Professional Documents

Culture Documents

Arc Welding Job Procedure

Uploaded by

Ganga DaranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Arc Welding Job Procedure

Uploaded by

Ganga DaranCopyright:

Available Formats

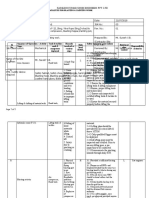

MAST

Safe Work Procedure

Division:

Analysis By:

Department:

Supervisor:

Job Title:

Approved By:

Job Title:

71 Arc Welding (RRC)

Date:

Frequency:

JSA Number:

Job Performed By:

REQUIRED PERSONAL PROTECTIVE EQUIPMENT: Safety Eyewear, Safety Footwear, Leather Gloves, Hearing Protection, Apron,

Welding Bib, Full-face Welding Helmet

GENERAL NOTES:

JOB SAFETY ANALYSIS:

Step

1

Description

Set up workpiece on fixture

Install electrode rod into

torch

Energize and set Arc Welding

Machine amperage/ current

Hazard

a) Strain/sprain from heavy and/or

awkward workpiece--b) Foot injury

from dropping workpiece--c) Trip/fall

in area around Arc Welding

workstation--d) Damage to

workpiece from incorrect set-up--e)

Hand/finger laceration from edge of

workpiece--f) Hand/finger contusion

from tool slippage while tightening

fixture

Electric shock/burn from electrode

rod

a) Electrical shock/burn from contact

with electrode rod holder--b)

Damage to workpiece from incorrect

amperage/current

Page 1 of 3

Controls

a) Use mechanical hoist or get assistance from co-worker to

set-up/ adjust workpiece--b) Wear recommended footwear.

Ensure workpiece is securely clamped to fixture--c)

Clean/clear work area/surfaces of unused tools/materials.

Remove dust/debris.--d) Workpiece should be clean and

secure to fixture--e) Wear recommended gloves when

handling workpieces with sharp edges--f) Use correct tool

and wear recommended gloves

Ensure Arc Welding machine power to arc is electrically deenergized when changing electrical rod

a) Ensure welding machine is properly grounded. Welder

should be insulated from live electrical parts and dry. Inspect

and replace cables, plugs and leads that show any signs of

defects. Wear recommended gloves and clothing.--b) Refer

to Op Sheet and/or Shop Order for correct

amperage/current--

Print Date: Jan/25/2008

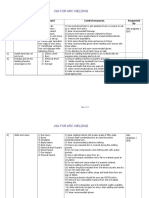

Turn on gas and set flow

a) Damage to workpiece from

incorrect gas flow rate--b) Bodily

injury from explosion of compressed

gas cylinder--

Weld workpiece

a) Eye injury from welding flash

and/or spatter--b) Burns from

welding spatter, UV/infrared

radiation and/or electrical contact--c)

Inhalation of welding fumes or

asphyxiation from displaced

oxygen--d) Bodily injury from

condition or type of workpiece being

welded--e) Electrical shock hazard--f)

Hearing loss from chronic exposure

to noisy machinery--g) Fire due to

combustible material in welding

area--h) Hand/finger contact burn

from hot electrode rod

Complete welding

Remove workpiece from

fixture and transport to

inspection

a) Electrical shock/burn or electrical

contact with conducting objects,

flammable liquids and/or

compressed gas cylinders due to

energized electrode rod holder

a) Strain/sprain from heavy and/or

awkward workpiece--b) Foot injury

from dropping workpiece--c) Trip/fall

in area around Arc Welding

workstation--d) Hand/finger

laceration from edge of workpiece-e) Hand/finger contusion from tool

slippage

a) Consult Op Sheet and/or Shop Order for correct flow rate-b) Practice caution around compressed gas cylinders.

Protect gas cylinders from excessive heat, mechanical

shocks and arcs. Ensure cylinder is insulated and fastened

so it will not fall. Do not use a compressed gas cylinder that

appears to be damaged and/or defective.-a) Wear welding helmet with proper grade of filter plate.

Ensure flash curtains/barriers are used to protect

bystanders/observers--b) Wear recommended protective

clothing. Ensure any exposed skin is covered during the

welding process. Do not wear metal jewelry and clothing

with cuffs and/or pockets. Stay a safe distance away from

arc--c) Use local exhaust ventilation and a fan to maintain

good air circulation--d) Do not weld workpiece unless it is

properly cleaned--e) Ensure welding machine is properly

grounded. Welder should be insulated from live electrical

parts and dry. Do not weld when wet. Inspect and replace

cables, plugs and leads that show any signs of defect.--f)

Wear hearing protection--g) Remove any combustible

material from the immediate welding site. Keep a fire

extinguisher readily available.--h) When electrode rod gets

too short, stop welding and restart with a new electrode rod.

