Professional Documents

Culture Documents

BP7 Safe Cleaning of Freight Containers

Uploaded by

khtibCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BP7 Safe Cleaning of Freight Containers

Uploaded by

khtibCopyright:

Available Formats

INTERNATIONAL SAFETY PANEL BRIEFING PAMPHLET NO 7

SAFE CLEANING OF FREIGHT

CONTAINERS

By

Jim Chubb, MNI

ICHCA INTERNATIONAL PREMIUM MEMBERS:

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

ICHCA INTERNATIONAL LIMITED is an independent, non-political international

membership organisation, whose membership comprises corporations, individuals,

academic institutions and other organisations involved in, or concerned with, the

international transport and cargo handling industry.

With an influential membership in numerous countries, ICHCA Internationals

objective is the improvement of efficiency in cargo handling by all modes of transport,

at all stages of the transport chain and in all regions of the world. This object is

achieved inter-alia by the dissemination of information on cargo handling to its

membership and their international industry.

ICHCA International enjoys consultative status with a number of inter-governmental

organisations. It also maintains a close liaison and association with many nongovernmental organisations.

ICHCA International has an Honorary President, a nine person Board and National

Sections and a Regional Chapter in various countries, together with an International

Registered Office in the U.K. The offices primary role is to co-ordinate the activities

of the organisation. It has an International Safety Panel and an International

Research Panel. The Registered Office maintains a unique and comprehensive

database of cargo handling information, publishes bi-monthly electronic newsletters,

an annual hard copy report and operates a dedicated technical enquiry service,

which is available to members. It also organises a biennial Conference.

Studies are undertaken and reports are periodically issued on a wide range of

subjects of interest and concern to members and their industry.

ICHCA International Limited

Suite 2, 85 Western Road,

Romford, Essex, RM1 3LS

United Kingdom

Tel:

Fax:

Email:

Website:

+44 (0) 1708 735295

+44 (0) 1708 735225

info@ichcainternational.co.uk

www.ichcainternational.co.uk

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

The International Safety Panel Briefing Pamphlet series consists of the following

subjects:

No. 1

No. 2

No. 3

No. 4

No. 5

No. 6

No. 7

No. 8

No. 9

No. 10

No. 11

No. 12

No. 13

No. 14

No. 15

No. 16

No. 17

No. 18

No. 19

No. 20

No. 21

No. 22

No. 23

International Labour Office (ILO) Convention No. 152 Occupational

Safety and Health in Dockwork (revised)

Ships Lifting Plant (revised)

The International Maritime Dangerous Goods (IMDG) Code (revised))

Classification Societies (Revised)

Container Terminal Safety

Guidance on the Preparation of Emergency Plans (under revision)

Safe Cleaning of Freight Containers (under revision)

Safe Working on Container Ships

Safe Use of Flexible Intermediate Bulk Containers (FIBCs) (Revised)

Safe Working at Ro-Ro Terminals

The International Convention for Safe Containers (CSC)

Safety Audit System for Ports

The Loading and Unloading of Solid Bulk Cargoes

The Role of the Independent Marine Surveyor in Assisting Claims

Handling

Substance Abuse

Safe Use of Textile Slings

Shore Ramps and Walkways

Port State Control

Safe Handling of Interlocked Flats

Unseen Dangers in Containers

Stow it right

Suspension Trauma

Safe Handling of Forest Products

The International Safety Panel Research Paper series consists of the following

subjects

No. 1

No. 2

No. 3

No. 4

No. 5

No. 6

No. 7

No. 8

No. 9

No. 10

No. 11

Semi-Automatic Twistlocks (under revision)

Fumes in Ships Holds (revised)

Health & Safety Assessments in Ports (under revision)

Container Top Safety, Lashing and Other Related Matters

Port & Terminal Accident Statistics (under revision)

Safe Handling of Radioactive Materials in Ports and Harbour Areas

(under revision)

Ship Design Considerations for Stevedore Safety (under revision

Safe Walkways in Port & Terminal Areas

Personal Protective Equipment & Clothing

Back Pain

Lifting Persons at Work for Cargo Handling purposes in the Port

Industry

The International Safety Panel Technical/Operational Advice series consists of the

following:

No. 1

No. 1A

Vertical Tandem Lifting of Freight Containers

Vertical Tandem Lifting Operations Checklist

Plasticised Pocket Cards

IIL/1

Dangerous Goods by Sea Documentation

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

IIL/2

Dangerous Goods by Sea: The IMDG Code Labels, Placards, Marks

and Signs

General Series

No. 1

Guidelines to Shipping Packaged Dangerous Goods by Sea advice

to consignors and shippers

Other titles in all the series are in preparation

This publication is one of a series developed by the International Safety Panel

("Safety Panel") of ICHCA International Limited ("ICHCA"). The series is designed to

inform those involved in the cargo-handling field of various practical health and safety

issues. ICHCA aims to encourage port safety, the reduction of accidents in port work

and the protection of port workers' health.

ICHCA prepares its publications according to the information available at the time of

publication. This publication does not constitute professional advice nor is it an

exhaustive summary of the information available on the subject matter to which the

publication refers. The publication should always be read in conjunction with the

relevant national and international legislation and any applicable regulations,

standards and codes of practice. Every effort is made to ensure the accuracy of the

information but neither ICHCA nor any member of the Safety Panel is responsible for

any loss, damage, costs or expenses incurred (whether or not in negligence) arising

from reliance on or interpretation of the publication.

The comments set out in this publication are not necessarily the views of ICHCA or

any member of the Safety Panel

All rights reserved. No part of this publication may be reproduced or copied without

ICHCA's prior written permission. For information, contact ICHCA's registered office.

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

ICHCA International Limited - INTERNATIONAL SAFETY PANEL

The International Safety Panel is composed of safety and training officers and directors,

transport consultants, representatives from leading safety and training organisations,

enforcement agencies, trade unions, insurance interests, institutions and leading

authorities on the subject area from around the world.

Mike Compton (Chairman), Circlechief AP, UK

John Alexander, UK

Paul Auston, Checkmate UK Limited, UK

David Avery, Firefly Limited, UK

Peter Bamford, Canada

Bob Barnes, UK

Mike Bohlman, Horizon Lines, USA (Deputy Chairman)

Roy Boneham, UK

Bill Brassington, GeSeaCo, UK

Jim Chubb, BMT Murray Fenton Limited, UK

Gary Danback, IICL, USA

Rob Dieda, SSA, USA

Patricia Esquival, OPCSA, SPAIN

Margaret Fitzgerald, Ireland

Jamie Frater, P&O Ports, UK

Fabian Guerra, Fabian Guerra Associates, EQUADOR

Harri Halme, Min. of Social Affairs & Health, Dept for Occupational Health & Safety,

FINLAND

Jeff Hurst, Hutchison Ports (UK) Limited, UK

Peter van der Kluit, THE NETHERLANDS

Fer van der Laar, IAPH, THE NETHERLANDS

Larry Liberatore, OSHA, USA

Shimon Lior, Israel Ports, Development and Assets, ISRAEL

Eric Luca, ECT, THE NETHERLANDS

Richard Marks, Royal Haskoning, UK

Joachim Meifort, Hamburger Hafen-u Lagerhaus A-G, GERMANY

Marios Meletiou, ILO, SWITZERLAND

John Miller, Mersey Docks & Harbour Company, UK

Al le Monnier, ITF/ILWU, CANADA

Eric Noterman, P&O/PSA, BELGIUM

Pedro J. Roman Nunez, Puertos del Estado, SPAIN

John Nicholls, UK

Nic Paines, Gordon, Giles & Coy Ltd, UK

Benoit Passard, PEMA, SWEDEN

Mick Payze, AUSTRALIA

Irfan Rahim, International Maritime Organization, UK

Captain Peter Lundahl Rasmussen, BIMCO, DENMARK

Risto Repo, Accident Investigation Bureau of Finland, FINLAND

Raymond van Rooyan, SAPO, SOUTH AFRICA

Ron Signorino, The Blueoceana Company, Inc., USA

Armin Steinhoff, Behrde fr Arbeit, Hamburg, GERMANY

Bala Subramaniam, INDIA

Andrew Synnott, Patrick Stevedoring, AUSTRALIA

Markus Theuerholz, MacGregor-Conver, GERMANY

Hubert Vanleenhove, Hessanatie, BELGIUM

Andrew Webster, TT Club, UK (Deputy Chairman)

