Professional Documents

Culture Documents

Review On Single-Phase Fluid Flow Distribution in Manifold

Uploaded by

bkkbrazilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Review On Single-Phase Fluid Flow Distribution in Manifold

Uploaded by

bkkbrazilCopyright:

Available Formats

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Review on Single-Phase Fluid Flow Distribution in

Manifold

Jafar M. Hassan1, Wahid S. Mohammed2, Thamer A. Mohamed3, Wissam H. Alawee4

1,2

University of Technology, Department of Mechanical Engineering, Baghdad, Iraq

Universiti putra Malaysia, Faculty of Engineering, Department of Civil Engineering,

43400 UPM Serdang, Selangor, Malaysia

4

University of Technology, Department of Mechanical Engineering, Baghdad, Iraq

Abstract: single-phase flow distribution from a manifold into parallel channels are found in various industrial applications employing

fuel cells ,agricultural irrigation systems, variety of piping system, chemical reactors, solar thermal collectors, Polymer processing, etc.

the flow distribution in manifold with multi-parallel channels has been studied over the past decade. Uneven flow distribution causes a

reduction in both the thermal and fluid-dynamic performance and in many cases the failure of the device. A uniform flow distribution

requirement is a very common issue in many engineering applications. This task is made complicated by the flow distribution in these

devices depended on the great number of variables which act together. Research on convective flow distribution in manifold of different

application has been extensively conducted in the past decade. This review summarizes numerous researches on two topics; the first

section focuses on studying the fluid flow behavior of different appellations. The second section concentrates on the effect design

parameters on flow distribution in manifold. The purpose of this article is to get a clear view and detailed summary of the influence of

several parameters such as flowrate in the header (or manifold), size of the header, diameter of the parallel channels, location and size

of inlet port to the header, flow direction, shape of the channels and the headers. In addition, operating conditions and flow properties.

Keywords: Manifold, Flow distribution, Uniformity.

1. Introduction

Flow in manifold is of great importance in many industrial

processes when it is necessary to distribute a large fluid

stream into several parallel streams and then to collect them

into one discharge stream. The applications in which

manifolds play a major role extend from traditional situations

such as municipal water distribution systems and automobile

engines to very recent, high-technology devices such as

microchannel heat sinks and critical biological systems such

as blood circulation in the human body [1].

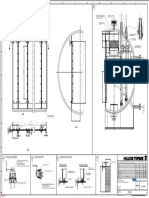

Manifolds can usually be categorized into one of the

following types [2]-[5]: dividing, combining, parallel, and

reverse flow manifolds as shown in Fig. 1. Parallel and

reverse flow manifolds are those which combine dividing

and combining flow manifolds and are most commonly used

in plate heat exchangers. In a parallel flow manifold, the

flow directions in dividing and combining flow headers are

the same which is generally referred as a Z-manifold. In a

reverse flow manifold, the flow directions are opposite is

referred as a U-manifold. A uniform flow distribution

requirement is a very common issue in many engineering

circumsta-nces because it has significant influence on the

performance of fluidic devices such as plate-type heat

exchangers, a variety of piping system, heat sinks for cooling

of electronic devices, fuel cells, chemical reactors, solar

thermal collectors, flow distribution systems in treatment

plant, the piping system of pumping stations. Therefore, for

most applications, the goal of manifold design is to achieve

the uniform flow distribution through all of the outlets.

Paper ID: 02013810

Figure 1: Different types of flow manifolds (A) dividing, (B)

combining, (C) Z-manifold and (D) U-manifold

2. Flow Distribution in Manifold

A great number experimental, analytical and numerical

studies deal with flow distribution in manifold. Bajura [6]

developed the first general theoretical model for

investigation of the performance of single-phase flow

distribution for both intake and exhaust manifolds. Primary

emphasis is placed on configurations in which the lateral

tubes form sharp-edged junctions at right angles to the

manifold axis. A mathematical model was formulated in

terms of a momentum balance along the manifold. Bajura

and Jones [7] extended the previous model and prediction for

the flow rates and the pressures in the headers for the

dividing, combining, reverse and parallel manifold

configurations. They found that the uniform flow distribution

in the laterals is attained only when the headers act as infinite

reservoirs, and they identified the most important parameters

affecting flow distribution: manifold area ratio (total lateral

tube area/inlet tube area), lateral flow resistance, header

length/diameter ratio, diameter ratio between headers, and

friction factor of the tube. Majumdar [8] developed a

Volume 3 Issue 1, January 2014

www.ijsr.net

325

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

mathematical model with one-dimensional elliptic solution

procedure for predicting flows in dividing and combining

flow manifolds. The mathematical model has been further

used by Datta and Majumdar [9] for numerically

investigation of flow distribution in parallel and reverse flow

manifolds. In both the studies, the authors have found two

non-dimensional parameters (area ratio and friction

parameter) which affect the flow distribution. Pigford et al.

[10] studied analytically and experimentally the flow

distribution in parallel and reverse flow manifolds using air.

They found that, for the same geometrical and operating

conditions, reverse flow manifold provides more uniform

flow distribution as compared to that in a parallel flow

manifold. Bassiouny and Martin [11],[12] presented an

analytical solution for the prediction of flow and pressure

distribution in both the intake and exhaust conduits of heat

exchanger for both types flow (U-type and Z-type) . From

the analysis, a general flow distribution and the pressure drop

can be determined by a general characteristic parameter m2.

Nearly uniform flow distribution may be obtained when m2

is equal to zero. In the case when m2 is positive, the channel

flow rates will increase in the direction of the intake stream.

If m2 is negative the channel flow rates will also increase in

the intake stream direction. The analysis also shows that the

total pressure drop in plate heat exchangers is practically the

same for both U- and Z- type arrangements. Mueller and

Chiou [13] presented in a review article the factors

influencing maldistribution in heat exchangers. The flow

distribution from manifold has become of interest in

predicting the heat transfer performance of compact heat

exchangers. Often, flow rates through the channels are not

uniform and in extreme cases, there is almost no flow

through some of them, which result in a poor heat exchange

performance.

