Professional Documents

Culture Documents

Glass Fibre Grids Methodology

Uploaded by

RaghavCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Glass Fibre Grids Methodology

Uploaded by

RaghavCopyright:

Available Formats

SOMA ENTERPRISE LTD.

Construction of 17.166 km long Nellore Bypass Project on NH-16

(old NH-5) from km 165.183 to km 182.349 on Annuity basis.

METHODOLOGY FOR STRENGTHENING WITH FIBRE GEOCOMPOSITE

SCOPE OF WORK

This work shall consist of laying geosynthetic materials either non-woven paving fabric

or fiber glass coated grid over existing bituminous surface, including preparation of

surface and joining, stitching or overlapping of geosynthetic fabric etc., as part of highway

pavement strengthening in layers as shown on drawings or as directed by the Engineer.

GLASS GRIDS

These will be either a composite glass fibre reinforced geogrid with continuous filament

non-woven Geotextile chemically or mechanically bonded to the grid; or bituminous

coated glass fiber geogrid with or without adhesive on one side of the grid. The physical

and mechanical properties of glass grid fabric shall conform to the requirements given in

following table.

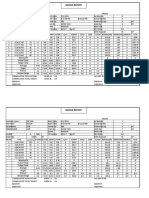

Property

Units

Tensile Strength

% Elongation at break

Minimum Mesh Size

Melting Point

KN/m

%

mm

0

C

Requirement

Tensile Strength in Both Median and CrossMachine Direction

ASTM D6637

50

1000

200

>4

>4

>4

25x25

12.5x12.5 12.5x12.5

ASTM D 276

>250

>250

>250

INSTALLATION

Weather Limitations

The air and pavement temperatures shall be at least 10 0C for placement of hot bitumen

and at least 160C for placement of asphalt emulsion. The asphalt tack coat or Glass grid

shall not be placed when weather conditions are not suitable.

Surface Preparation

The pavement surface shall be dry and cleaned of all dirt and oil to the satisfaction of the

Engineer. Cracks wider than 3 mm shall be cleaned and filled with bituminous material

approved by the Engineer. Potholes and locally failed and cracked pavement sections

shall be repaired as directed by the Engineer. If the existing pavement is rough or has

been milled, a leveling course shall be provided prior to installation of the Glass grid.

Version: 00

Date: 09.01.15

Page 1 of 4

SOMA ENTERPRISE LTD.

Construction of 17.166 km long Nellore Bypass Project on NH-16

(old NH-5) from km 165.183 to km 182.349 on Annuity basis.

Tack Coat

The tack coat used to impregnate the fabric and bond the fabric to the pavement shall be

paving grade Bitumen of VG-10. Glass fiber grids with adhesive on one side may not

require a tack coat.

The tack coat shall be applied using a calibrated distributor spray bar. Hand spraying,

squeegee and brush application may be used only in locations where the distributor truck

cannot reach. The tack coat shall be uniformly applied at a rate to bond the nonwoven

scrim to the existing pavement surface. The tack coat application rate shall be 1 kg per

square metre or as specified in the contract. When using emulsions, the application rate

must be increased as directed by the Engineer to take into account the water content in

the emulsion. The temperature of the tack coat shall be sufficiently high to permit a

uniform spray. Bitumen shall be sprayed at temperatures between 143 0C and 1630C. For

emulsions, the distributor tank temperatures shall be maintained between 55 0C and 710C.

The target width of the tack coat application shall be equal to the Glass grid width plus

100-150 mm. The tack coat shall be applied only as far in advance of Glass grid

installation as is appropriate to ensure a tacky surface at the time of Glass grid

placement. Traffic shall not be allowed on the tack coat. Excess tack coat shall be

cleaned from the pavement.

Glass Grid Placement

The glass grid shall be placed on the surface provided by the tack coat using mechanical

or manual lay down equipment capable of providing a smooth installation with a minimum

amount of wrinkling or folding. On curves, the Glass grid must be cut and realigned to

match the curvature.

