Professional Documents

Culture Documents

Electrical Power Supply

Uploaded by

Manuel Solar Rigoni DinkyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical Power Supply

Uploaded by

Manuel Solar Rigoni DinkyCopyright:

Available Formats

Service Information System

1/9

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sis...

Troubleshooting

C13 and C15 On-highway Engines

Media Number -RENR9343-06

Publication Date -01/11/2007

Date Updated -29/11/2007

i02582947

Electrical Power Supply - Test

SMCS - 1401-038

System Operation Description:

Use this procedure if the electronic service tool will not communicate with the Engine Control Module (ECM).

Also, use this procedure to troubleshoot these codes:

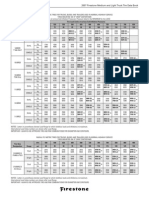

Table 1

Diagnostic Codes

J1939 Code

Description

158-2

Battery Potential (Voltage) Switched : Erratic, Intermittent, or Incorrect

168-2

Electrical Potential (Voltage) : Erratic, Intermittent, or Incorrect

168-3

Electrical Potential (Voltage) : Voltage Above Normal

168-4

Electrical Potential (Voltage) : Voltage Below Normal

The Electronic Service Tool Will Not Communicate with the ECM - If either unswitched battery voltage

or switched battery voltage is missing from the P1 connector, the Caterpillar Electronic Technician (ET) will

not communicate with the ECM. The ECM requires the keyswitch to be in the ON position in order to

communicate. Usually, the data link connector receives unswitched battery voltage. An indicator on the

communications adapter indicates when the communications adapter is receiving battery voltage.

158-2 (J1939) - The voltage on the keyswitch input transitions from a low voltage to a high voltage at least

three times in one second. A snapshot is triggered.

168-2 (J1939) - The engine is running. The battery voltage at the P1 terminals has fallen below 6 VDC for at

least 0.5 seconds. The ECM may stop injecting fuel. This depends on the length of time of the occurrence of

the problem. The check engine lamp and the warning lamp may come on. The engine may experience changes

in engine rpm. Intermittent engine shutdowns or complete engine shutdowns may occur.

168-3 (J1939) - The engine is running. The battery voltage at the P1 terminals is above 16 VDC for at least

0.5 seconds. A snapshot is triggered.

168-4 (J1939) - The engine is running. The battery voltage at the P1 terminals has fallen below 9 VDC for at

least three seconds. A snapshot is triggered and the engine is derated. The low voltage condition can be caused

by a problem on either the positive side or on the negative side of the battery circuit.

The following components can cause these codes:

Electrical connector or wiring

Keyswitch

ECM

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

10.12.2007 13:45

Service Information System

2/9

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sis...

The most likely cause of the code is a problem with an electrical connector or with the wiring. The least likely

cause is a problem with the ECM.

Power Circuit

The ECM receives battery voltage through wiring that is supplied by the vehicle manufacturer. Unswitched

battery voltage is supplied to three terminals on the ECM P1 connector. The negative battery is also supplied

to three terminals on the P1 connector.

Keyswitch Circuit

The ECM receives battery voltage from the keyswitch on terminal P1-70 when the keyswitch is in the ON

position or in the START position. When the ECM detects battery voltage on this input, the ECM will power

up. When battery voltage is removed from this input, the ECM will power down.

Engine Shutdown Systems

Some vehicles may be equipped with an engine protection shutdown system or an idle timer shutdown system

that interrupts electrical power to the keyswitch. The engine protection shutdown system can be an aftermarket

device and the idle timer shutdown system can be external to the ECM. Some of these systems will not supply

power to the ECM until one of the following conditions is met:

The engine is cranked.

The engine oil pressure achieves acceptable limits.

An override button is pressed.

Keep in mind that these devices may be the cause of intermittent power to the ECM. These devices may also

shut down the engine.

Diagnostics on Cat ET

Cat ET provides the following diagnostics:

Wiggle Test - The wiggle test allows you to monitor the "ECM Battery Voltage" parameter and the "Ignition

Key Switch" parameter while you wiggle the wiring. This helps to identify faulty electrical connections.

Snapshots - When these diagnostic codes occur, the ECM records the status of the "ECM Battery Voltage"

parameter and the "Ignition Key Switch" parameter for 9.6 seconds before the diagnostic code and 3.4 seconds

after the diagnostic code.

