Professional Documents

Culture Documents

Engine, Measuring Instruments & Safety Equipments: Technical Data

Uploaded by

ekichi_onizukaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine, Measuring Instruments & Safety Equipments: Technical Data

Uploaded by

ekichi_onizukaCopyright:

Available Formats

ENGINE, MEASURING INSTRUMENTS & SAFETY EQUIPMENTS

Since the aim of the present investigation was to study the effects on the performance of diesel engine by

using hydrogen as a fuel along with diesel, it was first necessary that a proper engine having required

accession was chosen.

TECHNICAL DATA:-

Description :- Vertical, Cold Start, Four Stroke Cycle, Compression Ignition, Water Cooled.

Diesel Engine.

Type:- UD1

No. of Cylinder:- One

Bore(mm):- 80

Stroke(mm):- 110

Cubic Capacity(c.c.):- 553

Output KW HP :- 3.67/5

Rated R.P.M :- 1500

Compression Ratio :- 16.5:1

Bumping Clearance 0.91mm to 1.05 (0.036” to 0.042”)

Fuel Injection release pressure:- 217 + 2% kg/cm2

Fuel Injection timing (by spill) :- 280 B.T.D.C

Fuel Oil- High Speed Diesel Oil

Fuel tank capacity :- 4.6 lit

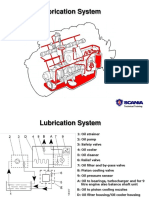

Lubricating oil:- SAE 30/40, HD 30/40

The pump has a rocker to prime the pump and cut-off the fuel to stop the engine. The fuel tank is

not mounted on the engine but it was hanged at a certain height near by. From that the fuel is

conveyed to the engine through a polyethylene pipe.

The separation of the fuel tank from the engine is due to the reason that it was more convenient

to measure the fuel consumption.

The valve timings of the engine are ensued below :-

Particulars Declared Values

a) Inlet Valve Opens (IVO) 03 to 10 Degree B.T.D.C.

b) Inlet Valve Closes (IVC) 30 to 40 Degree A.T.D.C.

c) Exhaust Valve Opens (EVO) 30 to 40 Degree B.B.D.C.

d) Exhaust Valve Closes (EVC) 03 to 10 Degree A.T.D.C

e) Fuel Injection

MEASURING DEVICES

DYNAMOMETER

Function : To load the diesel engine.

Type: Froude Hydraulic Dynamometer

Working: When in action the rotor discharges water at high speed from its periphery into the pockets

formed in the casing liners, by which it is then returned at diminished speed into the rotor pockets at a point

near the shaft.

The resistance offered by the water to the motion of the rotor reacts upon the casing, which

tends to turn on its anti-friction roller supports. The tendency is counteracted by means of a lever arm

terminating in a weighing device which measured the torque.

MEASUREMENT OF OUTPUT AND SPEED

The instrument indicates the output (bhp).

The engine under test condition is coupled to a dynamometer through a mechanical coupling at the

input of the dynamometer. The output shaft of the dynamometer is locked to a suitable capacity of load cell

(here 20 kg). The engine torque is applied to dynamometer through the coupling. The output torque is

applied through dynamometer to load cell and its instrument.

The output of the engine is obtained by the formula WN

2000

Speed is one of the basic measurements. A wide variety of speed measuring equipments are available in the

market. They range from mechanical tachometers to digital and triggered electrical tachometers.

Here, we have measured the speed with the help of contact type digital tachometer. The tachometer is

brought in contact with the rotating shaft and is kept in contact until a constant value is displayed on the

screen. This constant value indicates the rotations per minute of the engine.

FUEL CONSUMPTION MEASUREMENT

The fuel consumption of an engine is measured by determining the volume flow in a given time interval

and multiplying it with the specific gravity of fuel, which should be measured occasionally to get an

accurate reading. Another method is to measure the time read for consumption of a given mass of fuel.

In our testing, we have used burette method. The burette method is placed between the engine and the main

fuel tank through cocks where one is supplying the fuel to the burette and other to the engine. The time

taken for 50c.c fuel is measured by closing down the burette supplying cock and opening the cock which

supplies the fuel to the engine. Thus we allow the fuel to fall down upto the mark provided for 50c.c.

