Professional Documents

Culture Documents

Metal-Enclosed Medium Voltage Power Factor Correction System

Uploaded by

Yigit SarıkayaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metal-Enclosed Medium Voltage Power Factor Correction System

Uploaded by

Yigit SarıkayaCopyright:

Available Formats

Technical Data TD02607011E

Effective June 2011

Supersedes November 2008

Metal-enclosed medium voltage

power factor correction system

Contents

Description Page

Medium voltage power factor correction . . . . . . . 1

Product description . . . . . . . . . . . . . . . . . . . . . . 1

Application description. . . . . . . . . . . . . . . . . . . . 2

Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Univar XV (5 kV class). . . . . . . . . . . . . . . . . . . . . . 3

Product description . . . . . . . . . . . . . . . . . . . . . . 3

Application description. . . . . . . . . . . . . . . . . . . . 3

Features, benefits, and functions. . . . . . . . . . . . 3

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Univar (15 kV class). . . . . . . . . . . . . . . . . . . . . . . . 7

Product description . . . . . . . . . . . . . . . . . . . . . . 7

Application description. . . . . . . . . . . . . . . . . . . . 7

Features, benefits, and functions. . . . . . . . . . . . 7

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Autovar MV (2.414.4 kV) . . . . . . . . . . . . . . . . . . . 9

Product description . . . . . . . . . . . . . . . . . . . . . . 9

Features, benefits, and functions. . . . . . . . . . . . 9

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . 13

Medium voltage power

factor correction

Product description

Eatons metal-enclosed medium voltage capacitor

systems and harmonic filters are designed for

indoor or outdoor applications in commercial,

industrial, and utility power systems requiring

power factor correction, motor start support,

harmonic filtering, and IEEET 519 compliance, and

can increase system capacity. Fixed motor start

capacitors are available to assist in motor starting

applications. Designs are available with a host

of options and accessories to fit the requirements and desired configurations of virtually

any installation. Single-stage and multi-stage,

tuned or de-tuned filter banks can be supplied.

Metal-enclosed medium voltage capacitor banks

are designed for industrial, commercial, and utility

power systems involving motors, feeder circuits,

and transmission and distribution lines where

power factor improvement is required.

Technical Data TD02607011E

Metal-enclosed medium voltage

power factor correction system

Effective June 2011

Application description

Advantages

Utility customers

Eatons purchase of the Commonwealth Sprague capacitor systems

business, with its over 70 years of market experience, provides

a combination that allows the end user to obtain a world-class

solution to fill their power factor needs. Quality and reliability are

of paramount importance to not only the Eaton engineering team,

but are also the backbone of all Eaton products and services. This

commitment to quality means the customer can have a great deal

of confidence with the medium voltage capacitor or harmonic filter

solution from Eaton.

Metal-enclosed power factor correction systems are fully assembled, tested, and ready for installation. Very little field assembly

is required. Installation and maintenance costs for metal-enclosed

systems are low compared to pole and rack mounted capacitor

banks. Metal-enclosed systems and harmonic filters are less

vulnerable to wildlife and airborne contaminants that can cause

tracking and faults. In addition, metal-enclosed systems significantly

reduce the risks and the associated liability involving untrained

personnel. All live parts are contained in a grounded, key interlocked

enclosure, and no internal hardware is accessible. Metal-enclosed

systems are aesthetically pleasing due to their low profile, and

can be painted to match the surrounding architecture. These are

just some of the reasons more and more customers are using

metal-enclosed capacitor and harmonic filter systems.

Industrial customers

Many industrial power users can take advantage of the benefits

associated with medium voltage power factor correction and

harmonic filtering. Medium voltage solutions usually support the

scale and scope of larger services. Medium voltage applications

can be found in the following types of industries: automotive,

pulp and paper, plastics, petrochemical, and heavy manufacturing.

Individual fixed capacitors provide power factor correction directly

at the cause of the problem, such as large horsepower MV motors.

Medium voltage systems allow large industrials to correct power

factor at or close to the point of common coupling (PCC), where

the utility electrical system meets theirs. This allows correction for

an entire facility, instead of having to correct at multiple locations.

The NEMAT 3R design also allows the system to be placed outdoors, saving valuable manufacturing floor space. The savings

can be significant in materials, installation costs, and floor space.

In short, medium voltage solutions provide a cost-effective alternative to many local low voltage power factor correction units, while

protecting the customers entire electrical distribution system.

Commercial customers

Many commercial customers are purchasing power from their

utility at higher voltages today (2.415 kV), and can also take

advantage of medium voltage power factor correction systems.

These solutions can meet the needs of large office complexes,

hospitals, and universities, among others. The benefits of safety

(key interlocking, no exposed live parts, etc.) and aesthetics

(low profile, can be painted to match the environment) both meet

the needs of these applications where there are large numbers

of untrained personnel in proximity of electrical equipment.

Safety and aesthetics are just two compelling

reasons to use metal-enclosed PFC systems.

eaton corporation www.eaton.com

Benefits

Ease of installation

Eaton makes installation easy. All systems are completely assembled in the factory, with all equipment pre-wired and pre-tested

for easy on-site installation. Only shipping splits must be connected

in the field. Splice kits connect bus systems, and control wiring

is easily connected at each enclosure. Current limiting fuses,

contactor assemblies, and the incoming switch assembly can

be removed from the enclosure if needed. Line terminals are

completely accessible from the front of the system.

Personnel safety

A positive mechanical isolating switch with visible disconnect

completely grounds and isolates the unit from the line connectors.

A screened barrier protects personnel from live parts. All medium

voltage doors are mechanically interlocked with the disconnect

switch. Key interlocks are provided standard on all enclosure doors,

and can be coordinated with upstream disconnect devices. The low

voltage control section has a separate door-in-door design, and is

segregated from the medium voltage sections so that an operator

can work in that section safely.

Ease of maintenance

All components are front-accessible, facilitating routine inspection

or parts replacement. A viewing window is standard on all

compartment doors.

Flexibility

Systems are expandable. The customer can add stages in the future

by connecting the phase bus in the field via splice kits. Structures

can be bolted together in the field.

Insulated splice kits allow for simple interconnection in the field.

Technical Data TD02607011E

Metal-enclosed medium voltage

power factor correction system

Univar XV (5 kV class)

Effective June 2011

Application description

Large motors

Motor control centers

Branch circuits

Service entrances

Features, benefits, and functions

Standard features

Enclosure terminal box

Fourteen-gauge steel finished with durable baked-on enamel. The

wiring enclosure is gasketed to create a weatherproof, dustproof

seal. Universal mounting flanges are provided for floor installation.

