Professional Documents

Culture Documents

F.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure Vessel

Uploaded by

Iksan Adityo MulyoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure Vessel

Uploaded by

Iksan Adityo MulyoCopyright:

Available Formats

TITLE

PROCEDURE FOR REPAIRS, ALTERATION, AND

MODIFICATION PRESSURE VESSEL

DOCUMENT NUMBER

REV

DATE

SHEET

F.SQ-P.003

25 August 2010

1 of 7

PROCEDURE AUTHORIZATION

This procedure have been generated and implemented

to identify the control that shall be applied by members of

staff in the department when carrying out their duties

This confirms that this procedure has been approved for

official issue and that members of staff shall complete the

tasks assigned in accordance with the mechanisms

defined herein

The procedure forms part of a formal system within the

company which ensure that this document is handled in a

controlled manner in accordance with documented

procedures.

This procedure will be subject to audit as part of the

company policy towards quality

Department Authorization

Date:

Signed:

Corporate Authorization

(Company Director)

Date:

Signed:

Quality Authorization

(Quality Managements Reps)

Date:

Signed:

PROCEDURE REVISION

Rev.

Date

25 Aug 2010

Section

Outline of Changed

Authorization

First Issue

1

2

3

4

STATEMENT OF CONFIDENTIALITY

This procedure is for controlled circulation unless stamped "Uncontrolled Copy. The documents or

extracts from documents must nor be passed or copied to other companies, agents or persons without

the permission of the relevant Company Directors.

TITLE

PROCEDURE FOR REPAIRS, ALTERATION, AND

MODIFICATION PRESSURE VESSEL

DOCUMENT NUMBER

REV

DATE

SHEET

F.SQ-P.003

25 August 2010

2 of 7

TABLE OF CONTENT

Page

1.0

PURPOSE

2.0

SCOPE

3.0

DEFINITIONS

4.0

GOVERNMENT REGULATION

5.0

REFERENCES

6.0

RESPONSIBILITIES

7.0

PROCEDURES OF IN-SERVICE PRESSURE VESSEL INSPECTION

7.1

INTRODUCTION

7.2

PRE-INSPECTION MEETING

7.3

DOCUMENT REVIEW

7.4

PHYSICAL INSPECTION

7.5

REPORTING

TITLE

PROCEDURE FOR REPAIRS, ALTERATION, AND

MODIFICATION PRESSURE VESSEL

1.0

2.0

3.0

DOCUMENT NUMBER

REV

DATE

SHEET

F.SQ-P.003

25 August 2010

3 of 7

PURPOSE

a.

The purpose of this document is to ensure that the after repairs, alteration,

and modification of pressure vessel are in safe condition.

b.

Provide guideline for inspector to perform reviewing, inspection, verifying

and testing of pressure vessel after repairs, alteration, or modification are

complying with requirements.

SCOPE

a.

This procedure shall be applied for Pressure Vessels and Heat Exchanger

that have been placed and repaired by a repair organization.

b.

The procedure covers the minimum requirement International Code,

Standard, Owner/User specification, and Migas Regulation.

c.

This is Company approved procedure and shall be adhered to at all time

except where Owner/User requirements or contract documents species

other requirement.

DEFINITIONS

a.

Inspector

The person that takes any inspection of

pressure vessel under employed company

who has the Pressure Vessel Inspector

Certificate

b.

Company

PT. Sertco Quality

c.

Owner/user

The organization legally responsible for the

operation, maintenance and safety, including

the repair, modification or replacement of

items in the plant of pressure vessel

d.

Contractor

- The organization responsible for repairs,

alteration, or modification of Pressure

Vessel(s), either in its facilities or on site.

e.

Inspection

The work necessary to check the vessel for

defect such as corrosion, cracking or other

damage to certify the vessel as safe for

operation or in need of repair

i.

General Definition

For the purpose of this procedure the

definition given in references referred to shall

apply

TITLE

PROCEDURE FOR REPAIRS, ALTERATION, AND

MODIFICATION PRESSURE VESSEL

4.0

5.0

DOCUMENT NUMBER

REV

DATE

SHEET

F.SQ-P.003

25 August 2010

4 of 7

GOVERNMENT REGULATION

a.

Undang-undang No.22 tahun 2001 :

Minyak dan Gas Bumi

b.

Mijn Politie Reglement Stb No. 341 tahun 1930 :

Peraturan Keselamatan Kerja

c.

