Professional Documents

Culture Documents

Pipes and Bends Data Sheet

Uploaded by

Manali PatilCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipes and Bends Data Sheet

Uploaded by

Manali PatilCopyright:

Available Formats

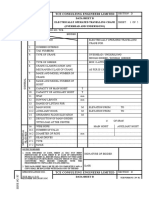

Pipes & Bends

E holes

F on D

bolt circle

Flanges

All conveying pipework, bends and fittings are supplied with flanges

drilled to BS4504 PN10 as standard, with (depending upon application),

either Code 101 flanges, or Clyde Process alignment flanges.

Available in the following material specification: BS1501 Part 1 - 151,

grade 360 or BS EN 10 025 Fe 430A

B Code 101

Flanges can also be supplied to client specification.

Conveying Pipework

Supplied in nominal standard 6 metre lengths with flanges, flange bolts

and gaskets. Brackets and other fixings necessary to attach pipework to

supports and structures are not included. Pipe is supplied unpainted.

Available in the following material specification: Mild steel (Schedule

40 or equal). BS1387 Heavy (up to 150mm n.b.) BS3601 H.F.S.

(200mm n.b. to 400mm n.b.) Stainless steel. BS4825 (Grade 316L)

Pipework can also be supplied to client specification.

C

E holes

F on D

bolt circle

n.b

50

80

100

125

150

175

200

250

300

350

400

450

A

61.5

90.5

116

141.5

170.5

195.2

221.5

276.5

327.5

359.5

411

462

BS4504 PN10 Flanges

B

C

D

20

165

125

20

200

160

22

220

180

22

250

210

24

285

240

24

315

270

24

340

295

26

395

350

R

26

445

400

28

505

460

32

565

515

36

565

565

E

4

8

8

8

8

8

8

12

12

16

16

20

Cast bends

Fabricated Bends

Cast Ni-Hard (BS4844 grade 2B) or Grade 250 Iron bends are

recommended for especially abrasive lumpy materials, such as bottom

ash, glass cullet, etc.

Plain bends with long radius are recommended for

cohesive powders or damp materials that fall into the

nonabrasive category.

B Code 101

A straight spool is designed into the bend before the

flange connection to assist clip attachment to support

brackets. Bends are manufactured from carbon steel

pipe and offer good resistance to wear when used with

the DensePhase low material velocity system.

Code 101

F

18

18

18

18

22

22

22

22

22

22

26

26

Fabricated Bends and Cast Bends

Fabricated

n.b.

Fitting

Cast

Wgt R

Wgt

50

150

610

To Spec.

14

500

45

13

80

150

915

To Spec.

30

750

30/45

17

100

150

1220

To Spec.

48

1000 10/30/45 40

125

150

1525

To Spec.

73

1524

150

150

1830

To Spec.

107

1500 10/30/45 120

175

150

1830

To Spec.

132

2133

45

30/45

200

150

1830

To Spec.

159

1830

10/45

250

150

1830

To Spec.

173

2000

30

300

150

1830

To Spec.

193

350

150

To Spec.

400

150

To Spec.

81

The standard bend fitting for dry materials is unique to the

DensePhase system. It is a compact, easily installed fitting for

redirecting the pipe system through 30, 45, 60, and 90 as

standard, or other angles as necessary.

The design overcomes the problem of high wear rates on long

radius bends whilst ensuring a smooth flow of material into the

new direction without causing problems due to blockages.

C

C

Weights (kg) are for 90 fabricated & 45 cast bends.

B

B

Basalt Lined

A

A

Bends are manufactured from carbon steel pipe with basalt

lining to offer greater resistance to wear.

Bend Fittings

20mm min.

Basalt

20mm

min.

Thickness

Basalt

Thickness

n.b.

80

R

R

15

15 7.5

7.5

Basalt Lined

Flange n.b.

R

n.b.

80

125

400

To Spec.

100

150

500

To Spec.

125

175

625

To Spec.

150

200

750

To Spec.

200

250

1000

To Spec.

250

300

1250

To Spec.

300

300

1500

To Spec.

350

400

1750

To Spec.

400

450

2000

To Spec.

