Professional Documents

Culture Documents

36m BowString PDF

Uploaded by

D SRINIVASOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

36m BowString PDF

Uploaded by

D SRINIVASCopyright:

Available Formats

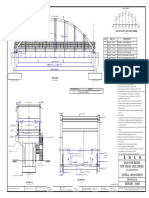

OF SYMMETRY

U3

U2

U2

U1

OF SYMMETRY

ARCH

B

L1

L0

OF BEARING

OF BEARING

HAND RAIL

L2

L3

L2

L1

L0

KEY ELEVATION - BOW STRING GIRDER

(SCALE 1:300)

WEIGHT OF STEEL

REMARKS

THIS VALUE IS APPROXIMATE SO SHOULD NOT BE USED

FOR PAYMENT PURPOSE

136 ton

HANGER

S.NO.

BEARING

CONCRETE PEDESTAL

U1

DRG. NO.

DESCRIPTION

1.

RDSO/B - 10407

GENERAL ARRANGEMENT

2.

RDSO/B - 10407/1

DETAILS OF STEEL FRAME

3.

RDSO/B - 10407/2

DETAILS OF ARCH & TOP JOINTS

4.

RDSO/B - 10407/3

DETAILS OF TOP TIE BEAM

5.

RDSO/B - 10407/4

DETAILS OF HANGER & JOINT L0

6.

RDSO/B - 10407/5

DETAILS OF BOTTOM LONG. BEAM

7.

RDSO/B - 10407/6

DETAILS OF BOTTOM CROSS BEAM

8.

RDSO/B - 10407/7

DETAILS OF CONCRETE DECK SLAB

9.

RDSO/B - 10407/8

SPLICING LOCATIONS

NOTE:

ELEVATION

1. All dimensions are in mm.

(SCALE 1:100)

SUITABLE FOUNDATION

SUITABLE FOUNDATION

2. No dimensions shall be scaled from this drawing, only written dimension shall be

followed.

3. This bridge span is designed for 70R and A-class loading as per IRC:6-2010.

4. This bridge span is designed for earthquake zone V.

5. Analysis and design of steel frame is as per IRC:24-2001.

6. Analysis and design of composite concrete deck is as per IRC:22-1986.

7. This bridge shall not be converted into three lane after removal of RCC crash barrier

because it is designed for two lane loading only ( as per IRC:6-2010).

6. All steel plates used in fabrication of this bridge are of grade Fe 490B.

Only ISMB 600 is of grade Fe 410C.

7. Grade of concrete for deck, crash barrier and concrete panels shall be M40.

OF CARRIAGE WAY

8. All material shall pass test/analysis prescribed by relevant IS specifications.

9. All steel work fabrication shall be done in accordance with Indian Codes.

10. Workshop welding:

ARCH

a. All workshop fabrication shall be done using SAW (Submerged Arc Welding)

process only.

TOP TIE BEAM

ARCH

11. On site welding:

a. All welding, other than workshop welding, shall be done through Gas Shielded

M. S. HAND RAIL

WITH WELD MESH

FCAW (Flux Core Arc Welding) process only. SMAW (Shielded Metal Arc

Welding) also known as Manual Metal Arc Welding shall NOT be permitted

RCC CRASH BARRIER

anywhere in the structure.

b. The gas Shield to be used in the FCAW process may be CO

POT/PTFE

BEARING

Argon or CO -Argon

mixture.

c. In FCAW process, wind screen and/or enclosures shall be provided around the

BOTTOM CROSS BEAM

welding location to prevent shielding gas from blown out.

RCC BEARING

PEDESTAL

STAIR CASE IS SITE SPECIFIC

d. Welding shall be performed on prepared metal surfaces free from rust, dust,

moisture etc. and before every new pass, slag must be carefully chipped off

from weld surface.

