Professional Documents

Culture Documents

Table 1: Composition of Refrigerators (KG and Per Cent) Over Time (With Estimated Years For Eventual Waste)

Uploaded by

MBA103003Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table 1: Composition of Refrigerators (KG and Per Cent) Over Time (With Estimated Years For Eventual Waste)

Uploaded by

MBA103003Copyright:

Available Formats

WASTE PLASTICS RECYCLING A GOOD PRACTICES GUIDE

BY AND FOR LOCAL & REGIONAL AUTHORITIES

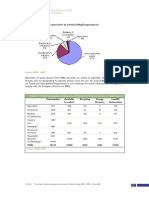

Plastics are increasingly becoming the material of choice by product designers. An indication of this

trend can be seen in the increased use of plastics in products such as cars and refrigerators over the

last 20 years (see Table 1 for data on refrigerators).

Table 1:

Composition of refrigerators (kg and per cent) over time

(with estimated years for eventual waste)

Material

1972 (1991)

ABS

PS

HIPS

Fibreglass

PU Foam

Total

kg

NON PLASTICS

Steel

Compressor

Aluminium

Copper

Misc.

kg

147.6

30.3

7.9

0.6

5.7

PLASTICS

kg

1980 (1999)

3.6

2.4

8.0

17.9

4.0

35,9

15,8

13.5

1.2

6.9

8.9

11.0

228.0

228.0

100

226.0

192,1

kg

1988 (2007)

%

kg

81,6

129.0

26.0

13.0

1.0

8.0

177,0

79,0

47,0

21,0

224.0

100

84,2

138.3

28.2

10.4

0.8

6.8

41,5

18,4

23.3

0.0

5.7

0.0

18.0

226.0

100

224.0

184,5

kg

Source = American Plastics Council

(http://www.plasticsresource.com/reading_room/reports/r_recycled_fridge.html

In the face of increasing waste generation and the increasing contribution of plastics to a number

of waste streams, L/RAs are confronted with a number of environmental, economic and social issues,

not only concerning the management of waste plastics, but solid waste in general. These issues

include:

the saturation of traditional waste disposal facilities landfills and incinerators

public demand for selective material collection services

visual pollution and the effects on tourism

legal obligations to comply with legislative targets (e.g. for recovery, recycling and

landfill diversion)

Saturation of Traditional Waste Disposal Facilities

Landfills

Establishing a new landfill site is a major challenge for any L/RA. A report for

the UK Governments Cabinet Office2 noted that:

Negative reactions to landfill are evident even without detailed knowledge, because of an

instinctive negative reaction to the idea of burying things in the ground. The image of the

plastics in particular appears to be a powerful symbolic image of landfill in the public

consciousness

2- Public Attitudes Towards Recycling and Waste Management Quantitative and Qualitative Review Research Study for the Strategy Unit,

Cabinet Office September 2002

WASTE PLASTICS RECYCLING A GOOD PRACTICES GUIDE

BY AND FOR LOCAL & REGIONAL AUTHORITIES

In such an environment, it is understandable that L/RAs will wish to prolong the life-span of existing

landfill sites when this is related to public sector activities, yet seek to minimise waste disposal costs

where the private sector is used.

Constraining factors in landfilling plastics (apart from issues of longevity) concern the volume of

space that plastics occupy in relation to their weight. Plastic bottles are estimated to occupy twice

as much space in landfill than mixed waste.

Legislative pressure directed at landfill practices and economic incentives to divert waste from landfill

aims to aid the management of existing and future landfill capacity. However, an effective waste

recycling and recovery strategy is necessary to achieving these objectives.

Incinerators

Plastics are the most significant contributors to the energy

content - calorific value - of MSW. Most waste plastics have

a high calorific value (CV) at about 40 MJ/kg - similar to

fuel oil (see Table 2).

