Professional Documents

Culture Documents

Egr4202 Operations and Quality Management - Course Structure

Uploaded by

Jeremy Lim Choon KeatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Egr4202 Operations and Quality Management - Course Structure

Uploaded by

Jeremy Lim Choon KeatCopyright:

Available Formats

INTI INTERNATIONAL UNIVERSITY

COURSE STRUCTURE

Programme: Bachelor of Engineering (Hons) in Mechanical Engineering

1.

Name of Course/Module : OPERATIONS AND QUALITY MANAGEMENT

2.

Course Code: EGR4202

3.

Rationale for the inclusion of the course/module in the programme : According to EAC Manual 2012, the subject is

under the area of management and economics

4.

Total Student

Independent Learning

Time

Total Face to Face

Student Learning Time (SLT)

L

L = Lecture

T = Tutorial

P = Practical(Lab)

O= Others

A= Assessment

B/O=Blended /Online learning

IL= Independent learning

B/O

IL

74

42

6.

Credit Value: 3 Credits

7.

Prerequisite (if any): -

8.

Learning outcomes:

On completion of the course, students will be able to:

1. Identify and propose the solution of the complex issues surrounding operations and quality.

2. Use systematic approaches in assessing operations and quality capability of organizations.

3. Apply process improvement tools to redesign an organization operation process.

4. Design and implement an effective operations management system.

9.

Synopsis: This course provides a detailed introduction to both Operations Management and Quality Management. It

looks at techniques for forecasting demand for a product or service, approaches to service or manufacturing facility,

how to set up the site according to various criteria, the management of product inventory, human resource planning

in the intermediate term and scheduling material inputs. It focuses on what quality is and how it is measured. A range

of quality tools are introduced and the importance of statistical thinking to the management of quality is covered in

studying statistical process control. Quality systems are investigated and the recognition of quality is explored.

10.

Mode of Delivery: Lectures and Blended delivery

11.

Assessment Methods and Types:

Test 1: 10%, Test 2: 10%, Assignment/Project: 20%, Final Examination: 60%.

12.

Content outline of the course/module and the SLT per topic:

Sessions

13

Topics

Introduction to Operations Management

A brief overview of the historical evolutions of

Operations Management. Their individual comparison

between manufacturing and service fields. Their crossfunctional relationships with other parts of the

organizations. Issues and trends in Operations

Management.

LO

1

L

5

B/O

1

IL

74

46

7 9

10 12

13 15

16 18

19 21

22 24

25 28

Forecasting

Elements of a good forecast. Steps in forecasting

process. Qualitative and quantitative approaches to

forecasting. Techniques used to solve various problems.

Measures of forecast accuracy. Evaluating and

controlling forecasts. Factors in choosing a forecasting

techniques.

Strategic Capacity Planning for Products and

Services

Importance of capacity planning. Ways of defining and

measuring capacity. Determinants of effective capacity.

Considerations related to developing capacity

alternatives. Approaches for evaluating capacity

alternatives

Process Selection and Facility Layout

Process selection in an organization. Automated

approaches to processing. Reasons of redesign of

layouts. Basic layout types. Line balancing. Designing

process layouts.

MRP and ERP

Conditions where MRP is appropriate. Requirements of

MPS translated to MRP. Benefits and requirements of

MRP. MRP in capacity requirements planning. Benefits

and difficulties encountered with MRP. MRP II and its

benefits. ERP and its hidden costs.

Management of Quality

Overview Of Quality Management. Definition of

quality. Consequences of poor quality. Costs associated

with quality. Quality Awards. Philosophies of quality

gurus. TQM definition. Problem solving. Use of quality

tools.

Quality Control

Elements of the control process. Monitoring a process.

Use and interpreting control charts. Assess process

capability

Process Improvement-Total Quality Management

and Six Sigma Methodology

This session introduces the continuous improvement

program and methodology. The philosophies of Total

Quality Management (TQM) and the DMAIC method

and its application in the process of organizations.

Obstacles to implementing TOM and Six Sigma are

discussed.

