Professional Documents

Culture Documents

MasterRehobuild 850 TDS

Uploaded by

Alec AbrahamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MasterRehobuild 850 TDS

Uploaded by

Alec AbrahamCopyright:

Available Formats

MasterRheobuild 850

(Formerly known as Rheobuild 850)

High range, water-reducing superplasticiser for rheoplastic concretes

DESCRIPTION OF PRODUCT

MasterRheobuild 850 is formulated from synthetic

polymers specially designed to impart rheoplastic

qualities to concrete.

A rheoplastic concrete is a fluid concrete with a

slump of at least 200mm, easily flowing, but at the

same time free from segregation and having the

same w/c ratio as that of a low slump concrete

(25mm) without admixture.

PACKAGING

MasterRheobuild 850 is available in 1000 ltr.

TYPICAL PROPERTIES

Colour:

Specific gravity:

Air-entrainment:

Chloride content:

Nitrate content:

Freezing point:

Dark brown liquid

1.21

Maximum 1%

Nil to BS 5075

Nil

0C; can be reconstituted if

stirred after thawing

MasterRheobuild 850 is chloride-free.

ADVANTAGES

MasterRheobuild 850 considerably improves the

properties of fresh and hardened concrete.

PRIMARY USES

Microsilica concrete

Mass concrete pours

Ready-mixed concrete

Long-distance transport

Pumped concrete

Casting in hot climates

TO OBTAIN

Reduced thermal peaks

High workability for longer periods

Lower pumping pressure

Delayed setting with longer workability

Higher ultimate strengths

Reduced permeability

Improved durability

COMPATIBILITY

MasterRheobuild 850 is compatible with all

cements and most air-entraining agents meeting

the ASTM standards.

The addition of MasterRheobuild 850 and MasterAir 111 (air-entraining agent) to concrete is

recommended where it is required to withstand

freezing and thawing cycles

STANDARDS

ASTM C-494 Type B, D and G

DOSAGE

Optimum dosage of MasterRheobuild 850 should

be determined in trial mixes. As a guide, the

following dosages are recommended as a starting

point for any trial: in normal concrete, a dosage of

between 0.8-2ltr/100kg of cement; in high

performance microsilica concrete, a dosage of

between 1.5-3ltr/100kg of cement. Dependent upon

mix requirement, it is possible to use a higher

dosage of MasterRheobuild 850 without causing

any adverse effects upon the concrete. Please

consult BASFs Technical Services Department for

further information.

DISPENSING

MasterRheobuild 850 is a ready-to-use liquid,

which is dispensed into the concrete together with

mixing water. The plasticising effect, or water

reduction, is higher if the admixture is added to the

concrete after 50-70% of the mixing water has been

added. The addition of MasterRheobuild 850 to

dry aggregate or cement is not recommended.

Automatic dispensers are available.

WORKABILITY

MasterRheobuild 850 ensures that rheoplastic

concrete remains workable in excess of 3 hours at

+20C.

MasterRheobuild 850

Workability loss is dependent on temperature, on

the type of cement, the nature of aggregates, the

method of transport and initial workability. It is

strongly recommended that concrete should be

properly cured particularly in hot and dry climates.

STORAGE

MasterRheobuild 850 must be stored where

temperatures do not drop below +5C. If product

has frozen, thaw and agitate until completely

reconstituted. Store under cover, out of direct

sunlight and protect from extremes of temperature.

(Formerly known as Rheobuild 850)

QUALITY STATEMENT

All products manufactured by BASF Egypt, or

imported from BASF affiliate companies world-wide,

are manufactured to procedures certified to

conform to the quality, environment, health & safety

management systems described in the ISO

9001:2008, ISO 14001:2004 & OHSAS 18001:2007

standards.

* Properties listed are based on laboratory controlled tests.

= Registered trademark of the BASF-Group in many countries

Failure to comply with the recommended storage

conditions may result in premature deterioration of

the product or packaging. For specific storage

advice, consult BASF's Technical Services

Department.

SHELF LIFE

Up to 24 months if stored according to

manufacturers instructions in unopened containers.

SAFETY PRECAUTIONS

MasterRheobuild 850 is not a fire or health hazard.

Spillages should be washed down immediately with

cold water.

For further information, refer to the material safety

data sheet.

NOTE

Field service, where provided, does not constitute

supervisory

responsibility.

For

additional

information, contact your local BASF representative.

BASF reserves the right to have the true cause of

any difficulty determined by accepted test methods.