Shen, P.I. [14] developed an analytical solution to evaluate

the effect of friction on flow distribution in both dividing and

combining flow manifolds. A constant cross-sectional area of

the manifold header and a constant friction factor along the

manifold were assumed in order to obtain the analytical

solution, expressed in terms of the lateral flow distribution as

a function of two performance parameters, (a) the friction

parameter and (b) momentum loss parameter. Numerical

results show that friction always increases flow imbalance in

the combining flow configuration, but it may either increase

or decrease flow imbalance in the dividing flow

configuration, depending on the ratio of the lateral area to the

cross-sectional area of the manifold. Choi et al. [15] studied

numerically the effect of the area ratio on the flow

distribution in manifolds of a liquid cooling module for

electronic packaging. Results showed that the flow rate in the

last channel was 2.75 times that in the first channel. It is

concluded that the area ratio is one of the most important

parameters affecting the coolant distribution and should be

carefully examined in the design of a liquid cooling module.

Choi et al. [16] studied numerically the effect of the

Reynolds number and the width ratio on the flow distribution

in manifolds of a liquid cooling module for electronic

packaging. They showed that the flow distribution in the

manifold strongly depended on the Reynolds number, and

Paper ID: 02013810

the width ratio. The flow distribution was also improved with

increasing width ratio. As the Reynolds number increased,

the flow rate in the last channel significantly increased;

consequently, the flows in the first several channels

decreased. The flow distribution was also improved with

increasing width ratio. Kim et al. [17] numerically

investigated the effects of header shapes and the Reynolds

number on the flow distribution in a parallel flow manifold

of a liquid cooling module for electronic packaging, for three

different header geometries (i.e., rectangular, triangular, and

trapezoidal) with the Z-type flow direction. Their results

indicated that the triangular shape provided the best

distribution regardless the inlet velocity. They assumed a

uniform velocity at the header inlet without considering the

entrance effect. The flow distribution of trapezoidal shape is

similar but is slightly worse than that of the triangular. For

the rectangular header, the last tube has the highest flow rate,

causing the flow mal-distribution. When the rectangular

header was replaced with a triangular header, the flow

distribution in the header was significantly improved.

Pretorius W.A. [18] demonstrated the use of a spread sheet

program to calculate the hydraulics of a dividing-flow

manifold. In this problem a (101.6 mm) diameter manifold

divides a flow of (50.97 m3/h) to (5) consecutive (50.8 mm)

diameter short laterals. Each lateral is orientated at (90 ) to

the manifold and is square-edged. The task is to determine

the flow distribution amongst the laterals. Depending on the

assumption of Hudson et al. [19], which assume that the head

loss in the energy line from manifold through lateral is the

same at every point, the researcher present solution of the

manifold-lateral system for two cases. In the first where a

fixed sized manifold (the diameter of the manifold remain

constant), the result shows that the discharge from lateral (1)

is (56%) less than that from lateral (5). The second case is

varying size manifold with constant lateral flow. In this case

the diameter is reduced from (0.126 m) to (0.056 m) and

produce an even discharge through (5) consecutive (0.051m)

diameter laterals. Lu Hua [20] developed a computational

model for the prediction of flow distribution in manifold type

flow spreaders, several numerical techniques are used to

address the difficulties associated with complex

configurations of manifold type flow spreaders which can be

found in many industrial applications, such that the manifold

type flow spreader used in the head box in the paper-making

system. The major effort in the work is to use and

generalized multi- grid elliptic grid generation program to

create grids for the tapered manifold spreader with different

cross sectional configurations, especially for the manifolds

with a circular cross section. The second step was to

compute several two-and three-dimensional laminar and

turbulent flows using CFD code to compared with other

numerical, experimental and analytical results as a validation

step to present computational method. A good agreement

with literature results obtained for laminar flow distribution;

also the effects of recirculation rate (flow out from manifold

end) on the manifold flow distribution are studied. It is found

that the flow rates from the downstream tubes drop

dramatically with a (15%) recirculation rate, and that the

zero recirculation rates causes high pressure and large flow

rate from tubes near the manifold end.

Volume 3 Issue 1, January 2014

www.ijsr.net

326

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Jones and Galliera [21] applied a Computational Fluid

Dynamics (CFD) approach to predict 3-D steady flow and

pressure fields in a T-junction coupled manifold with three

risers, which consist of dividing and combining flow. Using

standard and RNG k-s models in FLUENT to benchmark

their integral model for flow distribution. They achieved

good agreement between the two approaches and indicated

that FLUENT can predict the large-scale features (e.g.

distribution) of three-dimensional branching flows in a

coupled manifold. Without including the quality effect, the

application of single phase flow distribution study is still

limited.

3. Factors for affecting the flow distribution

From the previously reported result of the cited references,

the trends for the flow distribution affecting by several

parameters are briefly discussed in the following. Commenge

et al. [22] proposed a theoretical modeling approach in the

form of an electrical resistance network to optimize the

trapezoidal manifold geometry and obtain a uniform velocity

distribution among microchannels. The calculation results

were validated against numerical simulations. This

approximate model establishes a relationship similar to

Ohms law between pressure drop, flow rate, and flow

resistance. the losses in the manifolds (pressure losses due to

merging and branching effects) are neglected, and only wall

friction is considered. Therefore, the relationship established

between pressure drop and flow rate is linear. Anjun et al.

[23] investigated experimentally the effect of inlet header

angle and mass flow rate on flow maldistribution to optimize

the design of plate fin heat exchanger. The result showed that

optimum performance can be obtained for an inlet angle of

45. Also, they found the inlet angle of the distributor to have

negligible effects on pressure drop and were found to be

dependent only on Reynolds number.

Zhe Zhang and Yan Zhong Li., [24] developed a

computational model to predict the fluid flow distribution in

plate-fin heat exchangers. It is found that the flow

maldistribution is very serious in the y direction of header for

the conventional header used in industry. The results of flow

maldistribution are presented for a plate-fin heat exchanger,

which is simulated according to the configuration of the

plate-fin heat exchanger currently used in industry. The

numerical prediction shows a good agreement with

experimental measurement. By the investigation, two

modified headers with a two-stage-distributing structure are

proposed and simulated in this paper. The numerical

investigation of the effects of the inlet equivalent diameters

for the two-stage structures has been conducted and also

compared with experimental measurement. It is verified that

the fluid flow distribution in plate-fin heat exchangers is

more uniform if the ratios of outlet and inlet equivalent

diameters for both headers are equal. Jiao et al. [25]

investigated experimentally the effect of the inlet pipe

diameter, the first headers diameter of equivalent area and

the second headers diameter of equivalent area on the flow

maldistribution in plate-fin heat exchanger. For reducing

flow maldistribution in the header, the authors were

suggested modified header configuration. They installed a

Paper ID: 02013810

second header (B or C) after the first header to study the flow

velocity distribution. The header configuration B has five

holes in the connection part between the first and second

headers while the header configuration C has seven holes.

