Professional Documents

Culture Documents

Es 03895 1 R1

Uploaded by

jr_satish6965Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Es 03895 1 R1

Uploaded by

jr_satish6965Copyright:

Available Formats

IOM

TM

GO Switch 70 Micro Junction

Introduction

Mounting and Operation Best Practices

Installation

Special Conditions for Safe Use

The 70 Micro Junction integrates 70 series GO Switch with junction box allowing termination to the switch directly. Additionally, this product provides the full range of GO Switch

performances in the junction box and the reliability of the GO Switch for use in increased

safety applications. The junction box is available with an M20 or 1/2 NPT conduit entry

and has terminal blocks for ease of end user push-in installation.

Torque specs:

For heavy or inductive loads, arc suppression devices or interposing relays are

General

For installation in hazardous locations, check local electrical codes.

The maximum voltage and current shown in the rating label must not be

The integrated GO switches in the micro junction use permanent magnets which, when

actuated by the presence of a ferrous or magnetic target, change the state of electrical

contacts.

Mounting nuts:

3 lbfft [4.1 Nm]

Lid:

14 lbfft [19 Nm]

Recommended mounting bracket material: 300 series stainless steel

recommended for contact longevity.

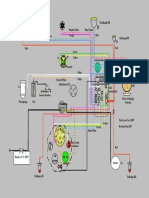

GO Switch

Example arc

snubber circuit

R

Target Material:

Ferrous metal; optional target magnets

Thread Options:

5/8-18 UNF; M18 x 1

Sensing Distance:

Ferrous target: 0.100 (2,54mm)

Temperature Rating:

Hazadarous Location: -40C to +75C

Ordinary Location:

-40C to +105C

Differential:

Ferrous target: 0.020 (0,51mm)

Contact resistance:

<0.5 ohm

Response time:

15 milliseconds

Enclosure Material:

Body tube and lid: 303 or 316 SST

-V

portion of switch and ferrous objects.

Specifications

Increased sensing distance possible with

TopWorx supplied target magnets

exceeded.

+V

For the maximum rated sensing distance, ensure a 0.500 gap between threaded

Contact Material:

Palladium silver

When using long runs of conduit or cable, place supports close to the switch assemenough to allow for movement, and positioned to eliminate binding or pulling.

Avoid contact between target and switch.

For ease of installation in Cl1 Div 1 environments, Topworx recommends either an

Contacts:

Single Pole, Double Throw, Form C

Appleton UNY50 or UNY50NR conduit union.

N/C

To prevent water ingression through the conduit entry, ensure that a drip loop and

COM

drain plug are installed within 6 inches of the switch.

N/O

Electrical Ratings: Resistive

4A @ 120VAC / 3A @ 24VDC

Connection Head Conduit Outlet:

1/2" -14NPT or M20.

Inadequate ingression protection

Good ingression protection

In order to achieve maximum contact pressure, ensure that the ferrous target distance

Axial Sensing

Axial Sensing

terminal unless multiple conductors have been joined in a suitable manner,

e.g. two conductors into a single insulated bootlace ferrule, or any method

indicated on the terminal certificate.

Suitably certified cable entry devices shall be installed in accordance with

IEC60079-14 and must maintain the ingress protection (IP) rating of the

enclosure. The cable entry device thread shall not protrude within the

enclosure body (i.e. shall maintain the clearance to the terminals).

Any unit marked Ex d must be fitted with an Ex d certified gland only.

Any unit marked Ex de may be fitted with either an Ex d or Ex e certified

gland as per the installation requirements.

II 2 GD

II 2 GD

0518

Baseefa 14ATEX0236X

IECEx BAS 13.0086X

Ex de IIC T6/T5/T4 Gb

Ex tb IIIC T85C/T100C/T135C Db IP66/68

Tamb: -40C to + 75C

For Topworx terms and conditions of sale, visit Topworx.com

Basic Dimensions

Normally

closed state

Wiring Diagram

Do not allow dust layers to build up on the surface of the switch.

No more than one single multi-stranded lead shall be connected to the

Baseefa 14ATEX0236X

IECEx BAS 13.0086X

Ex d IIC T6/T5/T4 Gb

Ex tb IIIC T85C/T100C/T135C Db IP66/68

Tamb: -40C to + 75C

Lateral Sensing

Normally

open state

ATEX/IECEx

The 70 Series GO Switch assembly shall be suitably earthed by its installa-

0518

from the switch is 5 times the rated sensing distance in the normally closed states and

1/2 the rated sensing distance in the normally open state.

Lateral Sensing

NEC

When installed in Cl I Div 1 or Div 2 environment, lead seal fittings are

tion via the male thread of the GO Switch body.

bly to avoid pulling the assembly out of position.

