Professional Documents

Culture Documents

Maxon EC20 Flat 5watt

Uploaded by

Electromate0 ratings0% found this document useful (0 votes)

158 views1 pageEC 20 flat AE20 mm, brushless, A with hall sensors B sensorless maxon flat motor M 1:1 Stock program Standard program Special program (on request) AE20. Mm 22 g 0.06 - 0. Nm Page 221 Values listed in the table are nominal.

Original Description:

Original Title

Maxon EC20 Flat 5Watt

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEC 20 flat AE20 mm, brushless, A with hall sensors B sensorless maxon flat motor M 1:1 Stock program Standard program Special program (on request) AE20. Mm 22 g 0.06 - 0. Nm Page 221 Values listed in the table are nominal.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

158 views1 pageMaxon EC20 Flat 5watt

Uploaded by

ElectromateEC 20 flat AE20 mm, brushless, A with hall sensors B sensorless maxon flat motor M 1:1 Stock program Standard program Special program (on request) AE20. Mm 22 g 0.06 - 0. Nm Page 221 Values listed in the table are nominal.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

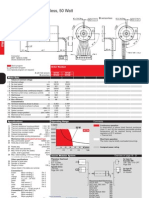

EC 20 flat Æ20 mm, brushless,

A with hall sensors B sensorless

maxon flat motor

M 1:1

Stock program

Standard program Order Number

Special program (on request)

A with Hall sensors 351005 351006 351007 351008

B sensorless 351054 351055 351056 351057

Motor Data (provisional)

Values at nominal voltage

1 Nominal voltage V 6.0 9.0 12.0 24.0

2 No load speed rpm 9350 9430 9380 9300

3 No load current mA 102 68.3 51.1 25.1

4 Nominal speed rpm 5110 5480 5250 5250

5 Nominal torque (max. continuous torque) mNm 7.01 8.2 7.43 7.69

6 Nominal current (max. continuous current) A 1.22 0.934 0.642 0.327

7 Stall torque mNm 17.2 22.4 18.9 19.9

8 Starting current A 2.93 2.54 1.61 0.838

9 Max. efficiency % 67 70.6 68.4 69.2

Characteristics

10 Terminal resistance phase to phase W 2.05 3.54 7.45 28.6

11 Terminal inductance phase to phase mH 0.189 0.424 0.754 3.09

12 Torque constant mNm / A 5.88 8.82 11.8 23.8

13 Speed constant rpm / V 1620 1080 812 402

14 Speed / torque gradient rpm / mNm 567 435 515 484

15 Mechanical time constant ms 30.3 23.2 27.5 25.8

16 Rotor inertia gcm2 5.1 5.1 5.1 5.1

Specifications Operating Range Comments

Thermal data n [rpm]

17 Thermal resistance housing-ambient 13.7 K / W Continuous operation

18 Thermal resistance winding-housing 2.66 K / W In observation of above listed thermal resistance

19 Thermal time constant winding 1.77 s 16000

5.0 (lines 17 and 18) the maximum permissible winding

20 Thermal time constant motor 22.8 s 351006 temperature will be reached during continuous

21 Ambient temperature -40 ... +100°C 12000 operation at 25°C ambient.

22 Max. permissible winding temperature +125°C = Thermal limit.

Mechanical data (preloaded ball bearings) 8000

Short term operation

23 Max. permissible speed 15000 rpm The motor may be briefly overloaded (recurring).

24 Axial play at axial load < 2.0 N 0 mm 4000

> 2.0 N 0.14 mm

25 Radial play preloaded

26 Max. axial load (dynamic) 1.8 N 5 10 15 Assigned power rating

27 Max. force for press fits (static) 20 N 0.5 1.0 1.5

(static, shaft supported) 200 N

28 Max. radial loading, 5 mm from flange 10 N

Other specifications maxon Modular System Overview on page 16 - 21

29 Number of pole pairs 4 Spur Gearhead

30 Number of phases 3 Æ20.3 mm

31 Weight of motor 22 g 0.06 - 0.25 Nm

Values listed in the table are nominal. Page 221

Connection with hall sensors sensorless Planetary Gearhead

Æ22 mm

Pin 1 4.5 ... 24 VDC Motor winding 1

0.5 - 2.0 Nm

Pin 2 Hall sensor 3 Motor winding 2

Page 224 / 226

Pin 3 Hall sensor 1 Motor winding 3

Pin 4 Hall sensor 2 neutral point

Pin 5 GND

Pin 6 Motor winding 3

Pin 7 Motor winding 2 Recommended Electronics:

