Professional Documents

Culture Documents

MS 1099 0002 Concrete Repair

Uploaded by

MuhammedHafisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

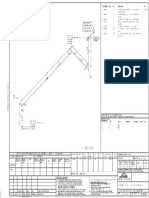

MS 1099 0002 Concrete Repair

Uploaded by

MuhammedHafisCopyright:

Available Formats

r- --

nit

JJf10f GRf.illP:

LINDE AG - GAS AND ENGINEERING I

CONSOLIDATED CONTRACTORS CO.

,)'2.0'

$%" ~4>'""'-k=",

~ta~

AL JUBAIL HAYCO!AMMONIA PLANT

PROJECT NO.: 2410 A049

PROJECT CODE: AL JUBAIL to

METHOD STATEMENT

FOR

CONCRETE REPAIR

SITE MASTER

111S-1099-0002

SA -oD

~I T

1 3 AUG 2013

eee - DeG

JHP PROJECT

comments:

Opt.:

Date:

Name:

LINDE AG - GAS AND ENGINEERING

No further submission.

Document accepted as final.

PO

Incorporate comments and

resubmit document.

XO

Document not accepted and

rejected.

AI JUBAIL HYCO / AMMONIA PLANT

This review does not constiMe acceptance or appro'J~1 of deSlgl

details, calculatioos, analysis. test, methods or maten~s

developed or selected by the supplier and does not reheve

suppti6r from full collliiance with spedfications and contractual

obliaations.

~

Dale:

Linde Engineering Middle East

12. Aug 2013

Dept

_E_N_D__

Name: Binu Kumar

Issued for Review & Approval

23.10.2012

Rev

Desrription

Date

Page 1 of8

Prepared By

Checked By

Verified By

WI'i' umit' 6f?I;,\iVr:

LINDE AG - GAS AND ENGINEERING /

CONSOLIDATED CONTRACTORS CO.

AL JUBAIL HA YCO/AMMONIA PLANT

PROJECT NO.: 2410 A049

PROJECT CODE:

JUBAIL 10

INDEX

1. PURPOSE

2. SCOPE

3. DEFINITIONS

4. REFERENCE DOCUMENTS

5. RESPONSIBILITIES

6. PROCEDURES

7. RESOURCES

8. SAFETY

Page 2 of8

W"dMfllil%w&:~ ~* =~%;;

fHf tmf;l'f:

(~ROUV

LINDE AG - GAS AND ENGINEERING I

CONSOLIDATED CONTRACTORS CO.

ALJUBAIL HAYCO/AMMONIA PLANT

PROJECT NO.: 2410 A049

PROJECT CODE : ALJUBAIL 10

"

j%""0~""" ""'h

~i:te

1.0 Purpose

The purpose of this Method Statement is to set guidelines and

methodology to be followed while repairing poured Concrete.

2.0 Scope

This method statement covers all works related to concrete repair in the

JUABIL HJyCO AMMONIA project unless their very special cassis is not

covered in 'this method.

3.0 Responsibilities

3.1

Construction Manager - To ensure that all work is executed as per

Project procedure, standard, and specification. Also he should make

sure that all project & SADARA safety requirements are applied during

construction.

3.2 Site lor section engineer - Responsible for the implementation of

This procedure as describe in this method and to mange, coordinate all

Activates /'. ','

3.3 Site Foreman - Responsible for the execution and site control of the

works on site.

3.4 QC Engineer - Responsible to ensure that all activities are carried out as

per the QC reqUirements of the project.

3.5 HSE Engineer - Responsible to ensure that all activities are carried out

safely and in compliance with SADARA regulations and the project

safety procedures. Also he is responsible to make sure that all permits

are obtained for any activity as SADARA requirements.

4.0 Definitions

4.1- Clint:

LINDE AG - GAS ENGINEERING

4.2 Contractor: CONSOLIDATED Contractor Company

4.3 JHAP:

JUBAIL HYCO\ AMMONIA PLANT PROJECT

5.0 REFERENCES

5.1

&AA-C-ZA-10001,001 STANDERD DRAWING CIVIL WORK

5.2 CCC-Q-PA-1230(QCP-1099-230) Quality Control plan for

Concrete work

5.4

Page 3 of8

CCC-Q-PB-1233(ITP-1099-233) lTP FOR CONCRETE WORK

'7

'HU: UM1.HtHWr-

LINDE AG - GAS AND ENGINEERING I

CONSOLIDATED CONTRACTORS CO.