12. Radiography test shall be conducted to ensure weld quality.

RCC PIER CAP

13. Method of launching shall be approved by RDSO.

14. Pier and foundation used here are to represent arrangement of bow string girder.

DRAIN PIPE

Actual dimensions of pier and foundation is site specific.

CARRIAGE WAY

15. Staircase is optional and may be modified as per site requirement.

200 THK. WEARING COAT

HANGER

65 MM THK. WEARING COAT

R.

RCC CRASH

BARRIER

EXISTING ROAD/OGL

2.5% SLOPE

2.5% SLOPE

RCC PIER

BOTTOM LONG.

BEAM

DRAIN PIPE

BOTTOM CROSS BEAM

GENERAL ARRANGEMENT

RCC SHUTTERING

PROVISIONAL

SECTION B-B

(SCALE 1:60)

(PAPER SIZE A1)

(SCALE 1:100)

CALCULATION REGISTER NO. DD/2014/8

AutoCAD FILE NO.: B-10407

DRAWN BY: M/S Abhinav Associates

DESIGNED BY:

CHECKED BY: V.K.PANDEY (SSE)

VIVEK KUMAR (ADEN/NCR/B&S/RDSO)

SCRUTINIZED & CHECKED BY:

SRIJAN TRIPATHI (DBS /SB-I)

O.

36m CLEAR SPAN

PCC LEVELING COURSE

SECTION A-A

S.

ROAD OVER BRIDGE

BOW STRING STEEL GIRDER

M.S HANDRAIL

RCC PILE CAP

SUITABLE FOUNDATION

D.

APPROVED BY:

A. K. DADARYA (EDBS)

RDSO/B - 10407

"THIS DRAWING IS THE PROPERTY OF RESEARCH DESIGN AND STANDARD ORGANIZATION ( MINISTRY

OF RAILWAY ), LUCKNOW-226011, INDIA, AND SHALL NOT BE USED, COPIED OR REPRODUCED IN PART

OR WHOLE, WITHOUT PRIOR CONSENT IN WRITING."

You might also like

- Approved AMC Registered CompaniesDocument2 pagesApproved AMC Registered CompaniesLori NobleNo ratings yet

- Modified LVUP DrawingsDocument1 pageModified LVUP DrawingsAldrinNo ratings yet

- Bridge Hand BookDocument50 pagesBridge Hand BookSunny Godugu100% (1)

- Brinch Hansen - An Extended Formula For Bearing Capacity PDFDocument21 pagesBrinch Hansen - An Extended Formula For Bearing Capacity PDFJuan Carlos Torres Hernández100% (4)

- DN-101A-Design of Friction Slab-R1Document4 pagesDN-101A-Design of Friction Slab-R1jithinNo ratings yet

- Stee Vs Concrete BridgesDocument19 pagesStee Vs Concrete BridgesvsballaNo ratings yet

- Two Way SlabDocument80 pagesTwo Way SlabD SRINIVAS100% (1)

- Dimns. & Reinf. of Pier CapDocument1 pageDimns. & Reinf. of Pier Capsantosh yevvariNo ratings yet

- Bangalore MetroRail ProjectDocument94 pagesBangalore MetroRail ProjectMANMATH ACHARYA100% (7)

- Secification For Clad Carbon Steel Bends Manufactured by Induction HeatingDocument19 pagesSecification For Clad Carbon Steel Bends Manufactured by Induction HeatingAdvisNo ratings yet

- Slab Culvert IRC 21 IRC 112Document5 pagesSlab Culvert IRC 21 IRC 112Ashish Bhoi100% (1)

- Beam DesignDocument8 pagesBeam DesignFaraaz FaisalNo ratings yet

- Slab CulvertDocument3 pagesSlab CulvertSHIVANK SINGH PARIHARNo ratings yet

- Foundation and Substructure: Section VIIDocument14 pagesFoundation and Substructure: Section VIIRinkesh MakawanaNo ratings yet

- Well Cap Design at Pier LocationDocument4 pagesWell Cap Design at Pier LocationkailashaharNo ratings yet