The time for 50c.c. fuel consumption is noted and fuel consumption rate can be calculated by the

following formula

Fuel Consumption (Kg/hr) = 50 x 3600 x specific gravity

Time in Seconds x 1000

AIR FLOW MEASUREMENT

For air measurement we have used an air tight drum fitted with orifice of known co-efficient of discharge.

Due to suction of engine, there is a pressure difference in the drum which causes the flow through orifice

for obtaining a steady flow. The volume of drum is sufficiently large as compared to the swept volume of

the cylinder. The pressure difference causing the air flow through orifice is measured with the help of

inclined tube manometer and then using the formula, air consumption rate is calculated.

INDICATED POWER AND FRICTION POWER

We have measured friction power by using the William’s line method. In this method, gross fuel

consumption v/s B.P. at a constant speed is plotted and then the graph is extrapolated back to zero fuel

consumption. The point where graph cuts the B.P. axis is an indication of the friction power at that speed.

This negative work represents the combined loss due to mechanical friction, pumping and blow by.

Indicated power cab be obtained by the formula –

I.P. = B.P. + F.P.

You might also like

- JCB 8017 Parts BookDocument216 pagesJCB 8017 Parts Bookjdgiaco100% (16)

- 10M134 AIC Assignment 1 & 2 PDFDocument14 pages10M134 AIC Assignment 1 & 2 PDFChandannnn92No ratings yet

- IC Engine Lab ReportDocument7 pagesIC Engine Lab ReportnewUserNo ratings yet

- Tuning Ing 06Document39 pagesTuning Ing 06sasubmariner71% (7)

- Ex.9 - Determination of Air Fuel Ratio & Volumetric Efficency With Variable Compression Ratio On 4Document7 pagesEx.9 - Determination of Air Fuel Ratio & Volumetric Efficency With Variable Compression Ratio On 4manojkhadka23No ratings yet

- Trial On Reciprocating.Document12 pagesTrial On Reciprocating.zen tenNo ratings yet

- Load Test On Single Cylinder 4s Diesel EngineDocument8 pagesLoad Test On Single Cylinder 4s Diesel EngineMathew JohnNo ratings yet

- Engine Testing TechniqueDocument8 pagesEngine Testing TechniqueNur YakhinNo ratings yet

- DYNAMOMETERS AND VALVE TIMING DIAGRAMSDocument83 pagesDYNAMOMETERS AND VALVE TIMING DIAGRAMSERKATHIRNo ratings yet

- Measure Engine Performance and Calculate Key ParametersDocument28 pagesMeasure Engine Performance and Calculate Key ParametersbroNo ratings yet

- Analysis and Experimental Research On The Influence of VVT Point Selection On Exhaust Temperature in Low Speed Operating ConditionsDocument8 pagesAnalysis and Experimental Research On The Influence of VVT Point Selection On Exhaust Temperature in Low Speed Operating Conditionsrosca raulNo ratings yet

- VCR EngineDocument6 pagesVCR EngineAbNo ratings yet

- Variable Compression Ratio ExperimentDocument7 pagesVariable Compression Ratio ExperimentMuruganNo ratings yet

- Expt. 2A - 4-Stroke Diesel Engine-Without DataDocument6 pagesExpt. 2A - 4-Stroke Diesel Engine-Without DataZen RuNo ratings yet

- Four-Stroke Engine Performance TestsDocument8 pagesFour-Stroke Engine Performance Testshassaan qayyumNo ratings yet

- SI Engine Performance TestDocument10 pagesSI Engine Performance TestGorilla GrooveNo ratings yet

- Lab ManualDocument31 pagesLab ManualSamuthra P TNo ratings yet

- IC Engine Lab ManualDocument11 pagesIC Engine Lab ManualVyankat Dev Singh100% (1)

- Methods of Improving Engine Performance and EfficiencyDocument34 pagesMethods of Improving Engine Performance and EfficiencyDavid ChikuseNo ratings yet

