Professional Documents

Culture Documents

Jual Pompa Sentrifugal Ebra

Uploaded by

احمد زكي زكيCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jual Pompa Sentrifugal Ebra

Uploaded by

احمد زكي زكيCopyright:

Available Formats

PRODUCT

CATALOGUE

Booster Pump

Close Couple Stainless Stell

SPECIFICATIONS

Flow

: 2 ~ 500m3/h

T. Head

: 8~300 m

L. Tem

: -150C ~+700C

Volt

: 380 V

Material

: SS 304/316 (Cast iron)

SPECIFICATIONS

Flow

: 0.5 ~ 22m3/h

T. Head

: Max. 54 m

L. Tem

: -150C ~+1100C

Volt

: 220/380 V

Material

: SS 304/316

Model Centrifugal end Suction Pump

Coupling

SPECIFICATIONS

Type

: 90-100-112-125-140-160

: 180-200-224-250-280-315

: 355-400-450-560-630

SPECIFICATIONS

Flow

: Max 300 lts/s

T. Head

: Max 100 m

Work Pres

: Max. 1 Mpa

L. Tem

: - 100C ~+1050C

Sealing

: Packing / Mech Seal

Diaphragm Pump

SPECIFICATIONS

Model

: 3/8 - 1-1 - 2 -3

Max Flow

: 4.6 - 237

Max Dischrage

Pressure

: 100 - 120

Max Solids

: 1/16 3/8

Fluid Ports

: 3/8 3

Material of

Contruction : Polyproplne, Groundable Acetal,

PDVF, Alumunium, Stainless

Steel, Cast Iron.

Seat Material : Polyproplne, Groundable

Acetal, PDVF, Alumunium,

Stainless Steel, Cast Iron,

Carbon Steel, Hytrel,

Santoprene.

Ball Material : Polyproplne, Groundable Acetal,

PDVF, Alumunium, Stainless Steel,

Cast Iron, Carbon Steel, Hytrel,

Santoprene, Viton, Teflon, Nitrile.

Diaphragm

Material

: Polyproplne, Groundable Acetal,

PDVF, Alumunium, Stainless Steel,

Cast Iron, Carbon Steel, Hytrel,

Santoprene, Viton, Teflon, Nitrile, EPR.

Gear Box

SPECIFICATIONS

WPA Worm Gear

Size

: 40-50-60-70-80-100120-135-155-175-200-250

Ratio

: 1/10 ~ 1/60

Gear Pump

SPECIFICATIONS

Flow

: 20 ~ 273 ltr/min

T. Head

: 2~6 kg/cm2

Power

: 0.33 ~ 4.5 kw

L. Tem

: < + 800C

Speed

: 280 ~ 930 rpm

Gear Motor

Induction Motor

SPECIFICATIONS

SPECIFICATIONS

Power

: 0.12 ~ 180 HP

Speed

: 2~ 8 Pole

Volt

: 230V, 380V, 400V

Mounted

: B3, B5, B35, B14

Gear

In

Line

Pump

Pump

Induction Motor Explosion Proof

SPECIFICATIONS

Delivery up to 25 m3/h.

Head up to 260 m

Maximum operating pressure max. 15 bar

Temperature of liquid: -20C to 120C

Version: Single phase, 220 - 240V/50Hz up to 2.2Kw

Three phase, 360 - 415V/50Hz up to 15Kw

Class F insulation

IP 55 protection

SPECIFICATIONS

Power

: 0.5 ~ 270 HP

Speed

: 2~ 10 Pole

Volt

: 380V

Mounted

: B3, B5, B35

Inverter

Hydrant

SPECIFICATIONS

BPK Standard

FOC

NFPA 20

UNE 23500-90

CREPEVEN R.T.2-ABA

Magnetic Pump

SPECIFICATIONS

Power

HP range

1 200V

~ 1 HP

3 220V

~ 100 HP

Characteristics

Output Frequency 0.5 ~ 240. Ohz

External analog setting DCO ~ 10V and DC4

~20mA

10 pattern and any V/F pattern

8-step speed setting

Automatic torque compensation and slip

compensation

The ran of DIN rail and tranditional screw

installations

Side- by-side installation (400C/1400F)