Peraturan Pemerintah No.11 tahun 1979 :

Keselamatan Kerja Pada Pemurnian dan Pengolahan Minyak dan Gas

Bumi

d.

Peraturan Pemerintah No. 19 tahun 1973 :

Peraturan dan Pengawasan Keselamatan Kerja Bidang Pertambangan

e.

Peraturan Pemerintah No.17 tahun 1974 :

Pengawasan dan Pelaksanaan Eksplorasi Minyak dan Gas Bumi di Daerah

Lepas Pantai

f.

Peraturan Pemerintah No.35 tahun 2004 :

Tentang Kegiatan Usaha Hulu Minyak dan Gas Bumi.

g.

Peraturan Pemerintah No.36 tahun 2004 :

Tentang Kegiatan Usaha Hilir Minyak dan Gas Bumi.

h.

Peraturan Mentamben No. 06P/0746/M.PE/1991 :

Pemeriksaan Keselamatan Instalasi, Peralatan dan Teknik yang

Dipergunakan Dalam Pertambangan Minyak dan Gas Bumi dan

Pengusahaan Sumberdaya Panasbumi

i.

Keputusan Dirjen Migas No. 84K/382/DJM/1998 :

Pedoman dan Tata Cara Pemeriksaan Keselamatan Kerja Atas Instalasi,

Peralatan dan Teknik yang Digunakan Dalam Usaha Pertambangan Minyak

dan Gas Bumi dan Pengusahaan Sumberdaya Panasbumi

REFERENCES

The following minimum reference for Pressure Vessel construction, but not

limited to :

a. SNI 13-3498-2002 : Inspeksi Bejana Tekan

b. SNI 07-3032-2002 : Kualifikasi Pengelasan

c. SNI 13-3563-1994 : Bejana tekan 1-A

d. ASME Sect.VIII Div.1 : Rules For Construction of Pressure Vessels

TITLE

PROCEDURE FOR REPAIRS, ALTERATION, AND

MODIFICATION PRESSURE VESSEL

DOCUMENT NUMBER

REV

DATE

SHEET

F.SQ-P.003

25 August 2010

5 of 7

e. ASME Sect.VIII Div.2 : Rules For Construction of Pressure VesselsAlternative Rules

f. TEMA : Tubular Exchanger Manufacturer Association

g. API 510 : Pressure Vessel Inspection Code: Maintenance Inspection,

Rating, Repair, And Alteration

h. ASME B 16.5 : pipe Flanges and Flanged Fitting

i.

ASME Sect. IX : Welding and Brazing Qualification

j.

API 572 : Inspection of Pressure Vessel (Towers, Drums, Reactors, Heat

Exchangers, and Condensers)

k. ASME Sect. II : Material

l.

6.0

7.0

ASME Sect. V : Non Destructive Examination

RESPONSIBILITIES

a.

The Company Management shall be responsible for ensuring that the

necessary resources are made available for the requirements of this

procedure to be carried out in the safe manner.

b.

Line Management shall be responsible for ensuring that the requirements of

this procedure are fully implemented at all times.

c.

All employee involved in the implementation of this procedure shall be

responsible for adherence to the requirements stated within.

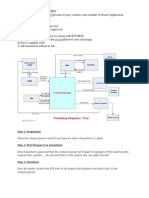

PROCEDURES

7.1 INTRODUCTION

The inspection services setup in this procedure is a general guidance that

shall be performed by inspection personnel. The detail inspection and the

acceptance criteria shall refer to applicable code and standard used that

stated in contract document or Owner/User specification.

The personnel who perform inspection shall be qualified by training and

experience; such personnel shall be capable performing the inspection

services mentioned detail below.

7.2 PRE-INSPECTION MEETING

TITLE

PROCEDURE FOR REPAIRS, ALTERATION, AND

MODIFICATION PRESSURE VESSEL

DOCUMENT NUMBER

REV

DATE

SHEET

F.SQ-P.003

25 August 2010

6 of 7

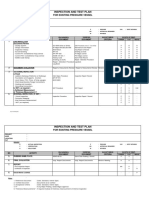

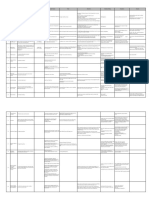

Prior to repairs, alteration, or modification of Pressure Vessel take in place,

a pre-inspection meeting shall be hold, to setup an inspection and test plan,

getting information regarding to schedule of repairs, alteration, or

modification, and other things that necessary required in performing

inspection. The pre-inspection meeting should be held between Company,

Owner/User and Contractor. If no such meeting held then requirement shall

be established.

