Professional Documents

Culture Documents

TB01 - Dual Pump Systems

Uploaded by

alsief1951Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TB01 - Dual Pump Systems

Uploaded by

alsief1951Copyright:

Available Formats

Multiple Pump Systems for

Continuous Flow or Independent

Modes

Basic Configurations, Setup, and Operation

Syringe Pumps Technical Bulletin

TB01

Overview

Valve Packages

Multiple pump systems can be used in either

constant pressure or constant flow mode, and can

operate in tandem (2 pumps), or independently (up

to 3 pumps), regulated by a single controller. The D

Series dual pump system consists of two syringe

pumps connected with an air or electric, or check

valve package, and one controller.

The valves may be passive (check valves) or

active (air or electric). Electric valves are

recommended for the following applications:

Liquefied gases

Heated viscous fluids delivered at low pressure

from a pressure pot

Viscous fluids requiring a forced valve closure

For the steps that follow, refer to Figures 2 and 3.

WARNING

Risk of injury. The pressure produced could be up

to 10,000psi (700 bar). Use only the appropriate

tubing and connections.

Valve Package Installation

.3

40.36cm

2

10

5.35

13.59cm

5.5

13.97cm

1. Position the pump bases 1.3 cm apart.

2. Use the plugs to close the ports that will not be

connected.

3. Loosely attach the tubing lengths from the valve

assembly to the pumps.

4. Allow the bracket to hang vertically and place

the straps around the pressure transducer caps.

Tighten the wingnuts.

5. Install the four bracket panhead screws on the

bottom of the bracket.

Plumbing Connections

30. 12

48c

m

46 18.4

.74

cm

0.5 cm

1.3

.7

1018cm

.

7

2

.91 m

21 .66c

55

1. Tighten the tubing nuts.

2. Connect the inlet tube to the supply reservoir.

3. Connect the outlet tee to your apparatus.

Electrical Connections

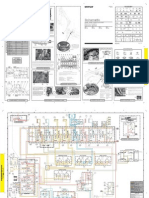

Figure 1: Dual pump system dimensions

Power Requirements

Line Frequency

100 10VAC, Pump A max 1.5A; Pump B max 1.5A

117 12VAC, Pump A max 1.5A; Pump B max 1.5A

234 23VAC, Pump A max 0.75A; Pump B max 0.75A

50 or 60 Hz

Electric Valve Package The

actively

controlled

electric valve package requires a special interface

board mounted inside the controller. Connect the

DB-25 cable to the controller rear panel SFX 220/

VALVES connector, as shown in Figure 2.

Air Valve Package The

actively

controlled

pneumatic valve package requires a pressurized air

source of 80-115psi (552-793KPa). As shown in

Figure 3, connect the two positive (red) wires to any

two of the 15VDC terminals on the rear of the

controller. Connect the black wire from solenoid #1

(IN) to DIGITAL OUTPUT 1. Connect the black wire

from solenoid #2 (OUT) to DIGITAL OUTPUT 2.

Syringe Pumps Technical Bulletin TB01

Electric Valve Package

Air Valve Package

Optional reducing

Optional reducing

fitting (for

/16

fitting (for

/16

Outlet

Outlet

1/8 nut and ferrule

(100/260D), or male

connector (500D)

/8 nut and ferrule

(100/260D), or male

connector (500D)

/8 nut

Pre-swaged pump

connection tubing

/8 nut

Pre-swaged pump

connection tubing

/8 ferrule

/8 ferrule

Strap

(1 of 2)

Strap

(1 of 2)

Inlet tee

(2 total)

Inlet tee

(4 total)

Check valve

Inlet (customer

reservoir)

Inlet (customer

reservoir)

Actuator

To controller

(Red wires =

Bracket panhead

Front View

Front View

Bracket panhead

DB-25 connector to

controller

SFX220/Valves

Controller Rear Panel

To Controller port

PUMP A

Controller Rear Panel

To Controller port

PUMP A

To Controller port

PUMP B

To Controller port

PUMP B

6-32 hex

nut

Overhead View

Overhead View

6-32 hex

nut

Wing nut

6-32 hex

nut

Wing nut

6-32 hex nut

Strap

Strap

Figure 2: Electric valve installation

Strap

Strap

Figure 3: Air valve installation Requires pressurized

air source @ 80-115 psi (5.5 - 7.93 bar)

Syringe Pumps Technical Bulletin TB01

Setting Up Continuous Flow

Both pumps must be operated manually during

initial setup, i.e. refill and purging of air. Active (air

or electric) valves are switched using the ACC CTRL

key. Lights on the air switches indicate which valves

are open. Once the valve package is installed and

you have ensured that fluid connections are leak

free, you are ready to program the system. Press the

keys on the controller front panel in the order shown

for the desired mode.

