Professional Documents

Culture Documents

Truss Design

Uploaded by

selvakumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Truss Design

Uploaded by

selvakumarCopyright:

Available Formats

STEEL BRIDGES - II

Job No:

Sheet 1 of 10

Rev

Job Title: TRUSS GIRDER RAIL BRIDGE

Worked Example - 1

Made by

Date 8-10-00

SSSR

Checked by

Date

VK

Structural Steel

Design Project

Calculation Sheet

PROBLEM:

Design a through type single lane truss bridge for broad gauge main line

loading. The effective span length of the bridge is 50 m. Consider m = 1.15.

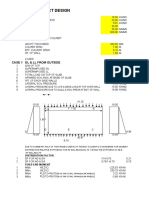

(1)TRUSS ARRANGEMENT [See Fig. E1]:

Effective Span of truss girder = 50 m.

Assume 10 panels @ 5 m interval.

Height and truss girder:

For economical considerations, height =

Assume, height = 6m. (

U1

U2

1

1

to

of span

8

10

1

of span) Hence, O.K.

8.33

U3

U4

U5

U6

U8

U7

U9

6m

L0

L1

L2

L3

L4

L5

L6

L7

L9

L8

L10

10 panels @ 5 m = 50 m

Fig. E1. Truss arrangement

(2) INFLUENCE LINE DIAGRAMS:

U1

(i) ILD for L0U1 (Diagonal member):

LoU1

Fig. E2. Free body diagram

Lo

1- (x/50)

Version II

5m

L1

44 - 16

STEEL BRIDGES - II

Structural Steel

Design Project

Calculation Sheet

Job No:

Sheet 2 of 10

Rev

Job Title: TRUSS GIRDER RAIL BRIDGE

Worked Example - 1

Made by

Date 8-10-00

SSSR

Date

Checked by

VK

(a) If, unit load is in between L1 and L10 (i.e. 5

50)

V = 0.

1

x

(1)

sin

50

(b) If, unit load is in between L0 and L1 ( i.e. 0 x 5 )

L0U1 sin

= 1 - (x/50)

L0U1 = -

1

sin

L0U1 =

9x

50

Then, we can get ILD as shown in Fig. E3.

1.17

Compression

Fig. E3. ILD for L0U1

(ii) ILD for L1U1 (Vertical member): [See free body diagram Fig. E4]

(a) If, unit load is in between L0 and L1 (i.e. 0

5)

ML0 = 0.

LoU1 cos

U1

5L1U1 = x

6m

x

L1U1 =

5

(b) If, unit load is in between L2 and L10 (i.e. 10

50 )

Lo

1- (x/50)

L1U1 = 0

5m

L2

L1

Fig. E4

1.0

Tension

Fig. E5 ILD for L1U1

Version II

44 - 17

STEEL BRIDGES - II

Job No:

Sheet 3 of 10

Rev

Job Title: TRUSS GIRDER RAIL BRIDGE

Worked Example - 1

Made by

Date 8-10-00

SSSR

Checked by

Date

VK

Structural Steel

Design Project

Calculation Sheet

(iii) ILD for U4U5 and L4L5 : (Top and Bottom chord members respectively)

U1

U2

U5

U4

U3

6m

5m

5m

5m

L0

L1

L2

5m

L3

L5

L4

1 - (x/50)

Fig. E6 Free body diagram

(a) If, the unit load is in between L0 and L4 (i.e. 0

20 )

M L5 = 0

6U4U5 + ( 25 x )*1 = 25*[1 - (x/50)]

U4 U5 =

1

x

[ 25 ( 1 ) - ( 25 - x )]

6

50

M U4 = 0

6L4L5 + ( 20 x )*1 = 20*[1 - (x/50)]

L4L5 =

1

x

[ 20 ( 1 ) - ( 20 - x )]

6

50

(b) If, unit load is in between L5 and L10 (i.e. 25

Then,

U4U5 =

1

x

[ 25 ( 1 )]

6

50

L4L5 =

1

x

[ 20 ( 1 )]

6

50

50 )

ILDs for U4U5 and L4L5 are shown in Fig. E7 and Fig. E8 respectively.

