Professional Documents

Culture Documents

Nhom 3 Managing Risk Through Effective Team-Based Decision Making

Uploaded by

Phuoc DangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nhom 3 Managing Risk Through Effective Team-Based Decision Making

Uploaded by

Phuoc DangCopyright:

Available Formats

9/6/08

09:18

Page 1

www.thetimes100.co.uk

Managing risk through effective

team-based decision making

Introduction

CURRICULUM TOPICS

Improving productivity

Contemporary work patterns

Methods of management

Production technology

GLOSSARY

Making sure that government, businesses and households have secure supplies of energy is a

huge commitment. Engineers working for the energy supply companies must make sure that

this commitment is met 24 hours a day, 365 days a year. This case study shows how the

engineers who work for one of the UKs major energy businesses, RWE npower, are involved

in securing energy supplies and in the management of risk.

Risk lies at the core of any enterprise activity. Businesses therefore have to manage risks

every day of the week, for 52 weeks in the year. Successful management of risk involves

getting the balance right between risk and other factors such as cost and return.

Engineering is an exciting career. Engineers deal with real problems involving real materials

and projects. The work of an engineer is varied and stimulating. For example, graduate

engineers working at a power station will not only work with computer models, but also will

help to run projects, control the materials, equipment and plant. This is engineering on a

grand scale. Engineers working for RWE npower are trained at all levels to combine technical

skills with commercial knowledge. To be successful they need to understand the business

implications of the decisions they make.

Management of risk: working

to avoid possible loss to the

organisation.

Enterprise activity: the

organisational and risk-taking

actions necessary for a business to

continue to exist.

Cost: the price of carrying out an

activity (can be in money, time or

people).

Return: the profit from an activity.

Utilities: organisations that supply

water, gas or electricity.

National grid: the system for

delivering electricity across the UK.

Turnover: the total value of all

sales made in a given period of

time. Sometimes referred to as sales

revenue.

Capital employed: the total

amount of capital (expressed in

money terms) used by the business

from all sources.

RWE npowers operating environment

It is important, when assessing risk, to be aware of the operating circumstances of the

business. The energy industry is at the heart of any modern economy. Electricity and gas

suppliers provide the essential power supplies for industry as well as for our homes. They seek

to keep energy costs low while operating for 365 days a year. RWE npower is an integrated

energy company. It is the third largest supplier of electricity and gas in the UK, through its

npower brand, and one of the largest electricity generators. It is also part of the larger

RWE Group which is one of the largest European energy utilities. Its main markets are the

UK, Germany, and Central Eastern Europe (including Hungary and the Czech Republic).

RWE in Europe

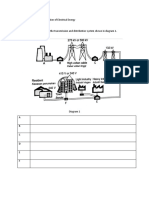

RWE npower not only provides and supplies to the national grid (electricity) and to the

national transmission system (gas), it also provides a huge economic contribution. This is

illustrated by the figures for turnover, capital employed and employment.

npower

28962_NPower

113

28962_NPower

9/6/08

09:18

Page 2

million

www.thetimes100.co.uk

2005

million (approx.)

million

2006

million (approx.)

Total revenue

6,385

4,405

8,493

5,791

Capital employed

6,645

4,580

6,969

4,752

Number of people employed

10,125

11,624

GLOSSARY

Competitive: involves

organisations performing against

one another to sell goods and

services.

Deregulated: the removal of

government rules and regulations.

These figures give a snapshot view of the scale of RWE npowers operations.

As one of the UK's leading companies RWE npower contributes to the economy by:

providing exciting jobs with prospects

selling energy to households and businesses, enabling a better standard of living

Sustainability: able to continue

over a period of time without

reducing the resources available

for the next generation to use.

investing in huge capital projects such as the building of power stations (including the

Supply chain: the

interconnected system of

consecutive processes linking the

manufacture of products with

physical distribution.

The most visible face of the company is its huge power stations such as those at Didcot in

Deviation: something different

from the usual way.

development of alternative power supplies such as wind farms and biomass plants).