",;<i

PROCEDURES

6.1 Air Bubbles

An air bubble doesn't need any repair.

6.2 Honeycombing

If minor honeycombs apparent on any orientation, where the

reinforcement not exposed:

1. Mark out the defective area and grind it.

2. Break out the area until a sound homogenous substrate

has been reached.

3. Wash the substrate with potable water to remove all dust

deposits.

4. Thoroughly soak the substrate with potable water

approximately one hour prior to application of repair.

5. Apply bonding agent to the concrete substrate by brush,

ensuring the concrete surface is wetted out.

6. Apply the repair material in layers, 20mm each whilst

bonding agent is still tacky. If bonding agent dries, the

substrate can be primed

7.

If the substrate can't be reached or hard to handle

by trowel, apply flow able material should be used.

8. If its need any cosmetic repair, fine grout will be used for

the last layer.

9. Cure the repaired area for 48 hours.

PIGvidot Und*"ut

fotKey

Palm Ib.'",nd",ct

Page 4 of8

*?

~--"

~iihe

AL JUBAIL HAYCO/AMMONIA PLANT

PROJECT NO.: 2410 A049

PROJECT CODE: ALJUBAIL 10

6.0

~"" -~

- - - - - - - -

HHl {.PUtt ~!jtOUf

LINDE AG - GAS AND ENGINEERING I

CONSOLIDATED CONTRACTORS CO.

AL JUBAIL HAYCO/AMMONIA PLANT

PROJECT NO.: 2410 A049

10

iiMttK@ W

reinforcement are exposed:

1. Break out the area until a sound homogenous substrate

has been reached.

2. Wash the substrate with potable water to remove all dust

deposits.

3. Make sure the reinforcement is clean and paint it with

Zinc-Rich epoxy bonding agent for all rebar sides.

4. Develop a form system which permits placement from the

top of the void with the form extending above the void by

at least a few inches.

5. Apply a shrinkage controlled, fluid micro-concrete

continuously Roding to ensure a sound placement. The

concrete shall be placed to extend above the void area.

6. Upon initial set, remove the form and chip excess

concrete from the repaired surface.

7. Cure the repaired area for 48 hours.

Provide Undercut

for Key

Form Extended

Above Void

Page 5 ofa

Y.->",!{

If major honeycombs apparent on any orientation, and the

Honey Comb

#f.:;j,

---------------------------------

-------------------

n~t

umt( ~llltwP

_0%'* rl,,*~""~,,"*,~~

LINDE AG - GAS AND ENGINEERING I

CONSOLIDATED CONTRACTORS CO.

AL JUBAIL HAYCO/AMMONIA PLANT

PROJECT NO.: 2410 A049

PROJECT CODE: AL JUBAIL 10

6.3 Cracks

-

for minor (surface) cracks, repair will be as follow:

1. Cracks equal to or less than O.2mm (Hair crack) which

are the capillary cracks will not need any repair

2. Cracks more than 0.2mm and less than 0.5mm (line

crack) will be repaired by open the crack using the

grinder.

3. Cracks between 0.5 and 3mm, the crack should be

opened in V shape.

4. Wash the substrate with potable water to remove all dust

deposits

5. Thoroughly soak the substrate with potable water

approximately one hour prior to application of repair.

6. Apply approved material of fine non-shrinkage grout.

7. Cure the repaired area for 48 hours.

for major (deep) cracks, repair will be as follow:

Deep cracks shall be studied on a case by case basis and the

corrective plan shall be proposed and agreed with LINDE prior

to commencement of work at site

6.4closing tie rod hole's concrete

1. Remove the plastic cones.

2. Thoroughly soak the hole with potable water

approximately one hour prior to application of nonshrinkage grout and cement mortar.

3. Apply cement mortar in the middle and non-shrinkage

grout in the edges of a depth of 20mm.

4. Compact the cement mortar into the tie rod hole by

trowel, and finish with a steel trowel.