(TOTAL

VOLUME

(PREVIOUS)

Press 2x to return

to run screen

(MORE

Figure 5: Keystrokes to reset volume totalizer

Defining Operation

SELECT PUMP This menu allows you to select any

pump to display its run screen (program and

operation data) and to make program changes.

Constant Flow Mode:

(Select pump)

(CONTIN

CONST

FLOW)

Valve specification To

prevent

pressure

fluctuation at switchover, you must specify the type

of valve package you are using.

or

(AIR)

(MORE

or

(CHECK

(MULTI-PUM

(2-WAY)

(3-WAY)

ELECTRIC

ELECTRIC

(VALV

Starts

operation

Figure 6: Keystrokes to set up constant flow

or

(MORE

(PREVIOUS)

Press 3x to

return to

run screen

Constant Pressure:

(PREVIOUS)

Press 3x to

return to run

(CONTIN

CONST

PRESS)

Figure 4: Keystrokes to specify valve type

Note

In older controller versions, only buttons 1 (ACTIVE) and

2 (PASSIVE) are selectable when specifying the valve

type being used (Figure 4). Active refers to air or

electric valves; Passive refers to check valves.

Options 3 & 4 only appear if the electric valve board is

installed in the controller.

(MORE

(MULTI-PUM

(PREVIOUS)

Press 3x to

return to

run screen

Starts

operation

Figure 7: Keystrokes to set up constant pressure

Volume totalizer The

total volume delivered is

displayed in liters at the top right corner of the

screen. Refer to the figure below to reset the volume

totalizer to zero.

Note

Before pressing RUN, ensure that ON CONT FLOW is

displayed on the screen, and that the set flow rate/

pressure is correct.

Always verify the valve settings before running a

program. If a controller is reset or moved to a

different power source, it will revert back to default

settings (Passive).

Syringe Pumps Technical Bulletin TB01

Tips for Running Continuous Flow

Liquids Checklist:

1. Degas liquids if appropriate.

2. Purge air from the system:

a. Fill both pumps completely by pressing REFILL

and selecting each pump to fill.

b. Route the outlet (see Figures 2 and 3) to

waste or reservoir and press RUN. Press STOP

when fluid comes out of the outlet.

c. Open the valves to atmosphere by pressing

ACC CTRL, then selecting each valve to open.

d. Zero the pressure in each pump by pressing

ZERO PRESS and selecting each pump to zero.

e. Connect the outlet tubing and fill each pump

once more.

3. Reset total volume (see Figure 5).

Equilibration When the pumps begin running, the

system will go through an equilibration phase,

during which both pumps must be full and

delivering fluid.

Liquefied Gases Checklist:

1. Open the valves to atmosphere by pressing ACC

CTRL, then selecting each valve to open.

2. Zero the pressure in each pump by pressing ZERO

PRESS and selecting each pump to zero.

3. Fill both pumps completely by pressing REFILL

and selecting each pump to fill.

4. Pressurize both pumps by pressing RAPID PRESS.

Maximum flow rate and target pressure value

will by displayed. Press D to continue pressurization.

5. Reset total volume (see Figure 5).

Additional guidelines Please become familiar with

the following guidelines provided by our research

laboratory:

Pressure limits for constant flow mode are set by

the limits of pump A.

Temperature changes can cause pressure

fluctuations, especially if a restrictor is being used

for backpressure. For available temperature

control options, contact Teledyne Isco.

For correct overpressure response, shutdown must

be set to ON under PUMP LIMIT options.

Enter the same refill rate separately for pumps A

and B.

The refill rate should always be at least twice the

flow rate setpoint to allow time for refill and

repressurization before the next switchover.

If the system is operating below 80psi or needs a

faster pressurized match, see Table1 for soft key

functions.

Table 1: Key Functions in the Multi-Pump

Mode

Key

Display Option

Description

Normal

Uses a finer (slower) pressure match control

when switching from one pump to the other.

Uses a coarser (faster) pressure match control

when switching from one pump to the other.

Uses pressure matching when switching from

one pump to the other.

Uses no pressure matching when switching

from one pump to the other.

Sets the pump into the delivery mode of operation.

Sets the pump into the receive mode of operation.

Sets the fill and refill marks that are used with

both continuous flow modes.