Version II

44 - 18

STEEL BRIDGES - II

Job No:

Sheet 4 of 10

Rev

Job Title: TRUSS GIRDER RAIL BRIDGE

Worked Example - 1

Made by

Date 8-10-00

SSSR

Checked by

Date

VK

Structural Steel

Design Project

Calculation Sheet

1.67

2.08 Compression

Fig. E7 ILD for U4U5

2.0

Tension

1.67

Fig. E8 ILD for L4L5

(3) LOADS:

(i) Dead load - Dead loads acting on truss girder are as follows:

Weight of rails

*Weight of sleepers =

0.25

Weight of fastenings (assumed)

0.6 = 1.2 kN/m.

7.5

0.25

= 2.34 kN/m.

0.4

= 0.25 kN/m.

Weight of stringers (assumed)

= 3.0 kN/m

Weight of cross girders (assumed)

= 5.0 kN/m.

**Self-weight of truss by Fullers Formula

Total dead load per track

**[ Fullers Formula

Version II

= 13.0 kN/m

= 24.8 kN/m

Therefore, Total dead load per girder =

*[Assume 250 mm 250 mm

and weight of 7.5 kN/m3]

RDSO

Specifications

24.8

2

= 12.4 kN/m

2m wooden sleepers @ 400 mm apart

15 + 550 15 50 550

= 13.0 kN/m]

=

100

100

44 - 19

STEEL BRIDGES - II

Structural Steel

Design Project

Calculation Sheet

Job No:

Sheet 5 of 10

Rev

Job Title: TRUSS GIRDER RAIL BRIDGE

Worked Example - 1

Made by

Date 8-10-00

SSSR

Checked by

Date

VK

(ii) Live load

(a) Areas of Influence line diagrams for truss members discussed:

Area of influence line for L0U1 =

1

50 1.17 = - 29.3

2

(Compression)

Area of influence line for L1U1 =

1

10 1.0 = + 5.0

2

(Tensile)

Area of influence line for U4U5 =

1

50 2.08 = - 52

2

(Compression)

Area of influence line for L4L5 =

1

50 2 = + 50

2

(Tensile)

(b) Live loads and impact loads from IRS Bridge Rules - 1982:

Live loads and impact factors for each loaded length are found from IRS

Bridge Rules - 1982. For maximum forces in chord members, the whole of the

span should be loaded and Live load is determined corresponding to maximum

B.M. For other diagonal and vertical members, part of the span as indicated by

influence line diagrams, should be loaded and the live load is determined

corresponding to S.F. The impact factor is found corresponding to loaded

length.

For maximum force in members L4L5 and U4U5:

Load length

= 50 m

Live load for B.M.

= 3895.2 kN

Impact factor = 0.15

8

6

(LL+ IL) per m per girder =

Version II

0.15

8

= 0.293

6 50

3895.2 1 0.293

= 50.36 kN/m

2 50

44 - 20

STEEL BRIDGES - II

Structural Steel

Design Project

Calculation Sheet

Job No:

Sheet 6 of 10

Rev

Job Title: TRUSS GIRDER RAIL BRIDGE

Worked Example - 1

Made by

Date 8-10-00

SSSR

Checked by

Date

VK

For maximum force in members L0 U1 and L1 U1:

L0U1:

Load length

Live load for B.M.

= 50 m

= 4184.6 kN

8

8

Impact factor = 0.15

= 0.293

0.15

6 50

6

4184.6 1 0.293

= 54.1 kN/m

(LL+ IL) per m per girder =

2 50

L1U1:

Load length

Live load for S.F.

= 10 m

= 1227.8 kN

8

8

= 0.65

6

6 10

1227.8 1 0.65

(LL+ IL) per m per girder =

= 101.3 kN/m

2 10

Impact factor = 0.15

0.15

(c) Longitudinal Loads from IRS Bridge Rules - 1982

Assume, there exist rail expansion joints in the bridge and prevent the transfer

of longitudinal loads to approaches. It may be noted that for broad gauge

bridges upto a loaded length of 44 m, the tractive effort is more than the

braking force and for loaded lengths more than 44 m the braking force is more

than the tractive effort.

Assume truss under consideration is simply supported by a hinge at L0 and a

roller at L10. The longitudinal force in a member can be tensile or compressive

depending on the direction of movement of train.