Wear recommended gloves.-Ensure Arc Welding machine power to arc is electrically deenergized. When not in use electrode rod should be

removed from holder and holder should be placed so it

cannot make electrical contact with conducting objects,

flammable liquids and/or compressed gas cylinders.

a) Use mechanical hoist or get assistance from co-workers to

transport workpiece--b) Wear recommended footwear.

Ensure workpiece is securely clamped to fixture--c)

Clean/clear work area/surfaces of unused tools/materials.

Remove dust/debris regularly--d) Wear recommended gloves

when handling workpieces with sharp edges--e) Use correct

tool and wear recommended gloves

AUTHORIZED EMPLOYEE INFORMATION:

ID NUMBER:

LAST NAME:

FIRST NAME:

REMARKS:

JOB HISTORY INFORMATION:

DATE:

REMARKS:

Page 2 of 3

Print Date: Jan/25/2008

Approval Signature:

Date:

Page 3 of 3

Print Date: Jan/25/2008

You might also like

- Arc Welding - JSADocument6 pagesArc Welding - JSAdroffilcz27No ratings yet

- Safe Work ProcedureDocument5 pagesSafe Work ProcedureSurya Narayan MahapatraNo ratings yet

- SWP 01 - Delivery, Unloading, Storage and Transferring of MaterialsDocument3 pagesSWP 01 - Delivery, Unloading, Storage and Transferring of MaterialsGerald Wong Ntt100% (1)

- AttachmentDocument12 pagesAttachmentChung TrịnhNo ratings yet

- SWMS-Pipe Instalation Work at Utility 25.01.21Document10 pagesSWMS-Pipe Instalation Work at Utility 25.01.21Ansari FaisalNo ratings yet

- MTA2018-JHA-012 Air Compressor OperationDocument10 pagesMTA2018-JHA-012 Air Compressor OperationKelvin TanNo ratings yet

- Warehouse Job Hazard AssessmentDocument2 pagesWarehouse Job Hazard AssessmentAnonymous cuHV7lTNo ratings yet

- Job Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechDocument3 pagesJob Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechMohamedSaidNo ratings yet

- Risk Assessment-Maintance of Tanks, VesselsDocument5 pagesRisk Assessment-Maintance of Tanks, VesselsKono Nor AtanNo ratings yet

- 11.pneumatic Pressure Testing.Document7 pages11.pneumatic Pressure Testing.Mohammad Fazal KhanNo ratings yet

- Welding Procedure: PurposeDocument14 pagesWelding Procedure: Purposeinfos2magi856No ratings yet

- Safety Alert 49 - Cable Pulling IncidentDocument1 pageSafety Alert 49 - Cable Pulling IncidentTareq Ziad KhalifaNo ratings yet

- JHA Lifting-Moving Heavy Objects - ROMODocument5 pagesJHA Lifting-Moving Heavy Objects - ROMOSAMUEL POBRENo ratings yet

- JHA For Crates-Boxes With Potential Hazardous SubstancesDocument4 pagesJHA For Crates-Boxes With Potential Hazardous SubstancesTnarg RagawNo ratings yet

- Z - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Document3 pagesZ - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Din JalilNo ratings yet

- JSA TrainingDocument28 pagesJSA Trainingkresna suryadiNo ratings yet

- Lifting Activity Permit To WorkDocument1 pageLifting Activity Permit To WorkBig ZaddyNo ratings yet

- Safety Award ApplicationDocument7 pagesSafety Award ApplicationJason Smith100% (1)

- Risk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelDocument3 pagesRisk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelMohamed ElnagdyNo ratings yet

- Task Risk AssesmentDocument3 pagesTask Risk Assesmentafsalkareem100% (1)

- Weekly Tower Light Check ListDocument1 pageWeekly Tower Light Check ListpjosesmNo ratings yet

- Project HSE Monthly Activity Plan: OH&S Management SystemDocument1 pageProject HSE Monthly Activity Plan: OH&S Management SystemBhagat Deepak100% (1)