Table 2: Typical calorific values

Polymers, Fuels & Mixed waste plastics

Net calorific Value (Mj/kg)

HDPE/ LDPE/ PP

45

Oil

40

Coal

25

PVC (wide variations between rigid and flexible PVC)

22

Mixed food Packaging

45

Mixed non-food packaging

37

However, municipal solid waste incinerators (MSWIs) have two main operational constraints:

the material flow, and the CV of the waste. With the growth in the waste plastics fraction, MSWIs

reach their CV limits more rapidly, and sometimes operators need to dilute the waste with material

of a lower energy content. L/RAs with incinerators face a choice: whether to limit the high calorific

fraction to the incinerator (through selective collection and recycling programmes) or whether to

build a new incinerator. The construction of a new incinerator will usually provoke the same Nimby

(not-in-my-backyard) reaction as a proposed landfill site.

A 2002 UK Cabinet Office study3 estimated that acceptance of new incinerator

appears.to be conditional upon several requirements, including:

that it is part of a recycling-led strategy where everything that can be recycled has been

recycled

that certain materials are separated out and not directly incinerated (for example plastics)

3- Public Attitudes Towards Recycling and Waste Management Quantitative and Qualitative Review Research Study for the Strategy Unit,

Cabinet Office September 2002

You might also like

- Recycling of Plastics - A Materials Balance Optimisation Model PDFDocument14 pagesRecycling of Plastics - A Materials Balance Optimisation Model PDFLeoChokNo ratings yet

- Recycled-Plastic Lumber Standards: From Waste Plastics To Markets For Plastic Lumber BridgesDocument12 pagesRecycled-Plastic Lumber Standards: From Waste Plastics To Markets For Plastic Lumber BridgesEmmanuelNo ratings yet

- App39931 PDFDocument14 pagesApp39931 PDFPatrick MacedoNo ratings yet

- Fdocuments - in - A Use Based Approach To Decision and Policy Making Blue Planet II Coverage ofDocument93 pagesFdocuments - in - A Use Based Approach To Decision and Policy Making Blue Planet II Coverage ofYash JoglekarNo ratings yet

- Macro Chemistry Physics - 20hvbhiojDocument17 pagesMacro Chemistry Physics - 20hvbhiojCarlo TonelloNo ratings yet

- Journal Plastic IntroductionDocument12 pagesJournal Plastic IntroductionNiammMbladdushNo ratings yet

- Recycling Plastic Packaging in The United States: Packaging Technology and Science VOLDocument6 pagesRecycling Plastic Packaging in The United States: Packaging Technology and Science VOLy.s.6saputroNo ratings yet

- !) '?III ./"+ ! 2) 6 - ?IIV 7) + ": 7Kh5Hgxfwlrqri Uhhqkrxvh DV (Plvvlrqviurpwkh&Hphqw, Qgxvwu/ BHJDocument8 pages!) '?III ./"+ ! 2) 6 - ?IIV 7) + ": 7Kh5Hgxfwlrqri Uhhqkrxvh DV (Plvvlrqviurpwkh&Hphqw, Qgxvwu/ BHJGaurav UppalNo ratings yet

- Introduction: Go ToDocument20 pagesIntroduction: Go ToDipu KhanNo ratings yet

- Figure 7: Waste Plastics Generation by Activity (50kg/european/year)Document2 pagesFigure 7: Waste Plastics Generation by Activity (50kg/european/year)MBA103003No ratings yet

- Recycling Plastics in GermanyDocument24 pagesRecycling Plastics in GermanyEvanCamilleriNo ratings yet

- Plastic Waste Management A Matter For The CommuniDocument3 pagesPlastic Waste Management A Matter For The CommuniKindricks Devon Labador LibreaNo ratings yet

- Solid Pellets From Municipal WasteDocument5 pagesSolid Pellets From Municipal Wastenebex12No ratings yet

- Carbon Dioxide Recycling: Emerging Large-Scale Technologies With Industrial PotentialDocument22 pagesCarbon Dioxide Recycling: Emerging Large-Scale Technologies With Industrial PotentialLoredana Veronica ZalischiNo ratings yet