The agreed inspection and test plan shall be as a reference of in performing

inspection for all parties who involved during repairs, alteration, or

modification of Pressure Vessel.

7.3 DOCUMENT REVIEW

Before and during inspection performing, the inspector/engineer shall be

review the repairs, alteration, or modification documents, as follow:

1. Certificate of Pressure Vesel (SKPP)

2. Historical record

3. Construction drawing

4. Copy Name Plate or Other marking

5. Work Safety Procedure

6. Repair/ alteration/ modification procedure

7. Repair/ alteration/ modification design calculation

8. Specification of substitute material

9. Review Working Procedure Specification (WPS) and Procedure

Qualification Record (PQR)

10. Non destructive Examination Procedure and NDE Personnel

certificate

11. Post Weld Heat Treatment Procedure (If required)

7.4 PHYSICAL INSPECTION

The Inspector shall be conduct physical inspection as follow :

1. Verification QC manual System

2. Identify Material to be used

3. Verification forming of pressure Vessel

4. Verification fit-up before welding

5. Verification welding preparation

TITLE

PROCEDURE FOR REPAIRS, ALTERATION, AND

MODIFICATION PRESSURE VESSEL

DOCUMENT NUMBER

REV

DATE

SHEET

F.SQ-P.003

25 August 2010

7 of 7

6. Visual inspection welding and NDE Result Verification

7. Dimensional check

8. Leak Test and Pressure Test (if needed)

9. Verification Manufacture Data Report and Name Plate

10. Verification thickness measurement which conduct by client

11. Measuring Actual Thickness

12. Verification Remaining Life Calculation

7.5 REPORTING

Arrange all inspection result on document form to submit to Direktur Teknik

Pertambangan Minyak dan Gas Bumi to evaluate for issued SKPP.

You might also like

- F.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselDocument6 pagesF.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselIksan Adityo MulyoNo ratings yet

- F.sq-wI.008 Procedure For Inspection of Existing Storage TankDocument17 pagesF.sq-wI.008 Procedure For Inspection of Existing Storage TankIksan Adityo MulyoNo ratings yet

- Pressure Vessel Repair ProcedureDocument7 pagesPressure Vessel Repair ProcedureAndy UgohNo ratings yet

- API 510 VesselsDocument11 pagesAPI 510 Vesselsmoonstar_dmeNo ratings yet

- ITP Tank RecertificationDocument3 pagesITP Tank RecertificationArisNo ratings yet

- Owner-User Pressure Equipment Integrity ManagementDocument43 pagesOwner-User Pressure Equipment Integrity ManagementInspection EngineerNo ratings yet

- ITP-PRESSURE VESSEL ExistingDocument2 pagesITP-PRESSURE VESSEL ExistingArisNo ratings yet

- Storage Tank Test & Inspection Report enDocument10 pagesStorage Tank Test & Inspection Report enMarketing CTNNo ratings yet

- Occidental Oil and Gas pressure vessel inspectionDocument17 pagesOccidental Oil and Gas pressure vessel inspectionedwinsazzzNo ratings yet

- Inspection of Unfired Pressure Vessel Std-128Document34 pagesInspection of Unfired Pressure Vessel Std-128dyke_engg100% (1)

- Content List MDR Storange TankDocument72 pagesContent List MDR Storange Tankunto gunungNo ratings yet

- Pressure Vessel Dimension InspectionDocument3 pagesPressure Vessel Dimension InspectionAnas Sarkiah0% (1)

- Api 571-1Document11 pagesApi 571-1Raghavan100% (1)

- Scope of Work - API 653 Inspections of Aboveground Storage TanksDocument14 pagesScope of Work - API 653 Inspections of Aboveground Storage Tanksgilbertjerry100% (1)

- Inspection and Test Plan (Itp) For Fabrication Pressure VesselDocument1 pageInspection and Test Plan (Itp) For Fabrication Pressure VesselNikki RobertsNo ratings yet

- Integrity Assessment of Pressure VesselDocument6 pagesIntegrity Assessment of Pressure Vesselmrb193100% (1)

- Peaking BandingDocument2 pagesPeaking Bandingsetak100% (4)

- QCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.Document6 pagesQCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.abdul aziz100% (1)

- Inspection & Test Plan For Nozzle Replacement On VS ShellDocument1 pageInspection & Test Plan For Nozzle Replacement On VS ShellQC Taner 453100% (2)

