Professional Documents

Culture Documents

Tjprcfile397 JK SP

Uploaded by

shamsukarim2009Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tjprcfile397 JK SP

Uploaded by

shamsukarim2009Copyright:

Available Formats

International Journal of Civil, Structural,

Environmental and Infrastructure Engineering

Research and Development (IJCSEIERD)

ISSN: 2249-6866

Vol.2, Issue 1 Mar 2012 20-56

TJPRC Pvt. Ltd.,

COMPARISON OF IS, BS AND ACI METHODS OF

CONCRETE MIX DESIGN AND PROPOSING FUNCTION

EQUATIONS BASED DESIGN

JEEVENDRA KUMAR CHANDRAKAR1 AND S.P. MISHRA2

1

Student, M.E. Civil (Structural Engineering), Bhilai Institute of Technology,

Durg 491001, Chhattisgarh India

E-mail: jeevendra27@ gmail.com

2

Associate Professor, Department Of Civil Engineering, Bhilai Institute Of

Technology Durg 491001, Chhattisgarh, India, E-mail : spmbits @ gmail.com

ABSTRACT

In this paper a comparison of mix design procedures of IS method Concrete mix proportioning guidelines (Bureau of Indian Standards-I.S.102622009), BS method ( BS EN 206-1 and its complementary standards BS 8500

parts 1& 2) and, ACI

method (ACI 211, 211.1-91, reapproved -2002) is

presented and combining the test results of these methods, function equations

based design of normal concrete mixes is proposed.

It was observed that the water-cement ratio is highest in the BS method,

whereas lowest in the IS method. The water-content in BS method is less as

compared to other two methods, whereas it is nearly identical in IS and ACI

methods. The IS method uses highest amount of cement, whereas BS method

uses the least amount of cement. The total aggregate content and the aggregatecement ratio in BS method is much high as compared to the other two methods.

The percentage of fine aggregate is highest in ACI method and lowest in IS

method. The fine aggregate content in ACI method appears to be more

consistent and it also contributed to the increased strength. The mixes designed

by BS method failed to achieve the target mean strength. The main reason of

failure appears to be due to the use of high water-cement ratio, less amount of

21

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

water-content, less amount of cement content and higher amount of aggregate

content. As a result, the quantity of cement content obtained appears to be

insufficient to completely coat all the aggregate particles and bind them together.

The mixes designed by IS method and ACI method achieved the target mean

strength, which indicate that these methods are consistent.

The proposed method - function equations based design of normal

concrete mixes uses simple function equations giving relationship between 28days compressive strength of concrete versus various influencing parameters of

mix design. There is no need of graphs, charts, tables etc. This method gives less

quantity of cement than the other two methods, hence appears to be more

economical. Also the fine aggregate content is higher for the same grades of

concrete, resulting in a dense concrete mix. The proposed method is validated

experimentally in the laboratory for concrete grades-15MPa, 20MPa, 25MPa,

30MPa and 35MPa, and achieved the targeted strength. The proposed method

can be used for mix design of normal concrete mixes of medium strength grades

and also by the field engineers for quick ascertainment of concrete mixes being

produced at the construction sites.

KEY WORDS: Concrete mix design, IS method, BS method, ACI method,

function equations, target mean strength, water cement ratio, water content,

cement content, workability, aggregate content, aggregate cement ratio.

1. INTRODUCTION

Concrete mix design is a well established practice around the world. Most

of the countries have standardized their concrete mix design methods. In the

recent years concrete has undergone rapid remarkable development. In addition

to traditional plain and reinforced cement concrete, high-performance concrete

(HPC), reactive powder concrete (RPC), and self compacting concrete (SCC)

etc. have been introduced. In addition, there is an increased thrust in the use of

chemical admixtures and supplementary cementitious materials like Fly ash,

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

22

Ground granulated blast-furnace slag (GGBS) Silica fume, Metakaolin, etc.

Continuing researches on mix design procedures standardized by different

countries, impact of variability of ingredients on properties of concrete in fresh

and hardened state, and use of different supplementary and recycled materials

are going on worldwide.

The IS, BS, and ACI methods of concrete mix design are mostly based on

empirical relations, charts, graphs, and tables developed through extensive

experiments and investigations using their own locally available materials.

Though all these methods in general follow the same basic principle in selection

of mix design parameters, but some procedural differences exist in each of these

methods.

1.1 Concrete Mix Design

Concrete is an extremely versatile engineering material used in most of the

civil engineering structures and like other engineering materials needs to be

designed for certain desirable properties in fresh as well as hardened state.

Properties desired in plastic state are workability, cohesiveness and initial set

retardation, and that in hardened state are strength, imperviousness and

durability.

The process of selecting suitable ingredients of concrete and determining

their relative amounts with the objective of producing a concrete of the required

strength, durability, and workability as economically as possible that satisfies

the job requirements is termed as the concrete mix design.

1.2 Basic ingredient of Concrete

The two major components of concrete are - cement paste and inert

materials. The cement paste consists of Portland cement, water, and some air

either in the form of naturally entrapped air or intentionally entrained air

bubbles. The inert materials are composed of aggregates. The basic ingredients

23

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

of concrete are cement, coarse aggregate, fine aggregate and water. In addition

to these chemical and mineral admixtures have been recognized as fifth and

sixth ingredient of concrete in recent years.

1.3 Basic data required for mix proportioning

The following basic data is required for concrete mix proportioning:

(i)

Grade designation: It gives characteristic compressive strength of

concrete. The target mean strength of concrete is fixed by adding a

suitable margin to the characteristic strength depending upon the

quality control to be envisaged.

(ii)

Type of cement: The type and grade of cement mainly influences

the rate of development of compressive strength of concrete.

(iii) Maximum nominal size of aggregate: The maximum nominal size

of the aggregate to be used in concrete is governed by the size of the

section to be concreted and spacing of the reinforcement.

(iv)

Maximum water-cement ratio: The maximum water cement ratio

to be used for a particular work is governed by the desired strength

and limited by the durability requirements.

(v)

Minimum cement content: The minimum cement content to be used

is governed by the respective environmental exposure conditions.