- Municipal Solid Waste Conversion Donald K. WalterDocument34 pagesMunicipal Solid Waste Conversion Donald K. WalterRifal MilanistiNo ratings yet

- Plastic Waste Management: Is Circular Economy Really The Best Solution?Document3 pagesPlastic Waste Management: Is Circular Economy Really The Best Solution?MEnrique ForocaNo ratings yet

- Bijlage 4 Ce Delft 210126 Monitoring Chemical RecyclingDocument50 pagesBijlage 4 Ce Delft 210126 Monitoring Chemical Recyclingmori24067No ratings yet

- Plastic Waste Management A Matter For The CommuniDocument3 pagesPlastic Waste Management A Matter For The Communihsri72639No ratings yet

- Advancing Waste-to-Energy Design and PerformanceDocument14 pagesAdvancing Waste-to-Energy Design and PerformanceConstantin StanNo ratings yet

- Bioplastic Wastes: The Best Final Disposition For Energy SavingDocument7 pagesBioplastic Wastes: The Best Final Disposition For Energy SavingTegar BudiNo ratings yet

- NON FWA SolutionDocument7 pagesNON FWA Solutionhaseeb ahmedNo ratings yet

- Plastic Waste ManagementDocument12 pagesPlastic Waste Managementikhamate emmanuelNo ratings yet

- A Mechanical Analysis On Recycled PETHDPE Composites - Ávila, Duarte - 2003Document10 pagesA Mechanical Analysis On Recycled PETHDPE Composites - Ávila, Duarte - 2003Ana MangasNo ratings yet

- Art 00008Document21 pagesArt 00008Ahmet AltunNo ratings yet

- Eng. Journal Wate ManagementDocument6 pagesEng. Journal Wate ManagementrahmatfadlizNo ratings yet

- Waste Plastic Pyrolysis: An Efficient Way of Plastic RecyclingDocument7 pagesWaste Plastic Pyrolysis: An Efficient Way of Plastic RecyclingShaunotNo ratings yet

- Guide for Local Authorities on Recycling Waste PlasticsDocument2 pagesGuide for Local Authorities on Recycling Waste PlasticsMBA103003No ratings yet

- Polymers 11 00696Document19 pagesPolymers 11 00696LaLa HaNo ratings yet

- Bioplastic Wastes: The Best Final Disposition For Energy SavingDocument8 pagesBioplastic Wastes: The Best Final Disposition For Energy SavingShanaiah Charice GanasNo ratings yet

- The Gasification of Residual Plastics Derived From Municipal Recycling FacilitiesDocument11 pagesThe Gasification of Residual Plastics Derived From Municipal Recycling FacilitiesYeong Leong LimNo ratings yet

- Thermochemical Routes For The Valorization of Waste Polyolefinic Plastics To Produce Fuels and Chemicals. A Review PDFDocument23 pagesThermochemical Routes For The Valorization of Waste Polyolefinic Plastics To Produce Fuels and Chemicals. A Review PDFZaulmNo ratings yet

- Problem Chosen 2020 Mcm/Icm Summary Sheet Team Control NumberDocument27 pagesProblem Chosen 2020 Mcm/Icm Summary Sheet Team Control NumbergeniusindisguiseNo ratings yet

- Schwarz 2021 (Plastic Recycling)Document12 pagesSchwarz 2021 (Plastic Recycling)maria helenaNo ratings yet

- Science of The Total Environment: J. Santos, A. Pham, P. Stasinopoulos, F. GiustozziDocument13 pagesScience of The Total Environment: J. Santos, A. Pham, P. Stasinopoulos, F. GiustozziWaqas HaroonNo ratings yet

- CO2 Utilisation and Storage Position PaperDocument18 pagesCO2 Utilisation and Storage Position PaperMohamed Ali HamidNo ratings yet

- Sustainability Impact Assessment of Increased Plastic Recycling and Future Pathways of Plastic Waste Management in SwedenDocument21 pagesSustainability Impact Assessment of Increased Plastic Recycling and Future Pathways of Plastic Waste Management in SwedenBetül SurNo ratings yet