Panel L4L5:

Version II

Loaded length

= 30 m

Tractive effort

= 637.4 kN

Force per chord = 637.4/2

318.7 kN

44 - 21

STEEL BRIDGES - II

Job No:

Sheet 7 of 10

Rev

Job Title: TRUSS GIRDER RAIL BRIDGE

Worked Example - 1

Made by

Date 8-10-00

SSSR

Checked by

Date

VK

Structural Steel

Design Project

Calculation Sheet

Unfactored loads:

Member

Area of ILD

Load in kN/m

DL

Forces in members (kN)

LL+IL

DL

LL+IL

Long.L

L0U1

- 29.3

12.4

54.1

-363.3

-1585.1

L1U1

+5.0

12.4

101.3

+ 62

+ 506.5

U4U5

- 52.0

12.4

50.36

-644.8 -2618.7

+ 50.0

12.4

50.36

+620

318.7

L4L5

+2518

Use following Partial safety factors for the loads:

DL

= 1.35;

LL

= 1.50;

LongL

= 1.50

Factored loads:

Member

Factored Forces in members (kN)

DL

LL+IL

Long.L

L0U1

-490.4

- 2377.6

L1U1

+83.7

U4U5

-870.5

L4L5

+ 837

Total load (kN)

- 2868.0

+ 759.8

+ 843.4

-3928

- 4798.5

+3777

478

+ 5092

- 478

Note: Negative sign represents compression and positive sign represents

tension.

Version II

44 - 22

STEEL BRIDGES - II

Structural Steel

Design Project

Calculation Sheet

Job No:

Sheet 8 of 10

Rev

Job Title: TRUSS GIRDER RAIL BRIDGE

Worked Example - 1

Made by

Date 8-10-00

SSSR

Checked by

Date

VK

(4) DESIGN FOR TRUSS MEMBERS:

(i)

Design of diagonal member (L0U1): Note that in this illustration of

this Member, the portal effect and fatigue are not considered.

Length of the chord, L0U1 =

Assume, effective length,

= 7810 mm

= 0.7* = 5467mm

Try a built up member with two ISHB350 spaced @ 300 mm

A = 18442 mm2

rx

= 146.5 mm

ry

= 158.8 mm

Then,

350 mm

ISMB 350

= 5467/146.5 = 37.3

c

= 221.8 N/mm2

300 mm

[See chapter on axially compressed columns using curve c]

Axial capacity = (221.8/1.15)*18442/1000 = 3556.5 kN > 2868 kN

Hence, section is safe against axial compression

(ii) Design of vertical member (L1U1):

Maximum tensile force = 843.4 kN

Try ISMB 350 @ 0.524 kN/m shown.

A = 6671 mm2

Axial tension capacity of the selected section = 6671* 250/1.15

= 1450 kN > 843.4 kN

Hence, section is safe in tension.

[Note: Welded connection assumed]

Version II

44 - 23

STEEL BRIDGES - II

Structural Steel

Design Project

Calculation Sheet

Job No:

Sheet 9 of 10

Rev

Job Title: TRUSS GIRDER RAIL BRIDGE

Worked Example - 1

Made by

Date 8-10-00

SSSR

Checked by

Date

VK

(iii) Design of top chord member (U4U5):

Member length,

= 5000 mm

Assume, effective length = 0.85 = 4250 mm

550 mm

Try the section shown.

2 plates of size

550 mm X 12 mm

A = 25786 mm2

ISMC 400

rx = 165.4 mm

350 mm

424 mm

ry = 210 mm

x

Then,

= 4250/165.4 = 25.7

c

= 239 N/mm2

[See chapter on axially compressed columns using column curve c]

Axial capacity = (239/1.15)*25786/1000 = 5359 kN > 4798.5 kN

Hence, section is safe against axial compression

(ii) Bottom chord design(L4L5):

Maximum compressive force = 478 kN

Maximum tensile force = 5092 kN

Try the box section shown.

A = 25386 mm2

rx = 144 mm

350 mm

ISMC 400

400 mm X 16 mm

ry = 210 mm

Axial tension capacity of the selected section = 25386* 250/1.15

= 5518 kN > 5092 kN

Hence, section is safe in tension.