The elimination of knockouts permits indoor/outdoor use. Unit

meets NEMA 1, 3R, and 12 requirements. Enclosure is painted

ANSI 61 gray.

Features

Viewing window

Top and side entry

Removable front cover

Fusing

Univar XV fixed medium voltage PFC unit

Product description

Capacitors for medium voltage, heavy-duty applications:

Fuses are rated 50,000A symmetrical interrupting capacity. Ratings

are 165% to 250% of rated current. Fuses have visual pop-up blown

fuse indication standard.

Discharge resistors

Univar capacitors are designed for power factor correction in applications where a fixed amount of capacitance (kVAR) is required

These reduce the residual voltage to less than 50V residual within

five minutes of de-energization.

Available in voltage ratings of 2400V, 4160V, and 4800V

Fast economical payback

Grounding stud

Individual units or multiple assemblies can be designed

Indoor dustproof/outdoor waterproof enclosures

(NEMA 12, NEMA 3R)

Floor mounting

Two- or three-phase fused options for 24004800V

NEMA 3R terminal box

NNote: NECT Article 460.8 (b)(1) requires capacitors to have overcurrent

protection in all ungrounded conductors (except when connected on the load

side of a motor overload protection device). Three-phase capacitors fused

only on two phases will not provide adequate protection if a line-to-ground

fault should occur in the unfused phase.

Standard

Power line terminals

Large size for easy connection

Plated copper one-hole termination pad

Operating temperature

40F to 115F (40C to 46C)

Optional features

CSAT testing and labels

Technical data

Table 1. Univar Three-Phase Ratings

Volts

Hz

kVAR

2400

4160

4800

60

60

60

25825

25900

25900

eaton corporation www.eaton.com

Technical Data TD02607011E

Metal-enclosed medium voltage

power factor correction system

Effective June 2011

Table 2. Two-Phase Fused

kVAR

2400V

4160V

4800V

Dimension (A)

Inches (mm)

Approximate

Weight Lbs (kg)

Figure Number

25

50

75

100

125

150

175

200

225

250

275

300

300

325

350

375

400

425

450

475

500

525

550

575

575

600

600

625

650

675

700

725

750

775

800

825

850

875

900

25243MVF

50243MVF

75243MVF

100243MVF

125243MVF

150243MVF

175243MVF

200243MVF

225243MVF

250243MVF

275243MVF

300243MVF

325243MVF

350243MVF

375243MVF

400243MVF

425243MVF

450243MVF

475243MVF

500243MVF

525243MVF

550243MVF

575243MVF

600243MVF

625243MVF

650243MVF

675243MVF

700243MVF

725243MVF

750243MVF

775243MVF

800243MVF

825243MVF

25413MVF

50413MVF

75413MVF

100413MVF

125413MVF

150413MVF

175413MVF

200413MVF

225413MVF

250413MVF

275413MVF

300413MVF

325413MVF

350413MVF

375413MVF

400413MVF

425413MVF

450413MVF

475413MVF

500413MVF

525413MVF

550413MVF

575413MVF

600413MVF

625413MVF

650413MVF

675413MVF

700413MVF

725413MVF

750413MVF

775413MVF

800413MVF

825413MVF

850413MVF

875413MVF

900413MVF

25483MVF

50483MVF

75483MVF

100483MVF

125483MVF

150483MVF

175483MVF

200483MVF

225483MVF

250483MVF

275483MVF

300483MVF

325483MVF

350483MVF

375483MVF

400483MVF

425483MVF

450483MVF

475483MVF

500483MVF

525483MVF

550483MVF

575483MVF

600483MVF

625483MVF

650483MVF

675483MVF

700483MVF

725483MVF

750483MVF

775483MVF

800483MVF

825483MVF

850483MVF

875483MVF

900483MVF

34.44 (875)

34.44 (875)

34.44 (875)

36.19 (919)

36.19 (919)

36.19 (919)

36.19 (919)

36.19 (919)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

36.19 (919)

36.19 (919)

36.19 (919)

36.19 (919)

36.19 (919)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

36.19 (919)

41.94 (1065)

36.19 (919)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

70 (32)

70 (32)

70 (32)

75 (34)

83 (38)

88 (40)

93 (42)

99 (45)

109 (49)

109 (49)

121 (55)

121 (55)

172 (78)

177 (80)

182 (83)

188 (85)

194 (88)

206 (93)

214 (97)

214 (97)

214 (97)

226 (103)

238 (108)

238 (108)

259 (118)

238 (108)

265 (121)

279 (127)

287 (131)

295 (134)

295 (134)

295 (134)

295 (134)

307 (140)

319 (145)

331 (151)

331 (151)

331 (151)

331 (151)

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

2

2

3

2

3

3

3

3

3

3

3

3

3

3

3

3

3

NNote: To be used on ungrounded delta systems or high resistance grounding systems only.

NNote: Add suffix C for CSA label.

eaton corporation www.eaton.com

Technical Data TD02607011E

Metal-enclosed medium voltage

power factor correction system

Effective June 2011

Table 3. Three-Phase Fused

kVAR

2400V

4160V

4800V

Dimension (A)

Inches (mm)

Approximate

Weight Lbs (kg)

Figure Number

25

50

75

100

125

150

175

200

225

250

275

300

300

325

350

375

400

425

450

475

500

525

550

575

575

600

600

625

650

675

700

725

750

775

800

825

850

875

900

25243MVF3

50243MVF3

75243MVF3

100243MVF3

125243MVF3

150243MVF3

175243MVF3

200243MVF3

225243MVF3

250243MVF3

275243MVF3

300243MVF3

325243MVF3

350243MVF3

375243MVF3

400243MVF3

425243MVF3

450243MVF3

475243MVF3

500243MVF3

525243MVF3

550243MVF3

575243MVF3

600243MVF3

625243MVF3

650243MVF3

675243MVF3

700243MVF3

725243MVF3

750243MVF3

775243MVF3

800243MVF3

825243MVF3

25413MVF3

50413MVF3

75413MVF3

100413MVF3

125413MVF3

150413MVF3

175413MVF3

200413MVF3

225413MVF3

250413MVF3

275413MVF3

300413MVF3

325413MVF3

350413MVF3

375413MVF3

400413MVF3

425413MVF3

450413MVF3

475413MVF3

500413MVF3

525413MVF3

550413MVF3

575413MVF3

600413MVF3

625413MVF3

650413MVF3

675413MVF3

700413MVF3

725413MVF3

750413MVF3

775413MVF3

800413MVF3

825413MVF3

850413MVF3

875413MVF3

900413MVF3

25483MVF3

50483MVF3

75483MVF3

100483MVF3

125483MVF3

150483MVF3

175483MVF3

200483MVF3

225483MVF3

250483MVF3

275483MVF3

300483MVF3

325483MVF3

350483MVF3

375483MVF3

400483MVF3

425483MVF3

450483MVF3

475483MVF3

500483MVF3

525483MVF3

550483MVF3

575483MVF3

600483MVF3

625483MVF3

650483MVF3

675483MVF3

700483MVF3

725483MVF3

750483MVF3

775483MVF3

800483MVF3

825483MVF3

850483MVF3

875483MVF3

900483MVF3

34.44 (875)

