Professional Documents

Culture Documents

Rub Test Method 115A

Uploaded by

Nisa_nisheCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rub Test Method 115A

Uploaded by

Nisa_nisheCopyright:

Available Formats

Whitford Corporation, Box 80, Elverson, PA 19520, USA

Telephone (610) 286-3500 Fax (610) 286-3510 Email: sales@whitfordww.com

WHITFORD TEST METHOD 115A

EVALUATION OF COMPLETENESS OF CURE BY SOLVENT

RUB TEST

1.

Scope:

This procedure is to be used to determine the degree of cure of a cured film by the

paint film's resistance to a specified solvent.

2.

Equipment and Materials:

2.1

Cheesecloth mesh size 28x24, but other mutually agreed upon cloth may be

used.

2.2

Test panel at least 5 inches [12.5 cm] long by 3 inches [7.5 cm] wide or other

object to be tested.

2.3

Solvent - to be mutually agreed on between seller and purchaser. Typically

the following solvents may be used:

2.3.1

2.3.2

2.3.3

2.3.4

2.4

3.

Methyl ethyl ketone (MEK)

Xylene

Methoxy Propyl Acetate (PMA)

Toluene specifically for rubber coatings

Suitable solvent resistant gloves.

Procedure:

3.1

Wrap two thicknesses of cloth around the index finger and immerse in

specified solvent. Immediately begin rubbing the test panel in a back and

forth motion in a straight line with a stroke at least three inches [8 cm] long

using moderate to heavy pressure. Approximate weight of pressure should

be between 2000 and 2500 grams. Rub at a rate of approximately 100

double rubs per minute. The rubs are counted (one forward and one

backward to be counted as one double rub) and continued until failure of the

film or until the required number of double rubs is reached.

NON-WARRANTY - The information presented in this publication is based upon the research and experience of Whitford. No

representation or warranty is made, however, concerning the accuracy or completeness of the information presented in this publication.

Whitford makes no warranty or representation of any kind, express or implied, including without limitation any warranty of

merchantability or fitness for any particular purpose, and no warranty or representation shall be implied by law or otherwise. Any

products sold by Whitford are not warranted as suitable for any particular purpose to the buyer. The suitability of any products for any

purpose particular to the buyer is for the buyer to determine. Whitford assumes no responsibility for the selection of products suitable to

the particular purposes of any particular buyer. Whitford shall in no event be liable for any special, incidental, or consequential

damages.

Whitford Test Method:

Page:

2 of 3

4.

5.

6.

115A

Evaluation:

4.1

The coating must withstand the required number of rubs. Record the

number of rubs to pass the specification or to failure.

4.2

Failure shall consist of removal of the film to expose the substrate at any

spot along the centre of the stroke.

4.3

Duplicate the test to confirm results.

Comments/Precautions:

5.1

Voids, scratches, dirt and dust on the test panel, solid particles on the cloth

or in the solvent or an irregular surface under the paint film can seriously

affect the test results.

5.2

Film thickness should be carefully controlled to ensure reproducibility.

5.3

The cloth must be kept constantly wet while rubbing. If the cloth dries,

quickly immerse in solvent and continue rubbing.

5.4

This test may be used to evaluate cure on an object, which does not have a

smooth, flat surface. In this case, select the flattest and smoothest area for

the test, and rub this area as consistently as possible.

5.5

To protect skin from solvents, wear a rubber glove when performing this test.

References

NCCA Technical Bulletin No. II-18

Detailed Procedure: 3115A

Date Issued:

30 Dec. 2003

Issue:

USA Issued by:

Europe Issued by:

USA Checked by:

Europe Checked by:

8

M. W. Miller

J. Gascoyne

H. C. Wilson

Whitford Test Method:

Page:

3 of 3

Appendix

115A

115A

Examples of Pass and Fail Results

Full Pass

Minimum Pass

Failure

You might also like

- Determining Abrasion Resistance of Inks and Coatings On Substrates Using Dry or Wet Abrasive MediumDocument3 pagesDetermining Abrasion Resistance of Inks and Coatings On Substrates Using Dry or Wet Abrasive MediumwerrteNo ratings yet