Contemporary issues - Lean Operation; Just-in-time

system and Value Streaming Mapping

1. The JIT Concept

2. Types of wastes

3. Kanban

4. Lead time and TAKT time

TOTAL

42

Lecture (L), Tutorial (T), Practical (P), O (Other), Assessment (A), B/O ((Blended/Online learning); Independent

Learning (IL); Learning Outcome (LO)

74

25.

Main reference(s) supporting course:

1. Stevenson. W.J., Operations Management, 11th Ed., McGraw Hill/Irwin, 2011.

Additional references (at least 2):

1. Oakland, John S. Statistical Process Control, 5th Ed., Butterworth-Heinemann, 2003.

2. Heizer, Jay & Render, Barry, Operations Management, 9th Ed., Prentice Hall: Upper Saddle River, New

Jersey, 2007.

26.

Other additional information (if any):

FINAL EXAMINATION FORMAT:

Duration: 2 hours

The paper consists of FIVE questions; students are required to answer THREE compulsory questions plus another

ONE selected question.

GRADING SCALE:

A+ (90-100), A (8089), A- (75-79), B+ (70-74), B (6569), B- (6064), C+ (5559) C (5054), C- (4549), D (40

44), F(039).

Note:

A student is deemed to have passed the module if the TOTAL of the coursework mark and the examination mark,

weighted as above, is at least 50 marks, and the student is also required to obtain at least 40 % of the 100 marks in

the final examination.

Course Outcomes - Programme Outcomes with

Instructions and Assessments Matrix

Learning outcomes

CO1

CO2

CO3

CO4

Programme

Outcomes that are

addressed in this

subject

PO7

Identify and propose the solution of the

complex issues surrounding operations and

quality.

Use systematic approaches in assessing

operations and quality capability of

organizations.

Apply process improvement tools to redesign

an organization operation process.

Design and implement an effective

operations management system.

PO12

Instruction

Assessment

Lecture

Examination, test,

assignment,

Lecture

Lecture

Lecture

Examination, test,

assignment,

Examination, test,

assignment, case

studies

Examination, test,

assignment, project

The Mechanical Engineering Discipline has adopted a set of 12 programme outcomes,

which, upon successful completion of the programme, graduates will be able to:

1. Apply knowledge of mathematics, science and engineering fundamentals to the solution of complex

engineering problems

2. Conduct investigation into complex problems using research based knowledge and research methods

including design of experiments, analysis and interpretation of data, and synthesis of information to

provide valid conclusions

3. Identify, formulate, research literature and analyse complex engineering problems reaching

substantiated conclusions using first principles of mathematics, natural sciences and engineering

sciences

4. Design solutions for complex engineering problems and design systems, components or processes that

meet specified needs with appropriate consideration for public health and safety, cultural, societal, and

environmental considerations

5. Demonstrate the knowledge of and need for sustainable development and understand the social and

environmental impacts of engineering solutions

6. Apply ethical principles and commit to professional ethics and responsibilities and norms of

engineering practice

7. Communicate effectively on complex engineering activities, not only with engineers but also with the

community at large

8. Function effectively as an individual and as a member or leader in diverse teams and in multidisciplinary settings

9. Apply reasoning informed by contextual knowledge to assess societal, health, safety, legal and cultural

issues and the consequent responsibilities relevant to professional engineering practice

10. Recognise the need for, and have the preparation and ability to engage in independent and life-long

learning in the broadest context of technological change

11. Create, select and apply appropriate techniques, resources, and modern engineering and IT tools,

including prediction and modelling, to complex engineering activities, with an understanding of the

limitations

12. Demonstrate knowledge and understanding of engineering and management principles and apply these

to ones own work, as a member and leader in a team, to manage projects and in multidisciplinary

environments.

You might also like

- Difference Between Isotropic and Orthotropic in Material Science Both the Term Isotropic in North Atrophic Are Related to Mechanical and Thermal Properties Along the Three Directions but There Exists a Distinct Difference bDocument1 pageDifference Between Isotropic and Orthotropic in Material Science Both the Term Isotropic in North Atrophic Are Related to Mechanical and Thermal Properties Along the Three Directions but There Exists a Distinct Difference bJeremy Lim Choon KeatNo ratings yet

- PP Hirarc ProjectDocument4 pagesPP Hirarc ProjectJeremy Lim Choon KeatNo ratings yet