Glass grid shall not be installed in areas where the bituminous overlay tapers to a

compacted thickness of less than 40 mm. when emulsions are used, the emulsion shall

be allowed to cure properly such that no water/moisture remains prior to placing the glass

grid. Wrinkles severe enough to cause folds shall be slit and laid flat. Brooming and/or

rubber-tire rolling will be required to maximize glass grid contact with the pavement

surface. Additional hand-placed tack coat may be required at overlaps and repairs as

required by the Engineer. Turning and braking of the paver and other vehicles shall be

done gradually and kept to a minimum to avoid movement and damage to the glass grid.

Damaged composite shall be removed and replaced with the same type of composite and

a tack coat.

All areas where glass grid has been placed shall be paved the same day. No traffic

except necessary construction traffic shall be allowed to drive on the glass grid.

Version: 00

Date: 09.01.15

Page 2 of 4

SOMA ENTERPRISE LTD.

Construction of 17.166 km long Nellore Bypass Project on NH-16

(old NH-5) from km 165.183 to km 182.349 on Annuity basis.

Overlaps shall be shingle lapped in the direction of paving. Additional tack coat shall be

placed between the overlap to satisfy saturation requirements of the fabric. Overlap shall

be sufficient to ensure full closure of the joint but not exceeding 150 mm.

Overlay Placement

Bituminous overlay construction shall closely follow the placement of glass-grid. Excess

tack coat that bleeds through the glass grid shall be removed by broad casting hot mix or

sand on the glass grid. Excess sand or hot mix shall be removed before beginning the

paving operation. In the event of rainfall prior to the placement of the asphalt overlay, the

glass grid must be allowed to dry completely before the overlay is placed. Overlay asphalt

thickness shall meet the requirements of the contract drawings and documents. The

minimum compacted thickness of the first lift of overlay asphalt concrete shall not be less

than 40 mm.

SAFETY MEASURES:

Provisions for workmen:

1. It is required that all persons working at the site shall be provided with the safety

equipments, protection means such as safety jackets, hand gloves, safety helmets

and other necessary kinds.

2. All the persons working on the site shall be trained by conducting the training course

for safety to ensure that they are fully aware of the contents.

Provisions for Equipments, Machine:

1. All equipment will be ensured to operate safely, maintained and repaired

periodically.

2. All power equipment should be insulted and covered to all exposed live parts.

3. A competent person shall inspect equipment during shift duty.

Provisions for job site:

1. Relevant caution boards and sufficient lighting system shall be installed at the

working area to ensure safety for construction activities at night time.

2. The working area shall be free from hazards before starting the work.

3. Unnecessary materials such as empty bags and rubbish shall be removed

periodically.

4. Proper safety measures like barricading, guard poles painted with florescent in

alternate bands, flags etc. will be provided prior to the commencement of excavation

operations.

5. Signal man will be placed at heavy traffic locations at the time of Execution.

6. Precautionary signs will be kept in both directions wherever necessary

7. Reflective sign boards will be placed during night near risky locations.

Version: 00

Date: 09.01.15

Page 3 of 4

SOMA ENTERPRISE LTD.

Construction of 17.166 km long Nellore Bypass Project on NH-16

(old NH-5) from km 165.183 to km 182.349 on Annuity basis.

8. All workers shall be educated in the use of excavators, bulldozers, backhoes,

graders and rollers such as the excavator arm & bucket distance and buffer zone in

order to prevent from injuries.

9. Site safety member shall be made available at all times and must be able to respond

correctly to emergency.

10. First Aid facility will be provided.

SAFETY MEASURES TO PROTECT THE ENVIRONMENT

1. All necessary measures shall be taken to maintain all plants and silencing

equipments in good conditions so as to maintain air and noise emission during the

operation.