For additional information regarding the use of these diagnostics, refer to the documentation that accompanies

your Cat ET software.

View Image

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

10.12.2007 13:45

Service Information System

3/9

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sis...

Illustration 1

g01204929

Test Step 1. Determine the Problem

If Cat ET will not communicate with the ECM, refer to the appropriate result for this Test Step.

If Cat ET will communicate with the ECM, use Cat ET to determine the diagnostic code.

Do not troubleshoot a logged code unless the code relates to an engine symptom. If the code is logged and the

code does not relate to an engine symptom, clear the code.

Results:

No Communication - Proceed to Test Step 2.

Active or logged 168-3 (J1939) code Repair: The most likely cause of the code is a problem with the charging system. Refer to Systems

Operation/Testing and Adjusting, "Charging System - Test".If the charging system is working correctly

and the code is still active, replace the ECM. Refer to Troubleshooting, "ECM - Replace".

STOP

Logged 168-4 (J1939) or 168-2 (J1939)code - Proceed to Test Step 4.

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

10.12.2007 13:45

Service Information System

4/9

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sis...

Logged 158-2 (J1939) code - Proceed to Test Step 5.

Active 168-4 (J1939) or 168-2 (J1939) code - Proceed to Test Step 6.

Active 158-2 (J1939) code - Proceed to Test Step 8.

Test Step 2. Check the Voltage at the P1 Connector

A. Measure the voltage at the battery terminals.

The battery voltage must be above 11 VDC in order to continue with this procedure.

B. Verify that the keyswitch is in the ON position.

C. Use 7X-1710 Multimeter Probes to measure the voltage between the following terminals:

P1-53 (Unswitched +Battery) and P1-65 (-Battery)

P1-70 (Keyswitch) and P1-65 (-Battery)

Both voltage readings should be within two volts of the battery voltage.

Expected Result:

At least one of the voltage readings is less than nine VDC.

Results:

Yes - At least one of the voltage readings is less than nine VDC.

Repair: Perform the following procedure:

1. Verify that there are no aftermarket devices that are preventing battery voltage from reaching the

ECM. Some type of override switch is interrupting the power to the ECM if the following

conditions are true:

Communication occurs when the engine is running.

No communication occurs when the engine is not running and the keyswitch is ON.

2. Disable the aftermarket device, if necessary.

3. Measure the voltages again. If either voltage measurement is below nine VDC, there is a problem

with the wiring between the P1 connector and the battery.

The wiring between the P1 connector and the battery is provided by the Original Equipment

Manufacturer (OEM). Determine the cause of the low voltage. Repair the wiring, when possible.

Replace parts, if necessary. Verify that the problem is resolved.

STOP

No - Both of the voltage readings are within two volts of the battery voltage. Both of the readings are

above nine VDC.

Repair: Perform the following procedure:

1. Turn the keyswitch OFF.

2. Disconnect the cable from the service tool connector.

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

10.12.2007 13:45

Service Information System

5/9

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sis...

3. Turn the keyswitch ON.

4. Connect the cable to the service tool connector.

5. Determine if Cat ET is communicating with the ECM.

If Cat ET is communicating with the ECM, the problem is resolved. If Cat ET is not

communicating with the ECM, continue with this procedure.

STOP

Test Step 3. Check the Voltage at the Service Tool Connector

Observe the power indicator on the communications adapter. If the power indicator is illuminated, refer to

Troubleshooting, "Data Link - Test". If the power indicator is not illuminated, perform the following

procedure:

A. Disconnect the cable from the service tool connector.

View Image

Illustration 2

g01205045

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

10.12.2007 13:45

Service Information System

6/9

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sis...

Battery terminals on the service tool connectors

B. Refer to Illustration 2. Measure the battery voltage at the service tool connector.

Expected Result:

The voltage measurement is not within two volts of the battery voltage.

Results:

The voltage measurement is not within two volts of the battery voltage. The voltage at the service

tool connector is low. Repair: There is a problem with the vehicle wiring between the service tool connector and the battery.

Determine the cause of the low voltage. Repair the wiring, when possible. Replace parts, if necessary.