Version II

44 - 24

STEEL BRIDGES - II

Structural Steel

Design Project

Calculation Sheet

Maximum unrestrained length =

x

Then,

Job No:

Sheet 10 of 10

Rev

Job Title: TRUSS GIRDER RAIL BRIDGE

Worked Example - 1

Made by

Date 8-10-00

SSSR

Checked by

Date

VK

= 5000 mm

= 5000/144 = 34.7

= 225 N/mm2

Axial capacity = (225/1.15)* 25386/1000 = 4967 kN > 478 kN

Hence, section is safe against axial compression also.

The example is only an illustration. The following have to be taken into

consideration:

Design of lacings/batten

Design of connections and effect of bolt holes on member strength

Secondary bending effects

Design for fatigue

Version II

44 - 25

You might also like

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Types of Truss Bridges ExplainedDocument12 pagesTypes of Truss Bridges ExplainedEkta MittalNo ratings yet

- Fettuccine Truss BridgeDocument34 pagesFettuccine Truss BridgeTsaiWanChing100% (1)

- Design of Welded Plate GirderDocument25 pagesDesign of Welded Plate GirderJinshad UppukodenNo ratings yet

- Detail Design of Bridge Abutment 1Document4 pagesDetail Design of Bridge Abutment 1mohammad azimNo ratings yet

- Design of Deck For COMPLEX Concrete BridgeDocument75 pagesDesign of Deck For COMPLEX Concrete BridgeJunaid AminNo ratings yet

- Steel Connections-Lacing-Bridge BearingDocument11 pagesSteel Connections-Lacing-Bridge BearingRaheelAfzaalNo ratings yet

- Chapter 7: Box Girder BridgesDocument26 pagesChapter 7: Box Girder BridgesPacha Khan KhogyaniNo ratings yet

- Bridge Deck AnalysisDocument12 pagesBridge Deck AnalysisCSEC Uganda Ltd.No ratings yet

- EN1994 4 HanswilleDocument73 pagesEN1994 4 Hanswilleoluomo1No ratings yet

- Bridge Design Report - Docx 150Document17 pagesBridge Design Report - Docx 150nephembaniNo ratings yet

- Bridge Design StudioDocument38 pagesBridge Design Studiobhargavramudu 2019No ratings yet

- Bridge Foundation Design FactorsDocument23 pagesBridge Foundation Design FactorsNisarga KeshavmurthyNo ratings yet

- Bridge TechnologyDocument67 pagesBridge Technologythanzawtun1981No ratings yet

- Steel Composite Bridge-5100Document27 pagesSteel Composite Bridge-5100Mahesh SurlaNo ratings yet

- T Girder Bridge Deck Diaphragm-20 MDocument14 pagesT Girder Bridge Deck Diaphragm-20 MAmitabha DebNo ratings yet

- Plate GirderDocument74 pagesPlate Girderarif_rubin100% (1)

- Plate GirderDocument6 pagesPlate GirderOkayNo ratings yet

- Network Tied Arch Bridges: Deepthi VDocument31 pagesNetwork Tied Arch Bridges: Deepthi VSafalsha BabuNo ratings yet

- Design of Truss BridgeDocument18 pagesDesign of Truss BridgeBCE 2074 B Teacher100% (2)

- Bridge EngineeringDocument2,360 pagesBridge EngineeringStructural SpreadsheetsNo ratings yet

- Truss BridgesDocument21 pagesTruss BridgesAzaz Ahmed50% (2)

- Design of Column BasesDocument9 pagesDesign of Column Basesdarshanakp100% (1)

- Unit Ii - Design ConceptsDocument85 pagesUnit Ii - Design ConceptsAguero AgueroNo ratings yet

- Flat Slab DetailsDocument65 pagesFlat Slab DetailsFABDXB100% (1)

- Masonry ArchDocument35 pagesMasonry ArchSaurabh PednekarNo ratings yet

- Design of Portal FramesDocument35 pagesDesign of Portal FramesPranav Prabhakar100% (2)