SPECIFICATIONS

Flow

: 1.6 ~ 25 m3/h

T. Head

: 11.5 ~ 32m

Power

: 0.08 ~ 7.5 kw

L. Tem

: < 600C

Material

: Polupropylene

Matering Pump

Mixed Flow Pump

SPECIFICATIONS

Dimensions

SPECIFICATIONS

Flow

: 180~ 4032 m3/h

T. Head

: 4~17 m

Speed

: 730 ~ 1600 rpm

Power

: 4.5 ~180 kw

: 6+ Hx8+ 7/8 Wx7 + D (Series 100 & 150)

: 6+ Hx12 +15/16 Wx7 + D (Series 100D)

Temperature Lim

: 1200F /510 C Max

Electrical Requirments : 1/60 HP. 115V/60cy; 230V/60cy and 230V/60cy

available on request

Shipping Weight

: 8 lbs./3.63 kg (Series 100& 150D)

12 lbs./5.4 kg (Series 100D)

Ring Blower

SPECIFICATIONS

Capacity

: 0.8 ~ 10.6 m3/min

Press

: 50~350 mbar

Power

: 0.15 ~ 7.5 kw

Volt

: 110/220V, 380V

Horizontal Multistage

Root Blower

SPECIFICATIONS

Capacity

Delivery head

Speed

Temperature

Casing Pressure

Shaft Sealing

Flange Connections

Direction of rotation

SPECIFICATIONS

Capacity

: 0.54 ~ 117.8 m3/h

Press

: 1000 ~ 6000 mmAq

Power

: 0.26 ~ 159.9 kw

Speed

: 1750 ~ 2600 rpm

: from 0,4 up to 35 m3/h

: from 10 up to 354

: 1450 rpm (max 1800rpm)

: max. 1200C, max 1800C for high temperature design

: PN 40

: Stuffing box or mechanical seal

: DIN 2501/ PN 40 anti-clockwise

: (When seen from the drive end)

Self Priming Pump

SPECIFICATIONS

Flow

: 0.4 ~ 35 m3/h

T. Head

: 10 ~ 140 m

Power

: 0.55 ~ 22 kw

L. Tem

: max + 1200C

Speed

: Max 1800 rpm

Splite Case

Vertical Multistage

SPECIFICATIONS

Flow

: 0.4 ~ 180 m3/h

T. head

: Max. 305 m

Volt

: 220/380V

Material

: SS 304/316 or CI

SPECIFICATIONS

Description

Option

Standar

Model

CSA, CNA

Type of liquid

Clean Water, Industrial Water, River Water

Liqiud Handled

Temperature

Construction

(1770F-2480F

16 Bar (16.3 kgf/cm2)

Mechanical Seal

Gland Packing

Mechanical Seal

Ball Bearing

Bearing

Greaser

Lubrication

Casing

810C 1200C

Below 800C (1760F)

Max. Working Pressure

Shaft seal

Cast Iron

Bronze (exep 250x150 CNKA & 300&200 CNKA)