(vi)

Workability: The desired workability for a particular job depends

upon the shape and size of section to be concreted, denseness of

reinforcement, and method of transportation, placing and compaction

of concrete.

(vii) Exposure conditions: The anticipated

environmental exposure

conditions in which the structure is intended to serve during its

service span defines the durability requirements.

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

24

(viii) Type of aggregate: It influences the workability and strength of

concrete. The relative proportions of coarse and fine aggregate are

determined from the characteristics of the aggregates such as grading,

shape, size and surface texture.

(ix)

Method of transporting and placing: It influences workability of

the mix.

(x)

Use of admixtures: Admixtures are used to enhance and modify one

or more properties of concrete in fresh as well as hardened state.

2. EXPERIMENTAL WORK

2.1 Design Constraints

The experimental work comprised of design of normal concrete mixes of

medium strength grades -15MPa, 20MPa, 25MPa, 30MPa and 35MPa, by IS, BS

and ACI methods. In the mix design only strength criteria was considered

irrespective of durability requirements, as it is site specific. The materials used

were Portland Slag cement (conforming to IS 455:1989) make ACC without

chemical/ mineral admixtures, Coarse aggregate natural crushed angular stones

from Nadini quarry of Durg district (C.G.) with the existing supplied grading

and fine aggregate natural river sand from Tandula river of Durg district

(C.G.). The workability of the mixes were measured in terms of slump and

vee-bee. The compressive strength of trial cubes were tested at 7 days and 28

days.

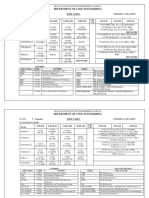

2.2 Concrete Mix Design Parameters

The properties of concrete making ingredients were tested in the laboratory.

Accordingly, the parameters used for design of concrete mixes were as per

Table 1, below:

25

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

Table 1 : Concrete mix design parameters

S.

No.

Parameters

1.

Characteristic compressive strength

15MPa, 20MPa,

25MPa,30MPa, and 35MPa

2.

Type of cement :

Portland Slag cement

(I.S.455: 1989) make

ACC

3.

Specific gravity of cement

3.15

4.

Nominal maximum size of Coarse

aggregate

20 mm

5.

Type of Coarse aggregate

Crushed natural stone

aggregate

6.

Type of fine aggregate

Natural River Sand

7.

Specific gravity

of :

Coarse

aggregate

2.62

Fine aggregate

2.59

Coarse

aggregate

1600 kg/m3

Fine aggregate

1700 kg/m3

Coarse

aggregate

7.30

Fine aggregate

2.44 (Zone II)

Coarse

aggregate

0.57%

Fine aggregate

1.00 %

Coarse

aggregate

Nil

Fine aggregate

2.32%

8.

9.

10.

11.

Unit weight of :

Fineness modulus

of :

Water absorption

:

Free surface

moisture :

Data

12.

Workability desired

25 to 50 mm slump

13.

Chemical/ mineral admixtures

Not used

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

a.

26

Sieve analysis

The sieve analysis results of coarse and fine aggregates are given in tables 2

and 3 respectively:

Table 2 : Sieve analysis of coarse aggregate

Weight of Sample Taken = 5.00 kg

Sieve Size

Weight

Cumulative

Cumulative

Cumulative

Retained

(In kg)

weight retained

(in kg)

% Retained

% Passing

80 mm

100.000

40 mm

100.000

20 mm

1.519

1.519

30.380

69.620

10 mm

3.444

4.963

99.260

0.740

4.75 mm

0.037

5.000

100.000

0.000

2.36 mm

0.000

5.000

100.000

0.000

1.18 mm

0.000

5.000

100.000

0.000

600 micron

0.000

5.000

100.000

0.000

300 micron

0.000

5.000

100.000

0.000

150 micron

0.000

5.000

100.000

0.000

TOTAL

5.000

729.64

Fineness Modulus = 729.64/100 = 7.30

27

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

Table 3 : Sieve analysis of Fine Aggregate

I.S. Sieve

Size

Weight of Sample Taken = 1000 gm.

Weight

Cumulative

Cumulative

Retained (In

weight

% Retained

Cumulative

% Passing

4.75 mm

11

11

1.100

98.900

2.36 mm

63

74

7.400

92.600

1.18 mm

141

215

21.500

78.500

600 micron

245

460

46.000

54.000

300 micron

214

674

67.400

32.600

150 micron

326

1000

100.000

0.000

TOTAL :

1000

243.400

Fineness Modulus = 243.40/100 = 2.44 ( Grading zone II of IS: 383)

2.4 Concrete Mix Design

The proportions of ingredients of concrete mixes designed by IS, BS and

ACI methods were as below. With these relative proportions of ingredients trial

mixes were prepared and the cubes were cast.

Table 4 : Proportions of concrete ingredients by IS, BS and ACI methods

Total

Free Coarse

Fine

Free

Cement

Total

Aggregat

Water

aggregat aggregat

Conten

Aggregat

Metho Concret WatereContent

e

e

No

t

e Content

d

e Grade Cemen

3

Cement

(litre/m

Content Content

.

3

3

t Ratio

(kg/m )

(kg/m )

)

(kg/m3) (kg/m3)

Ratio

S.

1.

2.

IS

Method

BS

Method

15MPa

0.59

182.63

310.00

1124.92

758.56

1883.48

6.08

20MPa

0.54

183.02

338.18

1129.29

730.02

1859.31

5.50

25MPa

0.49

183.40

372.00

1130.58

700.90

1831.48

4.92

30MPa

0.45

183.78

413.13

1127.03

669.50

1796.53

4.35

35MPa

0.39

183.85

465.00

1099.96

671.09

1771.05

3.81

15MPa

0.82

165.13

200.00

1143.00

862.00

2005.00

10.03

20MPa

0.73

166.32

226.67

1187.00

809.69

1996.69

8.81

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

28

Free Coarse

Fine

Total

Cement

Total

Free

Water

aggregat aggregat

Aggregat

Metho Concret WaterConten

Aggregat

Content

e

e

eNo

t

e Content

d

e Grade Cemen

(litre/m3

Content Content

Cement

.

3

3

(kg/m )

(kg/m )

t Ratio

)

(kg/m3) (kg/m3)

Ratio

S.

