Professional Documents

Culture Documents

Throttle FCV Double Acting, RS

Uploaded by

LibinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Throttle FCV Double Acting, RS

Uploaded by

LibinCopyright:

Available Formats

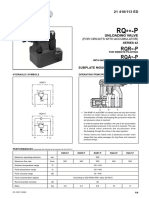

31 200/110 ED

RS *

DOUBLE-ACTING THROTTLE

FLOW CONTROL VALVE

SERIES 30

THREADED PORTS

CARTRIDGE TYPE

p max (see table of performances)

Q max (see table of performances)

OPERATING PRINCIPLE

The RS* and RS*-I valves are throttle flow control valves for in-line mounting,

directly in the line or as a cartridge complete with threading for in-block mounting.

Adjustment is obtained with a conical throttle that operates in a cylindrical seat and

allows a good linearity of the adjusted flow.

They are also used as flow shut-off valves since they guarantee good sealing when

completely closed.

The valves are always supplied with an adjustment knob that can be locked in any

position with a transverse positioned grub screw, as may be required.

PERFORMANCES

Valve code

(obtained with mineral oil with viscosity of 36 cSt at 50C)

Port

dimensions

BSP

Nominal

flow rate

[l/min]

Mass

RS2

1/4

15

0,2

RS3

3/8

30

0,4

RS4

1/2

50

0,6

RS5

3/4

80

1,3

RS6

150

2,6

RS7

200

3,0

RS8

220

4,2

RS2-I

15

0,15

RS3-I

30

0,2

RS4-I

50

0,3

RS5-I

80

0,6

RS6-I

150

1,2

Ambient temperature range

[kg]

Max. operating

pressure

[bar]

400

HYDRAULIC SYMBOL

320

320

-20 / +50

Fluid temperature range

-20 / +80

Fluid viscosity range

cSt

10 400

Fluid contamination degree

Recommended viscosity

31 200/110 ED

According to ISO 4406:1999 class 20/18/15

cSt

25

1/2

RS*

SERIES 30

1 - IDENTIFICATION CODE

R S

/ 30 /

Seals:

omit for mineral oils

V = viton for special fluids

Throttle flow control

valve

Nominal dimension:

2 = 1/4

5 = 3/4

3 = 3/8

6 = 1

4 = 1/2

7 = 1

8 = 1

Series No. (the overall and mounting

dimensions remain unchanged from 30 to 39)

I = In-block cartidge version, available only in dimensions 2-3-4-5-6

Omit for version with threaded ports

3 - HYDRAULIC FLUIDS

Use mineral oil-based hydraulic fluids HL or HM type, according to ISO 6743-4. For these fluids, use NBR seals. For fluids HFDR type

(phosphate esters) use FPM seals (code V). For the use of other kinds of fluid such as HFA, HFB, HFC, please consult our technical

department. Using fluids at temperatures higher than 80 C causes a faster degradation of the fluid and of the seals characteristics.

The fluid must be preserved in its physical and chemical characteristics.

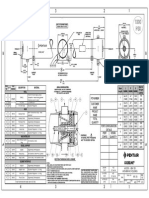

3 - OVERALL AND MOUNTING DIMENSIONS RS *

Valve

dimensioni in mm

BSP

E

max

RS2

1/4

12,5

49

20

78

50

RS3

3/8

12,5

59

25

93

70

RS4

1/2

15,5

68

30

107

80

RS5

3/4

17

86

40

132,5 100

RS6

20

105

50

167,5 120

RS7

22

120

55

172,5 120

RS8

24

134

65

181

120

4 - OVERALL AND MOUNTING DIMENSIONS RS * -I

dimensioni in mm

BONDED SEAL

seal excluded from the supply

sigla

valvola

RS2-I

RS3-I

RS4-I

RS5-I

RS6-I

50

70

80

100

120

max

49.5

57.5

66.5

76.5

102

26.5

30.5

40

44

52.5

6H

+ 0.2

0

M20x1.5

M20x1.5

M27x2

M33x2

M42x2

27

27

33

40

50

P

min

1

1

1.3

1.3

1.3

12

12

18

18

21.5

0.2

+ 0.2

0

H8

max

0.2

16.5

20

28

30.5

36.5

1

1.2

1.2

1.2

1.5

14

16

19

27

35

5

8

10

12

16

13.3

15.2

22

23

28.5

CH

min

27

32

41

45.5

55

27

27

32

41

50

OR

BK

BS*

type

type

type

2043

2050

2062

130

3118

2043

2050

2062

130

3118

400-513

400-513

400-520

400-515

400-516

DUPLOMATIC OLEODINAMICA S.p.A.