- ASTM D 714 - 87 r00Document6 pagesASTM D 714 - 87 r00Abi PutraNo ratings yet

- 11.03 Iso-6272-1-2011Document9 pages11.03 Iso-6272-1-2011hoanvuNo ratings yet

- Resistance To Fuels of Exteriors Automotive Materials and ComponentsDocument6 pagesResistance To Fuels of Exteriors Automotive Materials and ComponentsAnvarbek KarimovNo ratings yet

- Paints and Varnishes Pull-Off For Adhesion: First EditionDocument9 pagesPaints and Varnishes Pull-Off For Adhesion: First EditionmirzazubairNo ratings yet

- BS Iso 00048-9-2018Document30 pagesBS Iso 00048-9-2018Samwel TarimoNo ratings yet

- Worldwide Engineering Standards: Stone Impact Resistance of CoatingsDocument3 pagesWorldwide Engineering Standards: Stone Impact Resistance of CoatingsAnvarbek KarimovNo ratings yet

- Araldite Epoxy Adhesive - 2Document4 pagesAraldite Epoxy Adhesive - 2SatyamEngNo ratings yet

- Pds Hempel's Urethane 5595u En-UsDocument2 pagesPds Hempel's Urethane 5595u En-UsFreddy Carl FredricksenNo ratings yet

- TM0172 2015 Determining CorrosiveDocument16 pagesTM0172 2015 Determining Corrosiveahmed sobhyNo ratings yet

- AerFilmLHRHVA ApplicationDocument4 pagesAerFilmLHRHVA ApplicationAleksandr Tsymbal100% (1)

- F 1319 - 94 R00 - RjezmtkDocument4 pagesF 1319 - 94 R00 - RjezmtkshamrajjNo ratings yet

- AS 3894-5 Method 5 Surface-ProfileDocument6 pagesAS 3894-5 Method 5 Surface-Profilejonathan nachiroNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data Sheetajuhaseen100% (1)

- Setup Guide No 4 Weld Inspection WeldcheckDocument7 pagesSetup Guide No 4 Weld Inspection WeldcheckcarlosNo ratings yet

- Astm E96-96m 2014Document13 pagesAstm E96-96m 2014tsalemnoushNo ratings yet

- POLYPOXY-NF Technical Data SheetDocument2 pagesPOLYPOXY-NF Technical Data SheetCommando crawlerNo ratings yet

- Ascott Manual S Ip RangeDocument80 pagesAscott Manual S Ip Rangejeremias100% (1)

- ISO 8510-2 - Adhesives Peel Test For A Flexible-Bonded-To-Rigid Test Specimen Assembly 180° Peel 12-1-2006Document12 pagesISO 8510-2 - Adhesives Peel Test For A Flexible-Bonded-To-Rigid Test Specimen Assembly 180° Peel 12-1-2006axeldanyNo ratings yet

- Quality HandbookDocument8 pagesQuality HandbookGuillermo Guerrero VacasNo ratings yet

- Iso 14577 1 2002 FR en PDFDocument11 pagesIso 14577 1 2002 FR en PDFPaulo Jorge100% (1)

- MIL-PRF-23377 Rev. KDocument19 pagesMIL-PRF-23377 Rev. KRoban BieberNo ratings yet

- Astm g21 g22Document7 pagesAstm g21 g22ENZO CORSI0% (1)

- Is StandardDocument2 pagesIs Standardவிக்னேஷ் வரன்No ratings yet

- Data Sheet Proguard CN 200 A.SDocument3 pagesData Sheet Proguard CN 200 A.SAlexir Thatayaone NdovieNo ratings yet

- Certificate of Analysis: National Institute of Standards & TechnologyDocument3 pagesCertificate of Analysis: National Institute of Standards & Technologylehdruk7100No ratings yet

- As NZS 1580.481.1.10-1998 Paints and Related Materials - Methods of Test Coatings - Exposed To Weathering - DDocument2 pagesAs NZS 1580.481.1.10-1998 Paints and Related Materials - Methods of Test Coatings - Exposed To Weathering - DSAI Global - APAC100% (1)