- Part 3 ObservationsDocument7 pagesPart 3 ObservationsAmjadNo ratings yet

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- Officeriskassess 260109Document1 pageOfficeriskassess 260109api-330763254No ratings yet

- Risk Cooling TowerDocument4 pagesRisk Cooling TowerHariharan MuthukrishananNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- ExcavationDocument3 pagesExcavationprasanna ok100% (1)

- Index: Cv. Dira Utama SejahteraDocument12 pagesIndex: Cv. Dira Utama SejahteraFreshop SurabayaNo ratings yet

- JSA EmployeesDocument2 pagesJSA EmployeesburhanNo ratings yet

- Reinforcement WorksDocument5 pagesReinforcement Worksprasanna okNo ratings yet

- JHA For Hill Cutting Activities.R.01Document8 pagesJHA For Hill Cutting Activities.R.01SreekumarNo ratings yet

- HIRADocument7 pagesHIRAAkhilesh DubeyNo ratings yet

- Building De-Dusting JSADocument3 pagesBuilding De-Dusting JSAJayesh J PillaiNo ratings yet

- SOP 4 - Coal Bed Leveling in PGPDocument18 pagesSOP 4 - Coal Bed Leveling in PGPfaraz ahmedNo ratings yet

- JSA 08 Gas WeldingDocument1 pageJSA 08 Gas Weldingmuthuswamy77No ratings yet

- Jsa SMDB Maintenence...Document3 pagesJsa SMDB Maintenence...ASLAM MULANINo ratings yet

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- Towed Scraper Checklist V0810.1 PDFDocument1 pageTowed Scraper Checklist V0810.1 PDFcherifNo ratings yet

- Instructions For Using The Risk Assessment FormDocument9 pagesInstructions For Using The Risk Assessment FormMalik Khuram ShazadNo ratings yet

- Maintenance ProcduresDocument12 pagesMaintenance ProcduresashutoshNo ratings yet

- 4 HIRA Format - Sand Blasting ActivityDocument2 pages4 HIRA Format - Sand Blasting ActivityMD Abdullah100% (1)

- Jsa of Solvent Filling in VarnishesDocument3 pagesJsa of Solvent Filling in VarnishesMuhammad AliNo ratings yet

- Picture of Task/equipment: Task: Name of Shop or Dept: Job Title(s) : Analyzed By: Date: Required PPEDocument2 pagesPicture of Task/equipment: Task: Name of Shop or Dept: Job Title(s) : Analyzed By: Date: Required PPEArif RachmanNo ratings yet

- 015 CH 10 Tool InspectionDocument3 pages015 CH 10 Tool InspectionLinda BooysenNo ratings yet

- HIRA & JSA - R1 Conveyor Gallery Dismantling and ErectionDocument26 pagesHIRA & JSA - R1 Conveyor Gallery Dismantling and ErectionkrishnaengineeringhilNo ratings yet

- Risk Assessment WorksheetDocument2 pagesRisk Assessment WorksheetHergheligiu VasileNo ratings yet

- Stringing, Welding and Coating Process.Document3 pagesStringing, Welding and Coating Process.Beyar. ShNo ratings yet

- Safe Working Procedure For Loading and UnloadingDocument3 pagesSafe Working Procedure For Loading and Unloadingsizwe100% (1)

- HIRA For Work at HeightDocument4 pagesHIRA For Work at Heightdinesattri100% (1)

- Aj Infratech: Job Hazard AnalysisDocument5 pagesAj Infratech: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Nasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetDocument2 pagesNasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetRaza Muhammad SoomroNo ratings yet

- 50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Document3 pages50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Raza Muhammad SoomroNo ratings yet

- 71 Arc Welding - Job Procedure - 2Document3 pages71 Arc Welding - Job Procedure - 2Angga EHSKOINNo ratings yet

- 71 Arc Welding - JOB PROCEDUREDocument3 pages71 Arc Welding - JOB PROCEDUREAdilMunirNo ratings yet

- Safe Work Procedure: Required Personal Protective Equipment General Notes: Job Safety AnalysisDocument2 pagesSafe Work Procedure: Required Personal Protective Equipment General Notes: Job Safety Analysisrazed86No ratings yet

- Step Description Controls: HazardDocument3 pagesStep Description Controls: HazardMainak KhanraNo ratings yet

- Jsa For Arc WeldingDocument3 pagesJsa For Arc Weldingtnssbhaskar100% (5)

- ArcWeld Varias PDFDocument84 pagesArcWeld Varias PDFSistemcan Productivo100% (4)