- Truss Bridge Analysis - Truck Loads Deflection After 75 YearsDocument16 pagesTruss Bridge Analysis - Truck Loads Deflection After 75 YearsChrisYap100% (1)

- 6 Halaba Bridge PierDocument79 pages6 Halaba Bridge PierReader of Down HillNo ratings yet

- Lect2 - 1151 - Grillage AnalysisDocument31 pagesLect2 - 1151 - Grillage AnalysisCheong100% (1)

- Skew Bridges Calculation MethodsDocument9 pagesSkew Bridges Calculation MethodsIsidro P. BuquironNo ratings yet

- Study On The Behavior of Box Girder BridgeDocument96 pagesStudy On The Behavior of Box Girder BridgeIsaac Farfan OtondoNo ratings yet

- LRFD Pedestrian Bridge Example RevDocument13 pagesLRFD Pedestrian Bridge Example RevNacer AssamNo ratings yet

- BS 5950-2000 Example 001Document5 pagesBS 5950-2000 Example 001Anitha Hassan KabeerNo ratings yet

- Steel Bridge Design using FEM AnalysisDocument47 pagesSteel Bridge Design using FEM AnalysisROHANNo ratings yet

- 3 EC4-2 Background Gerhard HanswilleDocument67 pages3 EC4-2 Background Gerhard Hanswilleantonio111aNo ratings yet

- Grillage Analysis: Overview of Common Composite Bridge Deck Analysis ModelDocument9 pagesGrillage Analysis: Overview of Common Composite Bridge Deck Analysis Modelmonika chauhanNo ratings yet

- Temperature Effects in Bridge DecksDocument16 pagesTemperature Effects in Bridge Decksnaba1577No ratings yet

- Steel Bridge DesignDocument9 pagesSteel Bridge DesignĴetzaa Barragán ChávezNo ratings yet

- Bridge Deck Slab Design ProcedureDocument12 pagesBridge Deck Slab Design ProcedurePravin Awalkonde100% (1)

- Abutment Design Example To BD 30Document16 pagesAbutment Design Example To BD 30Muzammil Moosafeer100% (1)

- Portal FrameDocument7 pagesPortal FrameAzzren Azzrain100% (2)

- Steel Bridge DesignDocument24 pagesSteel Bridge DesignVarun ShastryNo ratings yet

- TrussDocument27 pagesTrussGaurav Nigam100% (1)

- Failure of Plate GirdersDocument27 pagesFailure of Plate GirdersKrina RathodNo ratings yet

- Example - Pile Cap DesignDocument4 pagesExample - Pile Cap DesignAnonymous xcFcOgMiNo ratings yet

- Analysis and Comparative Study of Composite Bridge GirdersDocument11 pagesAnalysis and Comparative Study of Composite Bridge GirdersIAEME PublicationNo ratings yet

- Economical Design of An Extra Dosed Bridge On 2Document16 pagesEconomical Design of An Extra Dosed Bridge On 2Ashok AgarwalNo ratings yet

- Redesign of Pedestrian Bridge at Kaneshie Market, Accra-GhanaDocument97 pagesRedesign of Pedestrian Bridge at Kaneshie Market, Accra-GhanaGagbe semanu kwameNo ratings yet

- Integral Bridges: What Is An Integral Bridge?Document20 pagesIntegral Bridges: What Is An Integral Bridge?Akhilesh Goje100% (1)

- Eurocode 3 - Design of JointsDocument18 pagesEurocode 3 - Design of JointsdineshNo ratings yet

- Composite Truss BridgesDocument6 pagesComposite Truss Bridgeszepedro_fernandes100% (1)

- Effective Length Calculations (Columns EC2)Document3 pagesEffective Length Calculations (Columns EC2)dhanya1995No ratings yet

- Design of TrussDocument29 pagesDesign of Trussfrancis100% (1)

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Part A - Part A Question No.1 Bookmark: (Chosen Option)Document26 pagesPart A - Part A Question No.1 Bookmark: (Chosen Option)selvakumarNo ratings yet

- Civil Engg QADocument67 pagesCivil Engg QAselvakumarNo ratings yet

- Part A - Part A Question No.1 Bookmark: (Chosen Option)Document27 pagesPart A - Part A Question No.1 Bookmark: (Chosen Option)selvakumarNo ratings yet