If switch assembly is mounted on a moving part, ensure that flexible conduit is long

0.63 diameter, 0.25 thick

Approximate weight, steel target: 0.32 oz (9g)

potting. Any attempt to separate the parts (except the threaded cover) will

void the warranty and certification.

A minimum of 5 threads engagement of the lid to the body tube must be

maintained when in service.

required within 18" of switch assembly.

Minimum recommended ferrous target dimensions:

The switch / terminal assembly is bonded together by the internal cement/

Asia-Pacific

1 Pandan Crescent

Singapore 128461

+65 6891 7550

Visit www.topworx.com for

comprehensive information

on our company, capabilities,

and products including model

numbers, data sheets,

specifications, dimensions,

and certifications.

To minimize undue stress cased by conduit or cables, ensure that the switch is

mounted such that the mounting bracket is near the center of the switch.

Technical Assistance

Info.topworx@emerson.com

TopWorx engineers are available to provide technical assistance on GO Switch

products. However, it is the customer's responsibility to determine the safety and

suitability of the product in their application. It is also the customer's responsibility to

install the switch using the current electrical codes in their region.

GLOBAL SUPPORT OFFICES

Americas

3300 Fern Valley Road

Louisville, Kentucky 40213 USA

+1 502 969 8000

Europe

Horsfield Way

Bredbury Industrial Estate

Stockport SK6 2SU

United Kingdom

+44 0 161 406 5155

Africa

24 Angus Crescent

Longmeadow Business Estate East

Modderfontein

Gauteng

South Africa

+27 11 451 3700

Middle East

P.O. Box 17033

Jebel Ali Free Zone

Dubai 17033

United Arab Emirates

+971 4 811 8283

2015 TopWorx, All rights reserved. TopWorx, and GO Switch are all trademarks of TopWorx. The

Emerson logo is a trademark and a service mark of Emerson Electric. Co. 2015 Emerson Electric Company. All

other marks are the property of their respective owners. Information herein including product specifications is

subject to change without notice.

ES-03895-1 R1

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Pressure Relief Valve Engineering HandbookDocument93 pagesPressure Relief Valve Engineering Handbookakrouti92% (12)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- L&T CHANGEOVER SW C-Line Catalogue PDFDocument15 pagesL&T CHANGEOVER SW C-Line Catalogue PDFchidambaram kasi67% (3)

- Asme SectionsDocument56 pagesAsme SectionsalperbogaNo ratings yet

- Stamford PI7Document2 pagesStamford PI7Donald Santana BautistaNo ratings yet

- Asme 46.1 2001Document25 pagesAsme 46.1 2001jr_satish6965No ratings yet

- Midas Venice ManualDocument29 pagesMidas Venice Manualcb4pdfsNo ratings yet

- R8505 KVTR100Document88 pagesR8505 KVTR100Rinda_RaynaNo ratings yet

- NORSOK P-001 Process Design PDFDocument26 pagesNORSOK P-001 Process Design PDFMarcelNo ratings yet

- ENGINEERING DESIGN GUIDELINES Relief Valves Sizing and Selection Rev WebDocument31 pagesENGINEERING DESIGN GUIDELINES Relief Valves Sizing and Selection Rev Webjr_satish6965No ratings yet

- IEC 60060-2 - High-Voltage Test Techniques - Part 2: Measuring Systems - Edition 3.0Document19 pagesIEC 60060-2 - High-Voltage Test Techniques - Part 2: Measuring Systems - Edition 3.0ONUR YILMAZNo ratings yet

- Swagelok-Thread and End Connection Identification Guide-MS-13-77 PDFDocument56 pagesSwagelok-Thread and End Connection Identification Guide-MS-13-77 PDFmac9papNo ratings yet

- 5.surge ArrestorDocument5 pages5.surge Arrestorraj_stuff006No ratings yet

- 9 Materials - Equivalent GradesDocument7 pages9 Materials - Equivalent GradesEzraHasibuanNo ratings yet

- DanLoad 6000 - Instruções para UsoDocument54 pagesDanLoad 6000 - Instruções para UsoEpson Souza100% (1)

- Induction Cooker TeardownDocument14 pagesInduction Cooker TeardownNguyễn Hồng DươngNo ratings yet

- ACB ManualDocument42 pagesACB Manual4usangeetNo ratings yet

- Bobcat Loader t590 Hydraulic Electrical SchematicDocument22 pagesBobcat Loader t590 Hydraulic Electrical Schematicscottmartin240600xro100% (130)