34.44 (875)

34.44 (875)

36.19 (919)

36.19 (919)

36.19 (919)

36.19 (919)

36.19 (919)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

36.19 (919)

36.19 (919)

36.19 (919)

36.19 (919)

36.19 (919)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

36.19 (919)

41.94 (1065)

36.19 (919)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

41.94 (1065)

70 (32)

70 (32)

70 (32)

75 (34)

83 (38)

88 (40)

93 (42)

99 (45)

109 (49)

109 (49)

121 (55)

121 (55)

172 (78)

177 (80)

182 (83)

188 (85)

194 (88)

206 (93)

214 (97)

214 (97)

214 (97)

226 (103)

238 (108)

238 (108)

259 (118)

238 (108)

265 (121)

279 (127)

287 (131)

295 (134)

295 (134)

295 (134)

295 (134)

307 (140)

319 (145)

331 (151)

331 (151)

331 (151)

331 (151)

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

2

2

3

2

3

3

3

3

3

3

3

3

3

3

3

3

3

NNote: Add suffix C for CSA label.

eaton corporation www.eaton.com

Technical Data TD02607011E

Effective June 2011

Metal-enclosed medium voltage

power factor correction system

Dimensions

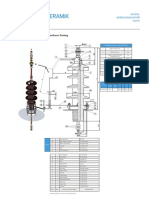

Figure 1. Univar XV Outline Drawing

Figure 2. Univar XV Outline Drawing

eaton corporation www.eaton.com

Figure 3. Univar XV Outline Drawing

Technical Data TD02607011E

Metal-enclosed medium voltage

power factor correction system

Univar (15 kV class)

Effective June 2011

Features, benefits, and functions

Standard features

Enclosure

Sixteen-gauge steel finished with durable baked-on enamel. The

wiring enclosure is gasketed to create a weatherproof, dustproof

seal. Universal mounting flanges are provided for floor installation.

The elimination of knockouts permits indoor/outdoor use. Unit

meets NEMA 1, 3R, and 12 requirements. Enclosure is painted

ANSI 70 gray.

Fusing

Fuses are rated 50,000A symmetrical interrupting capacity.

Ratings are 165% to 250% of rated current. Fuses have visual

pop-up blown fuse indication standard.

Discharge resistors

These reduce the residual voltage to less than 50V residual

within 5 minutes of de-energization.

Univar fixed medium voltage PFC unit

Grounding stud

Standard

Product description

Capacitors for medium voltage, heavy-duty applications:

Power line terminals

Univar capacitors are designed for power factor correction

in applications where a fixed amount of capacitance (kVAR)

is required

Available in voltage ratings of 6.6 kV, 7.2 kV, 12.47 kV and 13.8 kV

Fast economical payback

Individual units or multiple assemblies can be designed

Indoor dustproof/outdoor waterproof enclosures

(NEMA 12, NEMA 3R)

Floor mounting

Fuses supplied on all three phases

NEMA 3R terminal box

Application description

Large motors

Motor control centers

Branch circuits

Service entrances

Large size for easy connection

Operating temperature

40F to 115F (40C to 46C)

Optional features

CSA testing and labels

Technical data

Table 4. Univar Three-Phase Ratings

Volts

Hz

kVAR

6600

7200

12,470

13,800

60

60

60

60

50400

50400

50500

50500

eaton corporation www.eaton.com

Technical Data TD02607011E

Metal-enclosed medium voltage

power factor correction system

Effective June 2011

Table 5. Standard Three Fuses (660013,800V)

Standard Three Fuses

Dimensions in Inches (mm)

kVAR

6600V

7200V

12,470V

13,800V

(A)

(B)

(C)

(D)

Approx.

Weight

Lbs (kg)

Figure

Number

Standard

DWG

Number

50

100

150

200

250

300

350

400

450

500

50663FKED3

100663FKED3

150663FKED3

200663FKED3

250FKY66323

300FKY66323

350FKY66323

400FKY66323

50723FKED3

100723FKED3

150723FKED3

200723FKED3

250FKY72323

300FKY72323

350FKY72323

400FKY72323

50123FKED3

100123FKED3

150123FKED3

200123FKED3

250FKY12323

300FKY12323

350FKY12323

400FKY12323

450FKY12323

500FKY12323

50133FKED3

100133FKED3

150133FKED3

200133FKED3

250FKY13323

300FKY13323

350FKY13323

400FKY13323

450FKY13323

500FKY13323

4.25 (108)

4.25 (108)

4.25 (108)

5.62 (143)

5.62 (143)

5.62 (143)

5.62 (143)

5.62 (143)

5.62 (143)

5.62 (143)

45.50 (1156)

45.50 (1156)

45.50 (1156)

45.50 (1156)

48.50 (1232)

53.50 (1359)

53.50 (1359)

57.25 (1454)

57.25 (1454)

57.25 (1454)

14.46 (367)

14.46 (367)

14.46 (367)

14.46 (367)

17.46 (443)

17.46 (443)

17.46 (443)

22.46 (570)

22.46 (570)

26.21 (666)

0.25 (6)

0.25 (6)

0.25 (6)

0.25 (6)

0.25 (6)

0.25 (6)

0.25 (6)

0.25 (6)

0.25 (6)

0.25 (6)

198 (90)

198 (90)

198 (90)

220 (100)

246 (112)

246 (112)

246 (112)

281 (128)

281 (128)

336 (153)

4

4

4

4

4

4

4

4

4

4

5D10243

5D10243

5D10243

5D10243

5D10243

5D10243

5D10243

5D10243

5D10243

5D10243

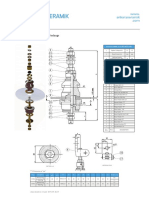

Dimensions

Removable

Top Cover

0.250-20

Ground Screw

34.00

16.42

Barriers When

Necessary

Solderless Conn.

for A #10 Solid

to A #4 Str'd. Conn.