Material

Impeller

SCS 13 for 250x150 CNKA, 300x200 CNKA

Shaft

Shaft sleeve

Flange

Submersible Pump

SUS316

SUS403

SUS304

Broze

Broze

Suction

JIS 16 KRF

Discharge

JIS 16 KRF

SPECIFICATIONS

Liquid handled

Max. Submergance

Speed

Material

: River water, sewage

: 0.25 to 1.5 kw

: 3000 min1/50Hz

: Cast iron, Stainless steel

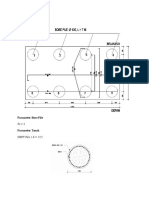

Tangki

SPECIFICATIONS

Diameter

Close Couple Cast Iron

Height

380

475

380

720

380

830

460

760

460

880

Water entry

Rubber

conection

membrane

Standard

Maximum

pre-loading

working

pressure

pressure

Working

temperature

External

finishing

colour

1,5

M 1 Gas

EFDM

10

-10+100

Blue/RAL

5015

2.5

SPECIFICATIONS

Pump Casing

Cast iron GJL 200 EN 1561

Lantem bracket

Impeller

NM 17

Bronze G-Cu SN 10 UNI

7013

Brass P- Cu Zn 40 Pb 2 UNI 5705

Cast iron GJL 200 EN 1561

Bronze G-Cu Sn 10 UNI

7013

Cr Stell AISI 430

Shaft

Cr Ni steel AISI 303 1,1

1,5 2,2 KW

Mechanical seal

Carbon Ceramic - NBR

Cr Ni Mo Steel AISI 316

Cr Ni Mo steel

AISI 316

Produk Unggulan

Sand Pump

SPECIFICATIONS

Pipa in/out

Kapasitas

Air:pasir

Head maks

Daya pancar

Diam. Impeller

Penggerak

Submersible Pump

Liquid handled

Liquid temperature

Max. Submergance

Speed

Material

: 6/6

: 120-160 m3/jam

: 30:70

: 40 m

: 150 m datar

: 345 mm

: mesin diesel 140 HP atau motor listrik 60 HP

Booster Pump

Hydrant

Inverter

Induction Motor

: River water, sewage

: 500C ~ 800C

: 0.25 to 1.5 kw

: 3000 min1/50Hz

: Cast iron

Centrifugal Pump

Clients

1. PT. Utama Jaya Teknik

19. PT. Royal Industri Indonesia

37. PT. Tras Studio

55. PT. Toyo Ink Indonesia

2. Lotte Mart

20. PT. Surya Borneo

38. PT. Kendali Paramita

56. PT. Astanita Sukses Apindo

3. PT. Satyamitra Surya Perkasa

21. PT. Tiomin Anugrah Mulia

39. PT. Kalbe Miko Indonesia

57. PT. Citra Galvalindo Suskes Mandiri

4. PT. Sparindo Alfa Persada

22. PT. DMI

40. PT. Ajinomoto

58. PT. Koyo Jaya Indonesia

5. PT. Indo Service Utama

23. PT. PAN Traya

41. PT. Medion

59. PT. Madusari Nusa Perdana

6. PT. Bangka Cakra

24. PT. Belitung Berdikari

42. PT. Alam Pelita Trisakti

60. PT. JRD Alloywheel Industries

7. PT. Mikatasa

25. PT. Tirta Sarana

43. PT. Surya Raya Rubberindo

61. PT. Prima Kaplas

8. PT. Grant Surya Multi Sarana

26. PT. General Multi Utama

44. PT. Cometa Can

62. PT. Krama Yudha Kesuma Motors

9. PT. Pelita Enamel Ware

27. PT. Brataco

45. PT. Sahabat Intim Plasindo

63. PT. Gistec Pratama

10. PT. Sanova

28. PT. DNX

46. PT. Shinto Kogyo Indonesia

64. PT. Lingkar Matra

11. PT. Bukit Perak

29. PT. Asmin Koalindo Tuhup

47. PT. Morita Tjokro Gearindo

65. PT. Mitshuba

12. PT. Bea Sari Jelita

30. PT. Prasada Samya Multi

48. PT. Duta Polykem Indo

66. PT. Wirajaya Packindo

13. PT. Baiksan

31. PT. Blue Sky

49. PT. Cilegon Fabricator

67. PT. Indofood Sukses Makmur

14. PT. Haengnam

32. PT. Gemini

50. PT. Metropolitan Kencana

68. PT. Temas Aplindo

15. PT. Kointek MST Indonesia

33. PT. Jakarta Martin Logamnido

51. PT. Duta Pertiwi Nusantara

69. PT. Timas Suplindo

16. PT. Kalbe Farma

34. PT. Aprinus Coating

52. PT. Intercipta Kimia Pratama

70. PT. Asia Pacific Fortuna

17. PT. Nufarm

35. PT. Sentralindo Teguh Gemilang

53. PT. Kimia Pratama

18. PT. DIC Astra Chemical

36. PT. Infra International

54. PT. Eastern Polymer

and many more...