- Design Circular Water Tank ReinforcementDocument45 pagesDesign Circular Water Tank ReinforcementBruno FrankellyNo ratings yet

- Box Culvert Design: Case 1 DL & LL From OutsideDocument8 pagesBox Culvert Design: Case 1 DL & LL From OutsideselvakumarNo ratings yet

- Steel To Concrete Joints Design-Manual II enDocument292 pagesSteel To Concrete Joints Design-Manual II enSujeevan Tharmakulasingam100% (2)

- GE July 1976 Foundations and Earthworks For Cylindrical Steel Storage TanksDocument113 pagesGE July 1976 Foundations and Earthworks For Cylindrical Steel Storage Tanksselvakumar100% (1)

- Design of Slab Bs-2 Calculation of Crack WidthDocument2 pagesDesign of Slab Bs-2 Calculation of Crack WidthD SRINIVASNo ratings yet

- GE July 1976 - Foundations and Earthworks For Cylindrical Steel Storage Tanks PDFDocument6 pagesGE July 1976 - Foundations and Earthworks For Cylindrical Steel Storage Tanks PDFselvakumarNo ratings yet

- TankPadfoundationConstruction-Vol6 2 6Document13 pagesTankPadfoundationConstruction-Vol6 2 6selvakumarNo ratings yet

- Ring Wall FoundationDocument7 pagesRing Wall Foundationnishant3333100% (1)

- Oil StorFage Tank Foundations BobergDocument3 pagesOil StorFage Tank Foundations BobergNabil Al-KhirdajiNo ratings yet

- Tank Beam and StiffenerDocument1 pageTank Beam and StiffenerselvakumarNo ratings yet

- Soil Mechanics Multiple Choice QuestionsDocument55 pagesSoil Mechanics Multiple Choice QuestionsselvakumarNo ratings yet

- Handbook of Machine Foundations - P (1) - Srinivasulu, C.V. Vaidhyanathan PDFDocument255 pagesHandbook of Machine Foundations - P (1) - Srinivasulu, C.V. Vaidhyanathan PDFselvakumarNo ratings yet

- Pipe Rack Design PhilosophyDocument18 pagesPipe Rack Design PhilosophyselvakumarNo ratings yet

- Answer:: A. B. C. D. EDocument51 pagesAnswer:: A. B. C. D. EselvakumarNo ratings yet

- Est SHTDocument26 pagesEst SHTselvakumarNo ratings yet

- TorsionDocument18 pagesTorsionRenganayagi BalajiNo ratings yet

- Composite Construction Design GuideDocument23 pagesComposite Construction Design Guiderameshbabu_1979No ratings yet

- Basic Operation and Function of Control ValvesDocument65 pagesBasic Operation and Function of Control ValvesEdgar Huanca0% (1)

- FC FY 35 415: Check For Shear For Beams Vu pt Width β Area Depth c vDocument2 pagesFC FY 35 415: Check For Shear For Beams Vu pt Width β Area Depth c vselvakumarNo ratings yet

- SP29 - 2 - p41 Detail of Nut and BoltsDocument1 pageSP29 - 2 - p41 Detail of Nut and BoltsSujay SantraNo ratings yet

- Connection Design-Design RequirementsDocument14 pagesConnection Design-Design Requirementsqatarstructz30No ratings yet

- International Codes Staad Pro V8iDocument950 pagesInternational Codes Staad Pro V8iJaganraj Sesuraj100% (8)

- Advt Niot 2016Document9 pagesAdvt Niot 2016selvakumarNo ratings yet

- Theory On Embedment Plates 132Document33 pagesTheory On Embedment Plates 132Damien MooreNo ratings yet

- Compression Member Design AiscDocument4 pagesCompression Member Design AiscselvakumarNo ratings yet

- Syllabus CWCDocument5 pagesSyllabus CWCDowlath BashaNo ratings yet

- Civil Newsletter FinalDocument8 pagesCivil Newsletter FinalAditya BhanjaNo ratings yet

- AXOR Specifications GuideDocument18 pagesAXOR Specifications Guideenzo7259No ratings yet

- Prestressed Girder ChecklistDocument3 pagesPrestressed Girder ChecklistMedhat HasanainNo ratings yet