Schenck Process UK Limited

Carolina Court, Lakeside, Doncaster

DN4 5RA England

Tel: +44 (0) 1302 321 313

Fax: +44 (0) 1302 554 400

enquires@schenckprocess.co.uk

www.schenckprocess.co.uk

A

450

B

100

C

400

30

457

216

305

45

450

225

286

60

450

225

287

75

457

100

610

127

559

550

250

355

45

600

300

387

60

228.5 228.5

90

30

75

305

90

610

305

125

720

150

635

30

660

305

406

45

750

375

487

60

75

90

762

381

381

150

30

765

375

530

45

920

460

610

60

75

90

900

450

450

200

30

45

60

1220

600

780

75

90

1200

600

595

You might also like

- Steps To Private Placement Programs (PPP) DeskDocument7 pagesSteps To Private Placement Programs (PPP) DeskPattasan U100% (1)

- Carbon Steel Pipe and Fittings GuideDocument10 pagesCarbon Steel Pipe and Fittings GuideavazcNo ratings yet

- Pipe Steel Pipe CatalogueDocument16 pagesPipe Steel Pipe Cataloguezishanf_1No ratings yet

- Introduction To Process Engineering and Design, Second Edition PDFDocument1,138 pagesIntroduction To Process Engineering and Design, Second Edition PDFYASH PATEL86% (7)

- Definition and Details of Flanges - Types of FlangesDocument11 pagesDefinition and Details of Flanges - Types of FlangesSUKANTA DALAINo ratings yet

- Bulk Material Density Guide - HapmanDocument56 pagesBulk Material Density Guide - HapmanManali PatilNo ratings yet

- GRP Puddle Pipe SpecificationDocument1 pageGRP Puddle Pipe SpecificationIshwar AltNo ratings yet

- IS 8329 - DI Pipe Specifications For Water, Gas & SewageDocument27 pagesIS 8329 - DI Pipe Specifications For Water, Gas & SewageChungath Linesh50% (2)

- UPVC Pipes & Fittings Upload 11.03.2019Document20 pagesUPVC Pipes & Fittings Upload 11.03.2019Rushan LakdimuthuNo ratings yet

- Waterfront Stoplogs GuideDocument1 pageWaterfront Stoplogs GuideiculasiNo ratings yet

- Design A Scrubber (Packed Column)Document14 pagesDesign A Scrubber (Packed Column)Manali PatilNo ratings yet

- Design A Scrubber (Packed Column)Document14 pagesDesign A Scrubber (Packed Column)Manali PatilNo ratings yet

- FIRE FIGHTING SPECIFICATIONSDocument25 pagesFIRE FIGHTING SPECIFICATIONSSudipto KumarNo ratings yet

- Piping Material Class C13B Carbon Steel GalvanizedDocument7 pagesPiping Material Class C13B Carbon Steel GalvanizedemanNo ratings yet

- Johnson Screen - Industrial - Screens - BrochureDocument20 pagesJohnson Screen - Industrial - Screens - BrochureManali PatilNo ratings yet

- Valves Pipe Fittings DimensionsDocument37 pagesValves Pipe Fittings DimensionstsoheilNo ratings yet

- 132KV Siemens Breaker DrawingDocument13 pages132KV Siemens Breaker DrawingAnil100% (1)

- Ball ValveDocument12 pagesBall ValveIdabaNo ratings yet

- Conflict of Laws (Summary Paper)Document13 pagesConflict of Laws (Summary Paper)Anonymous CWcXthhZgxNo ratings yet

- H Gravity Pipe Systems PN 1: Technical Product DataDocument42 pagesH Gravity Pipe Systems PN 1: Technical Product DataMensur TukicNo ratings yet

- Bond Strand 5000 eDocument8 pagesBond Strand 5000 eUmar KidaNo ratings yet

- Flange Pipe Support for 4-36Document1 pageFlange Pipe Support for 4-36indeskeyNo ratings yet

- MasterSeries 850 Specification SheetDocument2 pagesMasterSeries 850 Specification SheetFEBCONo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- En 1092-1 PN-10 Steel Pipe Flange - ValviasDocument5 pagesEn 1092-1 PN-10 Steel Pipe Flange - ValviasHoria ZecheruNo ratings yet