(2) 0.500 x 0.625

Slots [13 x 16]

24.12

25.08

Figure 4. Drawing Number 5D10243

eaton corporation www.eaton.com

Technical Data TD02607011E

Metal-enclosed medium voltage

power factor correction system

Autovar MV (2.414.4 kV)

Effective June 2011

Standard features

Enclosure

Free-standing, 11-gauge steel construction with three-point

padlockable latching handles and stainless steel hinges. The

enclosure is painted with a corrosion-resistant ANSI 61 light

gray powder-coated paint as standard. Other colors are available

as an option. NEMA 3R construction is standard; NEMA 3R

stainless steel is available as an option.

Enclosure type is ULT/CSA approved. Enclosure design is modular,

and future sections can be added on the left or the right.

See Figure 5 for typical dimensions and elevations.

See Figure 6 for a typical single-line drawing.

Medium voltage metal-enclosed PFC system

Product description

Autovar medium voltage automatic power factor capacitor systems

are designed for power factor correction in applications where

plant power factor can be constant or changing and a custom

solution is required. These systems can be a fixed amount of

capacitance with a disconnect, a number of switched capacitance

stages, or a combination of both. The Autovar medium voltage

capacitor system can switch stages of capacitance in and out

automatically based on information collected by the power factor

controller on the door-in-door control panel.

Medium voltage PFC enclosure

Features, benefits, and functions

Voltages from 2400 to 14,400V

Reactive power ratings through 15 MVAR

Harmonic tuned, de-tuned, or multi-tuned filter designs available

Externally fused capacitor units standard

Blown fuse indication standard

Integral load interrupter switch with NEMA two- or four-hole

termination pad for incoming cables

Factory tested and ready for interconnection

Integral protection and control system

Top or bottom cable entry

Grounding switch

60 kV BIL up to 4.8 kV

95 kV BIL from 7.2 kV to 14.4 kV

Up to 12 automatic switched capacitor stages

Warning labels

Removable air filters without opening enclosure doors

Adjustable blocking timers to prevent re-closing of a capacitor

stage in less than 200 seconds

Meets the following requirements:

ANSI

IEEE

NEC

NESC

CSA (when specified)

Main incoming fuses are rated 50 kAIC to provide main bus protection, as well as backup protection for the capacitor systems

4.00-inch base channel is standard

Bottom plate incoming cutout provided standard

Load interrupter air disconnect switch

Integral disconnect switch, externally operated, mechanically chain

driven with visible blades is available as per NEC requirements.

Disconnect switch is mechanically interlocked with the ground

switch, and with the customers upstream device (if applicable).

For safety, the incoming section is front-accessible only, and

a barrier isolates live components from the user.

Incoming section

eaton corporation www.eaton.com

Technical Data TD02607011E

Metal-enclosed medium voltage

power factor correction system

Effective June 2011

Ground switch

Individual capacitor fusing

A ground switch is provided to ground the load-side terminals

of the incoming switch (or MLO) for safety during maintenance.

Optional controls are available to permit closing contactors after

the grounding switch has been closed to ground capacitors

immediately (rather than waiting 5 minutes for full discharge).

Each capacitor is externally fused with current limiting fuses.

Fuses are equipped with blown fuse indication. Internally fused

capacitors are also available as an option. Fuses are rated for

capacitor protection. All fuses are rated 50 kAIC.

Vacuum switches and contactors rated for capacitor switching

On 2.4 to 4.8 kV multi-stage capacitor systems, each stage is

controlled by low maintenance Eaton SL AMPGARDT threepole vacuum contactors. On 6.6 to 14.4 kV multi-stage capacitor

systems, each stage is controlled by low maintenance single-pole

vacuum switches.

Environmental controls

Exhaust fans are provided for forced air ventilation of all

enclosures as standard

Thermostats are included as standard to help maintain an

acceptable internal environment for all components

Space heaters are provided to control moisture and humidity

inside all enclosures

Each compartment has individual thermostats for fan and space

heater controls

Capacitors

Low loss, double-bushing capacitors that meet or exceed IEC 871,

IEEE Std. 18, and CSA standards are supplied. Capacitors are

available in delta, ungrounded wye, or solidly grounded wye.

The dielectric fluid is environmentally friendly and biodegradable,

and contains no PCBs. Capacitor units are equipped with internal

discharge resistors that reduce the residual voltage to less than

50 volts within 5 minutes of de-energization.

Harmonic filtering

15 kV switched capacitor stage enclosure

The type SL power contactors are self-supporting, compact,

three-pole vacuum contactors, rated for capacitor switching.

The SL contactor uses a solid-state control board, allowing the

user maximum flexibility to change control voltages and dropout

times in the field simply by adjusting DIP switch settings. The

SL contactor is available in voltage ratings from 2.4 to 4.8 kV

with current ratings of 200A and 800A (the highest rated capacitor

switching contactor available), and the SL contactor has interruption

ratings of 8500A, allowing for better coordination with power fuses.

Eatons medium voltage harmonic filter systems are designed

for industrial, utility, and commercial power systems to improve

power factor, to reduce harmonic distortion, and to increase system

capacity. The reactors are typically tuned to either the 4.2nd or the

4.7th harmonic, to filter the 5th level harmonic. Other tuning orders

are available. This is the most common harmonic produced by sixpulse variable speed drives. These filters are designed to the unique

specifications of each electrical distribution system. Medium voltage

capacitor banks can also be configured with de-tuned anti-resonant

harmonic filters, typically set to the 4.2nd harmonic. Capacitor banks

tuned to the 4.2nd or 4.7th harmonic prevent parallel resonance

conditions, reduce transients, and provide harmonic filtering.

Harmonic filter capacitor stage enclosure

5 kV switched capacitor stage enclosure

10

eaton corporation www.eaton.com

Technical Data TD02607011E

Metal-enclosed medium voltage

power factor correction system

Effective June 2011

Key interlock system

Microprocessor-based controller

The key interlock system controls the sequential operation of

the load break switch (or circuit breaker) and the ground switch

to permit safe entry into the capacitor system. All capacitor

stage enclosures are also interlocked with the ground switch.

If applicable, the customers upstream disconnect device can

be interlocked as well. See Figure 6 for key interlock operation

on a typical single-line drawing.

All switched metal-enclosed capacitors and harmonic filter systems

come equipped with an automatic controller that switches each

capacitor stage based upon power factor. The customer simply

programs in the target power factor desired. The controller analyzes

the present power factor, the size of each stage, and turns on and

off stages to meet the customers programmed target. The power

factor controller comes with the following alarms as standard:

over/under compensation, no current input, step fault, step warning,

target PF not reached, total voltage harmonic distortion, total current

harmonic distortion, and over/under voltage.