Continue with this procedure when the power indicator on the communications adapter is

illuminated.When the power indicator on the communications adapter is illuminated, attempt to establish

communication between Cat ET and the ECM. If communication is established, the problem is

resolved.If communication is not established, refer to Troubleshooting, "Data Link - Test".

STOP

The voltage at the service tool connector is within two volts of the battery voltage. Repair: Attempt to establish communication between Cat ET and the engine ECM. If communication is

established, the problem is resolved.If communication is not established, refer to Troubleshooting, "Data

Link - Test".

STOP

Test Step 4. Perform the Wiggle Test for the Battery Circuit

Interview the operator. Determine if there were other electrical problems. If there were other electrical

problems, there is a problem with the battery or with the wiring between the battery and the overcurrent

protection devices.

Check the battery and the wiring between the battery and the overcurrent protection devices if there were other

electrical problems. Continue with this procedure if the logged code was the only indication of an electrical

problem.

A. Verify that the engine is OFF and that the keyswitch is ON.

B. Configure Cat ET for the wiggle test. Select the status group that includes the "ECM Battery Voltage"

parameter for viewing. Start the wiggle test.

C. Slowly wiggle the wiring harness and the connectors between the P1 connector and the battery. Pay

particular attention to the wiring near each connector. Be sure to wiggle all of the wiring between the P1

connector and the battery. This includes the wiring to the overcurrent protection devices and the wiring

to any aftermarket devices.

As you wiggle the wiring, observe the harness and the connectors. Look for these problems:

Improperly routed harnesses or wiring

Loose connectors or damaged connectors

Damaged insulation that is caused by excessive heat

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

10.12.2007 13:45

Service Information System

7/9

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sis...

Damaged insulation that is caused by chafing

Expected Result:

The wiring failed the wiggle test.

Results:

The wiring failed the wiggle test. Repair: The problem is in the vehicle wiring. Repair the wiring, when possible. Replace parts, if

necessary. Send the vehicle to the OEM dealer for repair, if necessary. Verify that the problem is

resolved.

STOP

The wiring passed the wiggle test. Repair: The original problem may have been caused by a battery with low voltage or with a faulty

charging system. Test the battery according to Systems Operation/Testing and Adjusting, "Battery Test". Replace the battery, if necessary.Test the charging system. Refer to Systems Operation/Testing

and Adjusting, "Charging System - Test".

STOP

Test Step 5. Perform the Wiggle Test for the Keyswitch Circuit

Interview the operator. Determine if there were electrical problems. If there were other electrical problems,

there is a problem with the battery or with the wiring between the battery and the keyswitch.

Check the battery, the wiring between the battery and the keyswitch, and the keyswitch if there were other

electrical problems. Continue with this procedure if the logged code was the only indication of an electrical

problem.

A. Verify that the engine is OFF and that the keyswitch is ON.

B. Configure Cat ET for the wiggle test. Select the "Ignition Key Switch" parameter for viewing.

C. Slowly wiggle the wiring harness between the P1 connector and the keyswitch. Pay particular attention

to the wiring near each connector. Be sure to wiggle all of the wiring between the ECM and the

keyswitch. This includes the wiring to the overcurrent protection and the wiring to any aftermarket

device that may be installed.

Expected Result:

The wiring failed the wiggle test.

Results:

The wiring failed the wiggle test. Repair: The problem is in the vehicle wiring. Repair the wiring, when possible. Replace parts, if

necessary. Send the vehicle to the OEM dealer for repair, if necessary. Verify that the problem is

resolved.

STOP

The wiring passed the wiggle test. -

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

10.12.2007 13:45

Service Information System

8/9

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sis...

Repair: Wiggle the key in the keyswitch. If the "Ignition Key Switch" parameter is unstable, replace the

keyswitch. Send the vehicle to the OEM dealer for repair, if necessary.

STOP

Test Step 6. Check the Battery Voltage at the P1 Connector

Determine if there are other electrical problems. If there are other electrical problems, there is a problem with

the battery or with the wiring between the battery and the overcurrent protection devices.

Continue with this procedure if there are no other indications of electrical problems.

A. Do not turn off the engine.

B. Use Cat ET to view the value of the "ECM Battery Voltage" parameter.

Expected Result:

The voltage is less than 9.0 VDC.

Results:

The voltage is less than 9.0 VDC - Proceed to Test Step 7.