The flow velocity distribution of the configuration C gives

the most uniform result among the cases considered in their

paper. The flow distribution was effectively improved by the

modified header configuration. Tonomura et al. [26]

developed a computational model to optimize the rectangular

manifold. Simulation results show that longer branched

channels enable fluid to be distributed equally into each

channel. Also demonstrated is the fact that the magnification

of the outlet manifold area makes the flow distribution

uniform. However, the extension of the outlet manifold

increases dead volume inside the microdevice, broadens

residence time distribution, and lengthens space time. The

results of 2D and 3D CFD simulations on the flow

distribution in microchannel structures with a triangular

manifold have been compared by Griffini and Gavriilidis

[27]. They concluded that for their study cases 2D

simulations were correct because they gave an accurately the

correct velocity distribution of flow required. Maharudrayya

et al. [28] studied one dimensional models based on mass

and momentum balance equations in the inlet and exhaust

headers of U-type and Z-type parallel configurations having

fuel cell applications. The models have been validated by

comparing the results with those obtained from threedimensional computational fluid dynamics (CFD)

simulations. Their results showed that mild to severe flow

maldistribution was possible in both the configurations for

typical fuel-cell distributor plate dimensions. The severity of

maldistribution depended strongly on the geometric factors

such as the channel dimensions, the header dimensions and

the rib width between parallel channels. Ramamurthy et al.

[29] applied Reynolds averaged Navier-Stokes (RANS)

equations to dividing flows in 90 deg rectangular conduit

junctions. They adopted the Three -dimensional kturbulence model for numerical simulation to obtain the

dividing flow characteristics. These characteristics include

the energy loss coefficients, pressure profiles, velocity

profiles, and the mean flow pattern. The results are validated

using experimental data. The experiment was carried out

using The Dantec Laser Doppler Anemometry (LDA) to

measure velocities in the test section. The zone of flow

separation predicted by the model qualitatively agrees with

the experimental data. They argued that their model can be

used to obtain results such as energy loss coefficients for

different area ratios and discharge ratios without too much

effort. Wen et al. [30] investigated flow characteristics in the

entrance region of plate-fin heat exchanger by means of

particle image velocimetry (PIV). The experimental results

indicate that flow maldistribution in the conventional header

is very serious, while the improved header configuration

with punched baffle can effectively improve the uniformity.

The flow maldistribution parameter in plate-fin heat

exchanger has been reduced from 1.21 to 0.21, and the ratio

of the maximum velocity to the minimum is reduced from

23.2 to 1.8 by installing the punched baffle. Lu et al [31]

formulated a discrete model for the calculation of flow

distribution in flow manifolds from first principles.

Experimental evaluation of flow characteristic parameters

Volume 3 Issue 1, January 2014

www.ijsr.net

327

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

had been carried out to support the discrete model.

Experiments were conducted to obtain the pressure

distribution in the header under specific conditions. The

validity of the theoretical discrete model has been performed

with experimental results, under specific conditions. Refined

experimental probes, for pressure heads with ultrasonic

measuring devices, have been used to obtain accurate results.

The experimental results fully substantiate the soundness of

the theoretical prediction. In addition, the advantage of the

ability to accommodate local disturbances in the discrete

model has been pointed out. The effect of some local

disturbances may be substantial. As a result of the analysis

presented in this article, improved designs of flow manifolds

in heat exchangers can be realized, to assure operation safety

under severe operating conditions. Tong et al. [32]

investigated numerically number of the strategies capable of

perfecting manifold design to achieve the same rate of mass

outflow through each of the exit ports of a distribution

manifold. The results show that are most effective for the

attainment of the goal of outflow uniformity, These are: (a)

enlargement of the cross-sectional area of the distribution

manifold, (b) variation of the cross-sectional areas of the

outflow channels, (c) linear tapering of the cross-sectional

area of the distribution manifold, and (d) non-linear tapering

of the cross-sectional area of the manifold by means of

quarter-elliptical contouring of the manifold wall.

Pan, Zeng, et al. [33] performed a three-dimensional

computational fluid dynamics (CFD) model to calculate the

velocity distribution among multiple parallel microchannels

with triangle manifolds. The simulation results showed that

the velocity distribution became more uniform with larger

microchannel length, depth or smaller width. Larger

horizontal ordinate, longitudinal ordinate and radius of

inlet/outlet, smaller lengths of bottom and side of

symmetrical manifolds could favor obtaining narrow velocity

distribution among microchannels. The effect of channel

width and channel spacing on flow distribution among

microchannels with U-shape rectangular manifolds has been

investigated by Mathew, John, and Hegab [34].

Andrew and Sparrow [35] present a method to investigate

the effect of the geometric shape of the exit ports on mass

flow rate uniformity effusing from a distribution manifold;

three candidate exit-port geometries were considered: (a) an

array of discrete slots, (b) an array of discrete circular

apertures, and (c) a single continuous longitudinal

rectangular slot. In order to have a valid comparison of the

impacts of these individual geometries, the total exit areas of

all three were made identical. The results of the per-port

mass effusion normalized to the average mass-flow rate of

the manifold demonstrate that the single continuous slot

provides the best performance with end-to end variations of

less than (5%). The discrete array of rectangular slots and

discrete array of circular holes provided uniformity of

(10%) and (15%), respectively. Also its found that the

pressure rise for the various types of slot geometries is

similar. Saber et al. [36] performed a model for rapid

estimation of flow distribution in a complex network

comprising several different scales under isothermal and

laminar flow conditions. They found that a two-scale

Paper ID: 02013810

configuration of the flow distributor yielded the most

uniform flow distribution. Tong et al. [37] applied a logicbased systematic method of designing manifold systems to

achieve flow rate uniformity among the channels that

interconnect a distribution manifold and a collection

manifold. The method was based on tailoring the flow

resistance of the individual channels to achieve equal

pressure drops for all the channels. The tailoring of the flow

resistance was accomplished by the use of gate-valve-like

obstructions. Huang and Wang [38] examined an inverse

design problem to determine the optimum variables for a

three-dimensional Z-type compact parallel flow heat

exchanger is with the LevenbergMarquardt Method (LMM)