- Hollow Sections Book WardenierDocument199 pagesHollow Sections Book WardenierANUSSBAUMER100% (3)

- Bow-String Girder - Design & Construction AspectsDocument12 pagesBow-String Girder - Design & Construction Aspectsepcepcepc100% (1)

- Bridge BookDocument76 pagesBridge BookSunkara Hemanth KumarNo ratings yet

- Approach Slabs - For BRIDGES VenkatDocument3 pagesApproach Slabs - For BRIDGES VenkatV Venkata Narayana0% (1)

- RDSO/B-10423/10 R0: Walls & Bridges (India) Pvt. LTDDocument1 pageRDSO/B-10423/10 R0: Walls & Bridges (India) Pvt. LTDSrikanth Patel DspNo ratings yet

- Spayed Wing Wall BBS 155+586 RHSDocument1 pageSpayed Wing Wall BBS 155+586 RHSHegdeVenugopal100% (1)

- Terzaghi and Meyerhof Bearing Capacity TheoriesDocument23 pagesTerzaghi and Meyerhof Bearing Capacity Theorieskiddho100% (2)

- Alok Panday Design & Construction of SuperstructureDocument57 pagesAlok Panday Design & Construction of SuperstructureBalakumaran GunasekaranNo ratings yet

- TB 9-2330-381-13-1Document92 pagesTB 9-2330-381-13-1AdvocateNo ratings yet

- Box CUlvert Drawings 5 X 3Document2 pagesBox CUlvert Drawings 5 X 3Soni Jitubhai100% (2)

- Bridge Elements GuideDocument86 pagesBridge Elements GuideAbhishekNo ratings yet

- Oms Infra Consultants PVT - Ltd. Roads and Buildings DeparmentDocument2 pagesOms Infra Consultants PVT - Ltd. Roads and Buildings Deparmentnandu523No ratings yet

- Transmission Stall Testing Procedure ExplainedDocument3 pagesTransmission Stall Testing Procedure Explainednamduong368No ratings yet

- Steel Stacks Desing GuideDocument23 pagesSteel Stacks Desing Guidecharlie kurzawskiNo ratings yet

- HPC & Slab PDFDocument3 pagesHPC & Slab PDFAbhijeet SahuNo ratings yet

- Bridge Design (Shear Force and Bending Moment Calculation) : Irc Class Aa Tracked VehicleDocument16 pagesBridge Design (Shear Force and Bending Moment Calculation) : Irc Class Aa Tracked VehicleRohit Gupta33% (3)

- Designed Date Details Checked Title DocnoDocument4 pagesDesigned Date Details Checked Title DocnovivekNo ratings yet

- Pipe Culvert Pkg-2Document667 pagesPipe Culvert Pkg-2Payal MondalNo ratings yet

- Re Wall Design As Per Irc 102Document16 pagesRe Wall Design As Per Irc 102munnijhaNo ratings yet

- AFV06-3 - Panzerbeobachtungswagen IV PDFDocument11 pagesAFV06-3 - Panzerbeobachtungswagen IV PDFLea Lea100% (1)

- Fluid Mechanics and Hydraulic Machines Textbook Scanned PDFDocument287 pagesFluid Mechanics and Hydraulic Machines Textbook Scanned PDFPullavartisrikanthChowdaryNo ratings yet

- Yamaha Fazer User Owner Manual FZ6SHG 2008 PDFDocument96 pagesYamaha Fazer User Owner Manual FZ6SHG 2008 PDFRobert NadeauNo ratings yet

- Pre CamberDocument10 pagesPre CamberVenkat PalliNo ratings yet

- Rdso Guide Lines FR BridgesDocument76 pagesRdso Guide Lines FR BridgesUtpal KantNo ratings yet

- Proposed Arch Bridge On Lower Lake of Bhopal: A Case StudyDocument3 pagesProposed Arch Bridge On Lower Lake of Bhopal: A Case StudyInnovative Research PublicationsNo ratings yet