- Le:Trial On Diesel Engine To Determine Variable: Load Performance and Energy BalanceDocument3 pagesLe:Trial On Diesel Engine To Determine Variable: Load Performance and Energy BalanceKhaire SushomNo ratings yet

- Diesel EnginesDocument15 pagesDiesel EnginesDivyansh kaushalNo ratings yet

- Experimental Test Rig Development and MethodologyDocument16 pagesExperimental Test Rig Development and MethodologyKonem SolutionsNo ratings yet

- 2-S Petrol EngineDocument5 pages2-S Petrol EngineAbNo ratings yet

- Experimental setup for diesel engine emissions testingDocument10 pagesExperimental setup for diesel engine emissions testingprasaad08No ratings yet

- Internal Combustion Engine Performance Testing MAE 408Document19 pagesInternal Combustion Engine Performance Testing MAE 408Tim WongNo ratings yet

- Unit 2 AMU Ic EnginesDocument43 pagesUnit 2 AMU Ic Enginesoliyad teferiNo ratings yet

- Lab Session # 2 Objective: To Draw The Valve Timing Diagram of Matchless Diesel EngineDocument6 pagesLab Session # 2 Objective: To Draw The Valve Timing Diagram of Matchless Diesel EngineHassanNo ratings yet

- Acceleration Test Method For A High Performance Two-Stroke Racing EngineDocument10 pagesAcceleration Test Method For A High Performance Two-Stroke Racing EngineFull ThrottleNo ratings yet

- MITE Energy Conversion Lab ManualDocument44 pagesMITE Energy Conversion Lab ManualSubuddhi DamodarNo ratings yet

- AMST1Document23 pagesAMST1gursagarvirdi1gmailcomNo ratings yet

- PPD Week 5.1 LectureDocument28 pagesPPD Week 5.1 LectureMaster CalculusNo ratings yet

- Performance of Internal Combustion EngineDocument45 pagesPerformance of Internal Combustion EngineAnurag BansalNo ratings yet

- Thermal Lab 2nd CycleDocument61 pagesThermal Lab 2nd Cycle019AJAY KRISHNA PNo ratings yet

- Presentation On Ic Engine Testing AnsDocument31 pagesPresentation On Ic Engine Testing AnsAshutoshNo ratings yet

- EXPERIMENT NO 3 Willan's LineDocument3 pagesEXPERIMENT NO 3 Willan's LineMohamad Ahmad100% (1)

- Need of Variable Valve ActuationDocument5 pagesNeed of Variable Valve Actuationjayendrakashyap01No ratings yet

- Dyno BlairDocument10 pagesDyno BlairAntonino ScordatoNo ratings yet

- MEE2003 Thermal Engineering Systems Lab Test QuestionsDocument4 pagesMEE2003 Thermal Engineering Systems Lab Test QuestionsKartik ChaturvediNo ratings yet

- Project Report TE LabDocument7 pagesProject Report TE LabRadhika GurjarNo ratings yet

- System and engine instruments ATPLDocument47 pagesSystem and engine instruments ATPLUlises HernandezNo ratings yet

- Automotive Vehicles: CarburetionDocument39 pagesAutomotive Vehicles: CarburetionVinodDahiya100% (1)

- Instruction Manual For 4 Stroke, 4 Cylinder, Mpfi Petrol Engine Test RIGDocument47 pagesInstruction Manual For 4 Stroke, 4 Cylinder, Mpfi Petrol Engine Test RIGAbhishek ShuklaNo ratings yet

- Kumaran 3Document4 pagesKumaran 3HANUMANT MORENo ratings yet

- Me 2301 - Thermal EngineeringDocument10 pagesMe 2301 - Thermal EngineeringsrajapratyNo ratings yet

- Determination of Performance Characteristics of Four Stroke Diesel Engine - Rev1Document12 pagesDetermination of Performance Characteristics of Four Stroke Diesel Engine - Rev1higaneshkumar32No ratings yet

- Exp 4 IC PrintedDocument5 pagesExp 4 IC PrintedDipendra TiwariNo ratings yet

- Engine Performance HandoutDocument17 pagesEngine Performance HandoutAbdallah Irfaan RamjanNo ratings yet