20015 PARABIAGO (MI) Via M. Re Depaolini 24

Tel. +39 0331.895.111

Fax +39 0331.895.339

www.duplomatic.com e-mail: sales.exp@duplomatic.com

31 200/110 ED

REPRODUCTION IS FORBIDDEN. THE COMPANY RESERVES THE RIGHT TO APPLY ANY MODIFICATIONS.

2/2

You might also like

- Accumulator Unloading Valve, Type RQ R PDocument4 pagesAccumulator Unloading Valve, Type RQ R PLibinNo ratings yet

- Manual HaskelDocument30 pagesManual HaskelMarcos Rodrigues Dos SantosNo ratings yet

- 02 110 BPS Foam Pump Skid With Foam Pump and RC ControllerDocument8 pages02 110 BPS Foam Pump Skid With Foam Pump and RC Controllerarachman297988No ratings yet

- E5174 RbeDocument4 pagesE5174 RbeVinod YbNo ratings yet

- Duplomatic ValveDocument4 pagesDuplomatic ValveHBracing1No ratings yet

- Hose Burst Valve PDFDocument4 pagesHose Burst Valve PDFnikhil nagannavarNo ratings yet

- Hi-Force Hydrostatic PDFDocument6 pagesHi-Force Hydrostatic PDFWong Chung MengNo ratings yet

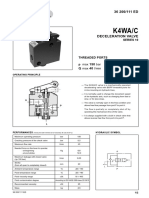

- Decceleration Valve, Cam Operated K4WA CDocument2 pagesDecceleration Valve, Cam Operated K4WA CLibinNo ratings yet

- PSI PumpsDocument12 pagesPSI PumpsagiacomuzoNo ratings yet

- Series 11: Operating PrincipleDocument4 pagesSeries 11: Operating PrincipleAnton Feny SaputraNo ratings yet

- Dokumen - Tips Operating and Maintenance Instructions Operating and Maintenance InstructionsDocument61 pagesDokumen - Tips Operating and Maintenance Instructions Operating and Maintenance InstructionsAri sofyan100% (1)

- Solenoid Select ChartDocument47 pagesSolenoid Select Chartسامح الجاسمNo ratings yet

- About Axial Displacement Pump A4VSoDocument68 pagesAbout Axial Displacement Pump A4VSomrkadu_61No ratings yet

- E5174 10 12 10 - Rbe 1 - 8 3 - 4Document4 pagesE5174 10 12 10 - Rbe 1 - 8 3 - 4romekgzp0% (1)

- CatalogDocument44 pagesCataloglangtu2011No ratings yet

- 2 Continental Hydraulics Directional Control Valves PDFDocument11 pages2 Continental Hydraulics Directional Control Valves PDFDaniel VillarroelNo ratings yet

- 43 430 UF Final PDFDocument4 pages43 430 UF Final PDFCarlos TarquinoNo ratings yet

- Ra 92711Document39 pagesRa 92711Agus Yulfizar100% (3)

- Rexroht PumpDocument45 pagesRexroht PumpmanualdeutsNo ratings yet

- Liquid Pump 1.5 HP 2 HP 2.2 HP Series Models A H XH S PDFDocument30 pagesLiquid Pump 1.5 HP 2 HP 2.2 HP Series Models A H XH S PDFHidroil Neuquen SrlNo ratings yet

- Hawe Rapid RangeDocument16 pagesHawe Rapid RangecinbrekNo ratings yet

- Regulator Pressure GaugeDocument32 pagesRegulator Pressure GaugeRahmat HidayatNo ratings yet

- TT US ShuttlesDocument5 pagesTT US ShuttleshaggNo ratings yet

- Burmad 400 Series-Globe Type Deluge ValveDocument8 pagesBurmad 400 Series-Globe Type Deluge Valvenastyn-1No ratings yet

- Liquid Pump 6 HP Series SDocument25 pagesLiquid Pump 6 HP Series SEduardo CramerNo ratings yet