- Test Track - Pluming Boq Final-GDocument12 pagesTest Track - Pluming Boq Final-Gsmathy68100% (2)

- E 50B 4KG1 - Fire PDFDocument2 pagesE 50B 4KG1 - Fire PDFdocrafiNo ratings yet

- Foam Chamber DatasheetDocument4 pagesFoam Chamber DatasheetMoorthy MuruganNo ratings yet

- BOQ Fire Detail NetDocument10 pagesBOQ Fire Detail NetrajuNo ratings yet

- Ace Model Cv-101wh Di Gate Valves. Resilient Seated. Flange EndsDocument2 pagesAce Model Cv-101wh Di Gate Valves. Resilient Seated. Flange EndsSatish Kumar MauryaNo ratings yet

- Y-Strainer Spears DatasheetDocument10 pagesY-Strainer Spears Datasheetmanoj_sitecNo ratings yet

- Poly Water Tank (Completed) PDFDocument2 pagesPoly Water Tank (Completed) PDFSopi LabuNo ratings yet

- Flanges Connecting Dimension According To DIN EN 1092-1 and DIN 2501-1Document2 pagesFlanges Connecting Dimension According To DIN EN 1092-1 and DIN 2501-1Lasandu WanniarachchiNo ratings yet

- Thermoseal Klingersil C-4401Document2 pagesThermoseal Klingersil C-4401timwright999No ratings yet

- 8329 2000 DI PipeDocument29 pages8329 2000 DI PipeSanjay Prakash100% (1)

- ANSI 150#RF BASKET STRAINER MODEL FB-150, FQ-150Document1 pageANSI 150#RF BASKET STRAINER MODEL FB-150, FQ-150royert80No ratings yet

- Conbextra EP Data SheetDocument4 pagesConbextra EP Data Sheetprabhu81No ratings yet

- BOQ-ValvesDocument4 pagesBOQ-ValvesGourav SharmaNo ratings yet

- Hyundai Pipe CatalogueDocument36 pagesHyundai Pipe Cataloguefelram100% (2)

- Copper TubesDocument9 pagesCopper TubesVarun AbrolNo ratings yet

- Victaulic Carbon Steel Couplings and Grooved FittingsDocument16 pagesVictaulic Carbon Steel Couplings and Grooved FittingsAnonymous 7I5qQ0eAxgNo ratings yet

- L&T Aquaseal Butterfly Check Valves PDFDocument28 pagesL&T Aquaseal Butterfly Check Valves PDFSanjay SahulNo ratings yet

- Sec 05100 - Structural SteelDocument10 pagesSec 05100 - Structural Steeltiju2005hereNo ratings yet

- Protect Storage Tanks from Fire with Foam ChambersDocument3 pagesProtect Storage Tanks from Fire with Foam ChambersGonzalo CabreraNo ratings yet

- Sample 02 Declaration of ConformityDocument2 pagesSample 02 Declaration of ConformitymamsikaNo ratings yet

- Eot Crane Datasheet-BDocument5 pagesEot Crane Datasheet-Bbashok20No ratings yet

- Guides and RestraintsDocument8 pagesGuides and RestraintserikohNo ratings yet

- Halar and CBR Lined Tank Design QuestionnaireDocument2 pagesHalar and CBR Lined Tank Design Questionnairemaxpower1984No ratings yet

- Astm F2561-16Document4 pagesAstm F2561-16hugoNo ratings yet

- Short List of Applied Piping Standard PDFDocument3 pagesShort List of Applied Piping Standard PDFmohamad3010No ratings yet

- Erection BOQ - ChamparanDocument170 pagesErection BOQ - ChamparanPrasanna kumar subudhiNo ratings yet

- Ventilación en Altura-Bolivia PDFDocument67 pagesVentilación en Altura-Bolivia PDFGrace Ayala EspinozaNo ratings yet

- En 1092-1 PN-40 Steel Pipe FlangeDocument5 pagesEn 1092-1 PN-40 Steel Pipe FlangeHoria ZecheruNo ratings yet

- North Stream Manufacturing of Lagre Steel Component and Valves - ArticleDocument6 pagesNorth Stream Manufacturing of Lagre Steel Component and Valves - ArticleMauro MLRNo ratings yet

