Professional Documents

Culture Documents

MDL164 C

Uploaded by

hermon_agustioCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MDL164 C

Uploaded by

hermon_agustioCopyright:

Available Formats

MODEL 164 'C'

PUMPS

INC.

P.O. BOX 80769 HIGHWAY 90 EAST LAFAYETTE, LOUISIANA 70598-0769

(337) 235-9838 FAX # (337) 235-9852 www.sidewinderpumps.com

Pneumatic Powered Plunger Pumps

Installation Operation Performance Power Requirements

Parts Lists Model Code Trouble Shooting

Installation & Operating Instructions for

Sidewinder Model 164 'C' Chemical Metering Pump

1)

Install Sidewinder Chemical Injector Pump in a vertical position with " NPT suction Check

Valve #22-164-2 facing down.

2)

Connect discharge line to " NPT discharge check valve. For safety, a " NPT line check

valve (LC-4S) is recommended for installation where discharge line connects to process line.

3)

Connect power gas or air line to " NPT supply inlet. The Sidewinder Controller accepts 10

to 150 psi.

4)

Turn lube body #14-42 180 degrees. Screw bottle of lube oil #92-122 onto lube body. Rotate

bottle and body so that bottle is upside down (do not squeeze or puncture bottle).

5)

Open bleeder plug #20-42-2 to remove air from pump chamber, and then close bleeder.

6)

Set supply regulator to provide sufficient supply pressure of gas or air to firmly stroke pump

against prevailing discharge pressure. (Note: If supply volume is restricted due to either too

small or too long of a supply line, pump control valve will blow through or act erratic.)

7)

Adjust speed of pump by rotating Time Knob #31-42 on top of Power Head Cap #4A-44-2.

Clockwise rotation decreases the number of strokes per minute. Counter-clockwise rotation

increases the number of strokes per minute. Further volume control can be accomplished by

varying the length of stroke with the Stroke Adjuster #1-42 also on top of the Power Head Cap.

8)

In order to gauge volumes, consult your Sidewinder Pump Distributor for the proper gauging

equipment.

10/05

SIDEWINDER MODEL 164 'C' SERIES PUMP

PARTS LIST for MODEL 164 'C' SIDEWINDER PUMP

Item #

1

2

*3

4A

4B

4C

Description

Stroke Adjuster

Locknut-Stroke Adjuster

Seal-Stroke Adjuster

4.00" Powerhead Cap

Powerhead Cylinder

Powerhead Tie Bolt

(6 required)

4D

Powerhead Tie Bolt Nut

(6 required)

4E

Powerhead Inlet Connector Fitting

*4F

Powerhead Cap O-Ring

*6

U-Cup (Viton U-Cup available see note 6a)

10

Mounting Flange

*11

Return Spring (Spring options see note 11a)

12

Mounting Tube

13A

Vent

14

Lube Body

14A

Lube Body O-Ring

15

Lube Tube

*16

Piston-Plunger Assembly

MATERIAL

316 Stainless Steel

440 'C' Stainless Steel

Stainless Steel Chrome Plated

Stainless Steel with Nickel Plating

Customer Specified (Consult Factory)

*17

Mounting Tube O-Ring

*18

Plunger Seal

MATERIAL

Teflon Graphite Uniseal

Techno Uniseal (Polyimede)

Viton O-Ring

Buna-N O-ring

Virgin Teflon Uniseal

Virgin Teflon Uniseal with Viton O-Ring Insert

Virgin Teflon Uniseal with Buna-N O-Ring Insert

Chemraz O-Ring

Hitec O-Ring

Virgin Teflon O-Ring

Polyblend Uniseal

Customer Specified Special (Consult Factory)

Note: O-Ring seals on model 164 require (1) each O-ring and (2) each narrow back up ring part number 18D-164.