- Astm d5682Document4 pagesAstm d5682Ernesto Morales100% (1)

- UL 2818 Certification-Greenguard 2017Document16 pagesUL 2818 Certification-Greenguard 2017brpereira100% (1)

- Iso 3005Document4 pagesIso 3005Pedro Perez La RosaNo ratings yet

- Bsi BS Iso 11359-1 - 2014Document14 pagesBsi BS Iso 11359-1 - 2014alferedNo ratings yet

- Iso 527Document3 pagesIso 527Vo Truong GiangNo ratings yet

- Gloss MeterDocument2 pagesGloss Meterravi00098No ratings yet

- D358 PDFDocument3 pagesD358 PDFChandraditya Iman FirmanshaNo ratings yet

- DC 781 Acetoxy SealantDocument3 pagesDC 781 Acetoxy SealantL.S.No ratings yet

- D 333 - 96Document6 pagesD 333 - 96PoyoeberNo ratings yet

- Polythionic Acid Stress Corrosion CrackingDocument3 pagesPolythionic Acid Stress Corrosion Crackingvajidqc100% (1)

- TCXDVN 269-2002 Coc - Phuong Phap Thi Nghiem Hien TruongDocument19 pagesTCXDVN 269-2002 Coc - Phuong Phap Thi Nghiem Hien Truongnadung01No ratings yet

- Cathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsDocument5 pagesCathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsMaryana c100% (1)

- SoniCell ASTM E85 Fire TestDocument10 pagesSoniCell ASTM E85 Fire TestAvs CrNo ratings yet

- ASTM-3574-11 Flexible Cellular Materials-Slab, Bonded, and Molded Urethane FoamDocument29 pagesASTM-3574-11 Flexible Cellular Materials-Slab, Bonded, and Molded Urethane FoamheobukonNo ratings yet

- 16 CFR 1500.44Document2 pages16 CFR 1500.44Milagros WieczorekNo ratings yet

- Fenomastic Hygiene Emulsion SilkDocument4 pagesFenomastic Hygiene Emulsion Silkمحمد عزتNo ratings yet

- Surface Vehicle StandardDocument5 pagesSurface Vehicle StandardanupthattaNo ratings yet

- BS en Iso 08624-2011Document18 pagesBS en Iso 08624-2011Guillermo VegaNo ratings yet

- NACE SP0188-2024 Discontinuity (Holiday) Testing of New Protective Coatings On Conductive SubstratesDocument17 pagesNACE SP0188-2024 Discontinuity (Holiday) Testing of New Protective Coatings On Conductive Substratesahugandkiss77071100% (1)

- C776-06 (2011) Standard Specification For Sintered Uranium Dioxide PelletsDocument4 pagesC776-06 (2011) Standard Specification For Sintered Uranium Dioxide PelletsAndré BerninzonNo ratings yet

- Slydring GB PDFDocument70 pagesSlydring GB PDFBruno BrepohlNo ratings yet

- Kevlar Cut Protection TestingDocument6 pagesKevlar Cut Protection Testingalvares90No ratings yet

- M008E IM Eng V3.2Document34 pagesM008E IM Eng V3.2Ganjar Septian100% (1)

- Iso 2578 1974Document8 pagesIso 2578 1974Phi PTNo ratings yet

- Shaft ConnectionsDocument6 pagesShaft ConnectionsDr_M_SolimanNo ratings yet

- Astm F21-20Document7 pagesAstm F21-20hashem Al-NasserNo ratings yet

- Abrasion TaberDocument2 pagesAbrasion TaberDiego Fernado AvendañoNo ratings yet

- Gujarat Water Supply and Sewerage Board (GWSSB) Sector 10, GandhinagarDocument25 pagesGujarat Water Supply and Sewerage Board (GWSSB) Sector 10, GandhinagarMehta MalayNo ratings yet