Version: 00

Date: 09.01.15

Page 4 of 4

You might also like

- 1977 Puch Maxi Moped Wiring DiagramDocument9 pages1977 Puch Maxi Moped Wiring DiagramMopedgal100% (1)

- Tbam: Dikkowita Fisheries HarbourDocument8 pagesTbam: Dikkowita Fisheries HarbourkskahatadeniyaNo ratings yet

- Ayala Triangle Gardens: Roughing Installation (Drop-Off Landscape Lightings)Document6 pagesAyala Triangle Gardens: Roughing Installation (Drop-Off Landscape Lightings)james alfarasNo ratings yet

- Example Method Statement For The Installation of Concrete Floor SlabsDocument8 pagesExample Method Statement For The Installation of Concrete Floor SlabsLombe Paul OkparaNo ratings yet

- Mix Design Using RAP 30Document4 pagesMix Design Using RAP 30Raghav100% (2)

- Mix Design Using RAP 30Document4 pagesMix Design Using RAP 30Raghav100% (2)

- Mix Design Using RAP 30Document4 pagesMix Design Using RAP 30Raghav100% (2)

- Design Mix GSBDocument1 pageDesign Mix GSBsoma100% (1)

- Transport Properties of Fluids PDFDocument497 pagesTransport Properties of Fluids PDFRaghavNo ratings yet

- PM High Strength Magnetic Alloys PDFDocument13 pagesPM High Strength Magnetic Alloys PDFSAMIT JAINNo ratings yet

- Office Safety ChecklistDocument3 pagesOffice Safety ChecklistJaijeev Pali100% (1)

- AASHTO T121 Testing FormDocument4 pagesAASHTO T121 Testing Formdep_vinNo ratings yet

- Method Statements InterLock WorksDocument3 pagesMethod Statements InterLock WorksNino Celso AstilleroNo ratings yet

- Method Statement-4Document4 pagesMethod Statement-4engr everNo ratings yet

- Interior Partition Wire MeshDocument9 pagesInterior Partition Wire MeshKağan ZorluoğluNo ratings yet

- Trial Pit During ExcavationDocument3 pagesTrial Pit During Excavationmujahid1137No ratings yet

- ERECTION METHOD STATEMENT Part 3Document6 pagesERECTION METHOD STATEMENT Part 3joseph chewNo ratings yet

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- METHOD OF STATEMENT - ALKHOMRA PROJECT - MarbleDocument9 pagesMETHOD OF STATEMENT - ALKHOMRA PROJECT - Marbleahmed samirNo ratings yet

- Method Statement For Cement Board Dry Wall PartitionsDocument10 pagesMethod Statement For Cement Board Dry Wall PartitionsComet GroupNo ratings yet

- Safety Method Statement: U (tÜÜ - Á U (tÜÜ - Á U (tÜÜ - Á U (tÜÜ - ÁDocument12 pagesSafety Method Statement: U (tÜÜ - Á U (tÜÜ - Á U (tÜÜ - Á U (tÜÜ - ÁnabillyusofNo ratings yet

- Data Sheet of Bitumen LuluBitucoat - WBDocument2 pagesData Sheet of Bitumen LuluBitucoat - WBhandhammer qatarNo ratings yet

- Method Statement of Brick Masonary WorkDocument6 pagesMethod Statement of Brick Masonary WorkMihirduttaNo ratings yet

- Qcs 2010 Section 21 Part 1 General Provisions For Electrical InstallaDocument15 pagesQcs 2010 Section 21 Part 1 General Provisions For Electrical Installabryanpastor106100% (1)

- Demolition Work Audit Checklist: Los Angeles Community College DistrictDocument6 pagesDemolition Work Audit Checklist: Los Angeles Community College DistrictJaycee PagadorNo ratings yet

- Work Method Statement PurposeDocument2 pagesWork Method Statement PurposeSetyawanNo ratings yet

- Stone Cleaning Method Statement and Risk Assessment-1 PDFDocument6 pagesStone Cleaning Method Statement and Risk Assessment-1 PDFحمودي معزNo ratings yet

- SDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Paving Method StatementDocument7 pagesPaving Method StatementOfentse LedwabaNo ratings yet

- 01-Checklist For Setting Out and LayoutDocument1 page01-Checklist For Setting Out and Layoutmd_rehan_2No ratings yet