Fast

B

Normal Pressure

Low Pressure

Deliver

Receive

Min/Max Points

Syringe Pumps Technical Bulletin TB01

Independent Control

One controller can run up to three syringe pumps

independently of each other in either constant

pressure or constant flow mode, or any combination

of the two. Each pump will operate at its defined

limit and rate. Programming steps are shown in

Figure 8.

HOLD PRESS After a pump in constant pressure

mode runs empty, if outlet pressure exceeds the

setpoint, this feature causes the pump to restart,

returning the system to setpoint pressure.

NORMAL This feature shuts off any pump that

runs empty in constant pressure mode.

Toggles between HOLD

and NORMAL

See above.

PRESS

(MORE)

(PREVIOUS)

Press 3x to return

to run screen

(MULTI-PUMP)

(INDEPENDENT)

4 will blink

(SELECT PUMP)

See above.

Starts operation for the

pump selected.

Figure 8: Keystrokes to set up independent

pumps

Teledyne Isco

P.O. Box 82531, Lincoln, Nebraska, 68501 USA

Toll-free: (800) 775-2965 Phone: (402) 464-0231 Fax: (402) 465-3001

E-mail: IscoService@teledyne.com

Teledyne Isco is continually improving its products and reserves the right to change product

specifications, replacement parts, schematics, and instructions without notice.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Acert 2007 CATDocument29 pagesAcert 2007 CATalsief1951100% (1)

- Acert 2007 CATDocument29 pagesAcert 2007 CATalsief1951100% (1)

- Acert 2007 CATDocument29 pagesAcert 2007 CATalsief1951100% (1)

- 8 Fgu 15Document618 pages8 Fgu 15German Briceño100% (4)

- GET Parts CaterpillarDocument917 pagesGET Parts Caterpillaralsief195167% (3)

- 320 D A8fDocument2 pages320 D A8fRudolph Prieto M100% (4)

- Engine Speed Timing Sensor - CalibrateDocument9 pagesEngine Speed Timing Sensor - Calibratewagner_guimarães_150% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Psychopathology: Dr. Shafqat Huma MBBS, FCPS (Psychiatry) Fellowship in Addiction Psychiatry (USA)Document48 pagesPsychopathology: Dr. Shafqat Huma MBBS, FCPS (Psychiatry) Fellowship in Addiction Psychiatry (USA)sfrtr100% (1)

- Get Parts CaterpillarDocument1,398 pagesGet Parts Caterpillaralsief1951100% (9)

- Universal Joint 2014 GMBDocument49 pagesUniversal Joint 2014 GMBalsief195171% (7)

- CHM Analysis and Comparisons of CRUS MULTHULLS2013Document60 pagesCHM Analysis and Comparisons of CRUS MULTHULLS2013kkd108No ratings yet

- St. John of The Cross - UnknownDocument19 pagesSt. John of The Cross - UnknownthepillquillNo ratings yet

- Genius+ Ba Cu en 1113Document72 pagesGenius+ Ba Cu en 1113AlbertNo ratings yet

- Preparation and Evaluation of Orthodontic Setup PDFDocument20 pagesPreparation and Evaluation of Orthodontic Setup PDFLiezty VioLen'sNo ratings yet

- Gidronasosy Serii PMV10Document48 pagesGidronasosy Serii PMV10alsief1951No ratings yet

- General Guidelines For Design and Construction of Concrete Diaphram (Slurry) WallsDocument108 pagesGeneral Guidelines For Design and Construction of Concrete Diaphram (Slurry) WallsharleyNo ratings yet

- Propshafts & Couplings: B E A R M A C HDocument31 pagesPropshafts & Couplings: B E A R M A C HJoao Espada100% (3)

- 1 Standard Parts, ServiceDocument161 pages1 Standard Parts, ServiceAngel Alberto Franco KukNo ratings yet

- Wa380 5Document12 pagesWa380 5alsief1951100% (3)

- Torque Converter Troubleshoot ChartDocument2 pagesTorque Converter Troubleshoot ChartKhoa PhạmNo ratings yet

- 7 Frame and WheelDocument12 pages7 Frame and Wheelalsief1951No ratings yet

- Safety Concerns Everybody!: Service InformationDocument37 pagesSafety Concerns Everybody!: Service InformationAngel Alberto Franco KukNo ratings yet

- Serq4103 NTS4Document75 pagesSerq4103 NTS4alsief1951100% (1)

- Wa200-5 Aess643-00Document12 pagesWa200-5 Aess643-00alsief1951100% (4)