Oxfordshire and Littlebrook in Kent. These power stations supply energy to the national grid.

The energy industry is very competitive. It is a deregulated market in which companies

are free to compete in supplying gas and electricity. RWE npower places a strong emphasis

on sustainability. Sustainability means using existing resources so that supplies of natural

resources and raw materials are passed on to future generations. For RWE npower sustainability

involves creating energy supplies with less pollution.

This is a major consideration in modern engineering decisions. A major aspect of energy

efficiency is that of seeking the best possible 'green solutions'. A 'green solution' is an

environmentally friendly one. In this way RWE npower engineers and other employees play

a significant role in working towards a sustainable future.

Health and safety underpins every action that RWE npower takes. For example, the company

has its own safety system based on years of experience of managing safety issues. RWE npower

sells its expertise in providing safe and sustainable energy supplies to other businesses around

the world.

RWE npower is involved in activities all through the supply chain of electricity and gas.

Types of problem-solving

Business problem-solving typically fits into three main categories:

1. Deviation problems. This is where a business is falling short of its expected targets. For

example, a power plant is contracted to supply 2,000,000 kilowatts of power to the

national grid and is falling short of this by 5%. The problem-solving involves getting

capacity back up to the required level.

2. An improvement problem. The business is doing well but wants to do better. For example,

are there more efficient ways of generating electricity or producing electricity from

alternative fuels?

3. An open-ended problem. There are no textbook answers to these problems. We use the

term thinking outside the box to describe the ways of thinking that are required here.

114

9/6/08

09:18

Page 3

The box refers to thinking in standard ways. So thinking outside the box involves looking for

alternative ways that involve new solutions and ways of tackling problems. This is where

creative thinking is required. Modern engineers need to show imagination. An imaginative

idea can save a company millions of pounds and lead to better solutions for customers.

www.thetimes100.co.uk

At RWE npower, engineers at all levels are expected to handle these three types of problems

every day of their working lives. For deviation problems and improvement problems there will

often be tried and tested techniques. Typically these techniques involve teamwork.

GLOSSARY

Teamwork is essential for effective decision-making. Groups of engineers with different skills

Teamwork: people working

together.

come together to shed light on problems and issues and to come up with improvements. In a

team there will be engineers with different technical knowledge and experience. These will

include mechanical, electrical and civil engineers, and computer specialists.

Commercial implications: the

effects on the business.

Contracts: agreements between

two parties that are binding in law.

Teamwork involves good communication skills, particularly the ability to listen to others ideas.

Being able to identify the route cause of the problem and understand the symptoms is

essential. Working in teams creates a buzz of excitement. Engineers enjoy solving problems.

They like to be creative. Working together allows them to bounce ideas off each other. Some

of the solutions RWE npower engineers have come up with have saved the company millions

of pounds.

Creative problem-solving

In business there is typically a direct relationship between risk and reward. The bigger the risk

you take, the greater the possibility of making a high return. The reverse side of this is that

high risks can also be associated with spectacular failure.

Engineers working for RWE npower need to understand the commercial implications of the

decisions they make. The best decisions will be those that provide good technical solutions while

at the same time are commercially successful. Learning to manage risks is important. Decisions

taken must be in line with other priorities such as safe working. At RWE npower, health and

safety is the number one priority.

Creative problem-solving involves dealing with problems for the very first time. While there

are tools and techniques to help find solutions, engineers will need to be creative. They need

to decide what methods to use and ultimately how the problems will be solved.

At senior management level, RWE npower has engineers with responsibility for running very

large units such as a power station. These senior managers are continually provided with

information about every aspect of the performance of the plant. They receive advice and

information from a range of specialists. The sorts of problems they encounter include what to

do when a weakness is spotted in materials. For example, the giant turbines which power the

generators can develop tiny defects over time. The turbines can weigh more than 250 tonnes

and rotate 3,000 times a minute. These defects are actively managed and carefully

monitored to ensure they do not deteriorate to present a potential safety risk.