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

Evert Wijdeveld, Environmental & Safety Affairs, Deltalinqs, THE NETHERLANDS

(Deputy Chairman)

Bill Williams, Maersk Inc. USA

OBSERVERS:

Capt. Jim McNamara, National Cargo Bureau, Inc., USA

Charles Visconti, International Cargo Gear Bureau, Inc., USA

CORRESPONDING/ASSOCIATED MEMBERS:

Gerrit Laubscher, Estivar pty, SOUTH AFRICA

Paul Ho, HIT, HONG KONG

Paul Rossi, OSHA, USA

Richard Day, Transport Canada, CANADA

Samuel Ng, Maritime Department, HONG KONG

The above lists those persons who were members of the Panel when the pamphlet was

published. However, membership does change and a list of current members can always be

obtained from the ICHCA International Secretariat.

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

About the Author

Jim Chubb, MNI, is a Master Mariner, whose sea-going career was mainly spent

serving on either general cargo or container vessels. On coming ashore in 1978 he

joined Associated Container Transport Services Ltd as a Marine Co-ordinator with

responsibilities for stowage planning and shipboard container lashing systems.

In 1989 he was appointed Cargo Care Manager responsible for day-to-day cargo

handling activities within Europe for Principals engaged in the container

transportation of general perishable and dangerous goods. An important aspect of

his work was the cleanliness of the containers.

Prior to joining the ICHCA International Safety Panel he undertook on their behalf a

research study into Semi-Automatic Twistlocks. The Research Paper was

published in January 1994 and looked to identify the various types currently available

and the working practices involved in their use.

At present he is a Director with BMT Murray Fenton Ltd, a leading firm of London

based Marine Consultants and Surveyors, and is using his specialist knowledge of

the stowage and securing of containers to expand the range of services offered by

the Company.

BMT Murray Fenton Ltd

London

+44 (0)20 7234 9160

Southampton +44 (0)23 8022 9787

South Shields +44 (0)191 427 7807

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

Contents

Page

1. Introduction

2. Residues

3. Identification of Residues

4. Cleaning Operations

5. IICL/ICS General Guide for Container Cleaning

6. Cleaning Methods

7. Conclusions

Appendix One: An example of advice issued by a container operator

Appendix Two: An example of the contents of an instructional label

affixed to the inside of the container doors

Bibliography

ISBN: 1 85330 061 6

978-1-85330-061-5

First published

Revised

1997

2006

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

SAFE CLEANING OF FREIGHT CONTAINERS

1

INTRODUCTION

1.1

The internal and external cleanliness of freight containers is very important if

unnecessary restrictions to their use and movement are to be avoided. It does

not matter whether containers are to be cleaned either for

quarantine control to prevent exportation of pests and diseases

maintenance of food quality containers

avoidance of cross taint between consecutive loads

removal of nails and other items that can damage cargo packaging

removal of cargo residue.

1.2

The cleaning operation must always be undertaken in a safe and controlled

manner.

1.3

This pamphlet considers the requirements for the safe cleaning of general

purpose, insulated and refrigerated (reefer) containers. The specialised

requirements for tank containers are not covered.

RESIDUES

2.1

Under the terms of a Bill of Lading for a full container load (FCL), it is normally

the consignees/receivers responsibility to ensure that a container is returned

to the carrier/container operator in a clean condition. Unfortunately, this duty is

frequently overlooked and containers are often returned with cargo residue and

securing material remaining inside.

2.2

Before any container cleaning operation is undertaken any cargo residue

should be precisely identified.

2.3

As regards dangerous and hazardous goods, the International Maritime

Dangerous Goods (IMDG) Code stipulates that for most dangerous goods

hazard placards should be affixed to the exterior of the side and end walls of a

freight container to provide a warning that the contents are dangerous goods

and present a hazard. This includes a warning sign if the cargo is moving

whilst under fumigation. The placards/sign should not be removed until the

dangerous goods and their residues have been totally removed from within the

container. If hazard placards/sign are removed on discharge of the cargo, but

prior to the removal of any residue, the next person(s) entering the container

can be unknowingly exposed to a substance that could be hazardous to their

health.