- Heat Engines VolDocument29 pagesHeat Engines VolEric CookNo ratings yet

- Supply Pump Internal Fuel FlowDocument7 pagesSupply Pump Internal Fuel FlowErlis SaputraNo ratings yet

- Improvement of Wankel Engine Performance at High Altitudes: L. Tartakovsky, V. Baibikov, M. VeinblatDocument23 pagesImprovement of Wankel Engine Performance at High Altitudes: L. Tartakovsky, V. Baibikov, M. VeinblatjavadjjjNo ratings yet

- 3-Torque and Power Output and Engine EfficiencyDocument18 pages3-Torque and Power Output and Engine EfficiencyAHMADNo ratings yet

- The IC Engine Criterion's, Lecture 3, IC Engine, (Week 7)Document19 pagesThe IC Engine Criterion's, Lecture 3, IC Engine, (Week 7)Shakeel MohmandNo ratings yet

- Anurag Porte - IC Engines Lab Report: Lab-1: Performance Measurement of The EngineDocument11 pagesAnurag Porte - IC Engines Lab Report: Lab-1: Performance Measurement of The EngineAnurag porteNo ratings yet

- ASA Prepware: Powerplant Engine Systems ReviewDocument11 pagesASA Prepware: Powerplant Engine Systems ReviewRami AliNo ratings yet

- Engine Performance Testing ParametersDocument39 pagesEngine Performance Testing ParametersashaNo ratings yet

- Lab ReportDocument9 pagesLab ReportAyaz BhattiNo ratings yet

- Velammal Engineering College Lab ManualDocument27 pagesVelammal Engineering College Lab ManualRanjit Rajendran100% (1)

- Performance of a Gasoline Engine at Partial LoadDocument5 pagesPerformance of a Gasoline Engine at Partial LoadGritz Kay Labucay MarforiNo ratings yet

- MORSE TEST ON 4 Cylinders Petrol EngineDocument22 pagesMORSE TEST ON 4 Cylinders Petrol EngineNavneet KumarNo ratings yet

- Turbocharger Matching For Two Cylinder Constant Speed Diesel Engine With Uneven Firing OrderDocument8 pagesTurbocharger Matching For Two Cylinder Constant Speed Diesel Engine With Uneven Firing OrderTJPRC PublicationsNo ratings yet

- Some Tips Using Adobe Illustrator v. 9.0: by John D. WinterDocument4 pagesSome Tips Using Adobe Illustrator v. 9.0: by John D. Winterekichi_onizuka100% (1)

- Tips To Go Green at WorkDocument2 pagesTips To Go Green at Workekichi_onizuka100% (1)

- Linux Vs WindowsDocument22 pagesLinux Vs Windowsekichi_onizuka100% (1)

- The Main Cause of Poverty or Financial Struggle Is Fear andDocument5 pagesThe Main Cause of Poverty or Financial Struggle Is Fear andekichi_onizukaNo ratings yet

- Matlab TutorialDocument6 pagesMatlab Tutorialekichi_onizuka100% (3)

- Firstly... What Is UML?: Software DevelopmentDocument12 pagesFirstly... What Is UML?: Software Developmentekichi_onizukaNo ratings yet

- 50 Tips For Fightinh ChanceDocument5 pages50 Tips For Fightinh Chanceekichi_onizukaNo ratings yet

- Why Dreams Are Forgotton Ater WakingDocument2 pagesWhy Dreams Are Forgotton Ater Wakingekichi_onizukaNo ratings yet

- Air PropertiesDocument2 pagesAir Propertiesekichi_onizukaNo ratings yet

- ROTAMETERDocument1 pageROTAMETERekichi_onizukaNo ratings yet

- Hydrogen As Future FuelDocument3 pagesHydrogen As Future Fuelekichi_onizuka83% (6)

- Fast Fourier TransformsDocument17 pagesFast Fourier Transformsekichi_onizuka100% (1)

- Alternative Fuels For AutomobilesDocument7 pagesAlternative Fuels For Automobilesekichi_onizukaNo ratings yet