- Upcycling Paper Industry Waste in Eco-Friendly Building MaterialsDocument9 pagesUpcycling Paper Industry Waste in Eco-Friendly Building MaterialsMauricio FariaNo ratings yet

- Development of Single Use Plastics To Valued Addition: (PROJECT ADVISOR - Dr. Radheshyam Giri)Document14 pagesDevelopment of Single Use Plastics To Valued Addition: (PROJECT ADVISOR - Dr. Radheshyam Giri)Nilanjana MishraNo ratings yet

- Construction and Building Materials: Colin Jacob-Vaillancourt, Luca SorelliDocument12 pagesConstruction and Building Materials: Colin Jacob-Vaillancourt, Luca Sorellipipers10No ratings yet

- Technology Readiness Level Assessment of Composites RecyclingDocument12 pagesTechnology Readiness Level Assessment of Composites RecyclingJohanes GigihNo ratings yet

- Energies 16 02199 PDFDocument15 pagesEnergies 16 02199 PDFMahmoud Hussein EbeidNo ratings yet

- Sustainable Energy Generation From Municipal Solid Waste: A Brief Overview of Existing TechnologiesDocument8 pagesSustainable Energy Generation From Municipal Solid Waste: A Brief Overview of Existing TechnologiesZaki KhanNo ratings yet

- Analysis of Energy Foorprints With Recycling of Glass and Plastic Case Studies For Inbdustrial EcologyDocument15 pagesAnalysis of Energy Foorprints With Recycling of Glass and Plastic Case Studies For Inbdustrial EcologyrelampagomxNo ratings yet

- Prod and Upgrading of Recovered Carbon Black 2022Document19 pagesProd and Upgrading of Recovered Carbon Black 2022yasirNo ratings yet

- 3 Energy Production From Plastic Solid Waste (PSW) : 3.1 Key ConceptsDocument20 pages3 Energy Production From Plastic Solid Waste (PSW) : 3.1 Key ConceptscoisasNo ratings yet

- Carbon Footprint Reduction in The Textile Process ChainDocument6 pagesCarbon Footprint Reduction in The Textile Process ChainAnonymous Zsi5ODm2PYNo ratings yet

- 1 s2.0 S0921344923000083 MainDocument10 pages1 s2.0 S0921344923000083 MainTHE MASTER SIDENo ratings yet

- Exam questions on sustainability and energy optionsDocument17 pagesExam questions on sustainability and energy optionsDong Nam ChuNo ratings yet

- IDP2 Challenge 2020 Challenge SpecificationDocument12 pagesIDP2 Challenge 2020 Challenge SpecificationFatima BibiNo ratings yet

- Studentpaper 4 - Voorbeeld ABMDocument30 pagesStudentpaper 4 - Voorbeeld ABMWisal BoujeddaineNo ratings yet

- Nisha FareenaDocument33 pagesNisha FareenaNisha FareenaNo ratings yet

- Garside 2020 J. Phys. Conf. Ser. 1569 022100Document7 pagesGarside 2020 J. Phys. Conf. Ser. 1569 022100Annisa GarsideNo ratings yet

- Biofuels 10Document6 pagesBiofuels 10scorpion2001glaNo ratings yet

- Qualitative and Energy Recovery Potential AnalysisDocument12 pagesQualitative and Energy Recovery Potential AnalysismarialejandrapuertoNo ratings yet

- Plastic Waste Management: Submitted By: Javeriya Siddiqui M.Tech (Env. Engg.) 2 Year Roll No.6104206008Document20 pagesPlastic Waste Management: Submitted By: Javeriya Siddiqui M.Tech (Env. Engg.) 2 Year Roll No.6104206008Harishwar ReddyNo ratings yet

- A Review On The Recycling of Waste Carbon Fbreglass FbrereinforcedDocument21 pagesA Review On The Recycling of Waste Carbon Fbreglass FbrereinforcedManelNo ratings yet