- SWP 03 - Hacking WorksDocument3 pagesSWP 03 - Hacking WorksGerald Wong NttNo ratings yet

- DieselStorage Tank Refurbishment - MOSDocument6 pagesDieselStorage Tank Refurbishment - MOSSaran rasayaNo ratings yet

- Method Statement For Roof Water ProofingDocument6 pagesMethod Statement For Roof Water ProofingSagar ParabNo ratings yet

- General Consideration For Stacking and StorageDocument4 pagesGeneral Consideration For Stacking and StorageSiddhantShrivastavNo ratings yet

- Scaffolding SafetyDocument4 pagesScaffolding Safetyrguy3223No ratings yet

- Concrete Floor Slab Construction ProcessDocument5 pagesConcrete Floor Slab Construction ProcessAh RashedNo ratings yet

- Method Statement - Temporary Stair - Rev1Document2 pagesMethod Statement - Temporary Stair - Rev1RodelNo ratings yet

- CIA Sec 3Document90 pagesCIA Sec 3Rock StarNo ratings yet

- Courier ManagementDocument4 pagesCourier ManagementLOVE IN UR WAY -INSTAGRAMNo ratings yet

- Method Statement For Temporary Access Road (Towayya) - (Rev.)Document14 pagesMethod Statement For Temporary Access Road (Towayya) - (Rev.)skystar100% (1)

- WEP For Gypsum Board False CeilingDocument6 pagesWEP For Gypsum Board False CeilingpalashNo ratings yet

- SWP-07 Excavation WorksDocument7 pagesSWP-07 Excavation WorksMd ShahinNo ratings yet

- Demolition RISK AssessmentDocument15 pagesDemolition RISK AssessmentAli KaziNo ratings yet

- Scaffold Safe Work Method Statement: Project TitleDocument11 pagesScaffold Safe Work Method Statement: Project TitleGirish R RaoNo ratings yet

- MOS of BackfillingDocument2 pagesMOS of BackfillingPoru ManNo ratings yet

- Mezzanine Installation InstructionDocument19 pagesMezzanine Installation InstructionfaustomariottNo ratings yet

- APPENDIX 1 Issues For Method Statements in Industrial Roof WorkDocument3 pagesAPPENDIX 1 Issues For Method Statements in Industrial Roof WorkJulianna BakerNo ratings yet

- Blockwork ChecklistDocument2 pagesBlockwork ChecklistArch PastoNo ratings yet

- 07 Method Sytatement For Drilling MachineDocument5 pages07 Method Sytatement For Drilling MachineNishar Balkavade100% (1)

- ### Method of StatementDocument5 pages### Method of StatementTAHER AMMARNo ratings yet

- Qcs 2010 Part 18.05 JoineryDocument5 pagesQcs 2010 Part 18.05 JoineryRotsapNayrbNo ratings yet

- Majestic True Beauty Matt: Technical Data SheetDocument3 pagesMajestic True Beauty Matt: Technical Data SheetBilher SihombingNo ratings yet

- Ako AcknowledgmentDocument1 pageAko Acknowledgmentclaude stanton0% (1)

- Pecc-J-1207 Method Statement For Cable Diversion WorksDocument6 pagesPecc-J-1207 Method Statement For Cable Diversion WorksMuneeswaran BalaguruNo ratings yet

- Tool Box Talk 2-07 Excavation Egress - OSHADocument3 pagesTool Box Talk 2-07 Excavation Egress - OSHAloveanbu24No ratings yet

- Method Statement PDFDocument2 pagesMethod Statement PDFAl Manar PetroleumNo ratings yet

- Method Statement Lopeduru DamDocument7 pagesMethod Statement Lopeduru Damdenis yatichNo ratings yet

- Method Statement Excavation Works ScribdDocument8 pagesMethod Statement Excavation Works ScribdMoshotle InnocentNo ratings yet

- Al Masaood Bergum: ExcavationDocument4 pagesAl Masaood Bergum: ExcavationAnonymous 3eHGEDbxNo ratings yet