[39] to obtain the uniform tube flow rates. Five different

optimization design problems are examined to demonstrate

the validity of the study. The results obtained from the LMM

are justified based on numerical experiments. They

concluded that the estimated optimal tube diameters and

entrance length of the header can indeed effectively

eliminate the eddy flow in the first tube due to the circulation

of the vortex flow near the header inlet. As a result, the nonuniformity observed in the flow rate of the system can be

minimized and the tube flow rate in the heat exchanger is

nearly uniform. Wang et al. [40] investigated experimentally

and numerically the single-phase flow into parallel flow heat

exchangers with inlet and outlet rectangular headers having

square cross section and nine circular tubes. The effects of

inlet flow condition, tube diameter, header size, area ratio,

flow directions (Z and U-type), as well as the gravity were

investigated. The experimental results indicated that flow

distribution for U-type flow is more uniform than Z-type

flow. Depending on the inlet volumetric flow rate, the flow

ratio of the first several tubes can be more than 50% lower

than the last tube for the Z-type arrangement, a phenomenon

becomes more and more pronounced with the rising velocity

at the intake conduit.

In review article, Rebrov et al. [41] presented an

experimental and numerical result on fluid flow distribution,

heat transfer and combination thereof for microstructure

reactors. They have given a special attention to the effect

flow maldistribution on the thermal and conversion behavior

of catalytic microreactors. Wang [42] presented

experimentally the results of liquid flow distribution in

compact parallel flow heat exchanger through a rectangular

and 5 modified inlet headers (i.e., 1 trapezoidal, one multistep, 2 baffle plates and 1 baffle tubes header). A jet stream

induced at the header inlet associated with vortexes affecting

the flow distribution to the front tubes. The flow distribution

in the header highly depends on the header shape and the

total flow rate. They concluded that the baffle tube has the

best flow distribution since the vortex flow can be removed

by using this header configuration. Wang [43] has examined

research and development of theoretical models and

methodology of solutions in flow in manifolds and highlight

remarkable advances in the past fifty years. Author has

reported three approaches: computational fluid dynamics

(CFD), discrete models and analytical models. Further,

author has reported three general characteristic parameters

(E, M, ) which control the flow and pressure distribution in

manifolds. Zeng, Pan, and Tang [44] performed a three-

Volume 3 Issue 1, January 2014

www.ijsr.net

328

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

dimensional computational fluid dynamics (CFD) model to

calculate the velocity distribution among microchannels with

two different manifold structures. It was found that, as

compared to the obtuse angled manifold, the right-angled

manifold resulted in a more uniform flow distribution for all

inlet velocities. A similar performance improvement with a

more uniform flow distribution in methanol steam reformers

was reported by Jang, Huang, and Cheng [45]. Such findings

affirm the influence of flow distribution uniformity on the

performance of microreactor devices and reflect the

importance of efficient manifold design. Hanfei Tuo and

Pega Hrnjak [46] investigation an experimentally and

numerically the flow maldistribution caused by the pressure

drop in headers and its impact on the performance of a

microchannel evaporator with horizontal headers and

vertically oriented tubes. Experimental results show that the

flash gas bypass method almost eliminates the quality

induced maldistribution. Nae-Hyun Kim and Ho-Won Byun

[47] studied experimentally the effect of inlet configuration

on upward branching of two-phase refrigerant in a parallel

flow heat exchanger. Three different inlet orientations

(parallel, normal, vertical) were investigated. The best flow

distribution was obtained from vertical inlet configuration.

Between other two inlet configurations, parallel inlet was

better for liquid distribution, and normal inlet was better for

gas distribution. Badar et al. [48] conducted a computational

fluid dynamics (CFD) analysis to find the pressure losses for

dividing and combining fluid flow through a tee junction of a

solar collector manifold. The results were in reasonable

agreement with the available experimental results for Uconfiguration. The proposed CFD based strategy can be used

as a substitute to setting up and performing costly

experiments for estimating junction losses.

4. Conclusion

In general, all previous studies with different applications

have shown that typical manifold design does not give a

uniform flow distribution among outlets. There will be a

nonuniform mass flow distribution such that the smallest

mass flowrate will occur in the outlet closest to the inlet and

the highest flowrate will be encountered in the outlet farthest

from the inlet. Correspondingly, the end-to-end pressure

drops in the respective laterals will also be nonuniform. the

cause as reported by several authors, the flow in the

distribution manifold is gradually depleted as mass is

extracted at each of the outlet. If the distribution manifold

were to be uniform longitudinal section, the axial momentum

would gradually decrease. This momentum decrease would

give rise to an increase in the static pressure. Such an

increase in static pressure should favor a higher efflux

through the downstream outlets. In this article, a

comprehensive review of previous efforts was presented for

different flow distribution regimes. there are several

approaches used by different research groups to achieve flow

uniformity in manifolds. The issue of flow equalization is

usually adequately tackled by using 3D numerical models.

2D CFD models could not adequately predict flow

distribution in flow distribution manifolds. The effects of

several parameters in geometry, boundary conditions, stream

velocity in the header (or manifold), size of the header,

Paper ID: 02013810

diameter of the parallel channels, location and size of inlet

port to the header, flow direction, operating conditions and

fluid properties were extensively investigated to improve the

uniformity degree of flow distribution.

Reference

[1] Jimmy c. k. tong, development of systematic solution

methodologies for the fluid-flow manifold problem,

University of Minnesota, Ph.D. Dissertation, 2006.

[2] McNown, J.S. Mechanics of manifold flow

Transactions of ASCE, 119. pp. 1103-1142, 1954.

[3] Acrivos, A., Babcock, B.D., Pigford,R.L. Flow

distributions in manifolds Chemical Engineering

Science, 10. pp. 112-124,1959.

[4] Pigford, R.L., Ashraf, M., Mlron, Y.D. (1983). Flow

distribution in piping manifolds. Ind. Eng. Chem.

Fundam. 22. pp. 463471.

[5] M. S. Gandhia, at al. CFD simulation for steam

distribution in header and tube assemblies chemical

engineering research and design 90 ( 2012) 487-506

[6] Bajura, R. A. A model for flow distribution in

manifolds, Journal of Engineering for PowerTransactions ASME, 1971, Vol. 93, No. 1, pp. 7-12.