DALLA TEKNIK

GENERAL SUPPLIER - MECHANICAL - ELECTRICAL

Jl. Pangeran Jayakarta Komplek 46 Blok G No. 8 - Jakarta Pusat

Telp. (021) 68888905 - 68888906 Fax. (021) 6266860

dalla-teknik.com | info@dalla-teknik.com

You might also like

- Pengecekan Daya Dukung Aksial Tekan Dan Tarik P.tiang (Pileload Capacity) Preestress 50x50Document11 pagesPengecekan Daya Dukung Aksial Tekan Dan Tarik P.tiang (Pileload Capacity) Preestress 50x50IvanHidayatNo ratings yet

- Lab Testing for Foundation, Embankment & Construction MaterialsDocument1 pageLab Testing for Foundation, Embankment & Construction Materialsyudhistiran_9No ratings yet

- Main Sentences - Review Report On Existing Studies - Hasang HPP Project 130225 PDFDocument94 pagesMain Sentences - Review Report On Existing Studies - Hasang HPP Project 130225 PDFMuhammad TrayaNo ratings yet

- Cycle Time Sheet Dredging For Pipeline Laying King Arthur 3 and King Richard 8 TSHDDocument1 pageCycle Time Sheet Dredging For Pipeline Laying King Arthur 3 and King Richard 8 TSHDNabigh NabiylNo ratings yet

- Sheet Pile Retaining Walls: Methods and Materials in Building ConstructionsDocument23 pagesSheet Pile Retaining Walls: Methods and Materials in Building ConstructionsHarshini YogaNo ratings yet

- Brosur Baja Gunung Raja Paksi Welded BeamDocument2 pagesBrosur Baja Gunung Raja Paksi Welded BeamRobbi Shobri RakhmanNo ratings yet

- Kapasitas Daya Dukung Tiang Pancang Berdasarkan Data SondirDocument1 pageKapasitas Daya Dukung Tiang Pancang Berdasarkan Data SondirIsti HaryantoNo ratings yet

- Trelleborg Marine Systems Catalogue PDFDocument220 pagesTrelleborg Marine Systems Catalogue PDFElsayedNo ratings yet

- TS S BLD 001 00Document306 pagesTS S BLD 001 00Robbi Shobri RakhmanNo ratings yet

- Detai Rip Plate: Penerangan Jalan UmumDocument1 pageDetai Rip Plate: Penerangan Jalan UmumGo PeaksNo ratings yet

- Calculation of Land SettlementDocument2 pagesCalculation of Land SettlementRaditiya PuteraNo ratings yet

- 900-Spe-Mn-Urs-1003 - B05 DredgingDocument18 pages900-Spe-Mn-Urs-1003 - B05 DredgingBambang Permana50% (2)

- Pondasi Foot Plat & Kolom OKDocument3 pagesPondasi Foot Plat & Kolom OKDyna ramadhaniNo ratings yet

- 05 - Bab III Studi GeologiDocument60 pages05 - Bab III Studi Geologideffi putri arumNo ratings yet

- Perhitungan Curah HujanDocument15 pagesPerhitungan Curah HujanDwi Rina MurniNo ratings yet

- Pompa Ebara Type SZ SpecDocument6 pagesPompa Ebara Type SZ SpecpatulNo ratings yet

- Tekcon - Spun Piles PropertiesDocument10 pagesTekcon - Spun Piles PropertiesChung Yiung YungNo ratings yet

- Brocure FDB 407 40 - 150Document1 pageBrocure FDB 407 40 - 150mandahandriNo ratings yet