Blown fuse detection system

A visual pop-up blown fuse detection system is provided

as standard.

Control power transformer

A fused control power transformer rated for 1.5 kVA is provided

for protection, control, and operation of the capacitor or harmonic

filter system.

Surge protective device (SPD)

An SPD unit is always supplied for protection of all low voltage

controls in the system, increasing the reliability of the system.

Control panel

A door-in-door NEMA 3R swing-out control panel is provided on the

main incoming structure as standard. This unit includes a viewing

window so that all controls and information can be viewed without

opening the panel. All low voltage controls and logic are accessible

from the front of the system, and are isolated from the medium

voltage section.

Included:

PFC power factor controller

Multifunction digital meter/relay

Full voltage LED lights for status, alarm, and trip indication

Manual stage operation switches

Any special controls requested by the customer

Up to 12 steps of capacitance can be designed into any system.

Customers can exploit this feature when designing systems for

future plant expansion.

Communication options

Communications of power factor data via RS-485. ModbusT is available as an option. Communicated information from the controllers:

Voltage

Current

Target power factor

Current power factor

Active power

Apparent power

Reactive power

Number of steps in the circuit

All alarm status

All counters

Time and date

Inrush reactors

Series air core inrush reactors are provided as standard on all

switched (non-harmonic filtered) capacitor systems for protection

against transients from back-to-back switching. Reactors in harmonic

filtered applications provide this same protection.

Bus

Standard main bus is continuous 1/4 x 2-inch silver-plated copper

bus rated 600A and is provided throughout the lineup for easy

interconnection, field installation, and future expansion.

Ground bus is continuous 1/4 x 1-inch silver-plated copper rated

300A and is provided throughout the lineup for easy interconnection, field installation, and future expansion. Ground studs

are available in all structures for customer connection.

Control panel

eaton corporation www.eaton.com

11

Technical Data TD02607011E

Metal-enclosed medium voltage

power factor correction system

Effective June 2011

Additional standard controls and features

Three-phase current monitoring of capacitor bank

Unbalance alarm and unit shutdown on all

wye-connected systems

Unit alarm and isolated fail-safe contacts for customer use on all

systems. Controls allow sufficient time (5 minutes) to allow the

capacitors time to discharge before re-energization can occur

Temperature alarms on all harmonic filter units

Manual stage controls (H-O-A selector switches)

Optional features

Harmonic filter reactors

Iron core reactors provide the necessary reactance to tune the

capacitor system to a desired frequency. Standard filters can be

tuned to 4.2, 4.4, 4.6, or 4.7, with other tuning frequencies available

if needed. Iron core reactors are 100% copper windings, 115C

rise with 220C insulation VPI varnish.

Lightning arresters

Optional heavy-duty distribution intermediate or station class

lightning arresters protect the capacitor system from lightning

and switching transients.

15 kV capacitor vacuum switch

15 kV capacitor vacuum switch is available in vacuum contactor in oil

dielectric or vacuum contactor in solid dielectric. Vacuum switches

are certified to ANSI C37.66 standard.

Harmonic manager multifunction digital meter/relay

Multifunction harmonic manager meter/relay with current and

voltage harmonic monitoring and various alarm/trip set points.

Enclosure options

NEMA 3R stainless steel construction for highly caustic

environments.

Alarm strobe

Strobe light can be provided for visual indication of faults and alarms.

Unbalance protection

Neutral PT or CT-based unbalance protection for wye ungrounded

capacitor configuration.

Power cable termination

Incoming power cable lugs are available when specified.

Time delayed enclosure entry interlock

Electrically controlled solenoid time delay to allow adjustable

time delay between opening of main switch and entry into

capacitor section.

Reactors for harmonic filter

Heavy-duty capacitor units

Capacitor units suited to the rigors of industrial power systems for

power factor, harmonic filter, and excessive switching applications.

Heavy-duty capacitor units have 125% continuous rms overvoltage

capability, 15,000A fault handling capability, 100 kA transient current

withstand capability, 131F (55C) ambient temperature operation,

and 135% peak overvoltage capability.

Other options

12

eaton corporation www.eaton.com

Second PT for voltage sensing of all three phases

Special CSA label for assembly

Individual harmonic filter current monitoring

Overload protection

Technical Data TD02607011E

Metal-enclosed medium voltage

power factor correction system

Effective June 2011

Technical data

Top Power

Cable Entry

Lifting Eyes

Shipping Split

Main Switch

Incoming Main Section

K1

Control

Panel

CAUTION

CAUTION

CAUTION

DANGER

DANGER

DANGER

Danger

High Voltage

Keep Out

Danger

High Voltage

Keep Out

Danger

High Voltage

Keep Out

Danger

High Voltage

Keep Out

K1

CAUTION

DANGER

D1

D2

D3

D2

8 Tie-Down Points

per Enclosure

Front and Rear

for 1/2 Inch Hardware

D3

D2

180.80

(4592.3)

Front Elevation

Rear Access Doors Optional

D1

Door Interlocks

90.33

(2294.4)

13.50

(342.9)

Base Channel

40-Inches High

15.00

(381.0)

18.00

(457.2)

13.50

(342.9)

21.79

(553.5)

Bottom Entry

Cover Plate

5.09

(129.3)

18.00

(457.2)

9.07

(230.4)

Front Access 5 Foot Clearane

(457.2)

Customer

Cable

Termination

(Approximate

Location, See

Actual Unit

for Exact

Dimensions)

Ground Bus

1/4-inch x 1-inch

Base Channel

Bottom Power

Cable Entry

49.00

(1244.6)

45.00

(1143.0)

1.50

(38.1)

(Typ)

24.00

(609.6)

18.00

Ground Switch

NAMEPLATE

92.56

(2351.0)

Right Side Elevation

Each Section is

45.00 (1143.0) W x 49.00 (1244.6) D

49.00

(1244.6)

1.00

(25.4)

Floor Plan

Top Entry MV Conduit Area

19.00

(482.6)

Top Entry

Control

Conduit

4.00 x 4.00

Top View

4.00

(101.6)

16.00

(406.4)

15.00

(381.0)

13.00

(330.2)

38.00

(965.2)

Figure 5. Typical Engineered Metal-Enclosed Power Factor Correction System Dimensional Data

eaton corporation www.eaton.com

13

Technical Data TD02607011E

Metal-enclosed medium voltage

power factor correction system

Effective June 2011

Utility Line

Utility

Transformer

Main Breaker

CT

A-Phase

Feeder Breaker

K0

Plant Loads

K-K Interlock

K-K Interlock (Optional)