When a plant manager is notified that tiny cracks have been found in the turbine, then he or

she must come to a decision very quickly. The options are:

1. Shut down part or all of the plant and start repairs. In the middle of winter this could prove

to be very costly. When demand is at peak this could lead to losing supply contracts

worth 2 million per day.

2. Take advice from specialist engineers to check whether it is still possible to continue

operating while carefully monitoring the weakness. Specialist fracture engineers would

need to prove that, if they continued to run operations, the impact on the materials would

remain within safety limits. Repairs would then be made as soon as possible.

npower

28962_NPower

3. Do nothing (at RWE npower this is not an option).

115

28962_NPower

9/6/08

09:18

Page 4

Managers will only consider options that do not involve a health and safety risk. Once they

are satisfied that this is the case they will consider commercial criteria. The best solution will

be the one that fully meets the requirements of customers while at the same time yielding the

optimum financial return.

www.thetimes100.co.uk

Creative problem-solving at graduate level

It is not only top level managers that make important commercial decisions. RWE npower

employs graduate engineers straight from university. They contribute to the decision making

processes from the start. Typically their salaries start at about 25,000. They receive training

and development throughout their career at RWE npower. They are encouraged to think for

themselves and to place a high importance on commercial criteria in making decisions.

For example, a decision made by a graduate engineer saved the company millions of

pounds. One of the problems in running a power station is that deposits accumulate on the

many kilometres of pipes in the giant power station boilers and they take a long time to be

removed. The deposits need to be removed so that the thickness of the metal in the pipes can

be checked. Over time the pipes wear down and will eventually need to be replaced.

Recently a RWE npower graduate engineer developed a specialised measuring probe. This

made it possible to test the thickness of the pipes without the need for removing the deposits.

The probe made it possible to check instantly on the thickness of the pipes. This gives

managers much more up-to-date data about how safe the equipment is so that repairs can

be planned in the most economical way.

Conclusion

The Times Newspaper Limited and MBA Publishing Ltd 2008. Whilst every effort has been made to ensure accuracy

of information, neither the publisher nor the client can be held responsible for errors of omission or commission.

The success of the UK economy depends on having secure and efficient energy supplies.

Each day the challenge is increasing as resources become more scarce. For example, the

worlds oil and gas reserves are running out. At the same time much of the capital plant that

makes up the national grid and many older power stations needs replacing. This creates

immense challenges and opportunities for todays graduate engineer. These are exciting times

to get involved in engineering.

116

Engineering provides great prospects for suitably qualified applicants. The engineers of today

and tomorrow are people who make important and sometimes vital decisions. They have to

be problem-solvers who enjoy working with people in teams and with real problems related to

materials, processes and equipment. The decisions they make affect our lives. The excitement

of a career in engineering comes from knowing that you will develop solutions to problems

which havent yet been thought of.

As you can see from this case study, good creative decision making can save millions of

pounds and improve environmental and safety performance.

Questions

1. What do you understand by the term, thinking outside the box? Give an example of how

this can be applied to engineers working for RWE npower.

2. How does encouraging thinking outside the box help RWE npower to make improvements

in the way in which it operates?

3. Explain how encouraging engineers at RWE npower

to think outside the box has led to increased

motivation for these employees.

4. Recommend ways in which another organisation

of your choice might improve results through

encouraging its employees to think in creative

ways about work-related problems.

www.npower.com

You might also like

- Npower 12 FullDocument4 pagesNpower 12 Fullapi-3705095No ratings yet

- HVAC ReportDocument46 pagesHVAC ReportNitish Shah67% (3)

- FOUR STEPS of Energy Management For EIP Website 071025 PDFDocument10 pagesFOUR STEPS of Energy Management For EIP Website 071025 PDFJulio RicardoNo ratings yet

- Pm3e PDFDocument8 pagesPm3e PDFEdwar ForeroNo ratings yet

- A Multifaceted GemDocument3 pagesA Multifaceted GemVivek PatelNo ratings yet

- Ni Green EngineeringDocument5 pagesNi Green EngineeringWasif MugheesNo ratings yet