- Calculation and limits of crack width in prestressed concreteDocument7 pagesCalculation and limits of crack width in prestressed concreteJeet DesaiNo ratings yet

- Calculation and limits of crack width in prestressed concreteDocument7 pagesCalculation and limits of crack width in prestressed concreteJeet DesaiNo ratings yet

- 42m BowStringDocument1 page42m BowStringsorowareNo ratings yet

- Pavement Engineering in Developing CountriesDocument35 pagesPavement Engineering in Developing Countriesuntoni100% (1)

- Image PDFDocument44 pagesImage PDFAkshay Kumar SahooNo ratings yet

- Well Tilt and Shift-Bangraghat1Document3 pagesWell Tilt and Shift-Bangraghat1ShaileshRastogiNo ratings yet

- Cable TrenchDocument22 pagesCable TrenchD SRINIVASNo ratings yet

- 6oilccopdngglobal2152008 Voll III 20piping 20 20 MechanicalDocument643 pages6oilccopdngglobal2152008 Voll III 20piping 20 20 Mechanicaldinesh2u85No ratings yet

- Efficient 3D and 2D Modelling of Pile Foundations in FEMDocument21 pagesEfficient 3D and 2D Modelling of Pile Foundations in FEMOmar Elio67% (3)

- BQ RoadDocument38 pagesBQ RoadFaeez Zain100% (1)

- Staad Pro and Circular SlabDocument10 pagesStaad Pro and Circular SlabP&D CIRCLE PWD0% (1)

- Eccentric FootingDocument15 pagesEccentric FootingD SRINIVASNo ratings yet

- Eccentric FootingDocument15 pagesEccentric FootingD SRINIVASNo ratings yet

- JK Prestressing CatalougeDocument60 pagesJK Prestressing Catalougeravi aroraNo ratings yet

- DESIGN OF PIER CAPDocument13 pagesDESIGN OF PIER CAPRohit VermaNo ratings yet

- Bridge Design Guide Line-IRCDocument4 pagesBridge Design Guide Line-IRCSK SwainNo ratings yet

- PipeDocument30 pagesPipepudumai100% (1)

- Pile Foundations in Engineering Practice by S PDFDocument784 pagesPile Foundations in Engineering Practice by S PDFD SRINIVASNo ratings yet

- North Western Railway: Sr. Den (Co) /JP CBE....... JPDocument1 pageNorth Western Railway: Sr. Den (Co) /JP CBE....... JPEr Navneet JassiNo ratings yet

- GAD of Structure - A-13 - 2 PDFDocument30 pagesGAD of Structure - A-13 - 2 PDFmayank007aggarwal0% (1)

- Part 1 Hydraulic Design Calculation 473Document13 pagesPart 1 Hydraulic Design Calculation 473shashi rajhansNo ratings yet

- 36 MTR SpanDocument13 pages36 MTR SpanAnonymous sfkedkymNo ratings yet

- Plate Girder Bridge BOMDocument8 pagesPlate Girder Bridge BOMankitNo ratings yet

- Traffic Final Report Group 7Document86 pagesTraffic Final Report Group 7erlyn alagonNo ratings yet

- PCC Breast Wall 11-05-2021-ModelDocument1 pagePCC Breast Wall 11-05-2021-ModelEr navneet jassiNo ratings yet

- A A AaaaaaaaaaaaaaaDocument19 pagesA A AaaaaaaaaaaaaaaSolmon SharmaNo ratings yet

- Package V bridge drawingsDocument67 pagesPackage V bridge drawingsMandeep Singh100% (1)

- RoB Cost Estimates For Alt - 1, 45m Plate GirderDocument20 pagesRoB Cost Estimates For Alt - 1, 45m Plate GirderHegdeVenugopalNo ratings yet

- Bow String Girder Launching ProgramDocument1 pageBow String Girder Launching ProgramrohitNo ratings yet