- Risk AssessmentDocument3 pagesRisk AssessmentAkinbami Olorunnifemi100% (1)

- JSW Roof Sheet PricesDocument1 pageJSW Roof Sheet PricesDhanraj PatilNo ratings yet

- Pds Maestro Matt Emulsion 594me En-GbDocument2 pagesPds Maestro Matt Emulsion 594me En-GbDipin Nediya Parambath0% (1)

- 33 Self Refurbishment Method Statement Phoenix Housing Co OpDocument11 pages33 Self Refurbishment Method Statement Phoenix Housing Co OpthomasNo ratings yet

- Block Work MSDocument19 pagesBlock Work MSjonesNo ratings yet

- Method Statement For ExcavationDocument2 pagesMethod Statement For ExcavationGkou Dojku100% (1)

- Sop Magnesium Anode Installation - ThiessDocument10 pagesSop Magnesium Anode Installation - ThiessbonnicoNo ratings yet

- Block Work MS (Sample)Document18 pagesBlock Work MS (Sample)jones100% (1)

- 18 - RA Roadworks Risk AssessmentDocument1 page18 - RA Roadworks Risk AssessmentkumarNo ratings yet

- Upgrading of Approximately 104Km of Road D104/D791 Chipata To Mfuwe in Eastern Province Surfacing PlanDocument8 pagesUpgrading of Approximately 104Km of Road D104/D791 Chipata To Mfuwe in Eastern Province Surfacing PlanSidney MusondaNo ratings yet

- Table 8.5: Environmental Monitoring Plan For Project Road Environmental Component Project Stage Parameter Standards Locations Duration / Frequency Implementation SupervisionDocument3 pagesTable 8.5: Environmental Monitoring Plan For Project Road Environmental Component Project Stage Parameter Standards Locations Duration / Frequency Implementation SupervisionRaghavNo ratings yet

- Specification For Furnace Oil (IS 1593 - 1982) MV2 Grade: SL - No. Parameter Specification STD - MethodDocument1 pageSpecification For Furnace Oil (IS 1593 - 1982) MV2 Grade: SL - No. Parameter Specification STD - MethodRaghavNo ratings yet

- Concrete PrintDocument5 pagesConcrete PrintRaghavNo ratings yet

- Bitumen EmulsionDocument2 pagesBitumen EmulsionSaurabh ShrivastavaNo ratings yet

- Recycling Hot-Mix Asphalt PavementsDocument28 pagesRecycling Hot-Mix Asphalt PavementsRaghavNo ratings yet

- Mastic Asphalt Mix DesignDocument3 pagesMastic Asphalt Mix DesignRaghav100% (4)

- Mix Design Using RAPDocument3 pagesMix Design Using RAPRaghav100% (1)

- Recycling Hot-Mix Asphalt PavementsDocument28 pagesRecycling Hot-Mix Asphalt PavementsRaghavNo ratings yet

- MaterialsDocument712 pagesMaterialsRaghavNo ratings yet

- AntharangaYatra 1 Aug 2006Document6 pagesAntharangaYatra 1 Aug 2006RaghavNo ratings yet

- Freyssinet - Post-Tensioning SlabstressDocument14 pagesFreyssinet - Post-Tensioning SlabstressRaghavNo ratings yet

- AntharangaYatra 3 Aug-Nov 2007-Vol 2 (1) .1Document6 pagesAntharangaYatra 3 Aug-Nov 2007-Vol 2 (1) .1RaghavNo ratings yet

- Astec Hot Mix Glossary enDocument68 pagesAstec Hot Mix Glossary enRaghavNo ratings yet

- ManajeevithaluDocument334 pagesManajeevithaluRaghavNo ratings yet

- Linhoff HRC PlantDocument6 pagesLinhoff HRC PlantRaghavNo ratings yet

- Vivekavani PDFDocument36 pagesVivekavani PDFRaghavNo ratings yet

- Dual Fuel HCCI Combustion - High Octane and High Cetane Number FuelsDocument22 pagesDual Fuel HCCI Combustion - High Octane and High Cetane Number Fuelsali reza ShakooriNo ratings yet