20

Bleeder Valve (316 SS)

*22

Suction Check Valve (316 SS)

*23

Discharge Check Valve (316 SS)

24

Fluid Pump Chamber (316 SS)

31

Time Knob

33

Timer Stem

**35

Timer Stem O-Ring

51

Control Valve Cover with Timer

**52

Control Valve Diaphragm

53

Control Valve Body

**54

Control Valve Actuator

**55

Control Valve Poppet

**56

Control Valve Body Seal

**57

Control Valve Spring

**58

Control Valve Mounting Screw

(2 required)

**75

Control Valve Mounting Screw Locknut

(2 required)

*91

Piston Grease (not shown)

*92

Plunger Lube (4 0z.) (not shown)

Model 164 'C'

1-42

2-42

3-42

4A-44-2

4B-44-2

4C-44-2

4D-44-2

4E-44-2

4F-44

6-44

10-164-B

11-164

12-164

13A-42

14-42

14A-42

15-43

16-164-2

16-164-3

16-164-7

16-164-8

16-164-9

17-164

18-164

18-164-1

18-164-2

18-164-3

18-164-4

N/A

N/A

18-164-5

18-164-6

N/A

18-164-8

18-164-9

20-42-2

22-164-2

23-164-2

24-164-2

31-42

33-42C

35-42

51T-42C-2

52-42

53-44-2

54-42

55-42

56-42

57-42

58-42

75-42

91-42

92-122

* Parts included in a pump end repair kit. Also included is 91-42 Silicon Piston Grease. This Kit is designated by a "K" preceding the pump model number.

The B & C series in the Model 164 use the same Pump End Repair Kit.

** Parts included in timer valve repair kit. The kit part number is KVC-40F. The series "C" Control Timer Valve does not require part #37-42 O-Ring Seal

in the the KVC-40 Kit.

6a Piston U-Cup in Viton part # 6-44-4.

11a Return Spring in Nii Cobalt Moly - Part # 11-164-MP

Chemical incompatibily between seal and

material being pumped

Scored or damaged plunger

Abrasive material in chemical

No lubricant or incorrect lube

- Check a Compatibility Chart or consult chemical manufacturer, and install seal made from

compatible material.

- Replace plunger.

- Install suction filter.

- Use Sidewinder Lube #91-42 on piston and #92-122 on plunger. Periodically check lube level.

Plunger

Size

1/4"

1/4"

1/4"

3/8"

3/8"

3/8"

1/2"

1/2"

1/2"

1"

Model

Number

40

42

44

60

62

64

80

82

84

164

4.00"

2.25"

4.00"

4.00"

1.25"

1.25"

2.25"

2.25"

4.00"

1.25"

Piston

Size

16:1

20:1

60:1

110:1

6.25:1

11:1

36:1

80:1

240:1

25:1

Amplification

Ratio

10 to 150

10 to 150

10 to 150

10 to 150

15 to 150

15 to 150

10 to 150

10 to 150

10 to 150

15 to 150

Supply

Pressure PSI(a)

0 to 2,400

0 to 3,000

0 to 9,000

0 to 10,000

0 to 935

0 to 1,600

0 to 5,400

0 to 10,000

0 to 10,000

0 to 3,750

40

55

30

30

60

60

55

55

35

60

MaximumDischarge Maximum Full Strokes

Pressure

Per Minute

0 to 680

0 to 275

0 to120

0 to 67

0 to 360

0 to 200

0 to 155

0 to 70

0 to 30

0 to 90

Output Volume

Qts. Per Day

Pump Selection Guide and Performance Chart

Premature Seal Failure

Discharge line plugged

- Open bleeder valve, fill chamber with fluid only, then close bleeder valve.

- Provide free flow of fluid to pump suction.

Air or vapor in pump chamber

Fluid flow to pump blocked by plugged line,

closed valve, extremely high viscosity or lack

of fluid supply

Suction or discharge check valve leaking

No Fluid Discharge With Control

Cycling And Piston Stroking

- Use drum gauge with handle in test position to determine which valve is leaking. Clean or

replace faulty valve.

- Clear or replace line.

- Replace Spring

- Clean and lubricat power head and piston with Piston Lube #91-42. Clean Plunger Lube

Chamber and fill Plunger Lube #92-122. Change piston and plunger seals if needed.

- Divide process line pressure by amplification ratio (see Performance Chart). Supply

pressure must exceed the result. (Standard Sidewinder Control operates from 10 to 150 psi.)