2.4

Unfortunately, on occasions dangerous goods have been inadvertently or

wilfully mis-declared. An example of this was a shipment of expandable

polymeric beads (UN No. 2211, Class 9) that had not been declared as

hazardous, but nevertheless evolved sufficient propane gas to create an

explosive atmosphere and the death of two individuals who were attempting to

unpack the freight container.

1

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

2.5

The air tightness of insulated and reefer containers, and even some general

freight containers, can result in the build up of a hazardous atmosphere inside.

The atmosphere could be toxic, oxygen deficient or even explosive. Ideally, the

atmosphere within a container should be checked to ensure that it is safe to

enter. A number of container terminals now have strict instructions and will not

allow their staff to enter a freight container until the atmosphere is checked by a

suitably qualified contractor with the necessary sampling equipment. In the

absence of equipment to check the atmosphere within a container it should not

be entered until sufficient time has elapsed for the atmosphere within the

container to have been adequately ventilated. At least two people should be

present, with one standing back, when the doors of a container are opened so

that if a person is overcome, an immediate alarm can be raised.

2.6

Anyone who is about to enter a container must recognise that the absence of

hazard placards/sign cannot be assumed to indicate that the container is safe

to enter. Hazard placards/sign may have been prematurely removed, may

never have been affixed, may not have been required in the first place, or,

undeclared dangerous goods may have been shipped.

2.7

There are attendant risks whenever the doors of a container are opened,

irrespective of whether the container is loaded or empty. For example such

risks could include cargo falling out and/or the container doors swinging open

abruptly and injuring anyone standing in the vicinity. To minimise such risk a

restraining strap should be looped around the locking bars of the two doors

prior to opening so that any immediate movement of the doors will be restricted

if cargo starts to fall out of the container.

2.8

When a container is swept out while mounted on a trailer, cargo residue should

not be allowed to fall onto the trailer. In one incident, although the container

had been swept out, the residue of a class 6.1 toxic powder covered the rear

end of the trailer. Shortly afterwards the residue was handled by a mechanic

maintaining the trailer. He became seriously ill after swallowing some of the

toxic powder, having not adequately cleaned his hands before a meal break.

2.9

Even if cargo residue that has been swept on to a trailer is not directly handled

it can become airborne and might be inhaled by persons standing near the

trailer as the particles of residue are blown off. Such incidents have resulted in

hauliers being prosecuted and fined for having dangerous goods residues

adhering to the outside of their vehicles.

2.10 The frequent imbalance in import and export container movements means that

large quantities of empty units are moved around the world. It may, therefore,

be some considerable time before a container is re-used. Consequently, if a

container has not been cleaned on discharge and cargo residue is present, it

may be found a long way from where the cargo itself was delivered.

2.11 Uncertainty about whether a container might contain residue or not has

resulted in some container operators issuing an advice to sub-contractors

regarding the caution that should always be exercised when entering a

container. For an example of such advice see Appendix 1.

2.12 Some container operators affix a label to the inside of the container doors to

highlight various points to shippers and receivers. For an example of such a

label see Appendix 2. Such advice and labels do not alter the responsibilities of

container operators and others such as shippers, packers, cleaners etc.

2

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

3

IDENTIFICATION OF RESIDUES

3.1

Irrespective of whether there is particular national legislation, all those

responsible for detailing persons to enter freight containers where unidentified

substances may be encountered should have a recognised procedure for the

reporting and handling of unidentified substances.