[7] Bajura, R. A. and E. H. Jones, , Flow distribution

manifolds, Journal o f Fluids Engineering-Transactions

ASME, 1976, Vol. 98, No. 4, pp. 654-666.

[8] Majumdar, A.K., Mathematical modelling of flows in

dividing and combining flow manifold Appl. Math.

Model. 4 (1984) 424432.

[9] Datta, A.B., Majumdar, A.K. Flow distribution in

parallel and reverse flow manifolds Int. J. Heat Fluid

Flow 2 (1980) 253262.

[10] Pigford, R.L., Asharf, M., Miron, Y.D., Flow

distribution in piping manifolds Ind. Eng. Chem.

Fundam. 22 (1983) 463471.

[11] Bassiouny, M.K., Martin, H., Flow distribution and

pressure drop in plate heat exchangers-I U-type

arrangement Chem. Eng. Sci. 39 (1984) 693700.

[12] Bassiouny, M.K., Martin, H., Flow distribution and

pressure drop in plate heat exchangers-II Z-type

arrangement Chem. Eng. Sci. 39 (1984) 701704.

[13] Mueller, A.C., Chiou, J.P., Review of various types of

flow maldistribution in heat exchangers Heat Trans.

Eng. 5 (1988) 3650.

[14] Shen P. I., The Effect of Friction on Flow Distribution

in Dividing and Combining Flow Manifold Transaction

of the ASME, J. of Fluids Engineering, vol. 114, 1992.

[15] Choi, S. H., Shin, S. and Cho, Y. I., "The effect of area

ratio on the flow distribution in liquid cooling module

manifolds for electronic packaging," Int. Comm. Heat

Mass Transfer, 20, (1993) 221-234.

[16] Choi, S. H., Shin, S. and Cho, Y. I., "The effect of

Reynolds number and width ratio on the flow

distribution of liquid cooling module manifolds for

electronic packaging," Int. Comm. Heat Mass Transfer,

20 (1993) 607-617.

[17] S. Kim, E. Choi, Y.I. Cho, The effect of header shapes

on the flow distribution in a manifold for electronic

packaging applications International Communications

in Heat and Mass Transfer 22 (1995) 329-341.

Volume 3 Issue 1, January 2014

www.ijsr.net

329

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

[18] Pertorius W.A., Dividing- flow Manifold Calculations

with a Spreadsheet, water science, vol. 23, No. 2, 1997.

[19] Hudson, H.E. et al., Dividing-Flow Manifolds with

Square-Edged Laterals, Journal of the Environmental

Engineering Division, (745-754) 1979.

[20] Lu Hua, Computational Modeling of Manifold Type

Flowspreaders, MSc Thesis, the University of

Columbia, 1998.

[21] Jones, G. F. and J. M. Galliera, , Isothermal flow

distribution in coupled manifolds: Comparison o f

results from CFD and an integral model Americtm

Society of Mechanical Engineers, Fluids Engineering

Division, Fairfield, NJ, 247 (1998) 189-195.

[22] Commenge, J., Falk, L., Corriou, J. P., & Matlosz, M.

Optimal design for flow uniformity in microchannel

reactors. AICHE Journal, 48 (2002) 345358.

[23] Anjun, J., Yanzhong, L., ChunZheng, C., and Rui, Z.,

Experimental

Investigation

on

Fluid

Flow

Maldistribution in Plate-Fin Heat Exchangers Heat

Transfer Engineering, 24 (2003) 25-31.

[24] Zhe Zhang and YanZhong Li., CFD simulation on inlet

configuration of plate-fin heat exchangers Cryogenics

43 (2003) 673678.

[25] A. Jiao, R. Zhang, S. Jeong, Experimental investigation

of header configuration on flow mal-distribution in

plate-fin heat exchanger Applied Thermal Engineering

23 (2003) 1235-1246.

[26] Tonomura, O., Tanaka, S., Noda, M., Kano, M., Hasebe,

S., & Hashimoto, L. CFD based optimal design of

manifold in plate-fin microdevices Chemical

Engineering Journal, 101(2004) 397-402.

[27] Griffini, G., & Gavriilidis, A. Effect of microchannel

plate design on fluid flow uniformity at low flow rates

Chem. Engineering & Technology 30 (2007) 395-406.

[28] Maharudrayya, S., Jayanti, S., and Deshpande, A. P.,

Flow distribution and pressure drop in parallelchanne

configurations of planar fuel cells Journal of Power

Sources, vol. 144 (2005) 94-106.

[29] Ramamurthy A. S., Junying Qu, Diep Vo, Chao Zhai,

3-D Simulation of Dividing Flows in 90 deg

Rectangular Closed Conduits, Transactions of the

ASME, J. of Fluids Engineering, Vol. 128, 2006.

[30] Wen, J., Li, Y., Zhou, A., Ma, Y.,P IV investigations of

flow patterns in the entrance configuration of plate-fin

heat exchanger Chin. J. Chem. Eng. 14 (2006) 1523.

[31] LU Fang, LUO Yong-hao and YANG Shi-ming.

Analytical and experimental investigation of flow

distribution in manifolds for heat exchangers. Journal

of Hydrodynamics, 20(2) (2008)179-185.

[32] J.C.K. Tong, E.M. Sparrow, J.P. Abraham, Geometric

strategies for attainment of identical outflows through all

of the exit ports of a distribution manifold in a manifold

system, Applied Thermal Eng. 29 (2009) 3552-3560.

[33] Pan, M., Zeng, D., Tang, Y., & Chen, D. CFD-based

study of velocity distribution among multiple parallel

microchannels J. of Computers, 4 (2009) 11331138.

[34] Mathew, B., John, T. J., & Hegab, H. Effect of

manifold design on flow distribution in multichanneled

microfluidic devices ASME Fluids Engineering

Division Summer Conference, FEDSM 2009, Vol. 2, pp.

543548.

Paper ID: 02013810

[35] Andrew W. Chen, Ephraim M. Sparrow, Effect of Exitport Geometry on the Performance of a Flow

Distribution Manifold, Applied Thermal Engineering,

29 (2009) pp. 2689-2692.

[36] Saber, M., Commenge, J., Falk, L., Rapid design of

channel multi-scale networks with minimum flow maldistribution Chem. Eng. Process, 48 (2009) 723733.

[37] J.C.K. Tong, E.M. Sparrow, J.P. Abraham, Attainment

of flowrate uniformity in the channels that link a

distribution manifold to a collection manifold, J. Fluids

Eng. 129 (2007) 11861192.