- HistoryOfBatavia LarryBarnesDocument400 pagesHistoryOfBatavia LarryBarnesNova Wazir100% (1)

- ALCBOOK11Document22 pagesALCBOOK11ชัยณรงค์ เทียนบุตรNo ratings yet

- SkyLift Operation ManualDocument25 pagesSkyLift Operation Manualcgeochoong100% (3)

- Funny AcronymsDocument6 pagesFunny AcronymsSachinvirNo ratings yet

- Methodology For Filter MediaDocument3 pagesMethodology For Filter MediaLaxminarayana Sastry100% (1)

- PANC - AnchorageDocument38 pagesPANC - Anchoragemvd spotterNo ratings yet

- Multicriteria Group Decision Making Technique For A Low-Class Road Maintenance Program AHPDocument11 pagesMulticriteria Group Decision Making Technique For A Low-Class Road Maintenance Program AHPana majstNo ratings yet

- Whitepod Hotel: Realizat De:vrancean AnaDocument13 pagesWhitepod Hotel: Realizat De:vrancean AnaVrancean AnaNo ratings yet

- VolvoDocument38 pagesVolvoMarculescu Nicolae CatalinNo ratings yet

- Hyundai Sonata Engine Failure Recall Lawsuit AttorneysstlwDocument4 pagesHyundai Sonata Engine Failure Recall Lawsuit Attorneysstlweraoboe4No ratings yet

- In Motion: Federal Bipartisan Infrastructure Law EnactedDocument4 pagesIn Motion: Federal Bipartisan Infrastructure Law EnactedJacob BeemanNo ratings yet

- Aashto 1972 CarolDocument30 pagesAashto 1972 CarolIjeal KuNo ratings yet

- ABC OverlayDocument5 pagesABC OverlayChemicro HoldingsNo ratings yet

- OrdnancesDocument1,478 pagesOrdnancesSome GuyNo ratings yet

- Multi - Modal Passenger Terminal Project Final Bus and Rail CompleteDocument175 pagesMulti - Modal Passenger Terminal Project Final Bus and Rail CompleteAnonymous HiQx2gFNo ratings yet

- BEZA Building Act-17Document23 pagesBEZA Building Act-17zakaria200811060No ratings yet

- ROJ-DOC-Report On Fuel Injection Equipment PDFDocument37 pagesROJ-DOC-Report On Fuel Injection Equipment PDFNitin Sakpal0% (1)

- Partes Pavimentadoras ITRDocument69 pagesPartes Pavimentadoras ITRMaria del Carmen Larruz100% (1)

- Where are places in your townDocument13 pagesWhere are places in your townJackeline ArellanoNo ratings yet

- Mathlinks9-Ch 11textbookDocument34 pagesMathlinks9-Ch 11textbookapi-171445363No ratings yet

- Spouses Teodoro and Nanette Perena v. Spouses Nicolas and Teresita L. Zarate, G.R. No. 157917, August 29, 2012Document38 pagesSpouses Teodoro and Nanette Perena v. Spouses Nicolas and Teresita L. Zarate, G.R. No. 157917, August 29, 2012JasenNo ratings yet

- COT Engineering equipment inventory listDocument19 pagesCOT Engineering equipment inventory listAF Dowell Mirin0% (1)

- ĐỀ THI THỬ ĐGNL VÀO CÁC TRƯỜNG CHUYÊN ANHDocument9 pagesĐỀ THI THỬ ĐGNL VÀO CÁC TRƯỜNG CHUYÊN ANHLinh LeNo ratings yet

- Passat B6 Footwell Light Install GuideDocument6 pagesPassat B6 Footwell Light Install GuideOlivierPeñaNo ratings yet

- Urban Design: Parameters For Study of Urban AreaDocument10 pagesUrban Design: Parameters For Study of Urban Areaankita kambleNo ratings yet

- Bullet Train Concept for Non-Stop TravelDocument18 pagesBullet Train Concept for Non-Stop TravelSaurabh KesarwaniNo ratings yet

- Torsen T-3 Technical SheetDocument2 pagesTorsen T-3 Technical SheetIsaac OlsonNo ratings yet