Pin 8 Motor winding 1 DECS 50/5 Page 288

Adapter Order Number Order Number DEC 24/1 288

see p. 308 220300 220310 DEC Module 24/2 289

Connector Article number Article number Notes 20

AMP 1-487951-1 487951-4

MOLEX 52207-1190 52207-0490

MOLEX 52089-1110 52089-0410 Sold & Serviced By:

Pin for design with Hall sensors: ELECTROMATE

FPC, 11 pole, pitch 1.0 mm, top contact style INDUSTRIAL SALES LIMITED

Wiring diagram for Hall sensors see page 29 PRECISION TECHNOLOGY & QUALITY

Toll Free Phone (877) SERVO98

186 Toll Free Fax (877) SERVO99 May 2009 edition / subject to change

sales@electromate.com

www.electromate.com

You might also like

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Solidwork Flow Simulation TutorialDocument298 pagesSolidwork Flow Simulation TutorialMilad Ah100% (8)

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsFrom EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNo ratings yet

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsFrom EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsRating: 3 out of 5 stars3/5 (5)

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- Digital Power Electronics and ApplicationsFrom EverandDigital Power Electronics and ApplicationsRating: 3.5 out of 5 stars3.5/5 (3)

- Understanding and Servicing Alarm SystemsFrom EverandUnderstanding and Servicing Alarm SystemsRating: 1 out of 5 stars1/5 (1)

- FIDIC delay and disruption standardsDocument7 pagesFIDIC delay and disruption standardsMohammad FayazNo ratings yet

- Asm Master Oral Notes - As Per New SyllabusDocument262 pagesAsm Master Oral Notes - As Per New Syllabusshanti prakhar100% (1)

- Siegfried Kracauer - Photography (1927)Document17 pagesSiegfried Kracauer - Photography (1927)Paul NadeauNo ratings yet

- EC 20 MOTOR SPECSDocument1 pageEC 20 MOTOR SPECSivanlawms6745No ratings yet

- Maxon EC20 Flat 3wattDocument1 pageMaxon EC20 Flat 3wattElectromateNo ratings yet

- Maxon EC-Max16 5wattDocument1 pageMaxon EC-Max16 5wattElectromateNo ratings yet

- Maxon EC22 20watt Integrated ElectronicsDocument2 pagesMaxon EC22 20watt Integrated ElectronicsElectromateNo ratings yet

- Maxon EC45 Flat 30wattDocument1 pageMaxon EC45 Flat 30wattElectromateNo ratings yet

- Maxon EC22 50wattDocument1 pageMaxon EC22 50wattElectromateNo ratings yet

- 12 156 enDocument1 page12 156 enLuka MadridNo ratings yet

- Maxon EC-Powermax30 200wattDocument1 pageMaxon EC-Powermax30 200wattElectromateNo ratings yet

- Maxon RE30 Graphite Brushes 60wattDocument1 pageMaxon RE30 Graphite Brushes 60wattElectromateNo ratings yet

- Maxon EC6 1.2wattDocument1 pageMaxon EC6 1.2wattElectromateNo ratings yet

- Maxon Ec45 136210Document1 pageMaxon Ec45 136210compimagmaticNo ratings yet

- En 21 250Document1 pageEn 21 250compimagmaticNo ratings yet

- Maxon EC-Max40 70wattDocument1 pageMaxon EC-Max40 70wattElectromateNo ratings yet

