMS Antioch, USA 1001Document2 pagesMeasurIT Tideflex Project TMS Antioch, USA 1001cwiejkowskaNo ratings yet

- MeasurIT Flexim WaveInjector 1003Document3 pagesMeasurIT Flexim WaveInjector 1003cwiejkowskaNo ratings yet

- MeasurIT Smart Company Measuring Up 0709Document2 pagesMeasurIT Smart Company Measuring Up 0709cwiejkowskaNo ratings yet

- MeasurIT KTek White Paper AccuTrak Level Transmitters 0806Document2 pagesMeasurIT KTek White Paper AccuTrak Level Transmitters 0806cwiejkowskaNo ratings yet

- MeasurIT Red Valve Pressure Sensors Series 40 0806Document1 pageMeasurIT Red Valve Pressure Sensors Series 40 0806cwiejkowskaNo ratings yet

- MeasurIT Tideflex CheckMate 1006Document8 pagesMeasurIT Tideflex CheckMate 1006cwiejkowska100% (1)

- MeasurIT Tideflex White Paper Effluent SystemsDocument8 pagesMeasurIT Tideflex White Paper Effluent SystemscwiejkowskaNo ratings yet

- MeasurIT KTek KM26 Application Power Plants 0807Document2 pagesMeasurIT KTek KM26 Application Power Plants 0807cwiejkowskaNo ratings yet

- MeasurIT Flexim FLUXUS BTU Scheme LinkDocument1 pageMeasurIT Flexim FLUXUS BTU Scheme LinkcwiejkowskaNo ratings yet

- MeasurIT Meaco RX Receiver 0911Document1 pageMeasurIT Meaco RX Receiver 0911cwiejkowskaNo ratings yet

- MeasurIT SINGER Project Brazil Sao Bernardo 0806Document1 pageMeasurIT SINGER Project Brazil Sao Bernardo 0806cwiejkowskaNo ratings yet

- MeasurIT Flexim Sound Velocity and Density 0910Document1 pageMeasurIT Flexim Sound Velocity and Density 0910cwiejkowskaNo ratings yet

- MeasurIT OilSpy Project Trieste 0909Document1 pageMeasurIT OilSpy Project Trieste 0909cwiejkowskaNo ratings yet

- MeasurIT TESTO Saveris Radio Monitoring QS Production 1002Document16 pagesMeasurIT TESTO Saveris Radio Monitoring QS Production 1002cwiejkowskaNo ratings yet

- MeasurIT OilSpy Project River Faughan 0803Document1 pageMeasurIT OilSpy Project River Faughan 0803cwiejkowskaNo ratings yet

- MeasurIT Amcor Dehumidifiers D850 D950 0911Document1 pageMeasurIT Amcor Dehumidifiers D850 D950 0911cwiejkowskaNo ratings yet

- MeasurIT TESTO Saveris Radio Monitoring 1002Document16 pagesMeasurIT TESTO Saveris Radio Monitoring 1002cwiejkowskaNo ratings yet

- MeasurIT Meaco HTX Transmitter 0911Document1 pageMeasurIT Meaco HTX Transmitter 0911cwiejkowskaNo ratings yet

- MeasurIT Meaco STX Transmitter 0911Document1 pageMeasurIT Meaco STX Transmitter 0911cwiejkowskaNo ratings yet

- MeasurIT Brune B500 Humidifier 0911Document8 pagesMeasurIT Brune B500 Humidifier 0911cwiejkowskaNo ratings yet

- MeasurIT OilSpy 0803Document1 pageMeasurIT OilSpy 0803cwiejkowskaNo ratings yet

- MeasurIT OilSpy Project Rosny Sur Seine 0909Document1 pageMeasurIT OilSpy Project Rosny Sur Seine 0909cwiejkowskaNo ratings yet

- MeasurIT Quadbeam Product Spill Monitor Calibration Guide 0810Document2 pagesMeasurIT Quadbeam Product Spill Monitor Calibration Guide 0810cwiejkowskaNo ratings yet

- Mpofana Municipality General Valuation Roll - 31 March 2019Document144 pagesMpofana Municipality General Valuation Roll - 31 March 2019Sherebanu KajeeNo ratings yet

- ECM Power Source CircuitDocument4 pagesECM Power Source CircuitErln LimaNo ratings yet

- Manual P250AF, P265F Gas Powered Burners EnglishDocument46 pagesManual P250AF, P265F Gas Powered Burners EnglishCARLOS RAMOSNo ratings yet

- Use & Care Manual: DishwasherDocument16 pagesUse & Care Manual: DishwashermacaronmaniacNo ratings yet

- MeasurIT Tideflex & Series40 Application Flow 0806Document1 pageMeasurIT Tideflex & Series40 Application Flow 0806cwiejkowskaNo ratings yet

- Watertown City Manager Status & Information Report April 12, 2019Document4 pagesWatertown City Manager Status & Information Report April 12, 2019NewzjunkyNo ratings yet

- Fsae Program PDFDocument84 pagesFsae Program PDFTan Gin HuiNo ratings yet

- STS 1ph-3ph Operating Manual REV B Low ResDocument49 pagesSTS 1ph-3ph Operating Manual REV B Low RessamuraivickyNo ratings yet

- Hazrdous Area Classification ReviewDocument2 pagesHazrdous Area Classification ReviewPillai Sreejith100% (1)

- AAI Empanelled Material Testing LaboratoriesDocument9 pagesAAI Empanelled Material Testing LaboratoriesAbozaid SalehNo ratings yet

- CD 4007 Datasheet PDFDocument6 pagesCD 4007 Datasheet PDFedwardNo ratings yet

- Mi-171A2 For UN MissionsDocument19 pagesMi-171A2 For UN MissionsГригорий ОмельченкоNo ratings yet

- Typical Sizes and Shapes of Concrete Masonry Units: TEK 2-1BDocument4 pagesTypical Sizes and Shapes of Concrete Masonry Units: TEK 2-1BfostbarrNo ratings yet

- Khaled Cheklam: Male 28/09/1992 AlgerianDocument2 pagesKhaled Cheklam: Male 28/09/1992 AlgerianCheklam KhaledNo ratings yet

- Page 29 PDFDocument1 pagePage 29 PDFJuan Ponce ManríquezNo ratings yet

- 4-20 Ma Current Loop Fundamentals PDFDocument5 pages4-20 Ma Current Loop Fundamentals PDFJoãoMiguelLacRoeheNo ratings yet

- Effect of Heat Rejection Load and Wet Bulb On Cooling Tower PerformanceDocument7 pagesEffect of Heat Rejection Load and Wet Bulb On Cooling Tower PerformancetarzantrapNo ratings yet

- Biofuels From AlgaeDocument2 pagesBiofuels From AlgaeAdolphout HNo ratings yet

- Certificate Program Details - Fundamentals of Concrete Construction PDFDocument1 pageCertificate Program Details - Fundamentals of Concrete Construction PDFM Anwar HanfyNo ratings yet

- Moq20 05 09Document6 pagesMoq20 05 09vassim123No ratings yet

- Ficha Tecnica LlantaDocument2 pagesFicha Tecnica LlantaJulio MartinezNo ratings yet