- GMW14698 ArranhõesDocument7 pagesGMW14698 ArranhõesRicardo F. SNo ratings yet

- International Standard: ISO 105-X12Document10 pagesInternational Standard: ISO 105-X12Tahir NizamNo ratings yet

- 2019 Whiteford NS Test Method TM 135GDocument3 pages2019 Whiteford NS Test Method TM 135GSYED MAZHARNo ratings yet

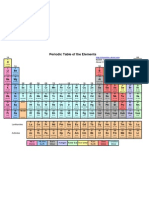

- Periodic Table All ColorDocument1 pagePeriodic Table All ColorcingggggggggggNo ratings yet

- Periodic Table All ColorDocument1 pagePeriodic Table All ColorcingggggggggggNo ratings yet

- Periodic Table All ColorDocument1 pagePeriodic Table All ColorcingggggggggggNo ratings yet

- Molybdenum Disulphide Data SheetDocument2 pagesMolybdenum Disulphide Data SheetNisa_nisheNo ratings yet

- 1052 and 1070 Color ChartDocument2 pages1052 and 1070 Color ChartNisa_nisheNo ratings yet

- Duplex Stainless BrochureDocument20 pagesDuplex Stainless BrochureFelipe ArceNo ratings yet

- 1021 Brochure - Operating TemperatureDocument4 pages1021 Brochure - Operating TemperatureNisa_nisheNo ratings yet

- Iso 7380Document1 pageIso 7380Nisa_nisheNo ratings yet

- Tommy Bar Holes DimensionsDocument1 pageTommy Bar Holes DimensionsaezeadNo ratings yet

- WHITFORD CatalogueDocument6 pagesWHITFORD CatalogueNisa_nisheNo ratings yet

- English Through TamilDocument90 pagesEnglish Through TamilKhalifullah100% (1)

- English Through TamilDocument90 pagesEnglish Through TamilKhalifullah100% (1)

- XYLAR HandlingDocument2 pagesXYLAR HandlingNisa_nisheNo ratings yet

- Whitford Engineering Design GuideDocument44 pagesWhitford Engineering Design GuideNisa_nisheNo ratings yet

- Staffing Management PlanDocument8 pagesStaffing Management PlanNisa_nisheNo ratings yet

- Bolt CapacityDocument2 pagesBolt CapacityMoonzeNo ratings yet

- Fastenal Product Standard: FNL - FHN.SS: Finished Hex Nuts, Stainless SteelDocument1 pageFastenal Product Standard: FNL - FHN.SS: Finished Hex Nuts, Stainless SteelNisa_nisheNo ratings yet

- Astm A36-A36m-2004 PDFDocument4 pagesAstm A36-A36m-2004 PDFmsalinasaguilarNo ratings yet

- Cotter Pin, Stainless Steel: Page 1 of 1 REV-02 Date: November 7, 2010 Pin - Cot.SsDocument1 pageCotter Pin, Stainless Steel: Page 1 of 1 REV-02 Date: November 7, 2010 Pin - Cot.SsNisa_nisheNo ratings yet

- Super Duplex Stainless SteelDocument3 pagesSuper Duplex Stainless SteelNisa_nisheNo ratings yet

- Astm A36-A36m-2004 PDFDocument4 pagesAstm A36-A36m-2004 PDFmsalinasaguilarNo ratings yet

- Measurement Advisory Committee Summary - Attachment 3Document70 pagesMeasurement Advisory Committee Summary - Attachment 3MauricioICQNo ratings yet

- Astm A29Document22 pagesAstm A29Brad BorgesNo ratings yet

- A 193 - 04bDocument12 pagesA 193 - 04bNisa_nisheNo ratings yet

- Spec 4140 & 4130Document7 pagesSpec 4140 & 4130Nisa_nisheNo ratings yet

- BOLTS (New Section) 972Document6 pagesBOLTS (New Section) 972Nisa_nisheNo ratings yet

- Electric Vehicle in IndonesiaDocument49 pagesElectric Vehicle in IndonesiaGabriella Devina Tirta100% (1)

- 6 Instrumentation PDFDocument144 pages6 Instrumentation PDFWanderley MandruzatoNo ratings yet