- Acids, Alkalis and Salts RevisionDocument19 pagesAcids, Alkalis and Salts RevisionJames EzardNo ratings yet

- Plant Mass Flow-50080091 - A4-P - 5.0 - ENDocument9 pagesPlant Mass Flow-50080091 - A4-P - 5.0 - ENHassan raufNo ratings yet

- Drilling Rig Selection - Guidelines Only)Document79 pagesDrilling Rig Selection - Guidelines Only)Edo Gawa77% (13)

- WEG CFW 09 Ebc1 Board Guide 0899.4973 Installation Guide EnglishDocument16 pagesWEG CFW 09 Ebc1 Board Guide 0899.4973 Installation Guide EnglishEvandro LhpNo ratings yet

- Hufcor 632 Paired F4149FDocument6 pagesHufcor 632 Paired F4149Fdoody.dpujaNo ratings yet

- Course OutlineDocument3 pagesCourse OutlineLIM ChanthaNo ratings yet

- Milling TypesDocument16 pagesMilling TypesDon ChurchillNo ratings yet

- Winter Camouflage Painting - Episode 1 Slightly Weathered: by Roman VolchenkovDocument9 pagesWinter Camouflage Painting - Episode 1 Slightly Weathered: by Roman VolchenkovBENo100% (1)

- Bar TrussDocument18 pagesBar TrussJithinGeorgeNo ratings yet

- Rev.02 Panther T8 Parts CatalogDocument184 pagesRev.02 Panther T8 Parts CatalogJovita UvijindiaNo ratings yet

- As LAB C5 Metrology & CalibrationDocument33 pagesAs LAB C5 Metrology & CalibrationedisuprNo ratings yet

- 02 Generic - Types - Grade1Document34 pages02 Generic - Types - Grade1Aravind BabuNo ratings yet

- Electric Conductivity (EC) MeterDocument3 pagesElectric Conductivity (EC) MeterThanh NguyênNo ratings yet

- Asm-35-2000 Aluminum Sheet Metal Work in Building ConstructionDocument31 pagesAsm-35-2000 Aluminum Sheet Metal Work in Building ConstructionSamuel Yu LiuNo ratings yet

- Samsung DVD v5600 v6600 SMDocument239 pagesSamsung DVD v5600 v6600 SMchuftaNo ratings yet

- Mechanical Properties of Modified Low Cobalt Powder Metallurgy UDIMET 700 Type AlloysDocument30 pagesMechanical Properties of Modified Low Cobalt Powder Metallurgy UDIMET 700 Type AlloysEnary SalernoNo ratings yet

- Meyco Segment HR PDFDocument16 pagesMeyco Segment HR PDFFabioSoaresNo ratings yet

- Kobe Welding Handbook 2004Document183 pagesKobe Welding Handbook 2004Nasywafi AlyaNo ratings yet

- Klüberlub NH1 11-222 EN enDocument2 pagesKlüberlub NH1 11-222 EN enKamila AriasNo ratings yet

- Fundamentals of Metal Casting (Richard A. Flinn)Document336 pagesFundamentals of Metal Casting (Richard A. Flinn)Formula Firestorm100% (1)

- Hydro Blasting StandardsDocument16 pagesHydro Blasting Standardsgorankajganic100% (1)

- Challenges and Opportunities of Solid Waste Collector in Case of Yeka Sub City by KENEAN BEDANEDocument73 pagesChallenges and Opportunities of Solid Waste Collector in Case of Yeka Sub City by KENEAN BEDANETigist HaileNo ratings yet

- Project Report On GearsDocument40 pagesProject Report On Gearsjai70% (27)

- Semi Detailed Lesson Plan in Health VIDocument3 pagesSemi Detailed Lesson Plan in Health VIJOANNE TALISICNo ratings yet

- Demolition of Post-Tensioned ConcreteDocument5 pagesDemolition of Post-Tensioned ConcreteIoan-Lucian Stan100% (1)