- Layout of Nuclear Power PlantDocument6 pagesLayout of Nuclear Power Plantekichi_onizuka67% (3)

- Brake Binding PreventionDocument40 pagesBrake Binding Preventionkr_abhijeet72356587100% (9)

- Suzuki SX4 - BrochureDocument16 pagesSuzuki SX4 - Brochurerazvan_matei100% (2)

- TM 9-2330-334-13P M1147 FMTV-LHST Trailer Part 8Document82 pagesTM 9-2330-334-13P M1147 FMTV-LHST Trailer Part 8AdvocateNo ratings yet

- Tecnical Data TYPE 139 L12R / L16RDocument1 pageTecnical Data TYPE 139 L12R / L16RLada LabusNo ratings yet

- Comparision of EmissionDocument13 pagesComparision of Emissionmyungkwan haNo ratings yet

- 2005 Audi A4 Quattro TRANSMISSION Continuously Variable Transmission (CVT) 01JDocument784 pages2005 Audi A4 Quattro TRANSMISSION Continuously Variable Transmission (CVT) 01JNP67% (3)

- Tailift 7L Series Electric Forklift Parts ManualDocument100 pagesTailift 7L Series Electric Forklift Parts ManualRoberto ManginiNo ratings yet

- Reachstacker Performance & SpecsDocument8 pagesReachstacker Performance & SpecsHugo Julian Sanchez MayorgaNo ratings yet

- Crankshaft Failures - Caterpillar Engines TroubleshootingDocument9 pagesCrankshaft Failures - Caterpillar Engines TroubleshootingAmeerNo ratings yet

- Workshop Manual Audi A6 C6Document198 pagesWorkshop Manual Audi A6 C6Alvaro Abajo100% (1)

- Catalogo MillardDocument152 pagesCatalogo MillardJhonny Hernán Angamarca AguilarNo ratings yet

- Report On Vacuum Braking SystemDocument16 pagesReport On Vacuum Braking SystemPramod Sharma P67% (3)

- Scavanging and TurbochargingDocument38 pagesScavanging and TurbochargingMeghanath AdkonkarNo ratings yet

- John Deere 524KDocument2 pagesJohn Deere 524KMMM-MMMNo ratings yet

- C232 Gen2 Ford 2 - 5L SM 1044 170220Document614 pagesC232 Gen2 Ford 2 - 5L SM 1044 170220XrosHunter DMO100% (1)

- Lubrikasi OliDocument18 pagesLubrikasi OliDeni SetiawanNo ratings yet

- R15 B3B1 - 2017 (1tb3b460e1)Document51 pagesR15 B3B1 - 2017 (1tb3b460e1)Alexander LautanNo ratings yet

- OMEGAS 2.16.4 manualDocument5 pagesOMEGAS 2.16.4 manualFrank FrankNo ratings yet

- Desarme Scorpio 2.5 2009Document162 pagesDesarme Scorpio 2.5 2009Luis Alarcón100% (1)

- BIGFOOT B 5440 Serial No 193200 To Present 2013 PresentDocument130 pagesBIGFOOT B 5440 Serial No 193200 To Present 2013 PresentbaboNo ratings yet

- Keyless Entry System: Wiring Diagram of The Main UnitDocument1 pageKeyless Entry System: Wiring Diagram of The Main UnithamayunNo ratings yet

- Man B&W WarningDocument284 pagesMan B&W WarningMarcin SrokaNo ratings yet

- Powerkit Engine 6M21 Series: General SpecificationsDocument2 pagesPowerkit Engine 6M21 Series: General SpecificationsstorkbNo ratings yet

- Installation Recommendations For Timing Systems On GM1 (1) .4 1Document2 pagesInstallation Recommendations For Timing Systems On GM1 (1) .4 1DNo ratings yet

- CarbsDocument4 pagesCarbs306jordanNo ratings yet

- S6D140E-2B-6 Cylinder Head Parts ListDocument2 pagesS6D140E-2B-6 Cylinder Head Parts ListUhanto Baik100% (1)