- Jual Forklift 5 Ton - Bomac FokliftDocument15 pagesJual Forklift 5 Ton - Bomac FokliftBakryRantoeNo ratings yet

- Driver TV Tuner Gadmei 3810eDocument2 pagesDriver TV Tuner Gadmei 3810eAl-Shahibul RahmanMSSNo ratings yet

- White Paper (Txdot)Document16 pagesWhite Paper (Txdot)Md Mamunur RashidNo ratings yet

- Sondir Digital + SoftwareDocument1 pageSondir Digital + SoftwareBiand Lab Teknik SipilNo ratings yet

- Analisis Dan Klasifikasi Sedimen Permukaan Dasar LDocument9 pagesAnalisis Dan Klasifikasi Sedimen Permukaan Dasar LBeby MarcNo ratings yet

- Lateral Earth Pressure Diagram Explained in 38 CharactersDocument17 pagesLateral Earth Pressure Diagram Explained in 38 CharactersFian Arif AmrullohNo ratings yet

- Cementaid Hydrophobic Waterproofing of Mall Ciputra Citra Raya Cikupa 040319 Tatamulia PDFDocument6 pagesCementaid Hydrophobic Waterproofing of Mall Ciputra Citra Raya Cikupa 040319 Tatamulia PDFRian fathurrohimNo ratings yet

- CS324 Real Time Systems Elective Syllabus Bahra Group Institutes PatialaDocument12 pagesCS324 Real Time Systems Elective Syllabus Bahra Group Institutes Patialabharatgupta35No ratings yet

- Katalog Pipa PPR Era Cv. Kinasih MariaDocument23 pagesKatalog Pipa PPR Era Cv. Kinasih MariaAhmad NajihullahNo ratings yet

- MC Quay Daikin Midea: Split Duct Split Wall Split Duct Split Wall Split Duct Split WallDocument3 pagesMC Quay Daikin Midea: Split Duct Split Wall Split Duct Split Wall Split Duct Split WallsatriapNo ratings yet

- Jotun Malathon TDSDocument5 pagesJotun Malathon TDSBiju_PottayilNo ratings yet

- PRACTICE TEST 1 - Choose the Best Answer for Grammar & Vocabulary QuestionsDocument4 pagesPRACTICE TEST 1 - Choose the Best Answer for Grammar & Vocabulary QuestionsCao Thanh LongNo ratings yet

- Curriculum Vitae (Permadi S S)Document3 pagesCurriculum Vitae (Permadi S S)Permadi Saputra SitanggangNo ratings yet

- Excel LikuifaksiDocument6 pagesExcel Likuifaksicressytambunan100% (1)

- Tabel 1. Analisa Debit dan Dimensi NodeDocument94 pagesTabel 1. Analisa Debit dan Dimensi NodeKresna WdjNo ratings yet

- PC Spun PilesDocument2 pagesPC Spun PilesFaridah Zahra100% (1)

- User Manual for COMCOT v1.7Document65 pagesUser Manual for COMCOT v1.7jesusoptimNo ratings yet

- Final Resume Hammer TestDocument7 pagesFinal Resume Hammer Testheni luthfiNo ratings yet

- Proyek Jembatan Perumahan Nelayan, Kappa, Aceh Timur Perhitungan Daya Dukung Dengan Menggunakan Data BH-01 Metode SPTDocument4 pagesProyek Jembatan Perumahan Nelayan, Kappa, Aceh Timur Perhitungan Daya Dukung Dengan Menggunakan Data BH-01 Metode SPTrahmadNo ratings yet

- Form RequestDocument18 pagesForm Requestnur wulan100% (1)

- Pengelolaan Risiko GeotekDocument21 pagesPengelolaan Risiko GeotekABDUL SALAM MUNIRNo ratings yet

- Geomembrane HDPE Smooth Black PDFDocument1 pageGeomembrane HDPE Smooth Black PDFandriarisetiawan0% (1)