- Plastic Waste ManagementDocument21 pagesPlastic Waste ManagementGopika GhNo ratings yet

- Banking On A Dual TransitionDocument31 pagesBanking On A Dual TransitionMr BigNo ratings yet

- Waste ManagementDocument18 pagesWaste Managementgabi1835No ratings yet

- The Carbon Dioxide Revolution: Challenges and Perspectives for a Global SocietyFrom EverandThe Carbon Dioxide Revolution: Challenges and Perspectives for a Global SocietyNo ratings yet

- Toilet Fixtures for Disabled: Clearances, Grab Rails & MountingDocument2 pagesToilet Fixtures for Disabled: Clearances, Grab Rails & MountingMBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part14Document2 pagesRevised Plumbing Code of The Philippines - Part14MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part15Document2 pagesRevised Plumbing Code of The Philippines - Part15MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part11Document2 pagesRevised Plumbing Code of The Philippines - Part11MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part12Document2 pagesRevised Plumbing Code of The Philippines - Part12MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part14Document2 pagesRevised Plumbing Code of The Philippines - Part14MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part13Document2 pagesRevised Plumbing Code of The Philippines - Part13MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part23Document2 pagesRevised Plumbing Code of The Philippines - Part23MBA103003No ratings yet

- Essential Elements of Plumbing SystemsDocument2 pagesEssential Elements of Plumbing SystemsMBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part25Document2 pagesRevised Plumbing Code of The Philippines - Part25MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part10Document2 pagesRevised Plumbing Code of The Philippines - Part10MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part29Document1 pageRevised Plumbing Code of The Philippines - Part29MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part26Document2 pagesRevised Plumbing Code of The Philippines - Part26MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part24Document2 pagesRevised Plumbing Code of The Philippines - Part24MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part27Document2 pagesRevised Plumbing Code of The Philippines - Part27MBA103003No ratings yet

- ACRRReport Part45Document2 pagesACRRReport Part45MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part28Document2 pagesRevised Plumbing Code of The Philippines - Part28MBA103003No ratings yet

- 2002 Recycling Levels: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pages2002 Recycling Levels: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003No ratings yet

- Waste plastics recycling guide for local authoritiesDocument2 pagesWaste plastics recycling guide for local authoritiesMBA103003No ratings yet

- ACRRReport Part48Document2 pagesACRRReport Part48MBA103003No ratings yet

- Type of Waste Plastic Kg/inh/y Per Cent: Table 37: Waste Plastics Management in France (1993)Document2 pagesType of Waste Plastic Kg/inh/y Per Cent: Table 37: Waste Plastics Management in France (1993)MBA103003No ratings yet

- Ban of Landfilling And/or Incineration: FranceDocument2 pagesBan of Landfilling And/or Incineration: FranceMBA103003No ratings yet

- ACRRReport Part41Document2 pagesACRRReport Part41MBA103003No ratings yet

- Selective Collection Costs: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pagesSelective Collection Costs: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003No ratings yet

- ACRRReport Part39Document2 pagesACRRReport Part39MBA103003No ratings yet

- Collection Sorting Processing Transport Total: PVC PipesDocument2 pagesCollection Sorting Processing Transport Total: PVC PipesMBA103003No ratings yet

- Ban of Landfilling And/or Incineration: FranceDocument2 pagesBan of Landfilling And/or Incineration: FranceMBA103003No ratings yet

- Selective Collection Costs: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pagesSelective Collection Costs: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003No ratings yet

- Environmental Law Clean Air ActDocument31 pagesEnvironmental Law Clean Air ActKyle NguyenNo ratings yet

- CLW 10 - 11 - Anaerobic Digestion - Text - 3 Solved ExercisesDocument10 pagesCLW 10 - 11 - Anaerobic Digestion - Text - 3 Solved ExercisesHosea100% (1)

- Memorandum of Agreement For Tree PlantingDocument2 pagesMemorandum of Agreement For Tree PlantingAnonymous 8aW4qU9SN82% (17)