- Weld Symbols On DrawingsDocument25 pagesWeld Symbols On Drawingshombre.muerto5959100% (2)

- Standarde Din FlangeDocument45 pagesStandarde Din Flangeadri2No ratings yet

- Corrosion AllowanceDocument35 pagesCorrosion AllowanceReni Mutiara Sari50% (2)

- Marechal Decontactors Plug and Socket SwitchDocument4 pagesMarechal Decontactors Plug and Socket SwitchrocketvtNo ratings yet

- Imc-101g Hig 4eDocument15 pagesImc-101g Hig 4emrs.arporn22No ratings yet

- Installation Manual: Medical Switching Power SupplyDocument4 pagesInstallation Manual: Medical Switching Power SupplytawfikNo ratings yet

- Pull Wire and Trip Switch PDFDocument76 pagesPull Wire and Trip Switch PDF450gasgas100% (1)

- 3089-99 RCCB F660Document16 pages3089-99 RCCB F660Nguyen SonNo ratings yet

- Inversor Abb 2 5kwDocument2 pagesInversor Abb 2 5kwapi-290643326No ratings yet

- 550.0029-Diode Pack Info PDFDocument0 pages550.0029-Diode Pack Info PDFAmir Hooshang Ghadymi MahaniNo ratings yet

- 100A Power Switching SolutionsDocument3 pages100A Power Switching SolutionsCésar Andrés Barrios ArroyoNo ratings yet

- NEOTHERM 70 EVO - 60V Manual - P1600 PDFDocument23 pagesNEOTHERM 70 EVO - 60V Manual - P1600 PDFm_armouti100% (1)

- Service Manual: LT-42EM91Document32 pagesService Manual: LT-42EM91Robert FilipNo ratings yet

- Midas Heritage 4000 ManualDocument78 pagesMidas Heritage 4000 ManualMaxReboNo ratings yet

- Quick Start Guide Rosemount 3095ma MV en 74230Document32 pagesQuick Start Guide Rosemount 3095ma MV en 74230aminebenyagoub0009No ratings yet

- C LineDocument16 pagesC LineSunil Kumar VishwakarmaNo ratings yet

- Midas Legend 3000 ManualDocument84 pagesMidas Legend 3000 ManualAleksandar MajorNo ratings yet

- Is WV450XDocument16 pagesIs WV450XLouie Angelo LaoNo ratings yet

- Sony kdl32 40 46 52 60-Ex700 Chassis Az1-LDocument76 pagesSony kdl32 40 46 52 60-Ex700 Chassis Az1-Ljordache81No ratings yet

- MKDocument21 pagesMKReuben JacobNo ratings yet

- ASCO Valve 8016gh Solenoid ImDocument6 pagesASCO Valve 8016gh Solenoid ImLeonardNo ratings yet

- MT506V46Install 060223 PDFDocument8 pagesMT506V46Install 060223 PDFHoa Lưu LyNo ratings yet

- O&M Manual For LSDocument17 pagesO&M Manual For LSdeepak2003100% (2)

- Telegatner Catalog Conectori RFDocument32 pagesTelegatner Catalog Conectori RFcodrelluNo ratings yet

- DVPPS01-02 Instruction TseDocument2 pagesDVPPS01-02 Instruction TseAndrés AracenaNo ratings yet

- Service Manual: Color Television ReceiverDocument42 pagesService Manual: Color Television ReceiverErnesto SuarezNo ratings yet

- J1939 Gateway™: Installation and Operation GuideDocument27 pagesJ1939 Gateway™: Installation and Operation GuideEmrol2No ratings yet

- TILT LEVEL CONTROL Installation Manual For New Model CT Control Units and Probes 0Document5 pagesTILT LEVEL CONTROL Installation Manual For New Model CT Control Units and Probes 0Guillermo CopedNo ratings yet

- Siemens 3TF Power Contactors GuideDocument21 pagesSiemens 3TF Power Contactors GuideShiva ShankarNo ratings yet

- Service Manual for DTV2784 Color TelevisionDocument30 pagesService Manual for DTV2784 Color TelevisionAldo Fernando Guerra SantanderNo ratings yet

- 3-2 Omc35191a Hub100 PDFDocument12 pages3-2 Omc35191a Hub100 PDFnachoborjasNo ratings yet

- DZB200M&JDocument41 pagesDZB200M&Jvijayrockz06No ratings yet

- Tro3964 Trolex Falcon Series Data Sheet Aw Pei FinalDocument16 pagesTro3964 Trolex Falcon Series Data Sheet Aw Pei FinalsourcNo ratings yet

- Service Manual: History Information For The Following ManualDocument56 pagesService Manual: History Information For The Following ManualMalanie Sriya De SilvaNo ratings yet