- 12 149 enDocument1 page12 149 enLuka MadridNo ratings yet

- EC 22 22 MM, Brushless, 50 Watt: Part NumbersDocument1 pageEC 22 22 MM, Brushless, 50 Watt: Part NumbersfurkanfurkanfurkanNo ratings yet

- Motores Maxon 2017Document1 pageMotores Maxon 2017--No ratings yet

- Maxon EC-Max22 25wattDocument1 pageMaxon EC-Max22 25wattElectromateNo ratings yet

- Motor Maxon 323772Document1 pageMotor Maxon 323772Henry Daniel VerdugoNo ratings yet

- 17 en 170 Lstage DatasheetDocument1 page17 en 170 Lstage DatasheetSana SyedNo ratings yet

- Maxon RE65 Graphite Brushes 250wattDocument1 pageMaxon RE65 Graphite Brushes 250wattElectromateNo ratings yet

- Maxon EC-Max30 40wattDocument1 pageMaxon EC-Max30 40wattElectromateNo ratings yet

- RE50Document1 pageRE50Yhony Gamarra VargasNo ratings yet

- RE 50 50mm Graphite Brushes 200W MotorDocument1 pageRE 50 50mm Graphite Brushes 200W MotorJorge Alejandro Barrutia BorbollaNo ratings yet

- MAXON Brushed Motor A-Max 26, 4.5 WDocument1 pageMAXON Brushed Motor A-Max 26, 4.5 WRadu BabauNo ratings yet

- Motor 30 WattDocument1 pageMotor 30 WattPRED4T0R85No ratings yet

- EC 90 Flat: 90 MM, Brushless, 600 WattDocument1 pageEC 90 Flat: 90 MM, Brushless, 600 WattDiy DoeNo ratings yet

- F2140 Eng DatasheetDocument4 pagesF2140 Eng Datasheettngyew leeNo ratings yet

- Maxon Re40Document1 pageMaxon Re40compimagmaticNo ratings yet

- En 21 251Document1 pageEn 21 251Froylan OchoaNo ratings yet

- Maxon Re40 DC Motor 148866 Datasheet PDFDocument1 pageMaxon Re40 DC Motor 148866 Datasheet PDFtoony reyesNo ratings yet

- Maxon RE-Max17 Graphite Brushes 4.5wattDocument2 pagesMaxon RE-Max17 Graphite Brushes 4.5wattElectromateNo ratings yet

- RE-max17 GP16 MR RE-max17 GB 4.5W #216013Document3 pagesRE-max17 GP16 MR RE-max17 GB 4.5W #216013Alexander MonteNo ratings yet

- EC 40 40 MM, Brushless, 170 Watt: Part NumbersDocument1 pageEC 40 40 MM, Brushless, 170 Watt: Part NumbersfurkanfurkanfurkanNo ratings yet

- Maxon EC22 50watt SterilisableDocument1 pageMaxon EC22 50watt SterilisableElectromateNo ratings yet

- 30 MM, Graphite Brushes, 60 Watt: Order NumberDocument1 page30 MM, Graphite Brushes, 60 Watt: Order NumberRatanieriNo ratings yet

- Graphite Brushes, 60 Watt Maxon DC MotorDocument1 pageGraphite Brushes, 60 Watt Maxon DC MotorRatanieriNo ratings yet

- RE 25 25 MM, Precious Metal Brushes CLL, 10 Watt: Part NumbersDocument1 pageRE 25 25 MM, Precious Metal Brushes CLL, 10 Watt: Part NumbersWALTER ANDRES CORDOBA CACERENo ratings yet

- RE 35 35 MM, Graphite Brushes, 90 Watt: Part NumbersDocument1 pageRE 35 35 MM, Graphite Brushes, 90 Watt: Part Numbersasd3a1s65a13f5v06W83 846W84 T6W8E464No ratings yet

- Maxon RE40 Graphite Brushes 150wattDocument1 pageMaxon RE40 Graphite Brushes 150wattElectromateNo ratings yet