- Adress: (Aljandaweel/amman/jordan) Phone: (0775592988) : EducationDocument1 pageAdress: (Aljandaweel/amman/jordan) Phone: (0775592988) : EducationssinokrotNo ratings yet

- ACERT™ 2007: Variable Nozzle TurbochargerDocument37 pagesACERT™ 2007: Variable Nozzle Turbochargeralsief1951No ratings yet

- A35769EDocument44 pagesA35769Ealsief1951No ratings yet

- C811526 PDFDocument28 pagesC811526 PDFalsief1951No ratings yet

- Poclain Hydraulics Selection GuideDocument44 pagesPoclain Hydraulics Selection GuideM S GokulNo ratings yet

- 432E - Hyd ComponentsDocument2 pages432E - Hyd Componentsalsief1951100% (2)

- SectionDocument180 pagesSectionalsief1951No ratings yet

- SK 140 HDLCDocument8 pagesSK 140 HDLCalsief1951100% (1)

- Object ServerDocument2 pagesObject Serveralsief1951No ratings yet

- Syllabus - 2nd Paper NTCDocument2 pagesSyllabus - 2nd Paper NTCajesharyalNo ratings yet

- Chem Tech South 2013 - ConferenceDocument5 pagesChem Tech South 2013 - ConferenceAbirami PriyadharsiniNo ratings yet

- Cloning of CELLDocument43 pagesCloning of CELLsashaikh1213No ratings yet

- 0580 w15 QP 42Document16 pages0580 w15 QP 42Shahrizan Noor100% (1)

- MSDS Corn CobDocument2 pagesMSDS Corn CobMUHAMMAD YOGA BRILLIANTONo ratings yet

- Ross 308 AP Broiler PO2019-EN PDFDocument16 pagesRoss 308 AP Broiler PO2019-EN PDFJORGE GALVISNo ratings yet

- Caterpillar 360 KWDocument6 pagesCaterpillar 360 KWAde WawanNo ratings yet

- Pancreatic NekrosisDocument8 pagesPancreatic Nekrosisrisyda_mkhNo ratings yet

- 19174the Rise of Industrial Big Data WP Gft834Document6 pages19174the Rise of Industrial Big Data WP Gft834em01803257No ratings yet

- JJ309 Fluid Mechanics Unit 6Document30 pagesJJ309 Fluid Mechanics Unit 6Adib AzharNo ratings yet

- Final Project Proposal Digital Stopwatch-1Document6 pagesFinal Project Proposal Digital Stopwatch-1Shahid AbbasNo ratings yet

- Basicline BL 21t9stDocument28 pagesBasicline BL 21t9stgabriel6276No ratings yet

- Design and Development of Manually Operated ReaperDocument8 pagesDesign and Development of Manually Operated ReaperIOSRjournalNo ratings yet

- Pricelist Mobil Area Jabodetabek Semester 2 2022 TerbaruDocument108 pagesPricelist Mobil Area Jabodetabek Semester 2 2022 TerbarutonymuzioNo ratings yet

- Projects in the Autonomous Region in Muslim MindanaoDocument4 pagesProjects in the Autonomous Region in Muslim MindanaoMark montebonNo ratings yet

- Traffic Sign Detection and Recognition Using Image ProcessingDocument7 pagesTraffic Sign Detection and Recognition Using Image ProcessingIJRASETPublicationsNo ratings yet

- BS 7941-1-2006Document20 pagesBS 7941-1-2006Willy AryansahNo ratings yet

- Ego7 Manual enDocument76 pagesEgo7 Manual ensullivanj69No ratings yet

- DPT ProcedureDocument3 pagesDPT ProcedureAmit HasanNo ratings yet

- Structural Notes SampleDocument14 pagesStructural Notes SampleNicole FrancisNo ratings yet

- STPM Chemistry Topic 16 Haloalkanes Short Notes PDFDocument2 pagesSTPM Chemistry Topic 16 Haloalkanes Short Notes PDFbendanNo ratings yet

- See Catalog: Get A QuoteDocument4 pagesSee Catalog: Get A QuoteahnafNo ratings yet

- PENERAPAN ARSITEKTUR TROPIS PADA HOTEL RESORT DI PANTAI KRAKALDocument12 pagesPENERAPAN ARSITEKTUR TROPIS PADA HOTEL RESORT DI PANTAI KRAKALleo adoNo ratings yet

- Personal Care Na Hair GuideDocument8 pagesPersonal Care Na Hair GuideIsabellaNo ratings yet