C1

K-K Interlock

K1

K0

Main

Switch

BLR-CM

CPT

1-Phase

Power Factor

Controller

Tap On

B&C

K1

S1

Ground

Switch

S1

S1

46

CT1

AS

AM

59

Alarm or Trip

Fuse

Enclosure

Door

C1

Vacuum

Contactor

Reactor

Capacitor

Delta/Wye

Capacitor

Delta/Wye

Capacitor

Delta/Wye

Figure 6. Typical Medium Voltage Automatic Power Factor Correction Single-Line Drawing

14

eaton corporation www.eaton.com

S2

S3

Control

Relays

Metal-enclosed medium voltage

power factor correction system

Technical Data TD02607011E

Effective June 2011

Figure 7. Automatic Capacitor Banks Medium Voltage Main-Tie-Main

eaton corporation www.eaton.com

15

Technical Data TD02607011E

Effective June 2011

Metal-enclosed medium voltage

power factor correction system

Eaton Corporation

Electrical Sector

1111 Superior Ave.

Cleveland, OH 44114

United States

877-ETN-CARE (877-386-2273)

Eaton.com

2011 Eaton Corporation

All Rights Reserved

Printed in USA

Publication No. TD02607011E / Z11009

June 2011

Eaton is a registered trademark

of Eaton Corporation.

All other trademarks are property

of their respective owners.

You might also like

- Td02607011e PDFDocument16 pagesTd02607011e PDFapic20No ratings yet

- MV PFC - Metal Enclosed - EatonDocument24 pagesMV PFC - Metal Enclosed - EatonlassasaNo ratings yet

- TD02300001EDocument8 pagesTD02300001EDavid J LopezNo ratings yet

- Abc of Power Modules: Functionality, Structure and Handling of a Power ModuleFrom EverandAbc of Power Modules: Functionality, Structure and Handling of a Power ModuleNo ratings yet

- Power Xpert FMX - Application Guide 6054036 02 ENGDocument52 pagesPower Xpert FMX - Application Guide 6054036 02 ENGcepchileNo ratings yet

- Integrated Power Assemblies 23-1: February 2007Document5 pagesIntegrated Power Assemblies 23-1: February 2007Ricardo LopezNo ratings yet

- K-Line Mini - Contactors, Overload Relays and Accessories: Class 8502Document48 pagesK-Line Mini - Contactors, Overload Relays and Accessories: Class 8502hassan karimiNo ratings yet

- Eaton Tb09500001e PDFDocument62 pagesEaton Tb09500001e PDFJuan E Torres MNo ratings yet

- Softstarters: Type PSR, PSS, Pse, PST and PSTBDocument64 pagesSoftstarters: Type PSR, PSS, Pse, PST and PSTBmoulin sitifisNo ratings yet

- Advantage NEMADocument28 pagesAdvantage NEMAJorge Sebastian Cifuentes UnibazoNo ratings yet

- AN-1849 An Audio Amplifier Power Supply Design: Application ReportDocument17 pagesAN-1849 An Audio Amplifier Power Supply Design: Application ReportJuzt AdhitNo ratings yet

- TB 01000001 eDocument61 pagesTB 01000001 eRicardo LopezNo ratings yet

- Catalog ATS48 USADocument36 pagesCatalog ATS48 USAFrancisco PerezNo ratings yet

- Catalogue - S811 Soft Starters PDFDocument28 pagesCatalogue - S811 Soft Starters PDFAnonymous HsNodUwzNo ratings yet

- Low Voltage Fixed and Automatic Power Factor Correction SystemsDocument6 pagesLow Voltage Fixed and Automatic Power Factor Correction Systemszabiruddin786No ratings yet

- Application Note: Replaces AN5947-1 With AN5947-2 November 2014 LN32141Document23 pagesApplication Note: Replaces AN5947-1 With AN5947-2 November 2014 LN32141Rifdian AntoNo ratings yet

- ICARDocument32 pagesICARKusnadi PerdanaNo ratings yet

- REN an-CM-314 AC-AC Automatic Voltage Regulator APN 20210928 1Document15 pagesREN an-CM-314 AC-AC Automatic Voltage Regulator APN 20210928 1vidalvis avila castillaNo ratings yet

- EatonDocument89 pagesEatonhernangycNo ratings yet

- IZMX Catalog ENG 20160419Document104 pagesIZMX Catalog ENG 20160419Mahesh BabuNo ratings yet

- Carrier 50TJ C4PDDocument36 pagesCarrier 50TJ C4PDFlavio PiresNo ratings yet

- SVX9000 ManualDocument84 pagesSVX9000 ManualGuillermo Alexis Mella CordovaNo ratings yet

- Catalogo Final de Carreras EATONDocument102 pagesCatalogo Final de Carreras EATONAriel Alexis Pinto PintoNo ratings yet

- Transformer Protection Relay: Technical Data TD02600003EDocument20 pagesTransformer Protection Relay: Technical Data TD02600003EJahidul IslamNo ratings yet

- Bonitron Model 3452Document60 pagesBonitron Model 3452Jesus SanchezNo ratings yet

- Eaton Cutler-Hammer Motor Control Center Info Cat.71.01t.e. - 2 PDFDocument42 pagesEaton Cutler-Hammer Motor Control Center Info Cat.71.01t.e. - 2 PDFDaniel Ajailla AveNo ratings yet

- GB-Delphys BC 160-200-Product Technical Guide 2012Document14 pagesGB-Delphys BC 160-200-Product Technical Guide 2012jbperfecto_csciNo ratings yet

- Snx5Lbc184 Differential Transceiver With Transient Voltage SuppressionDocument29 pagesSnx5Lbc184 Differential Transceiver With Transient Voltage SuppressionGabriel EscamillaNo ratings yet

- lm2576 PDFDocument44 pageslm2576 PDFLeonid MavroskiNo ratings yet

- LM2576xx Series SIMPLE SWITCHER 3-A Step-Down Voltage RegulatorDocument44 pagesLM2576xx Series SIMPLE SWITCHER 3-A Step-Down Voltage Regulator111No ratings yet

- Telemacanique K-Line ContactorsDocument48 pagesTelemacanique K-Line ContactorsBra BicabaNo ratings yet

- TB 01600004 eDocument146 pagesTB 01600004 emanly2909No ratings yet

- ACS800 Stand Alone Single Drives Rev A W Bookmarks Updated13012005Document48 pagesACS800 Stand Alone Single Drives Rev A W Bookmarks Updated13012005Jose MellaNo ratings yet

- 350002-013 UserGde F4cceb8fb3be6bDocument32 pages350002-013 UserGde F4cceb8fb3be6bNickolay YatsukovNo ratings yet