5. Cure the exposed surface area for 48 hours.

~

'\. CEMENT

MORTAR

Page 6 of8

""NON-SHRINKAGE

GROUT

--------------------------

f~H<m'tt ~aotii"

LINDE AG - GAS AND ENGINEERING I

CONSOLIDATED CONTRACTORS CO.

AL JUBAIL HA YCO/AMMONIA PLANT

PROJECT NO.: 2410 A049

PROJECT CODE: AL JUBAIL 10

"~

"am'"

"'" ""

~e

6.5 Repair the edge of joint

1. Detect poor finished surface and mark it.

2. Poor finished surtace should be chiseled to a sound

homogenous surtace.

3. Wash the substrate with potable water to remove all dust

deposits.

4. Thoroughly soak the substrate with potable water

approximately one hour prior to application of repair.

5. Apply bonding agent to the concrete substrate by brush.

ensuring the concrete surface is wetted out.

6. Repair material shall be applied in layers, 20mm each

whilst bonding agent is still tacky. If bonding agent dries,

the substrate can be primed.

7. Cure the exposed surface area for 48 hours.

6.6 Repair concrete around any sleeves

1. Detect dedicative area.

2. Break out the area until a sound homogenous substrate

has been reached.

3. Wash the substrate with potable water to remove all dust

deposits.

4. Thoroughly soak the substrate with potable water

approximately one hour prior to application of repair.

5. Apply bonding agent to the concrete substrate by brush.

ensuring the concrete surface is wetted out.

6. Apply the repair material in layers, 20mm each whilst

bonding agent is still tacky. If bonding agent dries, the

substrate can be primed

7.

If the substrate can't be reached or hard to handle

by trowel, flow able material should be used

8. Cure the repaired area for 48 hours.

Page 7 of 8

<'7

rHllIYlt1f:(tRt):i,W

LINDE AG - GAS AND ENGINEERING I

CONSOLIDATED CONTRACTORS CO.

AL JUBAIL HAyeO/AMMONIA PLANT

PROJECT NO.: 2410 A049

7.0

"~0

@*

c:2iiiJLe

RESOURCES:

7.1 Hand tools

Drill.

Electrical mixer.

Trowel.

Hammer.

Chisel.

7.2 Manpower

Supervisor/foreman.

Mason.

laborer.

8.0 SAFETY

All personnel involved in the above activity shall follow the

construction HSE Plans/Procedure as well as SADARA relevant

HSE manuals.

All safety measures defined in the relevant procedures shall be

implemented.

In case of contact with skin, rinse with plenty of clean water, then

cleanse thoroughly with soap and water.

In case of contact with eyes, rinse immediately with plenty of clean

water and seek medical advice.

Page 8 of8

All materials shall be stored, handled and used in a safe and proper

manner, and as advised by the material safety data sheet.

Contents of Material safety data sheet for a certain product shall be

explained to the workers in a Tool Box Talk prior to using this

product.

All personnel involved shall wear PPE.

rffi;M~ '=h

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- PR-UPP-TCC-WIS-QC-014: Above Ground Steel Piping Pressure Test ProcedureDocument1 pagePR-UPP-TCC-WIS-QC-014: Above Ground Steel Piping Pressure Test ProcedureMuhammedHafisNo ratings yet

- Tie in Joint Welding Gold Weld SpecDocument1 pageTie in Joint Welding Gold Weld SpecMuhammedHafisNo ratings yet

- Fiberstrong and Wavistrong Flange GuideDocument46 pagesFiberstrong and Wavistrong Flange GuideMuhammedHafisNo ratings yet

- Black Spots On DSS WeldsDocument4 pagesBlack Spots On DSS WeldsMuhammedHafisNo ratings yet

- t15b03-0102 - 0painting Specification For Whb&Steam DrumDocument36 pagest15b03-0102 - 0painting Specification For Whb&Steam DrumMuhammedHafisNo ratings yet

- Field Hydrotest (Restrained) PDFDocument5 pagesField Hydrotest (Restrained) PDFMuhammedHafisNo ratings yet

- Tie in Joint Welding (Gold Weld) SpecDocument8 pagesTie in Joint Welding (Gold Weld) Specrepository1100% (2)