3.2

Such procedures and advice to persons entering containers should include, but

may not be limited to the following points:

3.3

A warning to not smoke or use any ignition source in the vicinity of a

container that is being opened

A warning that CAUTION should always be exercised when first

entering a container

A warning to know the potential hazards associated with the

commodities and any associated packaging thought to be in the

container

A warning that any residual White Powder can be anything from

talcum powder to a lethal poison and must be Treated as the worst

possibility until proven otherwise

A warning that all personnel should leave the container immediately on

discovery of an unidentified substance, and the container placed out of

bounds until the substance can be identified

A warning that no attempt should be made to handle or remove any

such substance until it has been identified

A procedure whereby all staff and sub-contractors are readily aware of

whom they should contact on discovering an unidentified substance

Advice on Precautions and Actions to be taken if a person is overcome

inside a container, for example o

No one should enter the container without personal

protective equipment, for example Breathing Apparatus;

Emergency and medical aid should be summoned

immediately;

Whilst awaiting the emergency and medical services

consideration should be given to what further action could

be safely undertaken without jeopardising the safety of

others, for example:

Opening both doors fully to allow maximum natural

ventilation;

Forced air ventilation, or

Tipping an empty container to see if the unconscious

person will slide along the floor towards the doors.

The procedure should include a system for verifying the previous contents of

containers and their potential hazards. This may not only require checking the

immediate past cargo, but also the cargo carried in the last two or three

movements. The last cargo may have been loaded into an already dirty

container.

3

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

3.4

If the residue cannot be identified three possibilities may exist

The residue is of a non-hazardous substance applied to protect the

cargo, e.g. talcum powder on bales of rubber

The residue is from cargo that was non-hazardous

The residue is from cargo that was hazardous

3.5

Unless the residue can be instantly identified it should be treated as

hazardous until proven otherwise, based on the assumptions that the

residue was something not knowingly carried, that an undeclared or misdeclared hazardous cargo may have been shipped in the container or a haulier

may have used the container to carry his own unknown cargo.

3.6

If any doubt exists about the identification of a cargo residue or any unknown

substance inside a container a sample should be taken for analysis. The taking

of samples should be done in a controlled manner, by an authorised person

wearing appropriate personal protective equipment such as respiratory

protective equipment and impervious gloves.

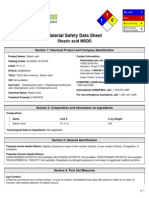

CLEANING OPERATIONS

4.1

Once the residue in a container is identified, the container operator should

appoint a cleaning contractor who has the experience and facilities for the

proper cleaning and disposal of the residue.

4.2

Before any cleaning operation is undertaken the following aspects should be

considered:

4.3

The health & safety data for the residue itself, and of any cleaning

agent to be applied and the observance of any advised precautions;

As certain substances can be absorbed through the skin and mucous

membranes the availability of suitable personal protective equipment,

such as respiratory protective equipment and/or protective suits and

boots, should be evaluated;

Whether the cleaning agent itself, when being used in a confined area,

might be hazardous. For example toxic and/or flammable and/or

corrosive;

Whether the proposed cleaning agent will have an adverse reaction

when combined with the residue in the container;

Whether the residue and/or cleaning agent should be allowed to enter

storm water or other drains, if not, what containment measures will be

necessary;

Requirements for the proper disposal of the residue and/or the

cleaning agent, for example, at an authorised site.

The cleaning operation for every container should be fully documented and

available. In the event of a subsequent allegation that persons engaged in a

cleaning operation may have been harmed, the cleaning contractor may need

to show that he has exercised the care and diligence for the health of persons

engaged in the cleaning operation.

4

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

5

IICL/ICS GENERAL GUIDE TO CONTAINER CLEANING

5.1

The Institute of International Container Lessors (IICL) and the International

Chamber of Shipping (ICS) have developed a General Guide for Container

Cleaning. The Guide is intended to be an adjunct to the existing IICL-5 Guide

for Container Equipment Inspections.

5.2

The Guide covers the cleaning of general-purpose freight containers only.

Open top, flat rack, refrigerated, insulated and tank containers are not covered.

The aim of the Guide is to set a standard of cleanliness necessary for the

carriage of most cargoes carried in general purpose freight containers and it

forms the basis for interchange agreements (on & off hire inspections). The

Guide aims to reduce the environmental effects of cleaning agents and the

range of certain components, e.g. hardwoods.