3.

ACI

Method

25MPa

0.63

166.76

261.54

1185.51

775.53

1961.04

7.50

30MPa

0.59

167.15

283.33

1191.44

747.17

1938.61

6.84

35MPa

0.52

167.57

320.75

1187.08

713.34

1900.42

5.92

15MPa

0.67

180.38

268.12

1049.60

821.52

1871.12

6.98

20MPa

0.59

180.82

308.33

1049.60

787.08

1836.68

5.96

25MPa

0.52

181.28

349.06

1049.60

751.53

1801.13

5.16

30MPa

0.44

181.92

411.11

1049.60

702.27

1751.87

4.26

35MPa

0.39

182.50

462.50

1049.60

657.22

1706.82

3.69

3. RESULTS

The workability of concrete mixes were measured in terms of Slump and

Vee-bee. After water curing of cubes, compressive strengths at 7 days and 28

days were tested. The experimental test results were obtained as below:

Table 5 : Experimental test results

Av. 7 Days Av. 28 Days

Av.

Av.

Target

Cube

Cube

Weight Density of

Mean

Compressive Compressive

S.

Concrete Slump

of three Concrete,

Method

Compressive Strength of Strength of

No.

Grade (mm)

Cube

of three

strength, f'ck

three

three

Samples Samples

(N/mm2)

Samples

Samples

(kg)

( kg/Cum)

(N/mm2)

(N/mm2)

1.

2.

IS

Method

BS

Method

15MPa

35

20.78

14.67

20.81

8.13

2408.89

20MPa

30

26.60

19.56

27.85

8.334

2469.33

25MPa

40

31.60

22.30

33.11

8.335

2469.83

30MPa

50

38.25

26.52

38.30

8.405

2490.47

35MPa

30

43.25

30.81

43.33

8.443

2501.73

15MPa

45

20.78

10.81

15.70

8.256

2446.22

20MPa

30

26.60

16.81

24.37

8.350

2474.07

25MPa

30

31.60

19.41

28.30

8.123

2406.81

29

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

Av. 7 Days Av. 28 Days

Av.

Av.

Target

Cube

Cube

Weight Density of

Compressive Compressive

Mean

S.

Concrete Slump

of three Concrete,

Method

Compressive Strength of Strength of

Cube

of three

No.

Grade (mm)

strength, f'ck

three

three

Samples Samples

2

Samples

(N/mm )

Samples

(kg)

( kg/Cum)

(N/mm2)

(N/mm2)

3.

ACI

Method

30MPa

45

38.25

20.44

29.02

8.269

2449.97

35MPa

60

43.25

22.37

31.85

8.37

2479.60

15MPa

30

20.78

14.96

20.89

8.478

2512.10

20MPa

35

26.60

19.41

27.78

8.325

2466.67

25MPa

30

31.60

23.41

33.48

8.257

2446.42

30MPa

30

38.25

26.96

38.59

8.352

2474.57

35MPa

30

43.25

30.81

43.26

8.413

2492.84

4. ANALYSIS

4.1 General observations of test results

(i)

The BS method of mix design is more comprehensive and more

tedious, whereas IS and ACI methods are simple and straight

forward.

(ii)

The mixes designed by IS and ACI methods achieved the target

mean strengths and were found to be consistent.

(iii)

The trial mixes designed by BS method failed to achieve the targeted

strength. The different grades of trial mixes achieved the 28-days

actual compressive strengths as below:

Table 6 : Targeted and actual 28 days compressive strength of trial cubes

(BS method)

Concrete Grades

15MPa

20MPa

25MPa

30MPa

35MPa

Target Mean Strength (in N/mm )

20.78

26.60

31.60

38.25

43.25

28-days

actual

strength(in N/mm2)

15.70

24.37

28.30

29.02

31.85

compressive

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

Percentage actual strength

75.55%

91.62 %

30

89.56%

75.87%

73.64%

The main reason for the failure of BS method appears to be due to the

use of high values of water-cement ratio specified by the relevant

standard, giving lower values of cement content and higher quantities

of aggregate contents as compared to the other two methods. As a

result, the quantity of cement content obtained appears to be

insufficient to completely coat all the aggregate particles and bind

them together.

(iv)

The free water-cement ratio decreases with the increase in targeted

strength in all the three methods. The water-cement ratio is highest in

the BS method, whereas lowest in IS method. It is identical for

30MPa and 35MPa grades of concrete in IS and ACI methods. (Refer

figures -1 and 2 below)

Figure 1 : Plot of 7 days Compressive strength Versus Water cement ratio

31

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

Figure 2 : Plot of 28 days Compressive strength Versus Water cement ratio

(v)

The water-content obtained in BS method is less as compared to

other two methods, whereas it is nearly identical in IS and ACI

methods. (Refer figures - 3 and 4 below)

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

32

Figure 3 : Plot of 7 days Compressive strength versus Water content

Figure 4 : Plot of 28 days Compressive strength Versus Water content

(vi)

The Cement-content increases with the increase in the targeted

strength. The IS method uses highest amount of cement. The BS

method uses the least amount of cement and appears to be the main

reason of failure to achieve the targeted strengths. (Refer figure-5

and 6 below):

33

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

Figure 5 : Plot of 7 days Compressive strength versus Cement content

Figure 6 : Plot of 28 days Compressive strength versus Cement content

(vii) In all the three methods trial mixes of all grades nearly achieved the

designed slump. (Refer figure- 7 and 8 below)

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

34

Figure 7 : Plot of 7 days Compressive strength versus Workability (slump)

Figure 8 : Plot of 28 days Compressive strength versus Workability (slump)

(viii) The total aggregate content and the aggregate-cement ratio in BS

method is much high as compared to the other two methods. The total

35

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

aggregate -content gradually decreases with the increase in the

targeted strength. (Refer figure-9 and 10 below)

Figure 9 :

Plot of 7 days Compressive strength versus Aggregate- cement

ratio

Figure 10 : Plot of 28 days compressive strength versus aggregate- cement

ratio

(ix)

The coarse aggregate content in the ACI method is constant for all

grades of concrete, whereas in BS and IS methods it is not stable. It is

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

36

highest in BS method whereas lowest in ACI method.(Refer

figure- 11 and 12 below)

Figure 11 : Plot of 7 days Compressive strength versus Coarse aggregate

content

37

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

Figure 12. Plot of 28 days Compressive strength versus coarse aggregate

content

(x)

The fine aggregate content decreases with the increase in the targeted

strength in all the three methods of mix design. The percentage of

fine aggregate is highest in ACI method and lowest in IS method.