- SKMBT 28316102714300Document2 pagesSKMBT 28316102714300MuhammedHafis100% (1)

- Field Hydrotest (Restrained)Document5 pagesField Hydrotest (Restrained)MuhammedHafisNo ratings yet

- AG+Piping+Test+Pack CompressedDocument61 pagesAG+Piping+Test+Pack CompressedMuhammedHafis67% (3)

- BLR - MD Pgdia Ppt.. 2014..Document26 pagesBLR - MD Pgdia Ppt.. 2014..MuhammedHafisNo ratings yet

- Copy of QC Folder Spine (檔案封條)Document11 pagesCopy of QC Folder Spine (檔案封條)MuhammedHafisNo ratings yet

- Tie in Joint Welding (Gold Weld) SpecDocument8 pagesTie in Joint Welding (Gold Weld) Specrepository1100% (2)

- 1ug L-ZL 16 1-1605-838.001 1.0Document1 page1ug L-ZL 16 1-1605-838.001 1.0MuhammedHafisNo ratings yet

- 1ug L-ZL 10 1-1003-847.001 1.0Document1 page1ug L-ZL 10 1-1003-847.001 1.0MuhammedHafisNo ratings yet

- 1ug L-ZL 96 1-9602-105.001 2.0Document1 page1ug L-ZL 96 1-9602-105.001 2.0MuhammedHafisNo ratings yet

- Galvocoat 16380Document2 pagesGalvocoat 16380MuhammedHafisNo ratings yet

- 1ug L-ZL 92 1-9201-101.003 2.0Document1 page1ug L-ZL 92 1-9201-101.003 2.0MuhammedHafisNo ratings yet

- 1ug L-ZL 16 1-1605-836.001 1.0Document1 page1ug L-ZL 16 1-1605-836.001 1.0MuhammedHafisNo ratings yet

- 1ug L-ZL 16 1-1606-841.001 1.0Document1 page1ug L-ZL 16 1-1606-841.001 1.0MuhammedHafisNo ratings yet

- 1ug L-ZL 15 1-1502-832.001 1.0Document1 page1ug L-ZL 15 1-1502-832.001 1.0MuhammedHafisNo ratings yet

- Valve & Flanch Box RecordeDocument7 pagesValve & Flanch Box RecordeMuhammedHafisNo ratings yet

- 1ug L-ZL 16 1-1605-837.001 1.0Document1 page1ug L-ZL 16 1-1605-837.001 1.0MuhammedHafisNo ratings yet

- 1ug L-ZL 15 1-1503-831.001 1.0Document1 page1ug L-ZL 15 1-1503-831.001 1.0MuhammedHafisNo ratings yet

- RT Request Form: Line No Sheet No Joint No Sch/Thicwelder Nowps No ProcessDocument2 pagesRT Request Form: Line No Sheet No Joint No Sch/Thicwelder Nowps No ProcessMuhammedHafisNo ratings yet

- 1ug L-ZL 16 1-1605-836.001 1.0Document1 page1ug L-ZL 16 1-1605-836.001 1.0MuhammedHafisNo ratings yet

- 1ug L-ZL 10 1-1003-846.001 1.0Document1 page1ug L-ZL 10 1-1003-846.001 1.0MuhammedHafisNo ratings yet

- Ultra SonicDocument1 pageUltra SonicMuhammedHafisNo ratings yet

- Jubail Hyco Ammonia Plant: Daily Welding ReportDocument4 pagesJubail Hyco Ammonia Plant: Daily Welding ReportMuhammedHafisNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Written Lockout/Tagout Program University of South Carolina (Enter Department Name Here)Document13 pagesWritten Lockout/Tagout Program University of South Carolina (Enter Department Name Here)SaidNo ratings yet

- Smart Sketch GuideDocument690 pagesSmart Sketch Guidesenthilsp3d100% (1)

- Borehole Imaging Tools PDFDocument4 pagesBorehole Imaging Tools PDFshahbazmirzaNo ratings yet

- Combustion Engine Development Utilizing Design For Six Sigma (DFSS)Document8 pagesCombustion Engine Development Utilizing Design For Six Sigma (DFSS)dilip sahooNo ratings yet