- Series 30: Operating PrincipleDocument8 pagesSeries 30: Operating PrincipleDgek LondonNo ratings yet

- Brueninghaus Hydromatik Rexroth A4VSG Pump: Closed Circuit Variable Hydraulic Piston A4VG PumpDocument14 pagesBrueninghaus Hydromatik Rexroth A4VSG Pump: Closed Circuit Variable Hydraulic Piston A4VG PumpLuciano AlencastroNo ratings yet

- Directional Control Valves: Log Splitter Control ValveDocument4 pagesDirectional Control Valves: Log Splitter Control ValveinvidiuoNo ratings yet

- HYD. PumpDocument40 pagesHYD. Pumprohitbhat2345No ratings yet

- Hermetic CAN&CNFDocument20 pagesHermetic CAN&CNFkikechuNo ratings yet

- Drawing 80H30Document3 pagesDrawing 80H30kpranjal15No ratings yet

- PRH04-300 FLG PDFDocument5 pagesPRH04-300 FLG PDFengp3077No ratings yet

- Ra92100 1997-10Document48 pagesRa92100 1997-10mmaldonado10No ratings yet

- (2012) Complete IELTS Bands 5-6.5 Student's BookDocument3 pages(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- Modular Throttle Valve NG4, Type QTM2Document2 pagesModular Throttle Valve NG4, Type QTM2LibinNo ratings yet

- Dynex PF 1300 SpecsDocument7 pagesDynex PF 1300 SpecsAdeel HassanNo ratings yet

- Actuated ValvesDocument4 pagesActuated ValvestjendraNo ratings yet

- Interruptor de Presion - AscoDocument9 pagesInterruptor de Presion - AscoJosephGutierrezNo ratings yet

- PPA PEMO Filter Press Pumps PresentationDocument18 pagesPPA PEMO Filter Press Pumps Presentationmakinist29No ratings yet

- Features: How To Order (AOC-08 Models Only)Document4 pagesFeatures: How To Order (AOC-08 Models Only)CarmenLinoBedoyaNo ratings yet

- Algunos Estandares de La Valvula de Control Entre OtrasDocument9 pagesAlgunos Estandares de La Valvula de Control Entre OtrasDoris Alfaro TorrezNo ratings yet

- Three Way ValvesDocument8 pagesThree Way ValvesWalter JosephNo ratings yet

- Engineering Recommendation 01Document2 pagesEngineering Recommendation 01Juan Carlos Franco OrtegaNo ratings yet

- PD07P 3/4" Port: Non-Metallic Diaphragm PumpDocument2 pagesPD07P 3/4" Port: Non-Metallic Diaphragm PumppavanmrNo ratings yet

- REFCOMPDocument20 pagesREFCOMPsibar.eirlNo ratings yet

- Product Range Overview RexrothDocument21 pagesProduct Range Overview RexrothEustahije BrzicNo ratings yet

- Flow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3Document4 pagesFlow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3LibinNo ratings yet

- HiP Gen CatDocument144 pagesHiP Gen CatÁlvaro Conti FilhoNo ratings yet

- Variable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Document8 pagesVariable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Dias EliNo ratings yet

- Index: Product List SR. NODocument40 pagesIndex: Product List SR. NOch_yustinusNo ratings yet

- Rexroth Z2S 6 - Check Valve Pilot OperatedDocument4 pagesRexroth Z2S 6 - Check Valve Pilot OperatedEBNo ratings yet

- LX325 (New Hi-Cyclic Low-ResDocument24 pagesLX325 (New Hi-Cyclic Low-ResGianna FrolaNo ratings yet

- 50B4KGDocument2 pages50B4KGonin007No ratings yet

- Installation, Commissioning and Servicing of Hydraulic Pumps and MotorsDocument2 pagesInstallation, Commissioning and Servicing of Hydraulic Pumps and Motorsbhaswath2000No ratings yet

- Alivio Cartucho - C010Document6 pagesAlivio Cartucho - C010DANIZACHNo ratings yet

- Tecumseh Refrigerant PipingDocument24 pagesTecumseh Refrigerant Pipingaries26marchNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