5.3

The Guide does not consider in detail the various safety issues relating to the

cleaning of containers. However, the Guide is very explicit regarding the action

to be taken when faced with residues that may be hazardous to health and

advises that any unknown substances must be considered as hazardous until

shown to be otherwise. (See paragraph 3.5 above).

CLEANING METHODS

6.1

A container may require cleaning for a number of reasons including -

6.2

Removal of signs and dangerous goods placards, etc.

Removal of cargo residue solid and/or liquid, either hazardous or nonhazardous

Infestation

Odours and Taints

Protruding Nails

Dunnage & packaging material removal

To return a container to a satisfactory acceptable condition, one or more of the

following cleaning methods may need to be used:

Dry sweep out

Vacuuming

Spreading absorbent powder, then sweeping out/vacuuming

Low pressure water wash, cold water, without specific cleaning agent

Scraping, sanding disc or wire brush

High pressure water wash:

o

Cold with or without specific cleaning agent

Hot with or without specific cleaning agent

Steam cleaning with or without specific cleaning agent

Solvent cleaning

Fumigation

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

6.3

Each cleaning method has its own advantages and disadvantages that can only

be considered in the light of the circumstances of each case.

6.4

Wherever possible the cleaning agent used should be biodegradable.

6.5

Sweeping will disturb dry particles causing dust to rise, which could be inhaled.

Whether a respirator will be sufficient or a self-contained breathing apparatus

required will depend upon the degree of risk presented by inhaling the

particular dust. If a respirator is used, it is essential that it has the correct filters

with the appropriate protection factor. Vacuuming is a preferable method of

cleaning, as less free dust is generated into the atmosphere.

6.6

The heat generated during a hot water wash or steam cleaning can result in

strong and irritating vapours being given off which could affect both personnel

and/or the container, for example ammonium bicarbonate can cause

respiratory problems and paint to peel.

6.7

Steam cleaning is undertaken with water temperatures of up to 150 degrees

Celsius. If the operator is not suitably trained and protected for using a steam

lance, improper use could result in severe scalding of the operator and/or other

personnel in the vicinity.

6.8

The treatment of mould on the internal surface of a container may require the

spray application of a fungicide. Before starting any such operation the

operator should ensure that he is suitably protected if the fungicide is

dangerous through skin contact and/or inhalation.

6.9

Solvents are sometimes applied with rags. When this is necessary it should be

ensured that there is adequate ventilation. Suitable, impervious gloves should

be worn by the operator to prevent drying out of the skin resulting in dermatitis.

Solvents may give off fumes or vapours that are harmful to health and suitable

precautions should be taken regarding their use. For transportation by sea oily

rags are classified as a Class 4.2. Spontaneously Combustible Substance, as

they are liable to ignite spontaneously according to the oil content. After use,

rags impregnated with oil, paint or solvent residue should be disposed of in a

controlled manner. They should not be left lying about as they could cause fire.

6.10 Every effort should be made to remove protruding nails, etc. When nails

cannot be removed without damaging the wooden component, i.e. floor, the

IICL/ICS repair method for protruding nails advises that the head of the nail

should be driven down until flush with the top surface of the wood and the point

of the nail should be bent against the underside of the wood.

6.11 Flexitanks should not be carried in general freight containers where nails have

been hammered flush into the floor as it has been found that, with the flexing of

the container during transportation, the nails can work free resulting in the

flexitank being punctured.

6.12 Regarding drummed cargo, the weight of loaded drums acting upon the floor of

a container has also been found sufficient to cause previously flush nail heads

to protrude and puncture the drums.

6.13 It is the responsibility of container operators to ensure that all cleaning

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

contractors are aware of the nature and properties of cleaning agents that

might be used, and are aware of any restrictions that might be placed on their

use internationally, and on the subsequent movement of containers.

6.14 Several countries have national regulatory requirements that relate to the type

of cleaning agents that may or may not be used. For example, there are

Federal Regulations in the USA that regulate the use of cleaning agents that

can be applied to containers that are destined to carry food. These

Regulations refer specifically to packaging and the phases of the food

distribution chain, and therefore apply to the internal surfaces of freight

containers. The Regulations require that when a material is not generally

recognised as safe it has to be authorised for use if it will come in direct or

incidental contact with a food product, or if there is a chance that the material

will impart a toxic substance, cause off-colours or otherwise contaminate the

food. This requirement covers cleaning and sanitising agents used to clean

the interiors of vehicles and containers; they must be authorised for safe use.