- POWER Sustainability1Document11 pagesPOWER Sustainability1Ion316No ratings yet

- Master Thesis Renewable Energy PDFDocument6 pagesMaster Thesis Renewable Energy PDFKathryn Patel100% (2)

- Energy Pro USA - Executive SummaryDocument7 pagesEnergy Pro USA - Executive SummaryS. Michael Ratteree100% (2)

- April 2015Document104 pagesApril 2015prasanta_bbsrNo ratings yet

- The Trafotek World of Renewable Energy and Efficient Power SolutionsDocument9 pagesThe Trafotek World of Renewable Energy and Efficient Power SolutionsBrahim MidouneNo ratings yet

- Guide to Decentralized Energy TechnologiesDocument49 pagesGuide to Decentralized Energy TechnologiesRavi Shankar SathyamurthyNo ratings yet

- NpowerDocument5 pagesNpoweribanurrachmanNo ratings yet

- Good Thesis Statement For Renewable EnergyDocument5 pagesGood Thesis Statement For Renewable EnergyWriteMyPaperReviewsSingapore100% (2)

- Thesis Proposal On Renewable EnergyDocument8 pagesThesis Proposal On Renewable Energynicolestewartknoxville100% (2)

- CT20131118 Solar Prod Catal Eng01 LOWRDocument84 pagesCT20131118 Solar Prod Catal Eng01 LOWRjoshmalikNo ratings yet

- JUWI Brochure Solar EnglDocument12 pagesJUWI Brochure Solar EnglRkantvyasNo ratings yet

- Energy Management Dissertation TopicsDocument7 pagesEnergy Management Dissertation TopicsBuyCollegePaperOnlineUK100% (1)

- SolarABCs 35 2013 Quality ChecksDocument16 pagesSolarABCs 35 2013 Quality CheckssuperklexNo ratings yet

- CV Dalila Ammar Tunisia Energy CnsultantDocument7 pagesCV Dalila Ammar Tunisia Energy Cnsultantdalila AMMARNo ratings yet

- Thesis Solar Power SystemDocument4 pagesThesis Solar Power Systemandreajimenezomaha100% (2)

- A Comparative Study of Financial Performance Using Ratio Analysis Between ABB and RockwellDocument6 pagesA Comparative Study of Financial Performance Using Ratio Analysis Between ABB and RockwellAMAL RAJNo ratings yet

- Catalogo InversorDocument84 pagesCatalogo InversorJóse Ignacio Flores EcheverriaNo ratings yet

- 1 ReDocument6 pages1 ReUsman HasnainNo ratings yet

- Demo 1 CertificateDocument17 pagesDemo 1 CertificateSergio FeitozaNo ratings yet

- Make The Most of Your Energy ™: Speaker's Name Date PlaceDocument18 pagesMake The Most of Your Energy ™: Speaker's Name Date PlaceDeepak R GoradNo ratings yet

- Role of Mechanical Engineering in Industries and SocietyDocument5 pagesRole of Mechanical Engineering in Industries and Societyayushthanthri2005No ratings yet

- Revised DMS ProposalDocument17 pagesRevised DMS ProposalApril UyanNo ratings yet

- Electricity Storage and RE For Island PowerDocument48 pagesElectricity Storage and RE For Island PowerFabiana ChusitNo ratings yet

- Lecture 1 Energy EngineeringDocument7 pagesLecture 1 Energy EngineeringCricket loversNo ratings yet

- Energy Saving Using 7epsilonDocument10 pagesEnergy Saving Using 7epsilonArjun KoduriNo ratings yet

- Rehva Journal Dic 2012Document76 pagesRehva Journal Dic 2012generoso67No ratings yet

- Arup Renewable Energy BrochureDocument6 pagesArup Renewable Energy BrochuretangoquebecNo ratings yet

- .Technopreneurship Assignment 2Document8 pages.Technopreneurship Assignment 2munyaradzi ChipereNo ratings yet