The voltage is greater than 9.0 VDC. - Cat ET indicates a "ECM Battery Voltage" that is greater than

9.0 VDC. However, there is an active 168-4 (J1939) code.

Repair: Replace the ECM. Refer to Troubleshooting, "ECM - Replace". Verify that the problem is

resolved.

STOP

Test Step 7. Check the Voltage at the Battery

Measure the voltage at the battery terminals.

Expected Result:

The voltage is less than 9.0 VDC.

Results:

OK - The voltage at the battery terminals is less than 9.0 VDC. There is a problem with the battery or

with the charging system.

Repair: Load test the battery. Replace the battery, if necessary. Test the charging system. Refer to

Systems Operation/Testing and Adjusting, "Charging System - Test".

STOP

Not OK - The voltage at the battery terminals is greater than 9.0 VDC. However, the voltage at the P1

terminals is less than 9.0 VDC.

Repair: The problem is in the vehicle wiring. The voltage drop can be caused by wiring or by a

component. Identify the cause of the voltage drop. Repair the problem, when possible. Replace parts, if

necessary. Send the vehicle to the OEM dealer for repair, if necessary. Verify that the problem is

resolved.

STOP

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

10.12.2007 13:45

Service Information System

9/9

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sis...

Test Step 8. Check the Keyswitch Input at the P1 Connector

A. Disconnect the P1 connector.

B. Measure the voltage between terminals P1-70 and P1-67.

C. Connect the P1 connector.

Expected Result:

The voltage is unstable.

Results:

The voltage is unstable - Proceed to Test Step 9.

The voltage is stable. - The voltage is stable. However, there is an active 158-2 (J1939) diagnostic

code.

Repair: Replace the ECM. Refer to Troubleshooting, "ECM - Replace". Verify that the problem is

resolved.

STOP

Test Step 9. Check the Keyswitch Input at the Keyswitch

Measure the voltage between terminal "R" of the keyswitch and vehicle ground.

Expected Result:

The voltage is unstable.

Results:

The voltage is unstable. Repair: The problem is in the vehicle wiring between the keyswitch and the battery. This includes the

wiring to any overcurrent protection devices and the wiring to any aftermarket device that may be

installed. Repair the wiring, when possible. Replace parts, if necessary. Send the vehicle to the OEM

dealer for repair, if necessary. Verify that the problem is resolved.

STOP

The voltage is stable. Repair: The problem is in the vehicle wiring between the keyswitch and the P1 connector. This

includes the wiring to any overcurrent protection devices and the wiring to any aftermarket device that

may be installed. Repair the wiring, when possible. Replace parts, if necessary. Send the vehicle to the

OEM dealer for repair, if necessary. Verify that the problem is resolved.

STOP

Copyright 1993 - 2007 Caterpillar Inc.

All Rights Reserved.

Private Network For SIS Licensees.

Mon Dec 10 2007 13:45:05 GMT+0200 (Suomen normaaliaika)

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

10.12.2007 13:45

You might also like

- Terminales AutomotricesDocument9 pagesTerminales AutomotricesManuel Solar Rigoni DinkyNo ratings yet

- Manual de Servicio Sensores Ws24Document4 pagesManual de Servicio Sensores Ws24Manuel Solar Rigoni DinkyNo ratings yet

- Tablas de Presiones Medium - Truck - TireDocument4 pagesTablas de Presiones Medium - Truck - TireManuel Solar Rigoni DinkyNo ratings yet

- Sensor de CombustibleDocument1 pageSensor de CombustibleManuel Solar Rigoni Dinky100% (1)

- DB DriveDocument2 pagesDB DriveManuel Solar Rigoni Dinky100% (1)

- CAN Interface SCANIADocument80 pagesCAN Interface SCANIAManuel Solar Rigoni Dinky89% (9)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Valvula de Leve MasterDocument20 pagesValvula de Leve Masterguillermo trejosNo ratings yet

- Catherineresume 2Document3 pagesCatherineresume 2api-302133133No ratings yet

- DVAIO R3 PRO HD Sound Quality In-Ear Wired Earphone Amazon - in ElectronicsDocument1 pageDVAIO R3 PRO HD Sound Quality In-Ear Wired Earphone Amazon - in Electronicsdinple sharmaNo ratings yet

- 01 - 01 - SK10 - JXNipponDocument1 page01 - 01 - SK10 - JXNipponredevils86No ratings yet