7

CONCLUSIONS

7.1

All incidents of cargo residue must be treated as being of the worst possibility,

i.e. hazardous toxic, flammable, corrosive, until proven otherwise.

7.2

All cleaning operations must be undertaken in a safe and controlled manner.

7.3

The cleaning operation for every container should be fully documented and

auditable as due care and diligence may need to be proven at a later date.

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

APPENDIX 1

An example of advice issued by a container operator

Re. CONTAINER CLEANING AND/OR REPAIRS

We wish to re-confirm to you the need for your operatives to be conscious of the fact that

containers delivered to you for cleaning and/or repair may contain residue of cargo,

some of which on rare occasions could be classified as hazardous or noxious.

We have no reason to believe that the current incidence of such containers is any

different from that which has prevailed over many years past, and when we are aware

that a container has carried special cargoes we will continue to advise you in

accordance with our past practices and procedures.

There are, however, occasions when we have no immediate knowledge of previous

cargoes carried, particularly when we are engaging leased containers, and we consider

it sensible to remind you that caution should always be exercised when first entering a

container.

If your operatives have any reason to query any residue substances with which they are

unfamiliar and consider suspect we will be pleased if you would advise us immediately to

allow us the opportunity to investigate and determine the substance, prior to he

operatives commencing work. The container should be place out of bounds until at last

the substance is identified.

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

APPENDIX 2

An example of the contents of an instructional label affixed to the inside of

the container doors

Before loading the shipper must check the proper condition of

the container.

By accepting the container the shipper

recognises its suitability for the loading of the cargo to be

carried.

Furthermore, attention is drawn to the fact that the consignee is

obliged to return the container after discharge clean and suitable

for the transport of every kind of cargo.

This applies especially when poisonous,

obnoxious cargo has been transported.

dangerous,

or

All labels referring to cargo shall be removed once the container

has been suitably cleaned and is free of residues.

ICHCA International Limited

ICHCA International Safety Panel Safety Briefing Pamphlet #7

BIBLIOGRAPHY

Institute of International Cargo Lessors/International Chamber of Shipping

General Guide for Container Cleaning

Guidelines to Department of Primary Industries + Energy

(DPE Inspections and Requirements)

The Australian Standards for Food Quality Shipping Containers

International Maritime Organisation

International Maritime Dangerous Goods Code

ICHCA International Limited

You might also like

- 179-CEN Air Quality - CEN TC 264Document6 pages179-CEN Air Quality - CEN TC 264khtibNo ratings yet

- BS en Iso 16911-1-2013 PDFDocument96 pagesBS en Iso 16911-1-2013 PDFkhtib100% (1)

- BS en Iso 7500-1-2015 PDFDocument28 pagesBS en Iso 7500-1-2015 PDFkhtib100% (2)

- Loading and Unloading of Solid Bulk Cargoes 2010Document34 pagesLoading and Unloading of Solid Bulk Cargoes 2010khtib100% (2)

- Sampling of Ambient Air For PM Concentration Using The Rupprecht and Patashnick (R&P) Low Volume Partisol® SamplerDocument40 pagesSampling of Ambient Air For PM Concentration Using The Rupprecht and Patashnick (R&P) Low Volume Partisol® SamplerkhtibNo ratings yet

- BP11 Container Safety Convention 2011 PDFDocument44 pagesBP11 Container Safety Convention 2011 PDFkhtib100% (1)

- BP10 Safe Working at RoRo TerminalsDocument29 pagesBP10 Safe Working at RoRo TerminalskhtibNo ratings yet

- Remote Controls For Lifting Equipment - GuidanceDocument7 pagesRemote Controls For Lifting Equipment - GuidancekhtibNo ratings yet

- ICHCA Chapter 9 Safe Use of Flexible Intermediate Bulk ContainersDocument27 pagesICHCA Chapter 9 Safe Use of Flexible Intermediate Bulk Containerskhtib100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Msds Klorin LengkapDocument5 pagesMsds Klorin LengkapDarzya OllongNo ratings yet