The fine aggregate content in ACI method appears to be more

consistent. It also appears that higher percentage of fine aggregate in

ACI method contributed to increased strength as the voids are filled

more closely. (Refer figure-13 and 14 below):

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

Figure 13 : Plot of 7 days compressive strength versus fine aggregate

content

Figure 14 : Plot of 28 days compressive strength Versus fine aggregate

content

38

39

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

4.2 Comparison of mix design procedures

4.2.1 Similarities

(i)

All the methods are applicable for design of concrete mixes using

different types of hydraulic cements, blended cements and with or

without other supplementary cementitious materials and chemical

admixtures.

(ii)

All the methods give guidelines for design of concrete mixes using

normal and heavy weight aggregates.

(iii)

The water-cement ratio of the mix governs the compressive strength

of concrete. Selection of water-cement ratio is primarily based on

generalized relationship between compressive strength of concrete

and water-cement ratio, though some minor variations exist in the

process of selection in different methods.

(iv)

All the methods specify different exposure conditions to meet the

durability requirements.

(v)

Selection of water- Content is based on workability of the mix

desired. The workability is specified in terms of slump, vee-bee or

compacting factor is different in different methods.

(vi)

Cement content is estimated by dividing the free water-content by

the free water-cement ratio in all the three methods and checked

against minimum cement requirements for durability.

(vii) All the methods are based on the absolute volume concept for

calculation of required proportion of materials.

(viii) The final mix proportion for the first trial mix is obtained by making

suitable adjustments for water absorption

carried by the aggregates.

and surface moisture

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

40

4.2.2 Differences

(a) Applicability

IS method : This method is applicable for Ordinary (10MPa 20MPa

grade) and Standard grades (25MPa to 55MPa grade) of concrete

only. This method does not give guidelines for design of Light weight

and heavy weight concrete. The compressive strength of hardened

concrete is to be specified on the basis of 150 mm cube test, determined

at 28 days.

BS method : This method is applicable for design of normal concrete

mixes having 28-days compressive strength up to 75 MPa. This

standard also gives guidelines for design of light weight and heavy

weight concrete. The compressive strength of hardened concrete is to

be specified on the basis of 150 mm cube test determined at 28 days

((fck,

cube),

in N/mm2 or 150 mm diameter by 300 mm cylinder tests,

determined at 28 days((fck, cyl ),in N/mm2.

ACI method : This method is applicable for design of normal and /or

heavy concrete, and mass concrete mixes. This standard is not

applicable for Light weight aggregate concrete and for special

admixtures for concrete products manufacture. This method is also not

applicable for using condensed Silica fume. The ACI method of mix

proportioning is applicable for normal and heavy weight concrete

having 28-days cylinder compressive strength of 45 MPa and slump

ranges of 25 to 100 mm.

(b) Type and shape of aggregates

IS method : This method takes in to account the type of aggregates as

- angular, sub angular and rounded, and nominal maximum size of

aggregates in computation of water content for the desired workability.

41

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

BS method : This method takes in to account the type of aggregates

as crushed and uncrushed only and upper size of coarse aggregate in

computation of water content for the desired workability.

ACI

method : This

method takes in to account the nominal

maximum size of aggregate, but it does not

differentiate between

crushed and uncrushed or rounded aggregate and flakiness and

elongation in computation of water content.

(c) Air content

IS method : In non air entrained concrete, air content is considered

not of much significant and is ignored. This Standard also does not give

guidance on proportioning of air - entrained concrete.

BS

method : For non-air entrained concrete, air content is not

specified. For air-entrained concrete, it specifies minimum total air

content with a maximum total air content being 4% higher than the

specified minimum.

ACI method : In this method, the air content percentage in concrete is

estimated depending upon the type of concrete, whether air entrained or

non air entrained, exposure conditions and the nominal maximum size

of aggregate.

(d) Exposure conditions and durability requirements

IS method: In this method the general environment is classified into

five levels of severity

- mild, moderate, severe,

very severe and

extreme and accordingly the limits of maximum water cement ratio

and minimum cement content are specified.

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

42

BS method: In this method exposure classes are classified as- No risk

of corrosion(X0), Carbonation-induced corrosion (XC1 to XC4),

Chloride-induced corrosion Sea water (XS1 to XS3) and Chloride

other than from sea water(XD1 to XD3), Freeze/thaw attack (XF1 to

XF4) and Aggressive chemical environments (XA1 to XA3), and specifies

maximum water cement ratio , minimum cement content and minimum

strength classes for different exposure classes.

ACI method: This Standard recommends use of special ingredients

such as low alkali cement, pozzolanas, GGBS, silica fume, or aggregate

selected to prevent harmful expansion to the alkali-aggregate reaction.

Entrained air is to be used in all exposed concrete in climates where

freezing occurs.

(e) Water cement ratio

IS method : This method suggests that relationship between strength

and free water-cement ratio should preferably be established for the

materials actually to be used. In the absence of such data the watercement ratio specified in the Table 5 of I.S. 456: 2000 for respective

environment exposure conditions may be used as starting point. The

supplementary cementitious materials i.e. mineral admixtures shall also

be considered in water-cement ratio calculations.

BS method : This method considers the influence of cement, type of

aggregate and target mean strength in computation of water-cement

ratio, which is selected from the table and curve specified in this

standard.

ACI method : This standard specifies to have or to develop the

relationship between strength and water- cement ratio for the materials

actually to be used. In the absence of such data, approximate values for

43

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

concrete containing type- I Portland cement can be taken from Table

A1.5.3.4(a) of ACI 211.1, based on compressive strength.