- Electrical Maintenance: How Does This Affect Your Company?Document12 pagesElectrical Maintenance: How Does This Affect Your Company?gaspartoNo ratings yet

- Panel Profiles - Energy DebateDocument3 pagesPanel Profiles - Energy DebateNETParkNetNo ratings yet

- WaveNet Full ReportDocument502 pagesWaveNet Full ReportpanicoscribdNo ratings yet

- Energy Technology SolutionsDocument94 pagesEnergy Technology SolutionsAlper KoçerNo ratings yet

- Health & Safety in Offshore Wind ConferenceDocument2 pagesHealth & Safety in Offshore Wind ConferenceIQPC GmbH100% (1)

- PEG Catalog Siemens PDFDocument419 pagesPEG Catalog Siemens PDFrukmagoudNo ratings yet

- PHD Thesis On Energy ManagementDocument8 pagesPHD Thesis On Energy Managementfjjf1zqp100% (2)

- Name Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentDocument12 pagesName Netid Group Number: Website Link: Tutorial Details Time Spent On Assignmentvcla436No ratings yet

- Chapter 1Document17 pagesChapter 1Dini Oktarina Sadega BachdimNo ratings yet

- Senior Executive or EnergyDocument6 pagesSenior Executive or Energyapi-78206403No ratings yet

- Environment and Sustainbility: Suzlon EnergyDocument9 pagesEnvironment and Sustainbility: Suzlon EnergySudhir KumarNo ratings yet

- Siemens Power Engineering Guide 2008Document419 pagesSiemens Power Engineering Guide 2008Roberto Fernandez50% (2)

- Electrical Product CatalogueDocument16 pagesElectrical Product CatalogueMuhammad MujtabaNo ratings yet

- aramco jdDocument7 pagesaramco jdNazbul HossainNo ratings yet

- Renewable EnergiesDocument17 pagesRenewable EnergiestatacpsNo ratings yet

- Thesis Topics On Energy EfficiencyDocument7 pagesThesis Topics On Energy EfficiencyBoston100% (1)

- Assessing Supply Chain Best PracticesDocument14 pagesAssessing Supply Chain Best Practiceshiemvanezi100% (1)

- INDUSTRY TICKER CURRENT HAPPENINGS AND EVENTSDocument2 pagesINDUSTRY TICKER CURRENT HAPPENINGS AND EVENTSPrudhvinadh KopparapuNo ratings yet

- Thesis On Electricity ConsumptionDocument4 pagesThesis On Electricity Consumptionfjn3d3mc100% (2)

- LCTPi Renewables Final ReportDocument40 pagesLCTPi Renewables Final ReportBradAllenNo ratings yet

- The Clean Tech Revolution (Review and Analysis of Pernick and Wilder's Book)From EverandThe Clean Tech Revolution (Review and Analysis of Pernick and Wilder's Book)No ratings yet

- Power Generation Technologies: Foundations, Design and AdvancesFrom EverandPower Generation Technologies: Foundations, Design and AdvancesNo ratings yet

- Optimal Design and Retrofit of Energy Efficient Buildings, Communities, and Urban CentersFrom EverandOptimal Design and Retrofit of Energy Efficient Buildings, Communities, and Urban CentersNo ratings yet

- Preface 2016 ValuationDocument2 pagesPreface 2016 ValuationPhuoc DangNo ratings yet

- 11 Valuation Issues 2016 ValuationDocument7 pages11 Valuation Issues 2016 ValuationPhuoc DangNo ratings yet

- Decision Making Using Game TheoryDocument215 pagesDecision Making Using Game Theorykaasim100% (13)

- 04 11 2020-TDocument5 pages04 11 2020-TPhuoc DangNo ratings yet

- 05 11 2020-SDocument5 pages05 11 2020-SPhuoc DangNo ratings yet

- Fibonacci Expansion: A Better Way To Time Price Targets: Trading TechniquesDocument4 pagesFibonacci Expansion: A Better Way To Time Price Targets: Trading TechniquesPhuoc DangNo ratings yet