- Dip Ipm App NoteDocument43 pagesDip Ipm App Noteamateur123456No ratings yet

- 50TJ Data SheetDocument68 pages50TJ Data SheetFlavio Pires100% (3)

- Banco de CapacitoresDocument8 pagesBanco de CapacitoresAlexandre HerreraNo ratings yet

- Cantactor Starter NEMA Cuttler HammerDocument48 pagesCantactor Starter NEMA Cuttler HammerAlfiansyah Dharma Setia DjaketraNo ratings yet

- LM2594MXDocument44 pagesLM2594MXtecnicogato27No ratings yet

- Altistart™ 48: Panel-Mount Soft StartsDocument40 pagesAltistart™ 48: Panel-Mount Soft StartsYasser SayedNo ratings yet

- StatcomDocument16 pagesStatcomksg9731100% (1)

- DRV10866 5-V, 3-Phase, Sensorless BLDC Motor Driver: 1 Features 3 DescriptionDocument23 pagesDRV10866 5-V, 3-Phase, Sensorless BLDC Motor Driver: 1 Features 3 DescriptionSitt Nyein SoeNo ratings yet

- Training - MotorpactDocument114 pagesTraining - MotorpactKléber Chávez CifuentesNo ratings yet

- EATON Vol07 Tab07 TransformadorDocument26 pagesEATON Vol07 Tab07 TransformadorJohn EvansNo ratings yet

- Power Meter 4300 ManualDocument52 pagesPower Meter 4300 ManualMiguel AngelNo ratings yet

- UCC21530Document47 pagesUCC21530Silvio QuerzoliNo ratings yet

- AD5171 64-Position OTP Digital Potentiometer Data SheetDocument24 pagesAD5171 64-Position OTP Digital Potentiometer Data SheetSherif EltoukhiNo ratings yet

- 2 Distribution System: Technology Upgrades For The Installed BaseDocument4 pages2 Distribution System: Technology Upgrades For The Installed BaseMarcos VeraNo ratings yet

- Vol12 TAB03Document168 pagesVol12 TAB03Antonio FaublaNo ratings yet

- Eng Ezm-4931 02 v03 05 - 16Document55 pagesEng Ezm-4931 02 v03 05 - 16Mithun KumarNo ratings yet

- Eaton Electrical Catalog Volume 1Document393 pagesEaton Electrical Catalog Volume 1mamcspadden100% (2)

- Foaie de Cataolg - Mc34063aDocument30 pagesFoaie de Cataolg - Mc34063aCovaci BogdanNo ratings yet

- Vol12 Tab03Document168 pagesVol12 Tab03ajeeshsivanNo ratings yet

- Transformadores EatonDocument22 pagesTransformadores EatonMarcos ValenzuelaNo ratings yet

- CH General CatalogDocument78 pagesCH General CatalogJossue Calvo MedinaNo ratings yet

- Abb CCMDocument60 pagesAbb CCMdaperroNo ratings yet

- 36 kV 250 А DIN 42531 Outdoor Transformer Bushing: Type Class a c g l1 Outdoor (f) Indoor (i)Document1 page36 kV 250 А DIN 42531 Outdoor Transformer Bushing: Type Class a c g l1 Outdoor (f) Indoor (i)Yigit SarıkayaNo ratings yet

- SEPAM ProtectionDocument14 pagesSEPAM ProtectionYigit SarıkayaNo ratings yet

- 36 KV 630 Din 42532 89 2606285Document1 page36 KV 630 Din 42532 89 2606285Yigit SarıkayaNo ratings yet

- MiCOM IDMT Curves CalculatorDocument2 pagesMiCOM IDMT Curves CalculatorYigit SarıkayaNo ratings yet

- 1 KV 250 A 3150 Din 42530 67 3370221Document2 pages1 KV 250 A 3150 Din 42530 67 3370221Yigit SarıkayaNo ratings yet

- Bushing PDFDocument92 pagesBushing PDFYigit SarıkayaNo ratings yet

- SL Ref542plus (En) A 1vcp000060Document63 pagesSL Ref542plus (En) A 1vcp000060Yigit SarıkayaNo ratings yet

- Terminal 01: External GridDocument2 pagesTerminal 01: External GridYigit SarıkayaNo ratings yet

- Page 10 117: Bas耂c HTML Vers耂onDocument2 pagesPage 10 117: Bas耂c HTML Vers耂onYigit SarıkayaNo ratings yet

- MiCOM IDMT Curves CalculatorDocument2 pagesMiCOM IDMT Curves CalculatorYigit SarıkayaNo ratings yet

- Pac E100 Ayar KilavuzuDocument15 pagesPac E100 Ayar KilavuzuYigit Sarıkaya0% (1)

- DIgSILENT PDFDocument1 pageDIgSILENT PDFYigit SarıkayaNo ratings yet

- Metering Is Our Business: High Precision Modular MeterDocument2 pagesMetering Is Our Business: High Precision Modular MeterYigit SarıkayaNo ratings yet

- ErneuerbareEnergien PROSP enDocument8 pagesErneuerbareEnergien PROSP enYigit SarıkayaNo ratings yet

- Hint: User Name and Password Are Case SensitiveDocument1 pageHint: User Name and Password Are Case SensitiveYigit SarıkayaNo ratings yet

- Transformer BushingsDocument92 pagesTransformer BushingsYigit SarıkayaNo ratings yet

- Brosura PTE-100-C Plus 1Document1 pageBrosura PTE-100-C Plus 1Yigit SarıkayaNo ratings yet

- Friem Industry en 07 2010Document2 pagesFriem Industry en 07 2010Yigit SarıkayaNo ratings yet

- High Power SwitchesDocument6 pagesHigh Power SwitchesYigit SarıkayaNo ratings yet

- GCRDocument2 pagesGCRYigit SarıkayaNo ratings yet

- Bomb-280 enDocument2 pagesBomb-280 enYigit SarıkayaNo ratings yet

- EW2.2 eDocument6 pagesEW2.2 eYigit SarıkayaNo ratings yet

- MT174 Polyphase MeterDocument2 pagesMT174 Polyphase MeterYigit SarıkayaNo ratings yet

- Pem735 D00084 D XxenDocument6 pagesPem735 D00084 D XxenYigit SarıkayaNo ratings yet

- Alptec 2444iDocument52 pagesAlptec 2444iYigit SarıkayaNo ratings yet

- Asset: User ManualDocument64 pagesAsset: User ManualYigit SarıkayaNo ratings yet

- Automatic Vehicle Classification Using Fast Neural Network and Classical Neural Network For Traffic MonitoringDocument29 pagesAutomatic Vehicle Classification Using Fast Neural Network and Classical Neural Network For Traffic MonitoringYigit SarıkayaNo ratings yet