- Mtl700 Series: For Safe Measurement and Control in Hazardous AreasDocument11 pagesMtl700 Series: For Safe Measurement and Control in Hazardous AreasPrithviNo ratings yet

- 3M Terminales 3MDocument92 pages3M Terminales 3MEDGARPRADOCNo ratings yet

- PQSI Coil Lock Model 1003Document2 pagesPQSI Coil Lock Model 1003prabuNo ratings yet

- BMRX Series Rotary Level Control: Operating InstructionsDocument10 pagesBMRX Series Rotary Level Control: Operating Instructionstono notoNo ratings yet

- AM Series UserMan 651217400F 092214Document16 pagesAM Series UserMan 651217400F 092214darkschneider666No ratings yet

- DTV2760CDocument57 pagesDTV2760Cplasmapete100% (1)

- R8501G K1RangeDocument208 pagesR8501G K1RangeRinda_RaynaNo ratings yet

- Differential Pressure Transmitter Model 3051 Level SensorDocument6 pagesDifferential Pressure Transmitter Model 3051 Level Sensormltgb1No ratings yet

- Moxa Imc 101 Series Qig v9.3Document13 pagesMoxa Imc 101 Series Qig v9.3Stéphane SintesNo ratings yet

- TRLF Broschure Large eDocument4 pagesTRLF Broschure Large eJoseph TingNo ratings yet

- Instruction Manual: Model 7SL High/Low LimitrolDocument48 pagesInstruction Manual: Model 7SL High/Low LimitrolkmpoulosNo ratings yet

- MK CatalogDocument44 pagesMK CatalogKrishna KumarNo ratings yet

- User Guide and Technical Manual: Soundcraft Ddps-33 Ppower SsupplyDocument16 pagesUser Guide and Technical Manual: Soundcraft Ddps-33 Ppower SsupplyMalay K GhoshNo ratings yet

- Daewoo Dtq-20u9sc 21u9ss CsDocument10 pagesDaewoo Dtq-20u9sc 21u9ss CsgongussNo ratings yet

- Operating Manual: High Voltage Isolated Gate Driver Power SupplyDocument8 pagesOperating Manual: High Voltage Isolated Gate Driver Power SupplyHubert Maraza JaliriNo ratings yet

- Spectrum Analyzer: User ManualDocument40 pagesSpectrum Analyzer: User ManualBenjaminBaezNo ratings yet

- IPCR1510Document4 pagesIPCR1510E FaisalNo ratings yet

- SUN2000 - (20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL) - M3 Quick GuideDocument20 pagesSUN2000 - (20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL) - M3 Quick GuideNicolae-Robert StanNo ratings yet

- 16410-Swiches & CBDocument15 pages16410-Swiches & CBuddinnadeemNo ratings yet

- User Manual EG8245Q EG8247Q 4065149Document13 pagesUser Manual EG8245Q EG8247Q 4065149Claudio Carrasco NavarreteNo ratings yet

- Maintainability RatingDocument2 pagesMaintainability Ratingjr_satish6965No ratings yet

- The Total Economic Impact of PTC Vuforia - 2019Document26 pagesThe Total Economic Impact of PTC Vuforia - 2019jr_satish6965No ratings yet

- What Is NACE and NORSOK Renown Engineering LTDDocument2 pagesWhat Is NACE and NORSOK Renown Engineering LTDjr_satish6965No ratings yet

- ICS 23.060.01 J16 - Specification of Minimum Thickness of The Shell of Valves PDFDocument19 pagesICS 23.060.01 J16 - Specification of Minimum Thickness of The Shell of Valves PDFjr_satish6965No ratings yet

- Valve Leakage Rates Test STDDocument6 pagesValve Leakage Rates Test STDkangNo ratings yet

- API527 - Seat TightnessDocument4 pagesAPI527 - Seat Tightnessjr_satish6965No ratings yet

- PED GuideDocument25 pagesPED GuideqatarjourneyNo ratings yet

- Wear Rings Bearings Specs ResourcesDocument34 pagesWear Rings Bearings Specs Resourcesjr_satish6965No ratings yet

- 201404Document2 pages201404jr_satish6965No ratings yet

- Bolt Grade Cross RefDocument3 pagesBolt Grade Cross Refsamnm1971No ratings yet

- BucklingDocument6 pagesBucklingZiyad12No ratings yet

- ASME B16.5 - List of Material SpecificationDocument3 pagesASME B16.5 - List of Material Specificationjr_satish6965No ratings yet