(f) Workability

IS method : In this method ( I.S. 456:2000), degree of workability in

Slump values have been specified for different placing conditions

ranging from 25 mm to 150 mm. For Tremie concrete, where the

degree of workability is very high, the workability is to be determined

by flow.

BS

method : In this method

different Consistence classes are

specified which covers the workability of concrete, and either a class

or target value can be used to specify consistence.

ACI method : In This method

Table A1. 5.3.1 of ACI 211.1

recommends different values of maximum slump ranging from 50 to

100 mm for various types of construction with a minimum slump value

of 25 mm.

(g) Water-content

IS method : In this method maximum water content is selected based

on the nominal maximum size of aggregate from table 2 of I.S.

10262:2009 for 25 to 50 mm slump range. These water estimates are to

be reduced by approximately 10 kg/cum for sub angular aggregates, 20

kg/cum for gravel with some crushed particles and 25 kg/cum for

rounded gravel to produce same workability (slump) . These values

may be increased by about 3% for every 25 mm increase in slump or

alternatively by use of chemical admixture.

BS method : In this method water content is selected from the table

specified in this standard for different consistence classes and different

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

44

sizes of aggregates and type of aggregate crushed or uncrushed.

Reduction in water content is also specified when additives are used in

combination with cement. In this method, when the coarse and fine

aggregates used are of different types, the water content is estimated by

the following expression :

W = ( 2 Wf/3) + ( Wc/3)

Where, Wf = water content appropriate to type of fine aggregate

Wc = water content appropriate to type of coarse aggregate

ACI method : In this method table A1 5.3.3 of ACI 211.1 specifies

water requirements for different slump values for different nominal

maximum sizes of aggregates for air-entrained concrete for moderate

exposure, for reasonably well-shaped angular aggregates graded

within limits of accepted specifications. Rounded coarse aggregate will

generally require I8 kg less water for non-air-entrained and 15 kg less

for air-entrained concretes. The use of water-reducing chemical

admixtures (ASTM C 494), may also reduce mixing water by 5 percent

or more.

(h) Cement Content : The computation of cement content in all the three

methods is identical and obtained by dividing the free water-content

with the free water-cement ratio.

(i) Estimation of coarse and fine aggregate contents

IS method: In this method proportion of coarse aggregate per unit

volume of total aggregate is determined first on saturated surface dry

basis, based on grading of fine aggregate in terms of fineness modulus

which is divided in different zones- Zone I, zone II, Zone III and zone

IV, for different nominal maximum size of coarse aggregate (10 mm,

20 mm and 40 mm).

45

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

BS method: In this method the total aggregate content is computed

from the wet density of concrete obtained from the figure specified in

this standard. The wet density of concrete depends on the specific

gravity of overall aggregates in the saturated surface dry condition. If

no information is available, specific gravity may be taken 2.60 for

uncrushed aggregate and 2.70 for crushed aggregate.

The percentage of fine aggregate is either specified or obtained

from the figures given in this standard expressed as a percentage of

total aggregate that will provide the target consistence of the fresh

concrete to be made with the given grading of fine aggregate, the

nominal upper size of coarse aggregate and the free water-cement ratio.

From the percentages of fine and coarse aggregate in total aggregate

content, the quantities of fine and coarse aggregates are determined.

ACI method: This method assumes that the optimum ratio of bulk

volume of coarse aggregate to the total volume of concrete depends

only on maximum size of coarse aggregate and on the grading (fineness

modulus) of fine aggregate. The volume of coarse aggregate, on an

oven-dry rodded basis, per unit volume of concrete is specifed in table

A1 5.3.6 of ACI 211.1 for different nominal maximum size of aggregate

and fineness modulus of fine aggregate. The dry mass of coarse

aggregate is obtained by multiplying the value from table A1.5.3.6 by

the dry-rodded unit mass of the aggregate. The volume of fine

aggregate is determined by subtracting the absolute volume of all other

ingredients from the unit volume of fresh concrete

(j) Adjustments for Aggregate Moisture and determination of final mix

proportions

The adjustments for determining free water content taking in to account the

aggregate surface moisture and water absorption and first mix proportions are

identical in all the three methods.

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

46

5. PROPOSED METHOD -FUNCTION EQUATIONS BASED

DESIGN OF CONCRETE MIXES

On the basis of experimental test results function equations based design

of concrete mixes is proposed by combining the key features of above methods.

Since the trial mixes designed using the BS method failed to achieve the targeted

strengths, the parameters of this method were not taken in developing the

proposed method. This method is based on use of function equations for

selection of water-cement ratio, water-content, total aggregate content and

percentage of fine aggregate in the total aggregate, using locally available

materials and Portland cement.

5.1 Procedure of mix design

The procedure of mix design involves following steps :

5.1.1

Target Mean Strength:

The Target Mean Strength fck can be obtained by adding a suitable margin

to the stipulated characteristic strength from the following relation:-

fck = fck + 1.65.S, (Where, S = Value of standard deviation)

The values of standard deviation for concrete grades 15MPa to 35MPa can

be taken from the following table 7, as specified by the IS method:

Table 7 : Values of Standard deviation

Concrete Grade

15MPa

20MPa

25MPa

30MPa

35MPa

Standard Deviation

3.5

4.0

4.0

5.0

5.0

47

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

5.1.2 Selection of Water Cement Ratio

The Water-Cement ratio can be selected from the following function

equation or from the graph given in Appendix (figure 15):

Function equation for selection of Water-cement ratio is given by:

y = f (x) = - 83.104225(x) + 74.931634

Where, y = Target mean strength (in N/mm2) and x = water-cement ratio

5.1.3 Selection of Water-Content

The water-content can be selected from the following function equation or

from the graph given in Appendix (figure 16):

Function equation for selection of Water-Content is given by:

y = f (x) = 13.235921 (x) - 2381.6066

Where, y = Target mean strength (in N/mm2), and x = water-content (in litres

/m3)

5.1.4 Estimation of Cement-Content

The Cement-Content can be obtained by dividing the water-content by free

water-cement ratio Thus, Cement-Content = Water-Content / free water-cement

ratio

5.1.5 Estimation of Total Aggregate-Content

The Total aggregate -content can be obtained from the following function

equation or from the graph given in Appendix (figure 17):

Function equation for selection of Total aggregate - Content is given by:

y = f (x) = - 0.16098056 (x) + 323.62374

Where, y = Target mean strength (in N/mm2) and x = total aggregate-content

(in kg /m3)

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

48

5.1.6 Selection of percentage of fine aggregate content

The Percentage of fine aggregate -content can be obtained from the

following function equation or from the graph given in Appendix (figure 18):

Function equation for selection of percentage of fine aggregate - Content in

total aggregate - content is given by:

y = f (x) = - 5.2479308 (x) + 239.5572

Where, y = Target mean strength (in N/mm2) and x = Percentage of fine

aggregate-content in total aggregate content.