- 4 - (4-Hydroxyphenyl) - 2-Butanone 5471-51-2Document7 pages4 - (4-Hydroxyphenyl) - 2-Butanone 5471-51-2AnibarNo ratings yet

- Phenolphthalein IndicatorDocument6 pagesPhenolphthalein IndicatorwindaratlinNo ratings yet

- Competency Based Learning MaterialsDocument72 pagesCompetency Based Learning MaterialsLynde MaputolNo ratings yet

- Tailing MSDSDocument2 pagesTailing MSDSZacNo ratings yet

- 3M0280 3M PSD Catalogue 2018 - 19 - ALL - FA - LR - Final (Single Pages) - Full LoRes 15nov17Document244 pages3M0280 3M PSD Catalogue 2018 - 19 - ALL - FA - LR - Final (Single Pages) - Full LoRes 15nov17Nathan NadavNo ratings yet

- Saftey of Ammonia Handling PDF-libreDocument51 pagesSaftey of Ammonia Handling PDF-libreHumaira Mirza100% (1)

- BentoniteDocument2 pagesBentoniteViệt AnhNo ratings yet

- Grodal RPSB 106 P (MSDS)Document4 pagesGrodal RPSB 106 P (MSDS)Pratik LadNo ratings yet

- CikloheksanonDocument7 pagesCikloheksanonmicaziv4786No ratings yet

- Mediawebserver PDFDocument55 pagesMediawebserver PDFmwilmerNo ratings yet

- MillerDocument88 pagesMillerkimba worthNo ratings yet

- Hample MsdsDocument13 pagesHample MsdsAmir ahmadNo ratings yet

- MSDS Sodium Hypochlorite SolutionDocument5 pagesMSDS Sodium Hypochlorite SolutionAhmed GhariebNo ratings yet

- Material Safety Data Sheet: 1 - Identification of SubstanceDocument9 pagesMaterial Safety Data Sheet: 1 - Identification of SubstanceelsadwihermiatiNo ratings yet

- Imiforce 200 SCDocument5 pagesImiforce 200 SCzpmNo ratings yet

- Navy Safety and Occupational Health Manual: OPNAV M-5100.23 5 Jun 2020Document500 pagesNavy Safety and Occupational Health Manual: OPNAV M-5100.23 5 Jun 2020Cristian GonzalezNo ratings yet

- MSDS ABS GF 20% V0 XindaDocument5 pagesMSDS ABS GF 20% V0 Xindaanisa novita sariNo ratings yet

- Effect of Construction Dust On Construction Workers: Dr. Biswajit ThakurDocument31 pagesEffect of Construction Dust On Construction Workers: Dr. Biswajit ThakurMASUM HAFIZNo ratings yet

- Msds KMnO4 - 2Document6 pagesMsds KMnO4 - 2dinia fitrianiNo ratings yet

- Plan Training Session by DahamDocument47 pagesPlan Training Session by DahamMoore DahamNo ratings yet

- Alkamuls OR36 SDSDocument14 pagesAlkamuls OR36 SDSJingYeeNo ratings yet

- Safety Data Sheet: Product Name: MOBILGARD 540Document11 pagesSafety Data Sheet: Product Name: MOBILGARD 540Deepak ShoriNo ratings yet

- Scaffix Si-270 MsdsDocument6 pagesScaffix Si-270 Msdstaufiq hidayatNo ratings yet

- SDS Asphalt Emulsion CRS-1 & CSS-1hDocument12 pagesSDS Asphalt Emulsion CRS-1 & CSS-1hTorero02No ratings yet

- Stearic Acid MsdsDocument5 pagesStearic Acid Msdsapi-263411629No ratings yet

- Advanced Electrostatic MediaDocument6 pagesAdvanced Electrostatic MediaPedro Câncio NetoNo ratings yet

- MSDS Carbon Tetra ChlorideDocument8 pagesMSDS Carbon Tetra ChlorideEvi PamayantiNo ratings yet

- Msds HCLDocument7 pagesMsds HCLbagus kustantoNo ratings yet