- OSHA Unit 1Document27 pagesOSHA Unit 1Jeremy Lim Choon KeatNo ratings yet

- Barred VibrationDocument1 pageBarred VibrationJeremy Lim Choon KeatNo ratings yet

- BoilerDocument5 pagesBoilerJeremy Lim Choon KeatNo ratings yet

- Q4Document1 pageQ4Jeremy Lim Choon KeatNo ratings yet

- Technology in Product DevelopmentDocument2 pagesTechnology in Product DevelopmentJeremy Lim Choon KeatNo ratings yet

- ColaDocument4 pagesColaJeremy Lim Choon KeatNo ratings yet

- HIRARC GuideLine From DOSHDocument34 pagesHIRARC GuideLine From DOSHMohd Hadri50% (2)

- Script Jeremy Estimating Project TimeDocument1 pageScript Jeremy Estimating Project TimeJeremy Lim Choon KeatNo ratings yet

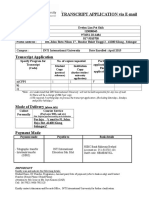

- Online Transcript Application FormDocument2 pagesOnline Transcript Application FormJeremy Lim Choon KeatNo ratings yet

- Test 2 SolutionDocument6 pagesTest 2 SolutionJeremy Lim Choon KeatNo ratings yet

- Module02 Brainstorming WorksheetDocument2 pagesModule02 Brainstorming WorksheetJeremy Lim Choon KeatNo ratings yet

- Presentation AprilDocument2 pagesPresentation AprilJeremy Lim Choon KeatNo ratings yet

- Estimating Total Project Time JeremyDocument2 pagesEstimating Total Project Time JeremyJeremy Lim Choon KeatNo ratings yet

- Enthalpies of GasesDocument17 pagesEnthalpies of GasesJeremy Lim Choon KeatNo ratings yet

- MEE3223 - Assignment 2Document2 pagesMEE3223 - Assignment 2Ihsan Samoh เพี่อนดีดีNo ratings yet

- EDP - Jan 2016 - Project Briefing - 15 Jan 16Document7 pagesEDP - Jan 2016 - Project Briefing - 15 Jan 16Jeremy Lim Choon KeatNo ratings yet

- 19th INTIMA Activity Proposal GK 1Document5 pages19th INTIMA Activity Proposal GK 1Jeremy Lim Choon KeatNo ratings yet

- Bmegi PlanDocument1 pageBmegi PlanJeremy Lim Choon KeatNo ratings yet

- Fluid Mechanics ExperimentDocument13 pagesFluid Mechanics ExperimentJeremy Lim Choon KeatNo ratings yet

- Sponsor BrandDocument1 pageSponsor BrandJeremy Lim Choon KeatNo ratings yet

- Book 40 Bikes for Event at RM5/hourDocument1 pageBook 40 Bikes for Event at RM5/hourJeremy Lim Choon KeatNo ratings yet

- 2007 KeyDocument1 page2007 KeyJeremy Lim Choon KeatNo ratings yet

- Solid Mechanics Chapter 2 ExercisesDocument2 pagesSolid Mechanics Chapter 2 ExercisesJeremy Lim Choon KeatNo ratings yet

- KenamaticsDocument1 pageKenamaticsJeremy Lim Choon KeatNo ratings yet

- Exercise 5Document2 pagesExercise 5Jeremy Lim Choon KeatNo ratings yet

- A Simple Guide To APA Referencing - Oct13Document7 pagesA Simple Guide To APA Referencing - Oct13Jeremy Lim Choon KeatNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Influence of RL in Supply Chain PerformanceDocument5 pagesThe Influence of RL in Supply Chain PerformanceElsa FauziahNo ratings yet

- CCV-RogneyPiedra ArencibiaDocument8 pagesCCV-RogneyPiedra ArencibiaRogney Piedra ArencibiaNo ratings yet

- Kyle Manleys CV GradDocument4 pagesKyle Manleys CV Gradapi-670485441No ratings yet

- Evaluating Childrens LiteratureDocument5 pagesEvaluating Childrens Literatureapi-296864651No ratings yet

- Balcikanli (2011) Metacognitive Awareness Inventory For Teachers (MAIT) PDFDocument24 pagesBalcikanli (2011) Metacognitive Awareness Inventory For Teachers (MAIT) PDFRizky KurniawatiNo ratings yet