- Visual Inspection of Tanks & Pressure VesselsDocument29 pagesVisual Inspection of Tanks & Pressure VesselsShahul Hameed Razik100% (5)

- Internal inspection calculation guidelinesDocument38 pagesInternal inspection calculation guidelinesAMAL VISHNUNo ratings yet

- Fabrication Procedure for Rolling Shell PlatesDocument10 pagesFabrication Procedure for Rolling Shell PlatesMuhammad Yunus NurdinNo ratings yet

- API 510 Spreadsheet To Calculate (Welding ScwiDocument2 pagesAPI 510 Spreadsheet To Calculate (Welding Scwibryandown100% (1)

- ITP Pressure VesselDocument21 pagesITP Pressure VesselSds Mani SNo ratings yet

- TDI41 Tank Inspection Repair & Alteration API 653 Sec 9Document13 pagesTDI41 Tank Inspection Repair & Alteration API 653 Sec 9Faizal Sattu100% (2)

- Inspection and Testing Plan for Pressure VesselDocument6 pagesInspection and Testing Plan for Pressure Vesselmuhammad afrizalNo ratings yet

- Standard Shell. Specifications Pressure VesselDocument20 pagesStandard Shell. Specifications Pressure Vesseledwin100% (1)

- A05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C DDocument14 pagesA05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C Dbingmin100% (4)

- Inspection and Test Plan: Offshore Pipeline RecertificationDocument3 pagesInspection and Test Plan: Offshore Pipeline RecertificationArisNo ratings yet

- Repair & Alteration of Storage TanksDocument150 pagesRepair & Alteration of Storage TanksRupesh Ubale100% (15)

- Tank Inspection NotesDocument5 pagesTank Inspection Notesaneeshjose013No ratings yet

- Vessel Inspection ProcedureDocument17 pagesVessel Inspection ProcedureVimal RajNo ratings yet

- MD PV Asme v0.1Document35 pagesMD PV Asme v0.1Kamlesh LuharNo ratings yet

- U-Stamp QapDocument6 pagesU-Stamp Qapchonubobby100% (1)

- Tank Maintenance ITPDocument24 pagesTank Maintenance ITPthomas varugheseNo ratings yet

- Bolt Torquing Tensioning Procedure PDFDocument29 pagesBolt Torquing Tensioning Procedure PDFric leonisoNo ratings yet

- M 111 Tank Weld Repair ProcedureDocument8 pagesM 111 Tank Weld Repair ProcedureAAISATNo ratings yet

- Detailed Fitness For Service Per API 579Document3 pagesDetailed Fitness For Service Per API 579Sajal KulshresthaNo ratings yet

- ITP For Field Erected Tank Rev ADocument9 pagesITP For Field Erected Tank Rev AHoang Tuan Kiet100% (1)

- BP Pressure Vessels GS146-2Document66 pagesBP Pressure Vessels GS146-2Tshilidzi Irene Netselo100% (3)

- API 653 Above Ground Storage Inspector Prep CourseDocument3 pagesAPI 653 Above Ground Storage Inspector Prep CourseArvind Shukla100% (1)

- ITP-Pressure Vessel Repair, Modification, AlterationDocument5 pagesITP-Pressure Vessel Repair, Modification, Alterationyosafateden67% (3)

- Contractor Quality Control Plan For Storage Tank ErectionDocument2 pagesContractor Quality Control Plan For Storage Tank ErectionHamid Alilou100% (4)

- Wi Insp 02 Heat ExchangerDocument6 pagesWi Insp 02 Heat ExchangerSamir Chaudhary100% (1)

- Using s275jr For Asme Div1 Vessel-UnassignedDocument6 pagesUsing s275jr For Asme Div1 Vessel-UnassignedNasrul AdliNo ratings yet

- Alvaer DNV2.7-3 PDFDocument23 pagesAlvaer DNV2.7-3 PDFThanhdong Do100% (1)

- This Is Very Common in Tank ConstructionDocument11 pagesThis Is Very Common in Tank ConstructionsbmmlaNo ratings yet

- Inspection and Test Plan For Process PipingDocument4 pagesInspection and Test Plan For Process PipingRobin GuNo ratings yet

- Piping External Visual Inspection ProcedureDocument3 pagesPiping External Visual Inspection Procedurecamasa2011100% (1)

- 498 Quality Plan Pressure VesselDocument20 pages498 Quality Plan Pressure Vesseldharwin100% (5)

- Storage Tank (API 650)Document20 pagesStorage Tank (API 650)sbmmla83% (6)