- Public Waste ReceptaclesDocument5 pagesPublic Waste ReceptaclesedmontonjournalNo ratings yet

- War on Waste Activity at Inawayan National High SchoolDocument3 pagesWar on Waste Activity at Inawayan National High Schoolrenato roqueNo ratings yet

- Green Buildings-Mili MajumdarDocument6 pagesGreen Buildings-Mili Majumdarrads_mathurNo ratings yet

- Comma Splices & Run-Ons Exercise 1 - Answer KeyDocument3 pagesComma Splices & Run-Ons Exercise 1 - Answer KeyGael KasongaNo ratings yet

- Relationship Between Population Welfare and Environmental Resource BaseDocument10 pagesRelationship Between Population Welfare and Environmental Resource BasePreetam PandeyNo ratings yet

- 70 - 3 - Ebara DL 0313Document8 pages70 - 3 - Ebara DL 0313AriefNo ratings yet

- Urban Drainage Design Manual: Hydraulic Engineering Circular No. 22, Third EditionDocument478 pagesUrban Drainage Design Manual: Hydraulic Engineering Circular No. 22, Third Editiondisgusting4allNo ratings yet

- Effects of Flooding in Jakarta on Social and Economic AspectsDocument1 pageEffects of Flooding in Jakarta on Social and Economic AspectsMuhammad Ihsan FarizaNo ratings yet

- Rain Water HarvestingDocument24 pagesRain Water Harvestinganon_100565624100% (1)

- Innovations in Chemical Admixture Technology As Related To Sustainability, Part 2Document9 pagesInnovations in Chemical Admixture Technology As Related To Sustainability, Part 2masteriragaNo ratings yet

- 2000 Project Oceanography Pollution and Water QualityDocument14 pages2000 Project Oceanography Pollution and Water QualityMartha Letchinger100% (1)

- Iucn CategoriesDocument9 pagesIucn CategoriesUzma Khan100% (2)

- Barangay ProfileDocument7 pagesBarangay ProfileEjay SalengaNo ratings yet

- Climate Change IGCSE SampleDocument15 pagesClimate Change IGCSE SampleMohammad Hassaan BariNo ratings yet

- Hydrazines 113Document6 pagesHydrazines 113Shumani PharamelaNo ratings yet

- Descriptive beach sentencesDocument7 pagesDescriptive beach sentencesMuhammad Hanif100% (1)

- LOAD I MIKE Hydro - 130614Document21 pagesLOAD I MIKE Hydro - 130614TNBR RingletNo ratings yet

- 6 GTZ Datasheet On Vacuum Sewer Systems (2005)Document5 pages6 GTZ Datasheet On Vacuum Sewer Systems (2005)EddiemtongaNo ratings yet

- The Greenhouse EffectDocument2 pagesThe Greenhouse Effectnoshabah.khattak0% (1)

- Fact Sheet Timeout For Fast FashionDocument7 pagesFact Sheet Timeout For Fast Fashionm_mihail100% (1)

- The Private Sector's Climate Change Risk and Adaptation Blind SpotsDocument8 pagesThe Private Sector's Climate Change Risk and Adaptation Blind SpotspeterNo ratings yet

- Pollution and RemediesDocument18 pagesPollution and RemediesJerome AmbaganNo ratings yet

- Garbage EnzymesDocument8 pagesGarbage EnzymesKaniamuthuNo ratings yet

- University of Cambridge International Examinations International General Certificate of Secondary EducationDocument28 pagesUniversity of Cambridge International Examinations International General Certificate of Secondary EducationxeonzwongNo ratings yet

- 05 Ballast Water Record BookDocument3 pages05 Ballast Water Record Bookuser123100% (1)

- Air PollutionDocument353 pagesAir PollutionAnonymous hd1ZUvFDL70% (1)

- Guidelines For Planning A Marina DevelopmentDocument20 pagesGuidelines For Planning A Marina DevelopmentJazline Villanueva Dela Cruz100% (1)