5.1.7 Estimation of Coarse and Fine aggregate contents

After the computation of total aggregate content and percentage of fine

aggregate in total aggregate content, the coarse aggregate-content and fine

aggregate content can be computed.

5.1.8 Adjustments for aggregate moisture and determination of final mix

proportions

Since the aggregates are batched on the basis of actual weights, adjustments

are to be made in the amount of mixing water to be added to take in to account

the absorption and the surface moisture contents of coarse and fine aggregates to

make it equivalent of saturated surface dry condition of aggregates.

5.1.9 Proportions of trial batches and testing:

From the proportions of ingredients of concrete obtained in the previous

steps prepare the first trial mix and cast test cubes. Test the trial cubes after

28-days wet curing and determine its actual compressive strength. If required,

suitable adjustments in the water-cement ratio or aggregate-cement ratio or in

proportions of cement, sand, and aggregate, is to be made in the trial mix

proportions and arrive at the final mix proportion.

49

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

5.2 Advantages of proposed method

Advantages of the proposed method - function equations based design of

concrete mixes, can be summarized as below:

(i) The proposed method of mix design is very simple and straight forward

and involves a single step calculation only. This method gives a simple

functional relationship between 28-days compressive strength of

concrete and various influencing parameters of concrete mix design.

Using the function equations of water-cement ratio, water-content, total

aggregate content and percentage of fine aggregate content in total

aggregate, these parameters can be easily calculated.

(ii) This method gives less quantity of cement for 15MPa to 25Mpa grades

of concrete which is most commonly used in India, than the other

methods. Hence, it appears to be more economical. This method also

gives higher amount of fine aggregate content than the other methods

for the same grades of concrete, resulting in a dense concrete mix

imparting higher strength.

6. CONCLUSIONS

Based on the above discussion following conclusions can be drawn:

(i)

The IS method of concrete mix design (IS 10262:2009) is almost in

line with ACI method (ACI 211.1) and is applicable for design of

Ordinary and Standard grades of concrete only. It is also applicable

for design of light weight and heavy weight concrete. This standard

also permits use of supplementary materials such as chemical and

mineral admixtures. Provisions of IS 456:2000 are applicable for

durability requirements with all types of exposure conditions.

(ii)

The IS method assumes that the volume of coarse aggregate in a unit

volume of concrete is dependent only on its nominal maximum size

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

50

and grading zone of fine aggregate. This method suggests computing

the quantities of fine aggregate and a coarse aggregate

from the

yield equation, which is based on the concept, that volume of

concrete is summation of absolute volumes of its ingredients.

(iii)

The BS method of concrete mix design is applicable for design of

normal concrete mixes having 28-days compressive strength up to 75

MPa. This standard also gives guidelines for design of light weight

and heavy weight concrete. This Standard specifies concrete as

designated concrete, prescribed concrete, standard prescribed

concrete and proprietary concrete.

(iv)

In the BS method quantities of fine and coarse aggregates are

calculated based on wet density of concrete, which depends upon

water-content of the mix and specific gravity of combined aggregate

on saturated surface dry basis. The proportion of fine aggregate in

total aggregate is obtained from the specified curves based on the free

water-cement ratio and workability desired in slump/Vee-bee, for

different nominal maximum size of coarse aggregate. This method

assumes that the volume of freshly mixed concrete equals the sum of

the absolute volumes of its constituent materials, i.e. the water,

cement, air content and total aggregate.

(v)

The BS method of mix design is much more comprehensive and

tedious, and appears to be inconsistent for our country.

(vi)

The ACI method of mix design is applicable for design of normal and

/or heavy concrete, and mass concrete mixes. This standard is not

applicable for light weight aggregate concrete and for special

admixtures for concrete products manufacture. This method is also

not applicable for using condensed Silica fume. The ACI method of

mix proportioning is applicable for normal and heavy weight

51

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

concrete having 28-days cylinder compressive strength of 45MPa and

slump ranges of 25 to 100 mm.

(vii) The ACI method is based on determining the coarse aggregate

content based on dry rodded coarse aggregate bulk density and

fineness modulus of sand. This method also gives separate tables for

air-entrained concrete. This method gives separate values of water

and sand content for maximum size of aggregate up to 150 mm.

Hence this method is most suitable for designing plum concrete. It

also gives separate values for 12.5 & 25 mm down coarse aggregate.

(viii) ACI method of concrete mix design appears to be most suitable for

medium as well as high strength concrete. This method is also most

suitable for air- entrained concrete as well as plum concrete.

(ix)

The proposed method- function equations based design of concrete

mixes can be conveniently used for design of normal concrete mix

of medium strength grades, which is most commonly used in general

construction work. This method can also be used by the field

engineers for quick ascertainment of concrete mixes being produced

at the construction sites without going through the detailed testing of

material properties and re-designing the concrete mixes each time by

the Standard prescribed mix design methods, provided the uniformity

of materials being used is ensured.

7. SUGGESTED FURTHER WORK

Concrete mix proportioning is more challenging now than before. This is

due to availability of a wide range of chemical and mineral admixtures which

can change the rheology of concrete to suit any challenging application and can

partially replace ordinary Portland cement. This is also underlined by the trend

of using manufactured sand to replace river sand in urban areas and use of

recycled aggregates. With the modern concrete technology it has increasingly

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

52

become a matter of hot research and application engineering to develop a unique

and simplified method of mix design for all types and grades of concrete to

produce a concrete possessing desirable workability and strength, high

dimensional stability, and excellent durability. The proposed method of mix

design function equations based design of concrete mixes, can be further

extended for all grades of concrete, high strength and high performance

concrete, and concretes using different cementitious materials and chemical

admixtures to suit the job requirements.