- Developer Feasibility StudyDocument9 pagesDeveloper Feasibility Studysam dorilloNo ratings yet

- Grading Spun Yarns For Appearance: Standard Test Method ForDocument5 pagesGrading Spun Yarns For Appearance: Standard Test Method ForShaker Qaidi100% (1)

- Rai Quo NK 001 0124Document5 pagesRai Quo NK 001 0124yudii.hidayatNo ratings yet

- Timber-framed homes guideDocument44 pagesTimber-framed homes guideMtkNo ratings yet

- Data Sheet 3196 MT-i - 3X4-13 - 130 m3h X 47 M GBQ - 49.991 - 14Document10 pagesData Sheet 3196 MT-i - 3X4-13 - 130 m3h X 47 M GBQ - 49.991 - 14Vinícius Toni MartinsNo ratings yet

- Race To The Sky Race To The Sky Heats Up in YangonHeats Up in YangonDocument2 pagesRace To The Sky Race To The Sky Heats Up in YangonHeats Up in YangonkenwongwmNo ratings yet

- Large vs Small Farms: Production Cost Per Acre Key FactorDocument40 pagesLarge vs Small Farms: Production Cost Per Acre Key FactorBrian WenaniNo ratings yet

- G-code Programming Language GuideDocument16 pagesG-code Programming Language GuideArnold NagyNo ratings yet

- CAT992Document24 pagesCAT992Miriam Ruiz Cabellos100% (1)

- ISO 6346 - Wikipedia, The Free EncyclopediaDocument10 pagesISO 6346 - Wikipedia, The Free EncyclopediaJogi Oscar SinagaNo ratings yet

- Stockdale Method Roundabout PDFDocument50 pagesStockdale Method Roundabout PDFAnonymous O7BzqVvmINo ratings yet

- Comsoal: Computer Method For Sequencing Operations For Assembly LinesDocument30 pagesComsoal: Computer Method For Sequencing Operations For Assembly LinesCarson HungNo ratings yet

- Coast Aluminum Catalog, 2019Document200 pagesCoast Aluminum Catalog, 2019roberto silvaNo ratings yet

- T100 Thrusters PropellerDocument15 pagesT100 Thrusters PropellerNikhilkrishna NairNo ratings yet

- LED LCD TV Repair Guide: WWW - Television-Magazine - Co.ukDocument47 pagesLED LCD TV Repair Guide: WWW - Television-Magazine - Co.ukShauna WhelanNo ratings yet

- RISK ASESSMENT For SKYLIGHTDocument23 pagesRISK ASESSMENT For SKYLIGHTadeoye Adeyemi100% (1)

- Business Process ModelingDocument89 pagesBusiness Process ModelingAhsan Zaman100% (2)

- Simulado 2 MMDocument16 pagesSimulado 2 MMThiago LimaNo ratings yet

- Method Statement For Installation of Aftercooler Compressor E-2180Document11 pagesMethod Statement For Installation of Aftercooler Compressor E-2180Anyanele Nnamdi FelixNo ratings yet

- E - Bike Market.Document86 pagesE - Bike Market.masterineducation100% (1)

- General Considerations For Residential Considerations in Singapore Residential PropertyDocument54 pagesGeneral Considerations For Residential Considerations in Singapore Residential PropertyhosamlockNo ratings yet

- WPD Wpbwall Fans Catalog 4820Document24 pagesWPD Wpbwall Fans Catalog 4820beemer03No ratings yet

- Module 7 (Maintenance Practices) Sub Module 7.1 (Safety Precautions-Aircraft and Workshop) PDFDocument42 pagesModule 7 (Maintenance Practices) Sub Module 7.1 (Safety Precautions-Aircraft and Workshop) PDFshareyhou100% (1)

- Upper West Side Town House Construction SetDocument34 pagesUpper West Side Town House Construction SethannahchiaroniclarkeNo ratings yet

- Ut Calibration Blocks DetailsDocument44 pagesUt Calibration Blocks Detailsmdsajidalam100% (4)

- Bartec Headed Bars Qualification File and References 2017.09.08Document35 pagesBartec Headed Bars Qualification File and References 2017.09.08Andres Hermoso MeijideNo ratings yet