- F.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentDocument13 pagesF.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentIksan Adityo Mulyo100% (1)

- Api 510Document9 pagesApi 510ALe InfinitoNo ratings yet

- API 570 E4 Addendum 2Document4 pagesAPI 570 E4 Addendum 2Joao Pedro92% (12)

- Inspection and Test Plan For Pressure Reliving Devices 1707841397Document16 pagesInspection and Test Plan For Pressure Reliving Devices 1707841397BernathTurnipNo ratings yet

- Ipa 510 Ad 2Document3 pagesIpa 510 Ad 2Santiago Cordova AlvaNo ratings yet

- PTT Public Company Limited Ratchaburi World Cogeneration Company LimitedDocument49 pagesPTT Public Company Limited Ratchaburi World Cogeneration Company LimitedzhangjieNo ratings yet

- Itp HeDocument15 pagesItp HeAldeline SungahidNo ratings yet

- All about ITPDocument10 pagesAll about ITPrmdarisaNo ratings yet

- Signature MT B313Document1 pageSignature MT B313Iksan Adityo MulyoNo ratings yet

- Signature Written PracticeDocument1 pageSignature Written PracticeIksan Adityo MulyoNo ratings yet

- P&IDDocument18 pagesP&IDhectornicolauNo ratings yet

- Summary ISO TR 15608 Metallic Materials Grouping SystemDocument4 pagesSummary ISO TR 15608 Metallic Materials Grouping SystemV SwamiNo ratings yet

- Standard Specification for Underground Piping InstallationDocument22 pagesStandard Specification for Underground Piping Installationt_solanki2001100% (1)

- Indikator Kunci Kinerja k3lDocument1 pageIndikator Kunci Kinerja k3lIksan Adityo MulyoNo ratings yet

- Risk MatrixDocument2 pagesRisk MatrixIksan Adityo Mulyo100% (1)

- Medevac & Tim TKTDDocument6 pagesMedevac & Tim TKTDIksan Adityo Mulyo100% (1)

- Standar ApdDocument1 pageStandar ApdIksan Adityo MulyoNo ratings yet

- Hse CommitteeDocument1 pageHse CommitteeIksan Adityo MulyoNo ratings yet

- List Kekurangan Isometric DrawingDocument8 pagesList Kekurangan Isometric DrawingIksan Adityo MulyoNo ratings yet

- Manufacture and Designation of SteelsDocument11 pagesManufacture and Designation of SteelsIksan Adityo MulyoNo ratings yet

- QP - 02 Magnetic Particle Test, Rev 01Document13 pagesQP - 02 Magnetic Particle Test, Rev 01Iksan Adityo MulyoNo ratings yet

- P CSLTD 028 Pnuematic TestDocument9 pagesP CSLTD 028 Pnuematic TestIksan Adityo MulyoNo ratings yet

- ASME Section IX Welding Code GuideDocument5 pagesASME Section IX Welding Code GuideIksan Adityo MulyoNo ratings yet

- TA1179-D-5212-100X-3 - P&ID (Marked-Up)Document40 pagesTA1179-D-5212-100X-3 - P&ID (Marked-Up)Iksan Adityo Mulyo100% (1)

- P CSLTD 028 Hydro TestDocument9 pagesP CSLTD 028 Hydro TestIksan Adityo MulyoNo ratings yet

- 23 - PT Q&a 1-3 - PDFDocument49 pages23 - PT Q&a 1-3 - PDFbassamNo ratings yet

- QP - 01 Penetrant Test, Rev. 02Document13 pagesQP - 01 Penetrant Test, Rev. 02Iksan Adityo Mulyo100% (1)

- Handout Liquid Penetrant Test Level II - Rev. 3 - 28 August 2009Document96 pagesHandout Liquid Penetrant Test Level II - Rev. 3 - 28 August 2009Iksan Adityo Mulyo100% (1)

- F.sq-wI.013.3 WORK INSTRUCTION For Visual Check Inspection at Switch GearDocument3 pagesF.sq-wI.013.3 WORK INSTRUCTION For Visual Check Inspection at Switch GearIksan Adityo MulyoNo ratings yet

- F.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentDocument13 pagesF.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentIksan Adityo Mulyo100% (1)

- F.sq-Wi.013.2 Work Instruction For Performing Test at Switch GearDocument3 pagesF.sq-Wi.013.2 Work Instruction For Performing Test at Switch GearIksan Adityo MulyoNo ratings yet