8. REFERENCES

1.

S.C. Maiti, Raj K. Agrawal and Rajeeb kumar - Concrete mix

proportioning: Page-23, The Indian Concrete Journal, December 2006.

2.

M.C. Nataraja and Lelin Das- Concrete mix proportioning as per IS

10262:2009 Comparison with IS 10262:1982 and ACI : 211.1-91 : Page 64 , The Indian Concrete Journal , September 2010.

3.

Khalid A.A.Zakaria, N. H. Al-jubory, and B.M. Jassim - The effect of

different influencing parameters on the design of concrete mixes: College

of Engineering, Civil Engineering Department, University of Mosul.

4.

Z. Wadud and S. Ahmad [21] ACI Method OF CONCRETE Mix DesignParametric Study: The Eighth East Asia-Pacific Conference on Structural

Engineering and Construction: 5-7 December 2001, Nanyang Technological

University, Singapore.

5.

Neville A.M. - Properties of concrete : Fourth and final edition, Pearson Education, Inc.

and Dorling Kindersley Publishing, Inc.

6.

Irving kett Engineered concrete mix design and test methods : CRC Press, Boca Raton

London New York Washington, D.C.

7.

Steven H. Kosmatka, Beatrix Kerkhoff, and William C. Panarese - Design and

control of concrete mixtures : Portland Cement Association.

53

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

8.

Durocrete - Mix Design Manual : Durocrete Engineering Services Pvt. Ltd.

9.

IS: 10262-1982 and 10262-2009- Concrete Mix Proportioning- Guidelines :

Bureau of Indian Standards, Manak Bhavan,9 Bahadur Shah Zafar Marg,

New Delhi-110002

10. IS: 456- 2002- Plain And Reinforced Concrete Code of practice, ( Fourth

Revision): Bureau of Indian Standards, Manak Bhavan, 9 Bahadur Shah

Zafar Marg, New Delhi-110002

11. IS: 2386-1963, Part I to VII- Methods of test for aggregates for concrete

,(Eleventh Reprint August 1997) : Bureau of Indian Standards, Manak

Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi-110002

12. BS

EN

206-1:2001,Part-1-

Concrete-

Specifications,

performance,

production and conformity: BSI, 389 Chiswick High Road London .

13. BS 8500-1: 2002- Concrete - Complementary British Standard to BS EN

206-1- Part-1 Method of specifying and guidance for the specifier : BSI,

389 Chiswick High Road London British standard ,

14. BS 8500-2: 2002- Concrete - Complementary British Standard to BS EN

206-1- Part-2 Specifications for constituent materials and concrete : BSI,

389 Chiswick High Road London

15. British DOE (Department Of Environment) Method, 1988- Design of

normal concrete mixes : BSI, 389 Chiswick High Road London

16. ACI : 211.1-91, (reapproved 2002) - Standard Practice for selecting

proportions for normal, heavyweight, and mass concrete : American

Concrete Institute .

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

54

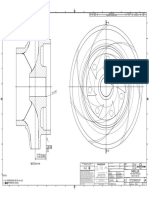

9. APPENDICES

Graphs for selection of water cement ratio, water content, total aggregate

content and percentage of fine aggregate for mix design by proposed method function equations based design of concrete mixes, are appended as below:

Figure 15 : Graph for selection of Water-Cement ratio by proposed

method function equations based design of concrete mixes

55

Comparison of IS, BS and ACI Methods of Concrete Mix Design and

Proposing Function Equations based Design

Figure 16 : Graph for selection of Water-Content by proposed method

function equations based design of concrete mixes

Figure 17 : Graph for selection of Total Aggregate Content by proposed

method function equations based design of concrete mixes

JEEVENDRA KUMAR CHANDRAKAR AND S.P. MISHRA

Figure 18 : Graph for selection of percentage of fine Aggregate by

proposed method function equations based design of concrete mixes

56

You might also like

- CES512 Set 2Document7 pagesCES512 Set 2shamsukarim2009No ratings yet

- CIPP BookDocument2 pagesCIPP Bookshamsukarim2009No ratings yet

- Accelerometer Sensor Data Analysis of Bridge Structural Health Monitoring SystemDocument7 pagesAccelerometer Sensor Data Analysis of Bridge Structural Health Monitoring Systemshamsukarim2009No ratings yet

- Letter of Appreciation Paper 90 Sharaf AhmadDocument1 pageLetter of Appreciation Paper 90 Sharaf Ahmadshamsukarim2009No ratings yet

- Understanding What Is Meant by Holistic AssessmentDocument4 pagesUnderstanding What Is Meant by Holistic Assessmentshamsukarim2009No ratings yet

- ArticleDocument7 pagesArticleshamsukarim2009No ratings yet

- Ces512 Jan 2017Document5 pagesCes512 Jan 2017shamsukarim2009No ratings yet

- Ces512 Jan 2017Document5 pagesCes512 Jan 2017shamsukarim2009No ratings yet

- CES512 Set 2Document7 pagesCES512 Set 2shamsukarim2009No ratings yet

- Jurnal Kemerosotan Aliran SainsDocument9 pagesJurnal Kemerosotan Aliran SainsnamujaNo ratings yet

- Supplementary Lab Sheet No 7. Name of Student: Group: DateDocument3 pagesSupplementary Lab Sheet No 7. Name of Student: Group: Dateshamsukarim2009No ratings yet

- CES 512: Finite Element Method Introduction, Theory, Applications & ImplementationDocument32 pagesCES 512: Finite Element Method Introduction, Theory, Applications & Implementationshamsukarim2009No ratings yet

- Corrosion-Damaged Beam Manuscript ImprovementsDocument3 pagesCorrosion-Damaged Beam Manuscript Improvementsshamsukarim2009No ratings yet

- MATLAB OPTIMIZATION (LINEAR PROGRAMMINGDocument13 pagesMATLAB OPTIMIZATION (LINEAR PROGRAMMINGshamsukarim2009100% (1)