- Car Washer CatalogueDocument24 pagesCar Washer Cataloguesra electricalsNo ratings yet

- EN545 Double Flange Pipe With Puddle FlangeDocument1 pageEN545 Double Flange Pipe With Puddle FlangeDaviwongNo ratings yet

- Storage and HandlingDocument6 pagesStorage and HandlingalagurmNo ratings yet

- Tender Specification - Potable WaterDocument12 pagesTender Specification - Potable WaterSuhas NatuNo ratings yet

- OH-900 Oxygen Hydrogen AnalyserDocument6 pagesOH-900 Oxygen Hydrogen AnalyserPham DuyetNo ratings yet

- Storage Tank Design GuidelinesDocument6 pagesStorage Tank Design GuidelinespaaryNo ratings yet

- AVK Gate Valve HandwheelDocument2 pagesAVK Gate Valve HandwheelQubit SizedNo ratings yet

- Price ListDocument68 pagesPrice ListZuberYousufNo ratings yet

- STP CatalogueDocument37 pagesSTP CataloguemmkattaNo ratings yet

- PL 008748Document10 pagesPL 008748ronaldxmenNo ratings yet

- 50 Flarweld Access FlarweldDocument3 pages50 Flarweld Access FlarweldMonica EguanNo ratings yet

- Hangers and Supports for Plumbing PipingDocument6 pagesHangers and Supports for Plumbing Pipingmichael_george291616No ratings yet

- T4E Brochure PDFDocument6 pagesT4E Brochure PDFgullenariNo ratings yet

- Navco b2 BrochureDocument16 pagesNavco b2 Brochurejorge28csNo ratings yet

- EHT System Schematic & LayoutDocument1 pageEHT System Schematic & LayoutManali PatilNo ratings yet

- Air Cooled Heat Exchangers Cooling Towers Book ReviewDocument4 pagesAir Cooled Heat Exchangers Cooling Towers Book ReviewManali PatilNo ratings yet

- Pressure Equipment RegulationsDocument22 pagesPressure Equipment RegulationsManali PatilNo ratings yet

- Leakage Class of Control ValvesDocument4 pagesLeakage Class of Control Valvesg1232003gNo ratings yet

- DIPE-IPA Packed Column DiaDocument5 pagesDIPE-IPA Packed Column DiaManali PatilNo ratings yet

- Wind Conversion FormulaeDocument3 pagesWind Conversion FormulaeManali PatilNo ratings yet

- Types of Rotary Filters and Their ApplicationsDocument12 pagesTypes of Rotary Filters and Their ApplicationsManali PatilNo ratings yet

- Manual For Ammonia PlantDocument30 pagesManual For Ammonia PlantManali PatilNo ratings yet

- How Toe FileDocument4 pagesHow Toe Fileirfanahmed.dba@gmail.comNo ratings yet

- Hno3 MSDSDocument9 pagesHno3 MSDSMashyem AhmedNo ratings yet

- Screw Conveyor & Venturi ScrubberDocument1 pageScrew Conveyor & Venturi ScrubberManali Patil0% (1)

- Building CodeDocument2 pagesBuilding CodeManali PatilNo ratings yet

- Essential Buttweld Pipe Fittings GuideDocument4 pagesEssential Buttweld Pipe Fittings Guidekamal_mdNo ratings yet

- Fixation of Atmospheric Nitrogen - ErnstDocument167 pagesFixation of Atmospheric Nitrogen - ErnstValentijn BrandNo ratings yet

- NaNO2-NaNO3 Phase DiagramDocument6 pagesNaNO2-NaNO3 Phase DiagramManali PatilNo ratings yet

- Synthesis of Titanium Dioxide by Ultrasound Assisted Sol-Gel Technique Effect of Calcination TimeDocument22 pagesSynthesis of Titanium Dioxide by Ultrasound Assisted Sol-Gel Technique Effect of Calcination TimeManali PatilNo ratings yet

- Nonlinear Differential EquationsDocument8 pagesNonlinear Differential EquationsManali PatilNo ratings yet

- ThermodynamicPropertiesTables PDFDocument50 pagesThermodynamicPropertiesTables PDFdharmeswarNo ratings yet