- Pem575 D00016 D Xxen 0Document6 pagesPem575 D00016 D Xxen 0Yigit SarıkayaNo ratings yet

- Pem533 D00013 D XxenDocument6 pagesPem533 D00013 D XxenYigit SarıkayaNo ratings yet

- Practical Approach in Designing Conducted EMI Filter To Mitigate Common Mode and Differential Mode Noises in SmpsDocument20 pagesPractical Approach in Designing Conducted EMI Filter To Mitigate Common Mode and Differential Mode Noises in Smpsbacuoc.nguyen356No ratings yet

- 9A02504 Power ElectronicsDocument4 pages9A02504 Power ElectronicsMohan Krishna100% (1)

- Us Cat Seismic Bracing Systems 5151 IlDocument48 pagesUs Cat Seismic Bracing Systems 5151 IlGianpietro de FilippoNo ratings yet

- Features: Programmable Frequency, One Cycle Control PFC IcDocument21 pagesFeatures: Programmable Frequency, One Cycle Control PFC IcАлексей АндрияшNo ratings yet

- A Formula For AlphaDocument4 pagesA Formula For AlphaHans SchauerNo ratings yet

- Tortech eDocument23 pagesTortech emuna7No ratings yet

- Power Semiconductor Drives Question BankDocument16 pagesPower Semiconductor Drives Question BankSaileela Reddy GangasaniNo ratings yet

- Circular Motion Problems SolutionsDocument2 pagesCircular Motion Problems Solutionskota_ak83% (12)

- Safety GroundingDocument183 pagesSafety GroundingBrij Mishra100% (1)

- S3 My WoW Live Hot Air Balloons Pupil WorksheetV2Document5 pagesS3 My WoW Live Hot Air Balloons Pupil WorksheetV2Dennis Gabriel WuNo ratings yet

- Harvesting Energy Through Yoga MatDocument17 pagesHarvesting Energy Through Yoga MatSudiptoGhoshNo ratings yet

- Es 62Document6 pagesEs 62Enrico Luis Caube BalisalisaNo ratings yet

- Charging System Troubleshooting Guide: Kawasaki Ninja 650R (ER-6F) & ER-6N ResourceDocument16 pagesCharging System Troubleshooting Guide: Kawasaki Ninja 650R (ER-6F) & ER-6N Resourcemarcelo ustarezNo ratings yet

- Memristor Project ReportDocument17 pagesMemristor Project ReportVarun MallyaNo ratings yet

- Physics Course ContentsDocument84 pagesPhysics Course ContentsAmbreen Khan100% (1)

- L LL L: The Vo Tage Across The para e Circuit Shows The FigureDocument50 pagesL LL L: The Vo Tage Across The para e Circuit Shows The Figure4630220No ratings yet

- R7 210205 Electromagnetic FieldsDocument2 pagesR7 210205 Electromagnetic FieldssivabharathamurthyNo ratings yet

- Em306a User ManualDocument2 pagesEm306a User ManualNguyễnĐìnhDầnNo ratings yet

- Bs Motor EngDocument36 pagesBs Motor Engjroyal692974No ratings yet

- 3.7.5.2 Moving Charges in A Magnetic FieldDocument67 pages3.7.5.2 Moving Charges in A Magnetic Fieldtheolamey1No ratings yet

- Protection Against Overload CurrentDocument21 pagesProtection Against Overload CurrentAzzhariff AHNo ratings yet

- DC Circuits.: Visit To Download All Latest EASA / DGCA CAR 66 Module Examination Question Papers and Study MaterialDocument33 pagesDC Circuits.: Visit To Download All Latest EASA / DGCA CAR 66 Module Examination Question Papers and Study MaterialUttam100% (1)

- E-J Definitions From NAWL BuilderDocument42 pagesE-J Definitions From NAWL BuilderDavid Daniel PerezNo ratings yet

- EE360 - Synchronous MachinesDocument85 pagesEE360 - Synchronous MachinesAliAl-jaziriNo ratings yet

- Speed Control of Reluctance MotorDocument156 pagesSpeed Control of Reluctance MotorSatyajit DasNo ratings yet

- Time Domain Electromagnetic MethodsDocument16 pagesTime Domain Electromagnetic MethodsAydin Nejati100% (1)

- ProximityDocument26 pagesProximityanjan778No ratings yet

- RIMA Datenblatt TADocument3 pagesRIMA Datenblatt TAnicolaslebigre.stsNo ratings yet

- AG312 Pin Diode PDFDocument18 pagesAG312 Pin Diode PDFtuwinnerNo ratings yet

- Hero Found: The Greatest POW Escape of the Vietnam WarFrom EverandHero Found: The Greatest POW Escape of the Vietnam WarRating: 4 out of 5 stars4/5 (19)

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureFrom EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureRating: 5 out of 5 stars5/5 (125)

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (58)

- When the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachFrom EverandWhen the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachRating: 3.5 out of 5 stars3.5/5 (6)

- The Future of Geography: How the Competition in Space Will Change Our WorldFrom EverandThe Future of Geography: How the Competition in Space Will Change Our WorldRating: 4 out of 5 stars4/5 (6)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyFrom EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNo ratings yet

- Four Battlegrounds: Power in the Age of Artificial IntelligenceFrom EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceRating: 5 out of 5 stars5/5 (5)

- The End of Craving: Recovering the Lost Wisdom of Eating WellFrom EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellRating: 4.5 out of 5 stars4.5/5 (82)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreFrom EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreRating: 4.5 out of 5 stars4.5/5 (33)

- The Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeFrom EverandThe Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeRating: 4.5 out of 5 stars4.5/5 (99)

- Mini Farming: Self-Sufficiency on 1/4 AcreFrom EverandMini Farming: Self-Sufficiency on 1/4 AcreRating: 4 out of 5 stars4/5 (76)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationFrom EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationRating: 4.5 out of 5 stars4.5/5 (46)

- Pale Blue Dot: A Vision of the Human Future in SpaceFrom EverandPale Blue Dot: A Vision of the Human Future in SpaceRating: 4.5 out of 5 stars4.5/5 (588)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Reality+: Virtual Worlds and the Problems of PhilosophyFrom EverandReality+: Virtual Worlds and the Problems of PhilosophyRating: 4 out of 5 stars4/5 (24)

- The Knowledge: How to Rebuild Our World from ScratchFrom EverandThe Knowledge: How to Rebuild Our World from ScratchRating: 3.5 out of 5 stars3.5/5 (133)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (54)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (122)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)