- 2.assessment of Dental Crowding in Mandibular Anterior Region by Three Different MethodsDocument3 pages2.assessment of Dental Crowding in Mandibular Anterior Region by Three Different MethodsJennifer Abella Brown0% (1)

- SCE Research Paper PDFDocument12 pagesSCE Research Paper PDFmuoi2002No ratings yet

- The Ultimate Safari (A Short Story)Document20 pagesThe Ultimate Safari (A Short Story)David AlcasidNo ratings yet

- English III Module 2 Simple Present Job and Job VerbsDocument4 pagesEnglish III Module 2 Simple Present Job and Job VerbsAdrian CortesNo ratings yet

- Dimensional Data: For Valves and ActuatorsDocument52 pagesDimensional Data: For Valves and ActuatorsPaulNo ratings yet

- Cell City ProjectDocument8 pagesCell City ProjectDaisy beNo ratings yet

- Cipac MT 185Document2 pagesCipac MT 185Chemist İnançNo ratings yet

- SM RSJ 420 800Document77 pagesSM RSJ 420 800elshan_asgarovNo ratings yet

- Hotel Housekeeping EQUIPMENTDocument3 pagesHotel Housekeeping EQUIPMENTsamahjaafNo ratings yet

- Notice: Use of Segways® and Similar Devices by Individuals With A Mobility Impairment in GSA-Controlled Federal FacilitiesDocument2 pagesNotice: Use of Segways® and Similar Devices by Individuals With A Mobility Impairment in GSA-Controlled Federal FacilitiesJustia.comNo ratings yet

- BIRADS Lexicon and Its Histopathological Corroboration in The Diagnosis of Breast LesionsDocument7 pagesBIRADS Lexicon and Its Histopathological Corroboration in The Diagnosis of Breast LesionsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Material Handling EquipmentsDocument12 pagesMaterial Handling EquipmentsRahul SheelavantarNo ratings yet

- Forest Fire Detection and Guiding Animals To A Safe Area by Using Sensor Networks and SoundDocument4 pagesForest Fire Detection and Guiding Animals To A Safe Area by Using Sensor Networks and SoundAnonymous 6iFFjEpzYjNo ratings yet

- Allium CepaDocument90 pagesAllium CepaYosr Ahmed100% (3)

- G10 Bio CellsDocument6 pagesG10 Bio CellsswacaneNo ratings yet

- 4.5 Cargo DischargingDocument2 pages4.5 Cargo DischargingHasan Cosalev100% (1)

- Roadblocks Overcome Cruise PurchaseTITLE Top 15 Cruise Hesitations Answered TITLE How to Convince People Cruises Worth CostDocument4 pagesRoadblocks Overcome Cruise PurchaseTITLE Top 15 Cruise Hesitations Answered TITLE How to Convince People Cruises Worth CostJanel Castillo Balbiran33% (3)

- A Sample of The Completed Essential Principles Conformity Checklist MD CCLDocument12 pagesA Sample of The Completed Essential Principles Conformity Checklist MD CCLAyman Ali100% (1)

- TA-Ingles IX - UAPDocument10 pagesTA-Ingles IX - UAPmanuel brennerNo ratings yet

- Goals Editable PDFDocument140 pagesGoals Editable PDFManuel Ascanio67% (3)

- XDocument266 pagesXTrần Thanh PhongNo ratings yet

- Bentel J408Document64 pagesBentel J408Bojan MarkovicNo ratings yet

- MLS 321 Aubf M6u2 Other Metabolic Diseases V2122Document7 pagesMLS 321 Aubf M6u2 Other Metabolic Diseases V2122proximusNo ratings yet

- Fuck Your LawnDocument86 pagesFuck Your Lawnhuneebee100% (1)

- Dr. Namrata Misra Head of Bioinnovations at KIIT UniversityDocument1 pageDr. Namrata Misra Head of Bioinnovations at KIIT Universitymanisha maniNo ratings yet

- How To Become A Coffee Aficionado: Tips & Tricks: Kate Macdonnell Brewing Updated: Feb 06 2023Document17 pagesHow To Become A Coffee Aficionado: Tips & Tricks: Kate Macdonnell Brewing Updated: Feb 06 2023sadenaikeNo ratings yet