- 90mm EC Brushless MotorDocument1 page90mm EC Brushless MotorLucas SuplinoNo ratings yet

- Maxon EC90 Flat 90wattDocument1 pageMaxon EC90 Flat 90wattElectromateNo ratings yet

- Maxon EC60 400wattDocument1 pageMaxon EC60 400wattElectromateNo ratings yet

- 16 275 enDocument1 page16 275 enmawadNo ratings yet

- 12 158 enDocument1 page12 158 enLuka MadridNo ratings yet

- Maxon RE16 Graphite Brushes 4.5wattDocument2 pagesMaxon RE16 Graphite Brushes 4.5wattElectromateNo ratings yet

- Galil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesDocument1 pageGalil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesElectromateNo ratings yet

- Electromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseDocument1 pageElectromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseElectromateNo ratings yet

- Exor X5 Wireless Press ReleaseDocument1 pageExor X5 Wireless Press ReleaseElectromateNo ratings yet

- Introducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionDocument1 pageIntroducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionElectromateNo ratings yet

- Electromate Recertified As A Great Place To Work' Press ReleaseDocument1 pageElectromate Recertified As A Great Place To Work' Press ReleaseElectromateNo ratings yet

- New LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsDocument1 pageNew LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsElectromateNo ratings yet

- Kollmorgen Debuts EKM Series Servo MotorsDocument1 pageKollmorgen Debuts EKM Series Servo MotorsElectromateNo ratings yet

- New High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesDocument2 pagesNew High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesElectromateNo ratings yet

- Mecademic Robotics Releases New Firmware For Its Meca500 RobotDocument2 pagesMecademic Robotics Releases New Firmware For Its Meca500 RobotElectromateNo ratings yet

- Electromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaDocument1 pageElectromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaElectromateNo ratings yet

- AMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMDocument2 pagesAMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMElectromateNo ratings yet

- Electromate Elated With Win at The 2022 Business Achievement AwardsDocument2 pagesElectromate Elated With Win at The 2022 Business Achievement AwardsElectromateNo ratings yet

- Electromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesDocument2 pagesElectromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesElectromateNo ratings yet

- Electromate Extends Its Product Portfolio To Include Robots From MecademicDocument1 pageElectromate Extends Its Product Portfolio To Include Robots From MecademicElectromateNo ratings yet

- ADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesDocument2 pagesADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesElectromateNo ratings yet

- Meet The World's Most Precise Six-Axis RobotDocument1 pageMeet The World's Most Precise Six-Axis RobotElectromateNo ratings yet

- Netzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsDocument1 pageNetzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsElectromateNo ratings yet

- Electromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardDocument2 pagesElectromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardElectromateNo ratings yet

- POSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsDocument1 pagePOSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsElectromateNo ratings yet

- New Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseDocument1 pageNew Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseElectromateNo ratings yet

- Electromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseDocument2 pagesElectromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseElectromateNo ratings yet

- Electromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsDocument2 pagesElectromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsElectromateNo ratings yet

- New LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsDocument1 pageNew LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsElectromateNo ratings yet

- New Integrated Spindle Drives Available From JVLDocument1 pageNew Integrated Spindle Drives Available From JVLElectromateNo ratings yet

- New 100 Amps Peak FlexPro Servo Drives Available From AMCDocument1 pageNew 100 Amps Peak FlexPro Servo Drives Available From AMCElectromateNo ratings yet

- Excellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesDocument2 pagesExcellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesElectromateNo ratings yet

- Electromate Recognized With 2021 AHTD Foundation AwardDocument1 pageElectromate Recognized With 2021 AHTD Foundation AwardElectromateNo ratings yet

- ADVANCED Motion Controls Releases The FM060-25-CMDocument1 pageADVANCED Motion Controls Releases The FM060-25-CMElectromateNo ratings yet

- Maxon's New IDX Integrated Motor - Power at The Press of A ButtonDocument1 pageMaxon's New IDX Integrated Motor - Power at The Press of A ButtonElectromateNo ratings yet

- Electromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020Document2 pagesElectromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020ElectromateNo ratings yet

- Nysc Editorial ManifestoDocument2 pagesNysc Editorial ManifestoSolomon Samuel AdetokunboNo ratings yet

- TSGE - TLGE - TTGE - Reduce Moment High Performance CouplingDocument6 pagesTSGE - TLGE - TTGE - Reduce Moment High Performance CouplingazayfathirNo ratings yet

- Excel Bill of Materials Bom TemplateDocument8 pagesExcel Bill of Materials Bom TemplateRavi ChhawdiNo ratings yet

- Chapter 2 Literature ReviewDocument10 pagesChapter 2 Literature ReviewSharan BvpNo ratings yet

- Afrah Summer ProjectDocument11 pagesAfrah Summer Projectاشفاق احمدNo ratings yet

- Purp Com Lesson 1.2Document2 pagesPurp Com Lesson 1.2bualjuldeeangelNo ratings yet

- Beyond B2 English CourseDocument1 pageBeyond B2 English Coursecarlitos_coolNo ratings yet

- OV2640DSDocument43 pagesOV2640DSLuis Alberto MNo ratings yet

- What Is Chemical EngineeringDocument4 pagesWhat Is Chemical EngineeringgersonNo ratings yet

- Case Study On Vivekananda Flyover BridgeDocument8 pagesCase Study On Vivekananda Flyover BridgeHeta PanchalNo ratings yet

- PSAII Final EXAMDocument15 pagesPSAII Final EXAMdaveadeNo ratings yet

- Programming Language II CSE-215: Dr. Mohammad Abu Yousuf Yousuf@juniv - EduDocument34 pagesProgramming Language II CSE-215: Dr. Mohammad Abu Yousuf Yousuf@juniv - EduNaruto DragneelNo ratings yet

- Roll Covering Letter LathiaDocument6 pagesRoll Covering Letter LathiaPankaj PandeyNo ratings yet

- FRABA - Absolute - Encoder / PLC - 1 (CPU 314C-2 PN/DP) / Program BlocksDocument3 pagesFRABA - Absolute - Encoder / PLC - 1 (CPU 314C-2 PN/DP) / Program BlocksAhmed YacoubNo ratings yet

- Diferencias Gas LP y Gas Natural: Adminigas, S.A. de C.VDocument2 pagesDiferencias Gas LP y Gas Natural: Adminigas, S.A. de C.VMarco Antonio Zelada HurtadoNo ratings yet

- UK Commutator Maintenance CatalogueDocument9 pagesUK Commutator Maintenance CatalogueCarlosNo ratings yet

- SIO 12 Syllabus 17Document3 pagesSIO 12 Syllabus 17Paul RobaiaNo ratings yet

- Gujarat Technological University: Aeronautical EngineeringDocument16 pagesGujarat Technological University: Aeronautical EngineeringumodiNo ratings yet

- UntitledDocument4 pagesUntitledMOHD JEFRI BIN TAJARINo ratings yet

- 1 20《经济学家》读译参考Document62 pages1 20《经济学家》读译参考xinying94No ratings yet

- KCL Thesis PrintingDocument4 pagesKCL Thesis PrintingMelinda Watson100% (2)

- Team Dynamics and Behaviors for Global ExpansionDocument15 pagesTeam Dynamics and Behaviors for Global ExpansionNguyênNo ratings yet

- Audi A3 Quick Reference Guide: Adjusting Front SeatsDocument4 pagesAudi A3 Quick Reference Guide: Adjusting Front SeatsgordonjairoNo ratings yet

- Batool2019 Article ANanocompositePreparedFromMagn PDFDocument10 pagesBatool2019 Article ANanocompositePreparedFromMagn PDFmazharNo ratings yet

- 6.standard CostingDocument11 pages6.standard CostingInnocent escoNo ratings yet

- Type of PoemDocument10 pagesType of PoemYovita SpookieNo ratings yet