- VSH Giaitrinh KQKD Q3 2017 HopnhatDocument2 pagesVSH Giaitrinh KQKD Q3 2017 HopnhatPhuoc DangNo ratings yet

- 04 11 2020-TDocument5 pages04 11 2020-TPhuoc DangNo ratings yet

- Agreement of VSHDocument4 pagesAgreement of VSHPhuoc DangNo ratings yet

- Annual Report of VSH 2019Document88 pagesAnnual Report of VSH 2019Phuoc DangNo ratings yet

- 04 11 2020-SDocument5 pages04 11 2020-SPhuoc DangNo ratings yet

- 02 11 2020-SDocument5 pages02 11 2020-SPhuoc DangNo ratings yet

- TraditionalTrade Shoppers Vs RetailersDocument21 pagesTraditionalTrade Shoppers Vs RetailersPhuoc DangNo ratings yet

- Bill For 12th PDFDocument1 pageBill For 12th PDFPhuoc DangNo ratings yet

- 04 11 2020-TDocument5 pages04 11 2020-TPhuoc DangNo ratings yet

- International Equity Investing: Investing in Emerging MarketsDocument20 pagesInternational Equity Investing: Investing in Emerging MarketsPhuoc DangNo ratings yet

- New Doc 2020-03-13 14.20.50 - 20200313142108 PDFDocument14 pagesNew Doc 2020-03-13 14.20.50 - 20200313142108 PDFPhuoc DangNo ratings yet

- Hoa Don Tien Dien Thang 12 PDFDocument1 pageHoa Don Tien Dien Thang 12 PDFPhuoc DangNo ratings yet

- Urban and Real Estate EconomicsDocument35 pagesUrban and Real Estate EconomicsPhuoc DangNo ratings yet

- Try Before Buying CD-DVD Guide and InstructionsDocument2 pagesTry Before Buying CD-DVD Guide and InstructionsPhuoc DangNo ratings yet

- Theworldstop10economies 2017 PDFDocument14 pagesTheworldstop10economies 2017 PDFAlberto AmparánNo ratings yet

- HPSF RepDocument1 pageHPSF RepPhuoc DangNo ratings yet

- Pham Thi Phuong Thao: (Address) Khuong Viet Street, Phu Trung Ward, Tan Phu District, HCMCDocument8 pagesPham Thi Phuong Thao: (Address) Khuong Viet Street, Phu Trung Ward, Tan Phu District, HCMCPhuoc DangNo ratings yet

- Read MeDocument1 pageRead MeDarma HusainNo ratings yet

- Ielts Simon Ebook Sample 2 PDFDocument5 pagesIelts Simon Ebook Sample 2 PDF390050% (6)

- Evaluating Black-Scholes and GARCH Models Using Currency Options DataDocument14 pagesEvaluating Black-Scholes and GARCH Models Using Currency Options DataPhuoc DangNo ratings yet

- Hoa Don Tien Dien Thang 12Document1 pageHoa Don Tien Dien Thang 12Phuoc DangNo ratings yet

- Cci Nghi Quyet HDQTDocument2 pagesCci Nghi Quyet HDQTPhuoc DangNo ratings yet

- 1 57871 Ectheory2 4824Document7 pages1 57871 Ectheory2 4824Phuoc DangNo ratings yet

- Do Stocks Hedge Inflation - Vietnamese and Thai EvidenceDocument41 pagesDo Stocks Hedge Inflation - Vietnamese and Thai EvidencePhuoc DangNo ratings yet

- E12 El-T&d KV Apr2014 GsokDocument16 pagesE12 El-T&d KV Apr2014 GsokNopadol PrasertkanchanaNo ratings yet

- Improving The Reliability of Power Supply SystemsDocument6 pagesImproving The Reliability of Power Supply SystemsAcademic JournalNo ratings yet

- Pte ListeningDocument49 pagesPte ListeningVishal MangalNo ratings yet

- Kerala Electricity Supply CodeDocument132 pagesKerala Electricity Supply Codekseb thrikkalangodeNo ratings yet