- Fasteners GradeDocument4 pagesFasteners GradeGilbert PereiraNo ratings yet

- Drill Hole and Location ToleranceDocument2 pagesDrill Hole and Location Tolerancejr_satish6965No ratings yet

- Engineering Design Guideline Fluid Flow Two Phase Rev01webDocument18 pagesEngineering Design Guideline Fluid Flow Two Phase Rev01webjr_satish6965No ratings yet

- 1258977346Document16 pages1258977346jr_satish6965No ratings yet

- ASME B16.5 - List of Material SpecificationDocument3 pagesASME B16.5 - List of Material Specificationjr_satish6965No ratings yet

- Datasheet 2205 Code Plus Two Hpsa Imperial Outokumpu en AmericasDocument9 pagesDatasheet 2205 Code Plus Two Hpsa Imperial Outokumpu en Americasjr_satish6965No ratings yet

- Asme Specifications SA36 ToSA423Document4 pagesAsme Specifications SA36 ToSA423nadhabindhu0% (1)

- Multi Terminal DC SystemsDocument12 pagesMulti Terminal DC SystemsRohit YadavNo ratings yet

- Faktor Kepelbagaian - LatestDocument32 pagesFaktor Kepelbagaian - LatestIzham HakimiNo ratings yet

- MG J2 Wiring DiagramDocument1 pageMG J2 Wiring DiagramAdam ShneierNo ratings yet

- ErviceDocument103 pagesErviceHitesh PanigrahiNo ratings yet

- Training Report in A 132 KV SubstationDocument34 pagesTraining Report in A 132 KV SubstationSajid BashirNo ratings yet

- Acme Electric CatalogDocument244 pagesAcme Electric CatalogAnonymous v4akjrQxKNo ratings yet

- Electrical Spare ListDocument434 pagesElectrical Spare ListYogendra Kumar SahuNo ratings yet

- Checklist For Pre Commissioning of SmartelementDocument2 pagesChecklist For Pre Commissioning of SmartelementAbhishek ShuklaNo ratings yet

- Expt - No.2 (The Direct Current Motor, Part 2)Document6 pagesExpt - No.2 (The Direct Current Motor, Part 2)Danwilliam NabutilNo ratings yet

- WMS Supplementary Protectors provide overcurrent protectionDocument7 pagesWMS Supplementary Protectors provide overcurrent protectionWilfredo MolinaNo ratings yet

- mb6s GraetzDocument3 pagesmb6s GraetzRobert HerčekiNo ratings yet

- Bias Scout Kit: Inventory of PartsDocument8 pagesBias Scout Kit: Inventory of PartsCesar TorrellesNo ratings yet

- Training Report On 220/132KV SubstationDocument34 pagesTraining Report On 220/132KV SubstationVinay ChandelNo ratings yet

- Optimized Title for Low Voltage Power Circuit Breaker SpecificationDocument5 pagesOptimized Title for Low Voltage Power Circuit Breaker SpecificationJose HernandezNo ratings yet

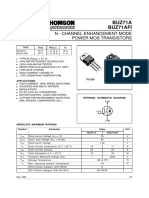

- Buz 71 ADocument8 pagesBuz 71 AChester NuroolNo ratings yet

- BP5151HCDocument2 pagesBP5151HCClear PassNo ratings yet

- Abb Price List PDFDocument128 pagesAbb Price List PDFWalter MenesesNo ratings yet

- K01160153 M0J143 1585490834 PDFDocument1 pageK01160153 M0J143 1585490834 PDFalifardsamiraNo ratings yet

- Soft Start of An Induction Motor Using DspaceDocument46 pagesSoft Start of An Induction Motor Using DspacedanNo ratings yet

- Diagrama de Ignitor BVS-006-ADocument1 pageDiagrama de Ignitor BVS-006-AHector Luis PalomoNo ratings yet

- DC Machines: AKHILESH KUMAR MISHRA Department of Electrical Engg. (UCER)Document52 pagesDC Machines: AKHILESH KUMAR MISHRA Department of Electrical Engg. (UCER)Akhilesh Kumar MishraNo ratings yet

- Degaussing Wand: Innovation in Magnetic Field Measuring InstrumentsDocument4 pagesDegaussing Wand: Innovation in Magnetic Field Measuring InstrumentsIVAYLO VASILEVNo ratings yet

- Overhaul Honda AlternatorDocument14 pagesOverhaul Honda Alternatorเพียร มานะNo ratings yet

- DSU Exercise PDFDocument5 pagesDSU Exercise PDFbangpaladinNo ratings yet

- Laptop Repair Complete Guide Including MotherboardDocument2 pagesLaptop Repair Complete Guide Including MotherboardOliver F ShankzNo ratings yet