- HCM 239Document199 pagesHCM 239Mohit VermaNo ratings yet

- Drugs and DosagesDocument40 pagesDrugs and DosagesGeraldine Marie Salvo100% (1)

- Pediatrics Rapid RevisionDocument72 pagesPediatrics Rapid RevisionWorld MedclickzNo ratings yet

- Q1 Health Status QuestionnaireDocument2 pagesQ1 Health Status QuestionnaireKathleen ChuaNo ratings yet

- Referral Letter To Specialist From GPDocument74 pagesReferral Letter To Specialist From GPyazz80% (5)

- Countryside in Figures 2019 Parañaque City PDFDocument282 pagesCountryside in Figures 2019 Parañaque City PDFJaimee Ruth LiganNo ratings yet

- Core CompetencyDocument9 pagesCore CompetencyCharm BarinosNo ratings yet

- AH1N1 PPT PresentationDocument28 pagesAH1N1 PPT PresentationIna Isabela CostiboloNo ratings yet

- Aldomet: (Methyldopa)Document6 pagesAldomet: (Methyldopa)Riska AuliahNo ratings yet

- ParecoxibDocument2 pagesParecoxibPeetah PanNo ratings yet

- VedicReport10 29 202211 43 48AMDocument1 pageVedicReport10 29 202211 43 48AMAvish DussoyeNo ratings yet

- Assisting Delivery Name: - Grade: - Year and Section: - DateDocument5 pagesAssisting Delivery Name: - Grade: - Year and Section: - DateCrisia Jane LotaNo ratings yet

- Comparative Analysis of National Pandemic Influenza Preparedness Plans - 2011Document64 pagesComparative Analysis of National Pandemic Influenza Preparedness Plans - 2011Mohamed WahbyNo ratings yet

- Community-Based Disaster Risk Reduction and Management Training CourseDocument3 pagesCommunity-Based Disaster Risk Reduction and Management Training CourseMARJORYL CLAISE GONZALESNo ratings yet

- Local Government Financial Statistics England #23-2013Document222 pagesLocal Government Financial Statistics England #23-2013Xavier Endeudado Ariztía FischerNo ratings yet

- Septic System Design ManualDocument31 pagesSeptic System Design ManualtonyNo ratings yet

- Epstein Barr Virus (EBV) PDFDocument33 pagesEpstein Barr Virus (EBV) PDFahmad mohammadNo ratings yet

- VF-VT AlgorithmDocument10 pagesVF-VT AlgorithmPuskesmas Pinang JayaNo ratings yet

- Diabetic Foot Ulcer Assessment and Management Algorithm - 0Document11 pagesDiabetic Foot Ulcer Assessment and Management Algorithm - 0Herlan BelaNo ratings yet

- Lesson Plan On Chronic Obstructive Pulmonary DiseaseDocument11 pagesLesson Plan On Chronic Obstructive Pulmonary DiseaseFriends Forever83% (6)

- Ateneo de Zamboanga University: Course Outline (Second Semester) ZOO 208Document1 pageAteneo de Zamboanga University: Course Outline (Second Semester) ZOO 208Almira AhamadNo ratings yet

- 60 Substance Abuse Group Therapy ActivitiesDocument7 pages60 Substance Abuse Group Therapy ActivitiesHanes Labajos100% (1)

- WRAS MarinasDocument4 pagesWRAS MarinasAdam ReesNo ratings yet

- F17 Reflection 383 FN - 15 Nov 17Document7 pagesF17 Reflection 383 FN - 15 Nov 17jigsawNo ratings yet

- National Library of Medicine (NLM) FY2011 Annual ReportDocument116 pagesNational Library of Medicine (NLM) FY2011 Annual ReportLJ's infoDOCKETNo ratings yet

- Treatment and Prognosis of Febrile Seizures - UpToDateDocument14 pagesTreatment and Prognosis of Febrile Seizures - UpToDateDinointernosNo ratings yet

- Aquatics AssignmentDocument12 pagesAquatics AssignmentTyrone WewpOgzNo ratings yet

- Annotated BibliographyDocument4 pagesAnnotated Bibliographyapi-455378107No ratings yet

- Manual Aromaterapia Español PDFDocument60 pagesManual Aromaterapia Español PDFPablo Andrés Mora SolísNo ratings yet

- Nahom ShewangizawDocument38 pagesNahom Shewangizawawel centerNo ratings yet