- Building Construction ReportDocument51 pagesBuilding Construction ReportAndrew Chee Man ShingNo ratings yet

- Perhitungan Bore PileDocument5 pagesPerhitungan Bore PileFitri Yani100% (1)

- Wind RoseDocument49 pagesWind RoseIzzy StardlinNo ratings yet

- SDC R 90163 Final Design Manual Coastal ProtectionDocument111 pagesSDC R 90163 Final Design Manual Coastal ProtectionfbturaNo ratings yet

- COMPANY PROFILE PT. JAYA OBAYASHI Reduced - Compressed-CompressedDocument24 pagesCOMPANY PROFILE PT. JAYA OBAYASHI Reduced - Compressed-CompressedMUMU WarungNo ratings yet

- MGU-DD-TX-0001 - Soil Investigation Report - AA PDFDocument52 pagesMGU-DD-TX-0001 - Soil Investigation Report - AA PDFcmu baliNo ratings yet

- Nitowrap FRC BaruDocument2 pagesNitowrap FRC BaruZax SantanaNo ratings yet

- Course 3 Site Selection and Investigation For InfrastructureDocument35 pagesCourse 3 Site Selection and Investigation For InfrastructureMik Wanul Khosi'inNo ratings yet

- Pelatihan Program Geotek Tingkat DasarDocument30 pagesPelatihan Program Geotek Tingkat DasargiegienzNo ratings yet

- Laporan WamenaDocument40 pagesLaporan WamenaxryosaNo ratings yet

- Notification For Physical TestDocument60 pagesNotification For Physical TestRohit kumarNo ratings yet

- Hec-Hms: The Hydrologic Engineering Center's Hydrologic Modeling System (HMS)Document62 pagesHec-Hms: The Hydrologic Engineering Center's Hydrologic Modeling System (HMS)Intu ShresthaNo ratings yet

- Tabel Baja ProfilDocument23 pagesTabel Baja ProfilChandra Eko PrasetyoNo ratings yet

- American Wide F Beam 6Document1 pageAmerican Wide F Beam 6bhaskarNo ratings yet

- Rgfgrid User ManualDocument146 pagesRgfgrid User Manualalfredo liraNo ratings yet

- MIKE21 TideTools ScientificDocDocument86 pagesMIKE21 TideTools ScientificDocGustavo VicierraNo ratings yet

- Toyo DPFDocument2 pagesToyo DPFMauricio OrtizNo ratings yet

- Lampiran Spesifikasi Alat MekanisDocument7 pagesLampiran Spesifikasi Alat MekanisAgung AnugrahNo ratings yet

- Kompetensi Keahlian Nama Alat Spesifikasi Tayang Harga Link: Daftar Peralatan Pendidikan Kejuruan Di E-Katalog TAHUN 2020Document4 pagesKompetensi Keahlian Nama Alat Spesifikasi Tayang Harga Link: Daftar Peralatan Pendidikan Kejuruan Di E-Katalog TAHUN 2020Muhammad Sidik BBMNo ratings yet

- The LMV-343 Pump: Appendix E: Specifications of Sundyne High Head Low-Flow Centrifugal PumpsDocument16 pagesThe LMV-343 Pump: Appendix E: Specifications of Sundyne High Head Low-Flow Centrifugal PumpsjafaristsNo ratings yet

- Neuber Technique For Elastic Plastic CorrelationDocument9 pagesNeuber Technique For Elastic Plastic CorrelationVamsee Gowtham AnanthapalliNo ratings yet

- Seismic Design of Steel ConnectionsDocument8 pagesSeismic Design of Steel Connectionsgutian259No ratings yet

- Ntcle 100Document17 pagesNtcle 100Roberto RicardoneNo ratings yet

- W/C RATIO AND ITS EFFECT ON CONCRETE STRENGTHDocument12 pagesW/C RATIO AND ITS EFFECT ON CONCRETE STRENGTHVijay BhanNo ratings yet