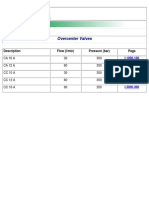

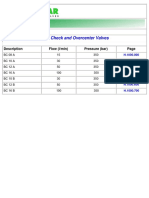

- Overcenter Valves: Description Flow (L/min) Pressure (Bar)Document1 pageOvercenter Valves: Description Flow (L/min) Pressure (Bar)LibinNo ratings yet

- 7 ValvesDocument6 pages7 ValvesLibinNo ratings yet

- Needle Valves: Description Flow (L/min) Pressure (Bar)Document1 pageNeedle Valves: Description Flow (L/min) Pressure (Bar)LibinNo ratings yet

- Pilot Check and Overcenter Valves: Description Flow (L/min) Pressure (Bar)Document1 pagePilot Check and Overcenter Valves: Description Flow (L/min) Pressure (Bar)LibinNo ratings yet

- Sequence Valves: Description Flow (L/min) Pressure (Bar)Document1 pageSequence Valves: Description Flow (L/min) Pressure (Bar)LibinNo ratings yet

- Solenoid Valves: Description Flow (L/min) Pressure (Bar)Document1 pageSolenoid Valves: Description Flow (L/min) Pressure (Bar)LibinNo ratings yet

- Check Valves: Description Flow (L/min) Pressure (Bar)Document1 pageCheck Valves: Description Flow (L/min) Pressure (Bar)LibinNo ratings yet

- Sequence Valves: Description Flow (L/min) Pressure (Bar)Document2 pagesSequence Valves: Description Flow (L/min) Pressure (Bar)LibinNo ratings yet

- Unit Conversion Table - NewDocument1 pageUnit Conversion Table - NewShankar PranavNo ratings yet

- 190 SpagesDocument4 pages190 SpagesIván López Pavez100% (1)

- ValvesDocument3 pagesValvesLibinNo ratings yet

- Hydraulic Integrated Circuits: Description Flow (L/min) Pressure (Bar)Document1 pageHydraulic Integrated Circuits: Description Flow (L/min) Pressure (Bar)LibinNo ratings yet

- Engineering Unit Conversion PDFDocument5 pagesEngineering Unit Conversion PDFBarcepandoNo ratings yet

- Conversion ChartDocument1 pageConversion ChartLibinNo ratings yet

- 3B000100Document2 pages3B000100LibinNo ratings yet

- Vaa /ru /DL 38: Pressure Relief ValvesDocument2 pagesVaa /ru /DL 38: Pressure Relief ValvesLibinNo ratings yet

- VMPP 20: Pressure Relief ValvesDocument2 pagesVMPP 20: Pressure Relief ValvesLibinNo ratings yet

- Solenoid Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesSolenoid Valves: Dimensions (MM) Hydraulic DiagramLibinNo ratings yet

- Solenoid Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesSolenoid Valves: Dimensions (MM) Hydraulic DiagramLibinNo ratings yet

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesPressure Relief Valves: Dimensions (MM) Hydraulic DiagramLibinNo ratings yet

- Effective Gas Volume For AccumulatorDocument3 pagesEffective Gas Volume For Accumulatorabbs_2305No ratings yet

- Vaddl 38: Pressure Relief ValvesDocument2 pagesVaddl 38: Pressure Relief ValvesLibinNo ratings yet

- HS - O Ring Sizes Thread AdaptorsDocument1 pageHS - O Ring Sizes Thread AdaptorsLibinNo ratings yet

- INOX 350bar LeafletDocument6 pagesINOX 350bar LeafletLibinNo ratings yet

- VM3B / VM3B1: High Performance Vane MotorDocument2 pagesVM3B / VM3B1: High Performance Vane MotorLibinNo ratings yet

- Gear Displacement Calculation: by Downloading This Document You Acknowledge Acceptance of Our Terms and Conditions of UseDocument1 pageGear Displacement Calculation: by Downloading This Document You Acknowledge Acceptance of Our Terms and Conditions of UseDheeraj ShuklaNo ratings yet

- High Performance Vane Pump: V A N E P U M P SDocument2 pagesHigh Performance Vane Pump: V A N E P U M P SLibinNo ratings yet

- VT67EBDocument2 pagesVT67EBLibinNo ratings yet

- VC 5 VDocument3 pagesVC 5 VLibinNo ratings yet

- Vab 04Document1 pageVab 04LibinNo ratings yet

- Academic Stress ScaleDocument3 pagesAcademic Stress Scaleteena jobNo ratings yet