- Research HowDocument70 pagesResearch Howsreedhar_vkNo ratings yet

- Pelco Iii Inspection ReportDocument4 pagesPelco Iii Inspection ReportAnthony VanNo ratings yet

- Ee423 Primary Distribution OverviewDocument41 pagesEe423 Primary Distribution OverviewCathryn FriasNo ratings yet

- A Fault Steady State Component-Based Wide Area Backup Protection AlgorithmDocument8 pagesA Fault Steady State Component-Based Wide Area Backup Protection Algorithmpmahesh268No ratings yet

- Big Data (Analytics) in Power SystemsDocument20 pagesBig Data (Analytics) in Power SystemsFatimaHMNo ratings yet

- Under Over Frequency Relay Simulink ModelDocument14 pagesUnder Over Frequency Relay Simulink Modelsengsouvanhphaysaly phaysalyNo ratings yet

- Our Household Energy Transition - Becoming A Fossil Fuel Free FamilyDocument114 pagesOur Household Energy Transition - Becoming A Fossil Fuel Free FamilyDave SouthgateNo ratings yet

- Worksheet Form 3 6.3Document4 pagesWorksheet Form 3 6.3Acyuta Raj50% (2)

- Attachment ReportDocument32 pagesAttachment Reportmigire kennedyNo ratings yet

- Key Players MicrogridDocument2 pagesKey Players MicrogridBogdan TeodorescuNo ratings yet

- Secure Grid '11 After-Action ReportDocument28 pagesSecure Grid '11 After-Action ReporthhrustNo ratings yet

- (5kw Inverter) Livoltek User Manual - Hyper On-Grid 3-5kWDocument70 pages(5kw Inverter) Livoltek User Manual - Hyper On-Grid 3-5kWArpit LahotiNo ratings yet

- SIMATIC RotaryKnife AddOn DCLPC V121 enDocument35 pagesSIMATIC RotaryKnife AddOn DCLPC V121 enAngelNo ratings yet

- LEITWIND Technical Data Sheet LTW42 250Document2 pagesLEITWIND Technical Data Sheet LTW42 250James MartinNo ratings yet

- SUN2000 - (12KTL, 15KTL, 17KTL, 20KTL) - M0 User ManualDocument112 pagesSUN2000 - (12KTL, 15KTL, 17KTL, 20KTL) - M0 User ManualThế Thuận HồNo ratings yet

- Nepal Final Energy Sector ScenarioDocument51 pagesNepal Final Energy Sector Scenarioravi03121No ratings yet

- Energy-Efficient Distribution in Smart Grid: Xu Wei, Zhou Yu-Hui, Zhu Jie-LinDocument6 pagesEnergy-Efficient Distribution in Smart Grid: Xu Wei, Zhou Yu-Hui, Zhu Jie-LinmrboyedNo ratings yet

- MGVCL Ind TrustDocument8 pagesMGVCL Ind TrustVAISHALINo ratings yet

- Swe Riktlinjer Anslutning BessDocument2 pagesSwe Riktlinjer Anslutning BessShyamal DlrNo ratings yet

- Technical Guidelines For Small EG ConnectionsDocument28 pagesTechnical Guidelines For Small EG ConnectionsdebasishNo ratings yet

- Ingeteam Wind Converter Catalogue 2019Document4 pagesIngeteam Wind Converter Catalogue 2019FBNo ratings yet

- Renewable Energy Research Report PDFDocument31 pagesRenewable Energy Research Report PDFOmar AwaleNo ratings yet

- USRP 0316 Resources 030812 v2 PDFDocument175 pagesUSRP 0316 Resources 030812 v2 PDFwrxinNo ratings yet

- Application of Intentional Islanding Algorithm For Distributed Energy Resources in Disaster ManagementDocument6 pagesApplication of Intentional Islanding Algorithm For Distributed Energy Resources in Disaster Managementeshwar GNo ratings yet

- Unipower Company 2018pptxDocument22 pagesUnipower Company 2018pptxAFANGA ZAKARYANo ratings yet