- 2.overview of Climate Change-Ms. Gerarda Asuncion MeriloDocument112 pages2.overview of Climate Change-Ms. Gerarda Asuncion MeriloZumera PaguitalNo ratings yet

- Introductio Effective Permeability and Relative PermabilityDocument12 pagesIntroductio Effective Permeability and Relative PermabilityMario Edgar Cordero SánchezNo ratings yet

- Johnson Magnets PDFDocument7 pagesJohnson Magnets PDFYawarNo ratings yet

- General Welding Procedure - Rev0Document27 pagesGeneral Welding Procedure - Rev0Jayan VKNo ratings yet

- Design Calculation of Single-Stage Radial Type Centrifugal Blower For Rice MillDocument5 pagesDesign Calculation of Single-Stage Radial Type Centrifugal Blower For Rice MillMuhammadTayyabNo ratings yet

- Pdata Tse397Document3 pagesPdata Tse397zakariiNo ratings yet

- Biomechanics: A PrimerDocument3 pagesBiomechanics: A PrimerjournalNo ratings yet

- Liquid-Propellant Rocket Engine ThrottlingDocument27 pagesLiquid-Propellant Rocket Engine Throttlingbmsprague100% (1)

- Refrigeration and Airconditioning Prof. M. Ramgopal Department of Mechanical Engineering Indian Institute of Technology, KharagpurDocument49 pagesRefrigeration and Airconditioning Prof. M. Ramgopal Department of Mechanical Engineering Indian Institute of Technology, KharagpurAbhinav VermaNo ratings yet

- Coagulation & FlocculationDocument35 pagesCoagulation & FlocculationAbdu BiruNo ratings yet

- Bernoulli Equation LectureDocument16 pagesBernoulli Equation LectureabasNo ratings yet

- Bram at 2011Document27 pagesBram at 2011mtiereanNo ratings yet

- Stop Shift TheoryDocument75 pagesStop Shift TheoryPaulinaNo ratings yet

- KPFM measures surface potential with nanoscale resolutionDocument8 pagesKPFM measures surface potential with nanoscale resolutionRaj TokasNo ratings yet

- Creep and Rupture Properties Continued: Comparison of Stress To Produce 1% Creep in 1,000 HoursDocument4 pagesCreep and Rupture Properties Continued: Comparison of Stress To Produce 1% Creep in 1,000 HourssuiafwgehjdfNo ratings yet

- Nano Concrete Ppt3Document22 pagesNano Concrete Ppt3shaik.faridmp0% (1)

- Phy Ix Mid Term 2021Document2 pagesPhy Ix Mid Term 2021salmanNo ratings yet

- Standard Civil Design Basis - Pump FoundationsDocument3 pagesStandard Civil Design Basis - Pump Foundationsnirmal sutharNo ratings yet

- B 863 PDFDocument5 pagesB 863 PDFGrato Jr SingcoNo ratings yet

- Meteorology PracticalDocument40 pagesMeteorology PracticalSuleiman MusaNo ratings yet

- Direct Displacement-Based Seismic Design of StructuresDocument64 pagesDirect Displacement-Based Seismic Design of StructuresMunyaNo ratings yet

- Pchem ExamDocument8 pagesPchem ExamDanielson CulanibanNo ratings yet

- 14 A Student Investigated Elastic Collisions Using An Air Track As Shown. The Friction BetweenDocument3 pages14 A Student Investigated Elastic Collisions Using An Air Track As Shown. The Friction BetweenAliza ImtiazNo ratings yet

- Tubular Non Tubular AWS D1 1 PDFDocument56 pagesTubular Non Tubular AWS D1 1 PDFRudy JakfNo ratings yet

- Auracast 100 BFLDocument2 pagesAuracast 100 BFLpeashNo ratings yet

- Preview Physics IGCSEDocument91 pagesPreview Physics IGCSEMahnoor Khalid50% (2)