[38] C.H. Huang, C.H. Wang, The design of uniform tube

flow rates for Z-type compact parallel flow heat

exchangers Int. J. Heat Mass Transfer (SCI&EI paper)

57 (2013) 608622.

[39] D.M. Marquardt, An algorithm for least-squares

estimation of nonlinear parameters, J. Soc. Ind. Appl.

Math. 11 (1963) 431441.

[40] C.C. Wang, K.S. Yang, J.S. Tsai, I.Y. Chen,

Characteristics of flow distribution in compact parallel

flow heat exchangers, part I: typical inlet header, Appl.

Therm. Eng. 31 (2011) 32263234.

[41] Rebrov, E.V., Schouten, J.C., de Croon, M., Singlephase fluid flow distribution and heat transfer in

microstructured reactors, Chem. Eng. Sci. 66 (2011)

13741393.

[42] C.C. Wang, K.S. Yang, J.S. Tsai, I.Y. Chen,

Characteristics of flow distribution in compact parallel

flow heat exchangers, Part II: Modified inlet header,

Appl. Thermal Eng. 31 (2011) 32353242.

[43] Wang, J., Theory of flow distribution in manifolds,

Chem. Eng. J. 168 (2011) 13311345.

[44] Zeng, D., Pan, M., & Tang, Y. Qualitative investigation

on effects of manifold shape on methanol steam

reforming for hydrogen production. Renewable Energy,

39 (2012) 313322.

[45] Jang, J.-Y., Huang, Y.-X., & Cheng, C.-H. The effects

of geometric and operating conditions on the hydrogen

production performance of a micro-methanol steam

reformer, Chem. Eng. Science, 65 (2010). 54955506.

[46] Hanfei Tuo a, Pega Hrnjak Effect of the header

pressure drop induced flow maldistribution on the

microchannel evaporator performance, international

journal of refrigeration 36 (2013) 2176-2186.

[47] Nae-Hyun Kim and Ho-Won Byun, Effect of inlet

configuration on upward branching of two-phase

refrigerant in a parallel flow heat exchanger int. j. of

refrigeration 36 ( 2013 ) 1062-1077.

[48] Badar et al., CFD based analysis of flow distribution in

a coaxial vacuum tube solar collector with laminar flow

conditions, International Journal of Energy and

Environmental

Engineering

2012,

http://www.journal-ijeee.com/content/3/1/24

Volume 3 Issue 1, January 2014

www.ijsr.net

330

You might also like

- Mal Distribution in PCHEDocument13 pagesMal Distribution in PCHEVinayak AgarwalNo ratings yet

- Design Optimization of Shell and Tube Heat Exchang PDFDocument7 pagesDesign Optimization of Shell and Tube Heat Exchang PDFSaiful ShokriNo ratings yet

- Screening Reactor For Water HammerDocument49 pagesScreening Reactor For Water HammerYu GanNo ratings yet

- VFD Minimum Speed EquationDocument4 pagesVFD Minimum Speed Equationforevertay2000No ratings yet

- Superheated SteamDocument15 pagesSuperheated SteamluriahNo ratings yet

- Vacuum Systems PDFDocument12 pagesVacuum Systems PDFSnigdha YadavNo ratings yet

- Modeling Mineral Size Reduction in The Closed-Circuit Ball Mill at The Pine Point Mines Concentrator (1981)Document18 pagesModeling Mineral Size Reduction in The Closed-Circuit Ball Mill at The Pine Point Mines Concentrator (1981)Ryan Cunningham100% (1)

- Thermocompressor PDFDocument4 pagesThermocompressor PDFYogesh GhanekarNo ratings yet

- Process Modeling and Simulation for Chemical Engineers: Theory and PracticeFrom EverandProcess Modeling and Simulation for Chemical Engineers: Theory and PracticeNo ratings yet

- Heat Transfer Assignment QuestionsDocument2 pagesHeat Transfer Assignment QuestionsMurali KrishnaNo ratings yet

- Studies On Bubble DynamicsDocument10 pagesStudies On Bubble Dynamicsvishnu cNo ratings yet

- Heat Conduction in 2 and 3 DimensionsDocument205 pagesHeat Conduction in 2 and 3 Dimensionsbogdyronnie100% (2)

- Basic Desuperheating TheoryDocument4 pagesBasic Desuperheating TheoryAnonymous CX51waINo ratings yet

- Pressure Drops Two PhasesDocument13 pagesPressure Drops Two PhasesSandro Goisis100% (1)

- Micro Heat Pipes and Micro Heat Spreaders - PetersonDocument37 pagesMicro Heat Pipes and Micro Heat Spreaders - PetersonprinciquesoNo ratings yet

- Kinetics of The Synthesis of Higher Aliphatic Alcohols From SyngasDocument8 pagesKinetics of The Synthesis of Higher Aliphatic Alcohols From SyngasLina ArevaloNo ratings yet

- JAQUET Greenline EDocument12 pagesJAQUET Greenline Eseriousguy2No ratings yet

- Condensate in HRSG PDFDocument15 pagesCondensate in HRSG PDFCoalhouse Walker JuniorNo ratings yet

- CFD Analysis of Heat Transfer in Helical CoilDocument5 pagesCFD Analysis of Heat Transfer in Helical CoilAnonymous kw8Yrp0R5rNo ratings yet

- 1 s2.0 S0263876299717624 MainDocument7 pages1 s2.0 S0263876299717624 Mainryan123459No ratings yet

- DesuperheaterDocument4 pagesDesuperheaterNaama RahavNo ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- Desplazamiento Positivo PDFDocument20 pagesDesplazamiento Positivo PDFMelina SbhNo ratings yet

- Friction Coefficient in PipesDocument16 pagesFriction Coefficient in PipesVanessa AyalaNo ratings yet

- Blowdown of Pipelines Carryng Flashing LiquidsDocument10 pagesBlowdown of Pipelines Carryng Flashing LiquidsMilson GomezNo ratings yet

- Performance Thermo CompressorsDocument8 pagesPerformance Thermo CompressorsclintoncNo ratings yet

- Flowmeter Installation EffectsDocument12 pagesFlowmeter Installation EffectsgykataiNo ratings yet

- Heat Transfer DoeDocument32 pagesHeat Transfer DoeArt RmbdNo ratings yet

- Wong Sandler (1992)Document10 pagesWong Sandler (1992)Anonymous PO7VwbBnNo ratings yet