- Process Equipment Design - by M V Joshi PDFDocument292 pagesProcess Equipment Design - by M V Joshi PDFkrishna sharma67% (3)

- 341 BDocument4 pages341 BHomero Ruiz Hernandez0% (3)

- The General Agreement On Trade in Services An IntroductionDocument22 pagesThe General Agreement On Trade in Services An IntroductionakyregisterNo ratings yet

- Shenzhen Gooky Technology Co.,Ltd.: Laptop Price ListDocument1 pageShenzhen Gooky Technology Co.,Ltd.: Laptop Price ListOusman KabaNo ratings yet

- Offer Letter For Marketing ExecutivesDocument2 pagesOffer Letter For Marketing ExecutivesRahul SinghNo ratings yet

- OrcaSecurity Solution OverviewDocument2 pagesOrcaSecurity Solution Overviewandini eldanantyNo ratings yet

- Festo Process Control - CatalogDocument3 pagesFesto Process Control - Cataloglue-ookNo ratings yet

- Csit 101 Assignment1Document3 pagesCsit 101 Assignment1api-266677293No ratings yet

- Kj1010-6804-Man604-Man205 - Chapter 7Document16 pagesKj1010-6804-Man604-Man205 - Chapter 7ghalibNo ratings yet

- Capital Asset Pricing ModelDocument11 pagesCapital Asset Pricing ModelrichaNo ratings yet

- MongoDB vs RDBMS - A ComparisonDocument20 pagesMongoDB vs RDBMS - A ComparisonShashank GuptaNo ratings yet

- Crypto Is New CurrencyDocument1 pageCrypto Is New CurrencyCM-A-12-Aditya BhopalbadeNo ratings yet

- Constitutional Law of India-II CCSU LL.B. Examination, June 2015 K-2002Document3 pagesConstitutional Law of India-II CCSU LL.B. Examination, June 2015 K-2002Mukesh ShuklaNo ratings yet

- Basic Concept of EntrepreneurshipDocument12 pagesBasic Concept of EntrepreneurshipMaria January B. FedericoNo ratings yet

- Modicon Quantum - 140DDI85300Document5 pagesModicon Quantum - 140DDI85300Samdan NamhaisurenNo ratings yet

- Counsel For Plaintiff, Mark Shin: United States District Court Northern District of CaliforniaDocument21 pagesCounsel For Plaintiff, Mark Shin: United States District Court Northern District of CaliforniafleckaleckaNo ratings yet

- Product Models Comparison: Fortigate 1100E Fortigate 1800FDocument1 pageProduct Models Comparison: Fortigate 1100E Fortigate 1800FAbdullah AmerNo ratings yet

- Term Paper Mec 208Document20 pagesTerm Paper Mec 208lksingh1987No ratings yet

- RIE 2013 Dumping and AD DutiesDocument21 pagesRIE 2013 Dumping and AD Dutiessm jahedNo ratings yet

- Deped Tacloban City 05202020 PDFDocument2 pagesDeped Tacloban City 05202020 PDFDon MarkNo ratings yet

- Yamaha Stagepas 300Document54 pagesYamaha Stagepas 300Ammar MataradzijaNo ratings yet

- Culture GuideDocument44 pagesCulture GuideLeonardo TamburusNo ratings yet

- Power Efficiency Diagnostics ReportDocument16 pagesPower Efficiency Diagnostics Reportranscrib300No ratings yet

- Ex 1-3 Without OutputDocument12 pagesEx 1-3 Without OutputKoushikNo ratings yet

- Caf 8 Aud Spring 2022Document3 pagesCaf 8 Aud Spring 2022Huma BashirNo ratings yet

- ID Analisis Persetujuan Tindakan Kedokteran Informed Consent Dalam Rangka Persiapan PDFDocument11 pagesID Analisis Persetujuan Tindakan Kedokteran Informed Consent Dalam Rangka Persiapan PDFAmelia AmelNo ratings yet

- UE Capability Information (UL-DCCH) - Part2Document51 pagesUE Capability Information (UL-DCCH) - Part2AhmedNo ratings yet

- Expert Java Developer with 10+ years experienceDocument3 pagesExpert Java Developer with 10+ years experienceHaythem MzoughiNo ratings yet