- 3.0 Effective Width of Tyres and Load Distribution For IRC Class Special Vehicle 385 T (SV Class)Document2 pages3.0 Effective Width of Tyres and Load Distribution For IRC Class Special Vehicle 385 T (SV Class)vivekNo ratings yet

- Drawing Title: Employer Project Design Consultant: HouseDocument5 pagesDrawing Title: Employer Project Design Consultant: HouseRoshan KejariwalNo ratings yet

- 30 M Bow String Girder-10409-7rDocument1 page30 M Bow String Girder-10409-7rprejithNo ratings yet

- Blending WMMDocument2 pagesBlending WMMPrasanna S Kulkarni100% (1)

- 40 M COMPOSITE GIRDER New-ModelDocument1 page40 M COMPOSITE GIRDER New-Modelabhijeet sahuNo ratings yet

- Pier Well Foundation Design LoadsDocument35 pagesPier Well Foundation Design LoadsPraveen Kumar KattamuriNo ratings yet

- Design of Bridges Foundations SlabsDocument3 pagesDesign of Bridges Foundations SlabsDeepak SinghNo ratings yet

- Amendment No. 1 To IRC 112 - 2014 PDFDocument3 pagesAmendment No. 1 To IRC 112 - 2014 PDFmrraee4729100% (3)

- Bar Bending Schedule For Box Culverts at CH: 128+820 For Service Road Total Length 40.092mDocument4 pagesBar Bending Schedule For Box Culverts at CH: 128+820 For Service Road Total Length 40.092mIrfan PatahnNo ratings yet

- Thulo Neti Khola Bridge - Abutment Design: Fig: Abutment (All Dimensions in Metres)Document4 pagesThulo Neti Khola Bridge - Abutment Design: Fig: Abutment (All Dimensions in Metres)Himal KafleNo ratings yet

- 2 - Axle Load PDFDocument17 pages2 - Axle Load PDFDebanjan MukherjeeNo ratings yet

- Detailed Survey Data: Public Works Region, Pune Public Works Circle, SolapurDocument23 pagesDetailed Survey Data: Public Works Region, Pune Public Works Circle, SolapurPravin MasalgeNo ratings yet

- Electricity Board DocsDocument41 pagesElectricity Board DocsM_D_MendisNo ratings yet

- Mid Section of Super Structure: C L of SpanDocument6 pagesMid Section of Super Structure: C L of SpanMohsin SyedNo ratings yet

- Ornamental Bridge (1) Str-ModelDocument1 pageOrnamental Bridge (1) Str-ModelSaurabh Kumar SharmaNo ratings yet

- Is.4880.1.1987 0 PDFDocument10 pagesIs.4880.1.1987 0 PDFD SRINIVASNo ratings yet

- 101 Math Short Cuts-Mental Ability PDFDocument20 pages101 Math Short Cuts-Mental Ability PDFsanits591100% (1)

- Shotcrete GuideDocument4 pagesShotcrete GuideVpln Sarma100% (1)

- 53 1f CTR PDFDocument70 pages53 1f CTR PDFJohneey DeepNo ratings yet

- Linings FOR: Irrigation CanalsDocument160 pagesLinings FOR: Irrigation CanalsmrmerajNo ratings yet

- vb6.0 Guide Made EasyDocument258 pagesvb6.0 Guide Made Easysb_rameshbabuNo ratings yet

- Connection FigDocument1 pageConnection FigD SRINIVASNo ratings yet

- Block Shear Capacity For Staggered BoltsDocument1 pageBlock Shear Capacity For Staggered BoltsD SRINIVASNo ratings yet

- Advancement of Is CodeDocument8 pagesAdvancement of Is CodeD SRINIVASNo ratings yet

- Crack WidthDocument1 pageCrack WidthD SRINIVASNo ratings yet

- Open Newel Stair Design with Quarter LandingDocument4 pagesOpen Newel Stair Design with Quarter LandingD SRINIVASNo ratings yet