- Section 01 - Typical Duties of Welding InspectorsDocument12 pagesSection 01 - Typical Duties of Welding InspectorsIksan Adityo MulyoNo ratings yet

- Const/Pip/QC Report June 2012Document17 pagesConst/Pip/QC Report June 2012Iksan Adityo MulyoNo ratings yet

- Indra: For ConstructionDocument13 pagesIndra: For ConstructionIksan Adityo MulyoNo ratings yet

- Oracle Purchase Order CycleDocument21 pagesOracle Purchase Order Cyclepaletir6593No ratings yet

- Worksheet II LPP SADocument5 pagesWorksheet II LPP SANikita Shah100% (1)

- Offshore Mag Poster - FPSODocument1 pageOffshore Mag Poster - FPSODing LiuNo ratings yet

- AWS D8.1M-2007 LeibleDocument40 pagesAWS D8.1M-2007 Leiblejorge solisNo ratings yet

- Testing SamplesDocument22 pagesTesting SamplesCarol Isaac Murphy100% (1)

- Buggs Bunny's SEO-Optimized CV TitleDocument3 pagesBuggs Bunny's SEO-Optimized CV Titleoptimist_919No ratings yet

- Ifs Food Version 5 Ifs Compendium of DoctrineDocument15 pagesIfs Food Version 5 Ifs Compendium of DoctrineNapo Rodolfo Galvez RamirezNo ratings yet

- BirkettDocument104 pagesBirkettscribdkhatnNo ratings yet

- Scope of Accreditation CABsDocument90 pagesScope of Accreditation CABsMidhunRameshThuvasseryNo ratings yet

- CCPW QC 504 Concrete Inspection FormDocument2 pagesCCPW QC 504 Concrete Inspection FormsaharuiNo ratings yet

- Tri WheelDocument6 pagesTri WheelAminul HoqueNo ratings yet

- SCMS 7035Document5 pagesSCMS 7035Jose Manuel CastroNo ratings yet

- Energy MeterDocument2 pagesEnergy MeterNagaraj VjNo ratings yet

- MU Brochure - Cavotec AirportsDocument36 pagesMU Brochure - Cavotec AirportsAshok AeroNo ratings yet

- 2011 Jay Feather SELECT Owners ManualDocument101 pages2011 Jay Feather SELECT Owners ManualJames SkilesNo ratings yet

- NI 9944/9945 Quarter Bridge Completion Accessory: User GuideDocument4 pagesNI 9944/9945 Quarter Bridge Completion Accessory: User GuideWeverthon Beiral0% (1)

- 3bc899b9-e56d-40c4-a304-1cc5edf4b6c7Document4 pages3bc899b9-e56d-40c4-a304-1cc5edf4b6c7Swamy Dhas DhasNo ratings yet

- Digital Weighing Indicator XK3190-A12 (E) : User ManualDocument17 pagesDigital Weighing Indicator XK3190-A12 (E) : User Manualiyol1No ratings yet

- Hong Seng CatalogueDocument54 pagesHong Seng CatalogueRajeshNo ratings yet

- Brisko Structural Steel BrochureDocument5 pagesBrisko Structural Steel Brochureyousef alfrkhNo ratings yet

- Sundance Supply®, LLC Framing GuideDocument15 pagesSundance Supply®, LLC Framing GuideHouariKouadriNo ratings yet

- ICTASEMDocument3 pagesICTASEMmanoish07No ratings yet

- LC1D95M7 Product SheetDocument4 pagesLC1D95M7 Product SheetLuiz Carlos PereiraNo ratings yet

- SKF India financial analysisDocument12 pagesSKF India financial analysisAmaan Manzoor RatherNo ratings yet

- Spring 2014 FGCU GraduatesDocument29 pagesSpring 2014 FGCU GraduatesNews-PressNo ratings yet

- OM Toyota Group1Document19 pagesOM Toyota Group1Shivam Jaiswal100% (1)

- Kanya Venkatappa ResumeDocument1 pageKanya Venkatappa ResumekansanNo ratings yet

- Engineering EcoDocument26 pagesEngineering EcoEric John Enriquez100% (2)

- Motor SeverDocument19 pagesMotor SevervanjalujicNo ratings yet

- Aplicação de Controle No Equilíbrio de Um Pêndulo Invertido Utilizando-Se Um Robô Feito Com o Kit LEGO MindstormsDocument15 pagesAplicação de Controle No Equilíbrio de Um Pêndulo Invertido Utilizando-Se Um Robô Feito Com o Kit LEGO MindstormsJessika PaiolaNo ratings yet