- Holistic Youth Development: A Short Guide ToDocument28 pagesHolistic Youth Development: A Short Guide Toshamsukarim2009No ratings yet

- Service Quotation PretechDocument2 pagesService Quotation Pretechshamsukarim2009No ratings yet

- Understanding What Is Meant by Holistic AssessmentDocument4 pagesUnderstanding What Is Meant by Holistic Assessmentshamsukarim2009No ratings yet

- Developing Research GapDocument2 pagesDeveloping Research Gapshamsukarim2009No ratings yet

- Program Bengkel CES512Document5 pagesProgram Bengkel CES512shamsukarim2009No ratings yet

- 07 Matrix FrameDocument72 pages07 Matrix FrameAminatul Fadillah MarpaungNo ratings yet

- 2014-04 Motorcycle Parking at StationsDocument14 pages2014-04 Motorcycle Parking at Stationsshamsukarim2009No ratings yet

- CES 512/513 computational analysis formative assessmentDocument1 pageCES 512/513 computational analysis formative assessmentshamsukarim2009No ratings yet

- Fyp1 184573Document31 pagesFyp1 184573shamsukarim2009No ratings yet

- Receipt Iem Renewal 2017Document1 pageReceipt Iem Renewal 2017shamsukarim2009No ratings yet

- Fyp2 184573Document107 pagesFyp2 184573shamsukarim2009No ratings yet

- Open 3rd Party Transfer: SuccessfulDocument1 pageOpen 3rd Party Transfer: Successfulshamsukarim2009No ratings yet

- IEM Renewal 2017Document1 pageIEM Renewal 2017shamsukarim2009No ratings yet

- FEA KeyDocument1 pageFEA Keyshamsukarim2009No ratings yet

- The Development of Skewness Correction Factor of Bridge SystemDocument3 pagesThe Development of Skewness Correction Factor of Bridge Systemshamsukarim2009No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sip TrainingDocument96 pagesSip Trainingronics123No ratings yet

- 08 Candelaria Punta Del Cobre IOCG Deposits PDFDocument27 pages08 Candelaria Punta Del Cobre IOCG Deposits PDFDiego Morales DíazNo ratings yet

- Introduction To Oracle GroovyDocument53 pagesIntroduction To Oracle GroovyDeepak BhagatNo ratings yet

- c1Document19 pagesc1vgnagaNo ratings yet

- ICSE Mathematics X PapersDocument22 pagesICSE Mathematics X PapersImmortal TechNo ratings yet

- Jaguar Land Rover Configuration Lifecycle Management WebDocument4 pagesJaguar Land Rover Configuration Lifecycle Management WebStar Nair Rock0% (1)

- MAINTAIN COOLANT LEVELDocument6 pagesMAINTAIN COOLANT LEVELAgustin BerriosNo ratings yet

- Pub - The Physics of The Standard Model and Beyond PDFDocument314 pagesPub - The Physics of The Standard Model and Beyond PDFEduardo Gareca100% (2)

- Ikan Di Kepualauan Indo-AustraliaDocument480 pagesIkan Di Kepualauan Indo-AustraliaDediNo ratings yet

- GX-2009 - Personal Multigas Detector. Operator's Manual (RKI, 2009)Document64 pagesGX-2009 - Personal Multigas Detector. Operator's Manual (RKI, 2009)Stasio80No ratings yet

- Power Theft Identification Using GSM TechnologyDocument3 pagesPower Theft Identification Using GSM TechnologyIJORAT100% (1)

- Methods For Assessing The Stability of Slopes During Earthquakes-A Retrospective 1Document3 pagesMethods For Assessing The Stability of Slopes During Earthquakes-A Retrospective 1ilijarskNo ratings yet

- Advu en PDFDocument65 pagesAdvu en PDFGustavo Rodrigues de SouzaNo ratings yet

- Steps For Charm ConfigurationDocument7 pagesSteps For Charm ConfigurationpoornasapNo ratings yet

- Time TableDocument7 pagesTime TableChethan .H.GNo ratings yet

- Delta VFD E Series User ManualDocument399 pagesDelta VFD E Series User ManualTendai AlfaceNo ratings yet

- Impeller: REV Rev by Description PCN / Ecn Date CHK'D A JMM Released For Production N/A 18/11/2019 PDLDocument1 pageImpeller: REV Rev by Description PCN / Ecn Date CHK'D A JMM Released For Production N/A 18/11/2019 PDLSenthilkumar RamalingamNo ratings yet

- Tutorial CorelDRAW-X8Document10 pagesTutorial CorelDRAW-X8Ajay BhargavaNo ratings yet

- SPPID QuestionsDocument2 pagesSPPID Questionsvivek83% (12)

- Oracle Data Integration - An Overview With Emphasis in DW AppDocument34 pagesOracle Data Integration - An Overview With Emphasis in DW Appkinan_kazuki104No ratings yet

- Craig Vaughan CHPTR 07Document44 pagesCraig Vaughan CHPTR 07Jorge CananeaNo ratings yet

- Notifier Battery Calculations-ReadmeDocument11 pagesNotifier Battery Calculations-ReadmeJeanCarlosRiveroNo ratings yet

- PF-CIS-Fall 2022 LABDocument4 pagesPF-CIS-Fall 2022 LABMuhammad FaisalNo ratings yet

- Submittal Chiller COP 6.02Document3 pagesSubmittal Chiller COP 6.02juan yenqueNo ratings yet

- Electrocraft EAD BLDC CatalogDocument16 pagesElectrocraft EAD BLDC CatalogElectromateNo ratings yet

- Die Science - Developing Forming Dies - Part I - The FabricatorDocument6 pagesDie Science - Developing Forming Dies - Part I - The FabricatorSIMONENo ratings yet

- Ferrites and AccessoriesDocument11 pagesFerrites and AccessoriesMaulik ShahNo ratings yet

- VLSI Design: Introduction & Motivation Introduction & MotivationDocument33 pagesVLSI Design: Introduction & Motivation Introduction & MotivationPriyanka SharmaNo ratings yet

- ITTC Validation of ManoeuvringDocument11 pagesITTC Validation of ManoeuvringFelipe IlhaNo ratings yet