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationFrom EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationNo ratings yet

- Chemical Reactor Design - NotesDocument4 pagesChemical Reactor Design - NotesJanaki Devi ParratNo ratings yet

- Radiation View FactorsDocument13 pagesRadiation View FactorsHarwinder SinghNo ratings yet

- Heat Transfer in Packed BedDocument10 pagesHeat Transfer in Packed BedNidhi JainNo ratings yet

- Energy Balances Procedure Single Component and Double Component SystemDocument24 pagesEnergy Balances Procedure Single Component and Double Component Systemhazyhazy9977100% (1)

- Two Phase Flow BibliographyDocument41 pagesTwo Phase Flow BibliographyShiv Pratap SinghNo ratings yet

- Chemical Engineering - Fluid Flow Heat Transfer and Mass Transfer - Vol. 1 J. M. Coulson J. F. Richardson J. R. Backhurst and J. H. H-LibreDocument128 pagesChemical Engineering - Fluid Flow Heat Transfer and Mass Transfer - Vol. 1 J. M. Coulson J. F. Richardson J. R. Backhurst and J. H. H-LibreRafaelMelo-González0% (1)

- AIChE Journal Volume 23 Issue 6 1977 (Doi 10.1002/aic.690230602) Karl Gardner Jerry Taborek - Mean Temperature Difference - A ReappraisalDocument10 pagesAIChE Journal Volume 23 Issue 6 1977 (Doi 10.1002/aic.690230602) Karl Gardner Jerry Taborek - Mean Temperature Difference - A Reappraisalneozero2006No ratings yet

- Arc Discharge ApplicationDocument15 pagesArc Discharge ApplicationHong Chun LeeNo ratings yet

- Steam GeneratorDocument8 pagesSteam GeneratorFrancesco CordellaNo ratings yet

- CP Pickheaters Jacketed Heating Special Report PDFDocument25 pagesCP Pickheaters Jacketed Heating Special Report PDFnitantharaniNo ratings yet

- Optimizing Pumping Systems P-IDocument4 pagesOptimizing Pumping Systems P-Imatrix69No ratings yet

- Chapter - 1 Condenser PerformanceDocument21 pagesChapter - 1 Condenser PerformanceAhmed HelmyNo ratings yet

- Condensing Economizer ArticleDocument4 pagesCondensing Economizer ArticleErhan KayabaşıNo ratings yet

- S-03710 M54161-2-Rev. 1-As F 8506-Steam Drum DetailsDocument1 pageS-03710 M54161-2-Rev. 1-As F 8506-Steam Drum Detailswylie01No ratings yet

- Methane Pyrolysis. Experimental.: Table: Experimental Runs. Reaction Temperature, Feed Composition by MFC, InnerDocument7 pagesMethane Pyrolysis. Experimental.: Table: Experimental Runs. Reaction Temperature, Feed Composition by MFC, InnerAlexei PyliloNo ratings yet

- Superheated SteamDocument51 pagesSuperheated SteamMiguel Loera BaronaNo ratings yet

- Measurements in A Pulsating FlowDocument13 pagesMeasurements in A Pulsating Flowusebio64No ratings yet

- The Prediction of Mineral Solubilities in Natural Waters: A Chemical Equilibrium Model For The Na-Ca-CI-S04-H20 System, To High Temperature and ConcentrationDocument17 pagesThe Prediction of Mineral Solubilities in Natural Waters: A Chemical Equilibrium Model For The Na-Ca-CI-S04-H20 System, To High Temperature and ConcentrationBiain A SecasNo ratings yet

- Different Between Nm3Document11 pagesDifferent Between Nm3Iskandar Zulkarnain HasibuanNo ratings yet

- ECF-SSF Actuator Catalogue DTD 08 11Document20 pagesECF-SSF Actuator Catalogue DTD 08 11manmohansingh1999No ratings yet

- Annular Condensation CFD Models For The Water-Steam in The Heat Pipe SystemsDocument9 pagesAnnular Condensation CFD Models For The Water-Steam in The Heat Pipe SystemsRashed KaiserNo ratings yet

- Two-Phase Flow Pressure DropDocument4 pagesTwo-Phase Flow Pressure DropStevenMvuyana100% (1)

- DP 07 Mechanical Bar Screen FDocument2 pagesDP 07 Mechanical Bar Screen FEsteban N. Yucra LopezNo ratings yet

- Pressure Relief Valves Transcritical Co2Document2 pagesPressure Relief Valves Transcritical Co2Edita SzuketiováNo ratings yet

- Dogger Bank 4pp - A4 Case Study - SDocument4 pagesDogger Bank 4pp - A4 Case Study - SbkkbrazilNo ratings yet

- Moving Bed Biofilm Reactor For Denitrification CoreyDocument19 pagesMoving Bed Biofilm Reactor For Denitrification CoreybkkbrazilNo ratings yet

- Promlem 1: A) The Discharge Through The Penstock. B) The Mean Annual Energy ProductionDocument4 pagesPromlem 1: A) The Discharge Through The Penstock. B) The Mean Annual Energy ProductionbkkbrazilNo ratings yet

- Promlem 1: A) The Discharge Through The Penstock. B) The Mean Annual Energy ProductionDocument4 pagesPromlem 1: A) The Discharge Through The Penstock. B) The Mean Annual Energy ProductionbkkbrazilNo ratings yet

- Fs Pri 004 Lamella Settling A20160220Document30 pagesFs Pri 004 Lamella Settling A20160220bkkbrazil100% (1)

- Cálculo de Custos de Sistemas de TratamentoDocument139 pagesCálculo de Custos de Sistemas de TratamentobkkbrazilNo ratings yet

- Cálculo de Custos de Sistemas de TratamentoDocument139 pagesCálculo de Custos de Sistemas de TratamentobkkbrazilNo ratings yet

- Cálculo de Custos de Sistemas de TratamentoDocument139 pagesCálculo de Custos de Sistemas de TratamentobkkbrazilNo ratings yet

- Moon O Theism Yoel NatanDocument1,193 pagesMoon O Theism Yoel Natandeca4100% (2)

- FfsDocument16 pagesFfsRoman KrautschneiderNo ratings yet

- Brochure CMDR2016 RGBDocument7 pagesBrochure CMDR2016 RGBbkkbrazilNo ratings yet