- Back out on stroke adjuster to desired setting.

Return spring broken

Piston stuck due to lack of Piston or Plunger

Lube

Supply pressure too low to buck process line

pressure

Stroke Length Adjuster screwed too far

Control Valve Not Cycling

Piston Not Stroking

Action

Leak in control or valve

Supply gas blowing through to exhaust due to

speed control too wide, trash under valve Seat

or restriction in air/gas supply line.

No supply pressure

Pump speed control closed

Possible Cause

- Check gauge on supply line near pump to verify adequate supply pressure . . . 10 to 150 psi.

- Rotate dial CCW three turns from full in position and then set desired rate. Rotate CW to

slow pump rate.

- Check for leak, pinched or missing seals, broken diaphragm or loose mounting screws.

- Rotate control dial CW to decrease setting. Block exhaust momentarily and then release.

DO NOT USE BARE FINGERS. If this does not work, replace Timer Seat O-Ring #37-42 or

increase supply line size and move pump closer to air/gas supply source.

Problem

Trouble Shooting The Sidewinder Chemical Pump

You might also like

- FisherDocument17 pagesFisherhermon_agustio100% (1)

- MuellerDocument2 pagesMuellerhermon_agustioNo ratings yet

- DS - In0002 - GB - 1372. en 837 PDFDocument4 pagesDS - In0002 - GB - 1372. en 837 PDFAldrin HernandezNo ratings yet

- SD SeriesDocument6 pagesSD Serieshermon_agustioNo ratings yet

- Type 434Document3 pagesType 434hermon_agustioNo ratings yet

- MuellerDocument2 pagesMuellerhermon_agustioNo ratings yet

- CameronDocument4 pagesCameronhermon_agustio0% (1)

- SD SeriesDocument6 pagesSD Serieshermon_agustioNo ratings yet

- Cam Tite2Document3 pagesCam Tite2hermon_agustioNo ratings yet

- Instrucciones de Montaje Actuador Fisher Vastago DeslizanteDocument6 pagesInstrucciones de Montaje Actuador Fisher Vastago DeslizantedajaimNo ratings yet

- 17680269Document2 pages17680269hermon_agustioNo ratings yet

- PentairDocument3 pagesPentairhermon_agustioNo ratings yet

- Atlas Copco - 2930 1390 01Document18 pagesAtlas Copco - 2930 1390 01hermon_agustioNo ratings yet

- Programmable, Isolated Voltage-to-Current Converter: LoadDocument4 pagesProgrammable, Isolated Voltage-to-Current Converter: Loadhermon_agustioNo ratings yet

- (L779) - NH Skid Steer Loader (7/80-7/83)Document3 pages(L779) - NH Skid Steer Loader (7/80-7/83)hermon_agustioNo ratings yet

- Klippon ELECTRICALS - WeidmullerDocument2 pagesKlippon ELECTRICALS - Weidmullerhermon_agustioNo ratings yet

- D101986 X 012Document8 pagesD101986 X 012hermon_agustioNo ratings yet

- Orifice PDFDocument11 pagesOrifice PDFb_wooNo ratings yet

- 13446000Document4 pages13446000hermon_agustioNo ratings yet

- Klippon ELECTRICALS - WeidmullerDocument2 pagesKlippon ELECTRICALS - Weidmullerhermon_agustioNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ISO 9001 Certified U4.70-U4.250 Series Oil-Flooded Vacuum PumpsDocument4 pagesISO 9001 Certified U4.70-U4.250 Series Oil-Flooded Vacuum PumpsAndy MulyonoNo ratings yet

- (865 VHP) - Motor Grader Tier 3 (Na) - Asn N8AF04429 (7/05-12/08) (02-16 (01) ) - AIR CLEANER - ASSEMBLY Case ConstructuionDocument3 pages(865 VHP) - Motor Grader Tier 3 (Na) - Asn N8AF04429 (7/05-12/08) (02-16 (01) ) - AIR CLEANER - ASSEMBLY Case ConstructuionRjg EarthmoversNo ratings yet

- (Process Industry Practices) Design of ASME B31.3Document24 pages(Process Industry Practices) Design of ASME B31.3aguiarv88100% (1)