BASF_CC-EG//Rheobuild_850_09_10/v1/06_14

You might also like

- Fig. (Hurd,: 2.1 Conventional Wood 1995)Document1 pageFig. (Hurd,: 2.1 Conventional Wood 1995)Alec AbrahamNo ratings yet

- Construction Chem CM 96Document2 pagesConstruction Chem CM 96Alec AbrahamNo ratings yet

- 1.9 Age PDFDocument8 pages1.9 Age PDFRusherNo ratings yet

- DevauxDocument1 pageDevauxAlec AbrahamNo ratings yet

- DevauxDocument1 pageDevauxAlec AbrahamNo ratings yet

- DevauxDocument1 pageDevauxCarolinaMachadoNo ratings yet

- %! % PostScript Program For Distilling and Combining An EntireDocument1 page%! % PostScript Program For Distilling and Combining An Entirekimlien120382No ratings yet

- DevauxDocument1 pageDevauxAlec AbrahamNo ratings yet

- Seed Orchards in DevelopmentDocument4 pagesSeed Orchards in DevelopmentAlec AbrahamNo ratings yet

- Fruit PhenologyDocument17 pagesFruit PhenologyAlec AbrahamNo ratings yet

- This Archive Contains The WinRAR Multifunctional IntegratedDocument1 pageThis Archive Contains The WinRAR Multifunctional IntegratedArifinMaulanaNo ratings yet

- Seed Orchards in DevelopmentDocument4 pagesSeed Orchards in DevelopmentAlec AbrahamNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ielts. Writing Task 1. ExamplesDocument3 pagesIelts. Writing Task 1. Examplestatianafl08No ratings yet

- Chapter I - The Research Problem: Introduction/Background of The StudyDocument4 pagesChapter I - The Research Problem: Introduction/Background of The StudyCha LinsengNo ratings yet

- Pectin-Based Bioplastics from Passion Fruit RindDocument3 pagesPectin-Based Bioplastics from Passion Fruit RindDyna Lou Jane CatanNo ratings yet

- Unilever LTDDocument37 pagesUnilever LTDSakib Hossain25% (4)

- Astm C 125-03 PDFDocument4 pagesAstm C 125-03 PDFArnold EspinozaNo ratings yet

- Ulta Beauty Hiring AgeDocument3 pagesUlta Beauty Hiring AgeShweta RachaelNo ratings yet

- Event Details Report - Algoma SteelDocument66 pagesEvent Details Report - Algoma SteelThe NarwhalNo ratings yet

- Signs and SymptomsDocument2 pagesSigns and SymptomsKristine GurimbaoNo ratings yet

- sm2000 GBDocument4 pagessm2000 GBRikky ChaniagoNo ratings yet

- Civil Engineering Final Year Projects Topic List - HTMLDocument4 pagesCivil Engineering Final Year Projects Topic List - HTMLJohn Meverick E EdralinNo ratings yet

- Extent of Compliance on Waste Disposal PracticesDocument13 pagesExtent of Compliance on Waste Disposal PracticesEzza Jean Paypa100% (3)

- ZDHCPNP V3.0Document13 pagesZDHCPNP V3.0Wendo BijaksonoNo ratings yet

- Ig2 of Bikas 00691520 x123Document20 pagesIg2 of Bikas 00691520 x123Engr. Imran Hasan Pathan100% (4)

- Doble M4000 User GuideDocument204 pagesDoble M4000 User GuidePablo Toro Lopez100% (1)

- Zara Restaurant and Lounge Business PlanDocument54 pagesZara Restaurant and Lounge Business Plankira572992% (12)

- HVDC Converter and System Control AnalysisDocument20 pagesHVDC Converter and System Control Analysiskarthik78% (9)

- Siemens Arcadis Avantic Installations LaserIIDocument22 pagesSiemens Arcadis Avantic Installations LaserIINelson AltuveNo ratings yet

- Template Nilai Gizi SusuDocument8 pagesTemplate Nilai Gizi SusuRiena CemonkNo ratings yet

- Module 1Document3 pagesModule 1Anonymous jhhtrnfNo ratings yet

- Flowers From 1970Document93 pagesFlowers From 1970isla62% (21)

- X1jet MX Manual PDFDocument97 pagesX1jet MX Manual PDFrithik srivastavaNo ratings yet

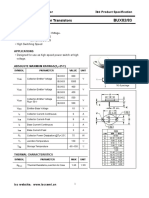

- Isc BUX82/83: Isc Silicon NPN Power TransistorsDocument2 pagesIsc BUX82/83: Isc Silicon NPN Power TransistorsCarlos HCNo ratings yet

- Methyldopa Drug DataDocument3 pagesMethyldopa Drug DataLaurel Joshua Reyes DauzNo ratings yet

- LPT22Document3 pagesLPT22Leonardo Vinicio Olarte CarrilloNo ratings yet

- 7 HO Clearance Consent FormDocument2 pages7 HO Clearance Consent FormzanehfncbusinessNo ratings yet

- Margaret Sanger's Role in Population Control AgendaDocument11 pagesMargaret Sanger's Role in Population Control AgendaBlackShadowSnoopy100% (1)

- MR Safe Conditional PDFDocument4 pagesMR Safe Conditional PDFAKSNo ratings yet

- Nursing Management of Patients With DementiaDocument9 pagesNursing Management of Patients With DementiaSabita Paudel60% (5)

- TuflineLinedBallValve 332148 2-07Document12 pagesTuflineLinedBallValve 332148 2-07Marcio NegraoNo ratings yet

- Shoplifting's Impact on Consumer BehaviorDocument3 pagesShoplifting's Impact on Consumer BehaviorJerico M. MagponNo ratings yet