- GE 8 ETHICS Week2 9Document54 pagesGE 8 ETHICS Week2 9Jay Ar OmbleroNo ratings yet

- Data Analaysis and InterpretationDocument56 pagesData Analaysis and Interpretationporkodisvl100% (2)

- AYLS Annual Report 2019 LampDocument136 pagesAYLS Annual Report 2019 LampHigh FourNo ratings yet

- Advanced Numerical Modelling of Geogrids and Steel Wire Meshes - Daniele TubertiniDocument94 pagesAdvanced Numerical Modelling of Geogrids and Steel Wire Meshes - Daniele TubertiniSze Mian KuehNo ratings yet

- Michael J. Flynn - Some Computer Organizations and Their Effectiveness, 1972Document13 pagesMichael J. Flynn - Some Computer Organizations and Their Effectiveness, 1972earthcrosserNo ratings yet

- Uc3842b 3843BDocument10 pagesUc3842b 3843Bbob75No ratings yet

- Service and Technology Marketing Service and Technology MarketingDocument27 pagesService and Technology Marketing Service and Technology MarketingVinudeep MalalurNo ratings yet

- As 4587-1999 Water Mist Fire Protection Systems - System Design Installation and CommissioningDocument10 pagesAs 4587-1999 Water Mist Fire Protection Systems - System Design Installation and CommissioningSAI Global - APAC100% (1)

- Innoversant Solutions - Business Consulting Services IndiaDocument15 pagesInnoversant Solutions - Business Consulting Services Indiaispl123No ratings yet

- Computer Typing History of TypingDocument9 pagesComputer Typing History of TypingRamNo ratings yet

- Cop4600 Exam1 sp13Document2 pagesCop4600 Exam1 sp13chavNo ratings yet

- Ballsim DirectDocument58 pagesBallsim DirectDiego GaliciaNo ratings yet

- Enabling Secure Broadband Access Anywhere Anytime Access Anywhere, AnytimeDocument4 pagesEnabling Secure Broadband Access Anywhere Anytime Access Anywhere, AnytimeEmmanuelNo ratings yet

- Urban Problems and SolutionsDocument12 pagesUrban Problems and SolutionsJohn Lloyd Agapito50% (2)

- Porphyry Tin Deposits in BoliviaDocument15 pagesPorphyry Tin Deposits in Boliviasebastian tiriraNo ratings yet

- Grieving The Loss of A Life You WantedDocument11 pagesGrieving The Loss of A Life You WantedNiftyNo ratings yet

- AbstractDocument1 pageAbstractJignesh PrajapatiNo ratings yet

- Chapter7 Ex PDFDocument5 pagesChapter7 Ex PDFSathish Kumar100% (1)

- Chapter 1 Philosophical Perspective of The SelfDocument64 pagesChapter 1 Philosophical Perspective of The SelfSUSHI CASPENo ratings yet

- Measuring PovertyDocument47 pagesMeasuring PovertyPranabes DuttaNo ratings yet

- SF DumpDocument17 pagesSF DumpBeatríz YañezNo ratings yet

- Pdpa CraDocument3 pagesPdpa CraAdyrah RahmanNo ratings yet

- Crystal Gallery: AccountabilityDocument15 pagesCrystal Gallery: AccountabilityJitesh ManwaniNo ratings yet

- HTTPHeader LiveDocument199 pagesHTTPHeader LiveDenys BautistaNo ratings yet

- QuestionnaireDocument5 pagesQuestionnairePrisca FolorunsoNo ratings yet

- Sebu6100-02 MDocument74 pagesSebu6100-02 MSa CruCerNo ratings yet

- UA5000 V100R019C06 Hardware Description 05 PDFDocument563 pagesUA5000 V100R019C06 Hardware Description 05 PDFdabouzia slahNo ratings yet

- Climate Transition Finance Handbook Related Questions: 9 December 2020Document4 pagesClimate Transition Finance Handbook Related Questions: 9 December 2020glenlcyNo ratings yet

- CHCDIV001 - Student Assessment Booklet ECEC.v2.0Document59 pagesCHCDIV001 - Student Assessment Booklet ECEC.v2.0Dink DinkNo ratings yet