- MSS SP-104-2018Document14 pagesMSS SP-104-2018Денис Пекшуев0% (1)

- CPS Refrigerant Leak Detector LS790BDocument20 pagesCPS Refrigerant Leak Detector LS790BRichard WeimerNo ratings yet

- Trane XR202 Programmable Thermostat: TCONT202AS11MA Installation and User GuideDocument12 pagesTrane XR202 Programmable Thermostat: TCONT202AS11MA Installation and User GuideOsvaldo Milla100% (2)

- Modified Asphalt Binders: Need of Present PavementsDocument85 pagesModified Asphalt Binders: Need of Present PavementsPalika ChopraNo ratings yet

- Electro-Hydraulic Lab SheetDocument6 pagesElectro-Hydraulic Lab SheetSyahzlan IskandarNo ratings yet

- Standard Equipment: Hitachi Construction Machinery Co., LTDDocument15 pagesStandard Equipment: Hitachi Construction Machinery Co., LTDDemo OnlyNo ratings yet

- ds511 Specification Sheet EnglishDocument4 pagesds511 Specification Sheet EnglishAntonio BocanegraNo ratings yet

- PrimeProbe3+ PPS-PP3-044-2.0Document18 pagesPrimeProbe3+ PPS-PP3-044-2.0Kishan ChandrasekaraNo ratings yet

- DSS Site Visit ReportDocument13 pagesDSS Site Visit Report39 - Deep MandokarNo ratings yet

- Knuckle Joints DesignDocument10 pagesKnuckle Joints DesignKvrd Prasad100% (1)

- SD 14 eDocument12 pagesSD 14 eseaqu3stNo ratings yet

- 6 Cylinder MBE906: Engine PerformanceDocument2 pages6 Cylinder MBE906: Engine Performanceguillermo meza huamanNo ratings yet

- 980a1003 PDFDocument48 pages980a1003 PDFMichael DavenportNo ratings yet

- TheArtofAviation 10016620 PDFDocument270 pagesTheArtofAviation 10016620 PDFangelo dosramosNo ratings yet

- Physio Mechanical Properties-8Document2 pagesPhysio Mechanical Properties-8Umesh MishraNo ratings yet

- Boiler Furnace DefectsDocument4 pagesBoiler Furnace DefectskrishnaNo ratings yet

- DR650SEL2 Catalogo Partes PDFDocument75 pagesDR650SEL2 Catalogo Partes PDFEderNo ratings yet

- Innovex Lead Seal Casing Patch March2022a-1Document10 pagesInnovex Lead Seal Casing Patch March2022a-1Christian MatteoNo ratings yet

- Tubular Bowl CentrifugeDocument22 pagesTubular Bowl CentrifugeTouhid Islam100% (1)

- Install the Myson T6 IVC Series radiatorDocument2 pagesInstall the Myson T6 IVC Series radiatorValentin OpreaNo ratings yet

- Man P2862 Le ProjectDocument406 pagesMan P2862 Le ProjectMuhammad Subhan IrfandyNo ratings yet

- Forklift Daily Checklist ElectricDocument2 pagesForklift Daily Checklist Electricmikel derrickNo ratings yet

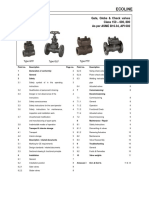

- Type GTF Type GLF Type PTF Type SCF: Gate, Globe & Check Valves Class 150 - 600, 800 As Per ASME B16.34, API 602Document12 pagesType GTF Type GLF Type PTF Type SCF: Gate, Globe & Check Valves Class 150 - 600, 800 As Per ASME B16.34, API 602Qaswa Imran KhanNo ratings yet

- Strength & failure modes of concreteDocument12 pagesStrength & failure modes of concretemaneeshaNo ratings yet

- Test 924G, 1. General Testing and AdjustingDocument7 pagesTest 924G, 1. General Testing and Adjustingmijael1393100% (1)

- Innovative Bridge Bearing SolutionsDocument12 pagesInnovative Bridge Bearing SolutionsyhszaNo ratings yet