- Healing and Keeping Prayer (2013)Document2 pagesHealing and Keeping Prayer (2013)Kylie DanielsNo ratings yet

- Soal Uh English XDocument1 pageSoal Uh English XhenniherawatiNo ratings yet

- Ejercicio 1 Curso BRBDocument2 pagesEjercicio 1 Curso BRBAlex MolinaNo ratings yet

- Single Conductor 15KV, Shielded, MV-105Document2 pagesSingle Conductor 15KV, Shielded, MV-105henry hernandezNo ratings yet

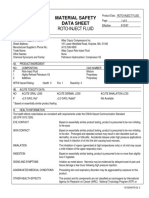

- Material Safety Data Sheet Roto-Inject FluidDocument5 pagesMaterial Safety Data Sheet Roto-Inject FluidQuintana JoseNo ratings yet

- OGJ Worldwide Refining Survey 2010Document67 pagesOGJ Worldwide Refining Survey 2010Zahra GhNo ratings yet

- 9 SolutionsDocument31 pages9 SolutionsLaurertan TavaresNo ratings yet

- Scooty PepDocument1 pageScooty PepYASHNo ratings yet

- Equipment Available From SJ Turbine Inc.: LM Package Parts LM Package Parts High VoltageDocument59 pagesEquipment Available From SJ Turbine Inc.: LM Package Parts LM Package Parts High VoltageAnibal QuezadaNo ratings yet

- Jurnal Kasus Etikolegal Dalam Praktik KebidananDocument13 pagesJurnal Kasus Etikolegal Dalam Praktik KebidananErni AnggieNo ratings yet

- Eastman Methyl N-Amyl Ketone (MAK) and Eastman Methyl Isoamyl Ketone (MIAK)Document4 pagesEastman Methyl N-Amyl Ketone (MAK) and Eastman Methyl Isoamyl Ketone (MIAK)Chemtools Chemtools100% (1)

- The Room - SartreDocument14 pagesThe Room - SartreYue Biohazard100% (1)

- Fourier Ptychography Stivi ElbiDocument20 pagesFourier Ptychography Stivi ElbistiviNo ratings yet

- History of Crime and Criminal Justice in America EditedDocument7 pagesHistory of Crime and Criminal Justice in America EditedcarolineNo ratings yet

- Outback MenuDocument2 pagesOutback MenuzeeNo ratings yet

- Zook Rupture Disc URADocument2 pagesZook Rupture Disc URAmd_taheriNo ratings yet

- Guest-302344325-Quantitative Process AnalysisDocument4 pagesGuest-302344325-Quantitative Process AnalysisAhmedNo ratings yet

- Thyroid OphthalmopathyDocument59 pagesThyroid OphthalmopathyLavanya MadabushiNo ratings yet

- 8-Critical Appraisal of An ArticleDocument20 pages8-Critical Appraisal of An ArticleMohmmed Abu MahadyNo ratings yet

- AcuityPDR BrochureDocument3 pagesAcuityPDR BrochureJulian HutabaratNo ratings yet

- What Is A Walkable Place The Walkability Debate inDocument20 pagesWhat Is A Walkable Place The Walkability Debate inBADR HAMDAN ALATEBENo ratings yet

- Leadership 29Document32 pagesLeadership 29Efe AgbozeroNo ratings yet

- PNOZ E1vp EN-23-27Document5 pagesPNOZ E1vp EN-23-27Rachid MoussaouiNo ratings yet

- Material SelfDocument9 pagesMaterial Selfic perlasNo ratings yet

- Liquid Fertilizer PresentationDocument17 pagesLiquid Fertilizer PresentationAnna RothNo ratings yet

- Human Nutritional RequirementsDocument3 pagesHuman Nutritional RequirementsAgnesMagadiaNo ratings yet

- Psicologia BuenisimoDocument6 pagesPsicologia BuenisimoSophieNo ratings yet

- Lesson 3.3 Inside An AtomDocument42 pagesLesson 3.3 Inside An AtomReign CallosNo ratings yet