- En Micro Hydro Design Aids GIZ 2005Document27 pagesEn Micro Hydro Design Aids GIZ 2005D SRINIVASNo ratings yet

- Design of Slab Bs-2 Calculation of Crack WidthDocument2 pagesDesign of Slab Bs-2 Calculation of Crack WidthD SRINIVASNo ratings yet

- Helmsdale Walks Sutherland Scotland BackDocument7 pagesHelmsdale Walks Sutherland Scotland BackDavid MasonNo ratings yet

- Potsdam Village Police Dept. Blotter Jan. 30, 2016Document3 pagesPotsdam Village Police Dept. Blotter Jan. 30, 2016NewzjunkyNo ratings yet

- Glass BeadsDocument20 pagesGlass BeadsbinunalukandamNo ratings yet

- Kyoto: 2 HistoryDocument19 pagesKyoto: 2 Historyderrida1930No ratings yet

- Bridge 1Document3 pagesBridge 1binanceNo ratings yet

- Street lighting design and construction guideDocument72 pagesStreet lighting design and construction guidekevin_au18No ratings yet

- Driver Drowsiness Detection With Audio-Visual WarningDocument7 pagesDriver Drowsiness Detection With Audio-Visual WarningIJIRSTNo ratings yet

- Prelim Exam Dizon 09.18.20 PDFDocument12 pagesPrelim Exam Dizon 09.18.20 PDFErick MangalinoNo ratings yet

- Houston - Galvestontr - New Improved Welcome Letter 2013Document2 pagesHouston - Galvestontr - New Improved Welcome Letter 2013Maryt Anaguari RamosNo ratings yet

- Motor Vechicle OrdinanceDocument127 pagesMotor Vechicle Ordinancemuhammad nazirNo ratings yet

- Assessement of Perception Reaction Parameters On Akure Owo Highway in Ondo State NigeriaDocument21 pagesAssessement of Perception Reaction Parameters On Akure Owo Highway in Ondo State NigeriaAliu AdekunleNo ratings yet

- Oak Cliff Gateway Merged OrdinancesDocument177 pagesOak Cliff Gateway Merged OrdinancesrappletonNo ratings yet

- 04 Lectures 03-06 FlexiPaveDesignFactors NOTESDocument20 pages04 Lectures 03-06 FlexiPaveDesignFactors NOTESIsaac SenyohNo ratings yet

- Road Accident Investigation Guidelines For Road Engineers: 2013R07EN Cycle 2004-2007Document0 pagesRoad Accident Investigation Guidelines For Road Engineers: 2013R07EN Cycle 2004-2007Alina BurlacuNo ratings yet

- Detail Design Guidelines For Asian Highway NetworkDocument267 pagesDetail Design Guidelines For Asian Highway NetworkShoayful islamNo ratings yet

- Tiger 800 XC BrochureDocument9 pagesTiger 800 XC BrochureAnand IyerNo ratings yet

- Motocultor 437 TM10 DDocument52 pagesMotocultor 437 TM10 DSamuelNo ratings yet

- The Bike Narrative and WorksheetDocument3 pagesThe Bike Narrative and Worksheetcash samuelNo ratings yet

- Indian Auto Industry . The Way: Presentation By-Sunil Kakkar General Manager (Supplychain) Maruti Suzuki India LTDDocument35 pagesIndian Auto Industry . The Way: Presentation By-Sunil Kakkar General Manager (Supplychain) Maruti Suzuki India LTDViral JainNo ratings yet

- An Example To Renovation-Revitalization Works in Historical City Centres: Kunduracılar Street/Trabzon-TurkeyDocument14 pagesAn Example To Renovation-Revitalization Works in Historical City Centres: Kunduracılar Street/Trabzon-TurkeySura A. YaseenNo ratings yet

- The Story of Canal Zone StampsDocument194 pagesThe Story of Canal Zone StampsRafaelSánchezNo ratings yet