- High Quality Collaboration Benefits Teachers and StudentsDocument3 pagesHigh Quality Collaboration Benefits Teachers and StudentsFRANCHESCA GUGULUNo ratings yet

- Thesis Statements For Personal EssaysDocument4 pagesThesis Statements For Personal Essaysf5dkcpkf100% (2)

- Pilgrim Christian College Research GuideDocument11 pagesPilgrim Christian College Research GuideLeo TiempoNo ratings yet

- Strategic Management of Technological Innovation 5th Edition Schilling Solutions ManualDocument42 pagesStrategic Management of Technological Innovation 5th Edition Schilling Solutions Manuala46925023550% (4)

- Final Thesis Proposal - MuseumDocument26 pagesFinal Thesis Proposal - MuseumJobriel Gauuan44% (9)

- The Guild Concept and The Structure of Ecological Communities 1991Document30 pagesThe Guild Concept and The Structure of Ecological Communities 1991Ava LoneNo ratings yet

- Practical Research 2 Chap 1 3Document23 pagesPractical Research 2 Chap 1 3Cyrus ReyesNo ratings yet

- Speaking AbilityDocument14 pagesSpeaking Abilityagus setyawanNo ratings yet

- Christian Addai ManuDocument101 pagesChristian Addai ManuAnonymous yy8In96j0rNo ratings yet

- Meta Analysis Study: Effect of STEM (Science Technology Engineering and Mathematic) Towards AchievementDocument12 pagesMeta Analysis Study: Effect of STEM (Science Technology Engineering and Mathematic) Towards AchievementAhmad KhoiriNo ratings yet

- Urbanization and Globalization Transform Traditional Gbagyi HousingDocument10 pagesUrbanization and Globalization Transform Traditional Gbagyi HousingSylvester Ejembi InnocentNo ratings yet

- Literary Onomastics A TheoryDocument173 pagesLiterary Onomastics A TheoryAndrea CastilloNo ratings yet

- Social Media and Cultural ChangeDocument8 pagesSocial Media and Cultural Changemeghna.149699No ratings yet

- Applying Means-End Theory to Study Host AttitudesDocument20 pagesApplying Means-End Theory to Study Host AttitudesEris Jan Casapao100% (1)

- ProposalDocument19 pagesProposalJoseph Von RyanNo ratings yet

- Implications of Research On Indigenous African Child Development and Socialization - UNESCODocument37 pagesImplications of Research On Indigenous African Child Development and Socialization - UNESCOJhony CoboyNo ratings yet

- Solid Waste Disposal Practices of Selected Schools in Mangagoy, Bislig CityDocument24 pagesSolid Waste Disposal Practices of Selected Schools in Mangagoy, Bislig CityDenise PascuaNo ratings yet

- Evolution of Clinical Legal Education in IndiaDocument2 pagesEvolution of Clinical Legal Education in IndiaRajshree ShekharNo ratings yet

- Mobile Banking in IndiaDocument14 pagesMobile Banking in IndiaDeepak KumarNo ratings yet

- MKT Test 2 Study GuideDocument22 pagesMKT Test 2 Study GuideAlejandro RamirezNo ratings yet

- Hand To Hand Combat Lesson PlanDocument3 pagesHand To Hand Combat Lesson PlanJulia CarringtonNo ratings yet

- Mason Draeger - Locker Project Design Brief 2020-21Document2 pagesMason Draeger - Locker Project Design Brief 2020-21Mason DraegerNo ratings yet

- An Appraisal of Inventory Management and Control in Manufacturing Firms. A Study of Nigeria Breweries and Unilever Plc.Document84 pagesAn Appraisal of Inventory Management and Control in Manufacturing Firms. A Study of Nigeria Breweries and Unilever Plc.Oderinde OluwaseyiNo ratings yet

- Panarchy Theory and Application 2014Document13 pagesPanarchy Theory and Application 2014giuvulNo ratings yet

- A Concept Analysis of Conceptual Learning A Guide For Educators-MinDocument10 pagesA Concept Analysis of Conceptual Learning A Guide For Educators-MinNeo YapindoNo ratings yet