- Sedimentation Tank DesignDocument12 pagesSedimentation Tank DesignbkkbrazilNo ratings yet

- P&IDDocument139 pagesP&IDArif Rahman Hakim100% (1)

- District of Sechelt Wastewater Treatment FacilityDocument20 pagesDistrict of Sechelt Wastewater Treatment FacilitybkkbrazilNo ratings yet

- US Diffusion of Submerged Jets 1950Document60 pagesUS Diffusion of Submerged Jets 1950janduirfilho100% (3)

- PVRVDocument4 pagesPVRVbkkbrazil100% (1)

- Kubuta MBR ManualDocument35 pagesKubuta MBR ManualbkkbrazilNo ratings yet

- Dividing ManifoldDocument4 pagesDividing ManifoldbkkbrazilNo ratings yet

- Municipal Waste Water TreatmentDocument30 pagesMunicipal Waste Water Treatmentakhilt2994% (18)

- Turbulent JetDocument8 pagesTurbulent JetaeroacademicNo ratings yet

- Design and Analysis of OrificesDocument46 pagesDesign and Analysis of Orificesbkkbrazil0% (1)

- 6110 L23 Manifold Hydraulic DesignDocument22 pages6110 L23 Manifold Hydraulic DesignEugenio DurbanNo ratings yet

- P&IDDocument18 pagesP&IDhectornicolauNo ratings yet

- Pipe Flow-Friction Factor Calculations With Excel CourseDocument30 pagesPipe Flow-Friction Factor Calculations With Excel CourseMohamed ZahranNo ratings yet

- P&IDDocument18 pagesP&IDhectornicolauNo ratings yet

- Airlift PaperDocument44 pagesAirlift PaperbkkbrazilNo ratings yet

- Tube Settling ThailandDocument110 pagesTube Settling ThailandbkkbrazilNo ratings yet

- Narrative FixDocument6 pagesNarrative Fixfitry100% (1)

- Glory in The Cross - Holy Thursday - Schutte PDFDocument1 pageGlory in The Cross - Holy Thursday - Schutte PDFsharon0murphyNo ratings yet

- Jurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIDocument9 pagesJurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIMarsaidNo ratings yet

- SchedulingDocument47 pagesSchedulingKonark PatelNo ratings yet

- Actara (5 24 01) PDFDocument12 pagesActara (5 24 01) PDFBand Dvesto Plus CrepajaNo ratings yet

- Nugent 2010 Chapter 3Document13 pagesNugent 2010 Chapter 3Ingrid BobosNo ratings yet

- Vietnamese Alphabet and PronounDocument10 pagesVietnamese Alphabet and Pronounhati92No ratings yet

- Mufti ReligionMilitancy WebDocument0 pagesMufti ReligionMilitancy WebAyaz Ahmed KhanNo ratings yet

- 2015 Grade 4 English HL Test MemoDocument5 pages2015 Grade 4 English HL Test MemorosinaNo ratings yet

- Enzymes WorksheetDocument5 pagesEnzymes WorksheetgyunimNo ratings yet

- BQ - Structural Works - CompressedDocument163 pagesBQ - Structural Works - CompressedLee YuxuanNo ratings yet

- Catalog de Aparatura Si Instrumentar Veterinar Eikemeyer-GermaniaDocument336 pagesCatalog de Aparatura Si Instrumentar Veterinar Eikemeyer-GermaniaDr. Dragos CobzariuNo ratings yet

- Unit 6B - PassiveDocument18 pagesUnit 6B - PassiveDavid EstrellaNo ratings yet

- 2002 CT Saturation and Polarity TestDocument11 pages2002 CT Saturation and Polarity Testhashmishahbaz672100% (1)

- CIVE2304 C1-1 Hydrological CycleDocument54 pagesCIVE2304 C1-1 Hydrological CyclenaserNo ratings yet

- Vmware It Academy Program May2016Document26 pagesVmware It Academy Program May2016someoneNo ratings yet

- Application of The Ritz Method To The Analysis of Non-Linear Free Vibrations of BeamsDocument12 pagesApplication of The Ritz Method To The Analysis of Non-Linear Free Vibrations of BeamsKuldeep BhattacharjeeNo ratings yet

- Integrated Management System 2016Document16 pagesIntegrated Management System 2016Mohamed HamedNo ratings yet

- CMS156Document64 pagesCMS156Andres RaymondNo ratings yet

- Appsc Aee Mains 2019 Electrical Engineering Paper III 1fcbb2c9Document12 pagesAppsc Aee Mains 2019 Electrical Engineering Paper III 1fcbb2c9SURYA PRAKASHNo ratings yet

- MHR Common SFX and LimitsDocument2 pagesMHR Common SFX and LimitsJeferson MoreiraNo ratings yet

- EIL 6-51-0051-Rev 06 - 1.1kv-Xlpe - Dimension Cat - B Armour-BbpDocument2 pagesEIL 6-51-0051-Rev 06 - 1.1kv-Xlpe - Dimension Cat - B Armour-BbpShubham BaderiyaNo ratings yet

- HAI ROBOTICS Introduction ENV2022.0829 MarketingDocument40 pagesHAI ROBOTICS Introduction ENV2022.0829 MarketingKit WooNo ratings yet

- Datasheet of STS 6000K H1 GCADocument1 pageDatasheet of STS 6000K H1 GCAHome AutomatingNo ratings yet

- Xbox One S Retimer - TI SN65DP159 March 2020 RevisionDocument67 pagesXbox One S Retimer - TI SN65DP159 March 2020 RevisionJun Reymon ReyNo ratings yet

- Protected PCM USB Memory Sticks For Pa3X.Document1 pageProtected PCM USB Memory Sticks For Pa3X.mariuspantera100% (2)

- Deictics and Stylistic Function in J.P. Clark-Bekederemo's PoetryDocument11 pagesDeictics and Stylistic Function in J.P. Clark-Bekederemo's Poetryym_hNo ratings yet

- Tourism and GastronomyDocument245 pagesTourism and GastronomySakurel ZenzeiNo ratings yet

- Rules of Bursa Malaysia Securities Clearing 2019Document11 pagesRules of Bursa Malaysia Securities Clearing 2019Evelyn SeethaNo ratings yet

- Promotion of Coconut in The Production of YoghurtDocument4 pagesPromotion of Coconut in The Production of YoghurtԱբրենիկա ՖերլինNo ratings yet