Professional Documents

Culture Documents

14 Fs-Ahm-jrp-cmv Expansion Joint Treatment 9-2-2014

Uploaded by

viratCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

14 Fs-Ahm-jrp-cmv Expansion Joint Treatment 9-2-2014

Uploaded by

viratCopyright:

Available Formats

Conference on: Trends and Challenges of Civil Engineering in Todays Transforming World

EXPANSION JOINT TREATMENT: MATERIAL &

TECHNIQUES

Farhana M. Saiyed 1, Ashish H. Makwana2, Jayeshkumar Pitroda3, Chetna M. Vyas4

Final Year Student, BE Civil Engineering, BVM Engineering College, Vallabh Vidyanagar, Gujarat, India 1

Final Year Student, ME C E & M., BVM Engineering College, Vallabh Vidyanagar, Gujarat, India 2

Assistant professor, Civil Engineering Dept., BVM Engineering College, Vallabh Vidyanagar, Gujarat, India 3

Assistant professor, Civil Engineering Dept., A.D. Patel Institute of Technology, New Vallabh Vidyanagar,

Gujarat, India 4

Abstract: Although buildings are often constructed using flexible materials, roof and

structural expansion joints are required when plan dimensions are large. It is not possible to

state exact requirements relative to distances between expansion joints because of the many

variables involved, such as ambient temperatures during construction and the expected

temperature range during the life of a building. Expansion joints are periodic breaks in the

structure of the buildings. An expansion joint is a gap in the building structure provided by

an architect or engineer to allow for the movement of the building due to temperature

changes. An expansion joint is an assembly designed to safely absorb the heat-induced

expansion and contraction of various construction materials. They are commonly found

between sections of slabs, bridges, and other structures. The assembly can be as simple as

a caulked separation between two sections of the same materials. More recently, expansion

joints have been included in the design of, or added to existing, brick exterior walls for

similar purposes. In concrete and concrete block construction, the term applied is control

joint, but serves similar purposes. Throughout the year, building faces and concrete slabs

will expand and contract due to the warming and cooling of our planet through the seasons.

The structures would crack under the stress of thermal expansion and contraction if

expansion joint gaps were not built into the structures. Even today the expansion joint gaps

are often neglected during the design process, and simple caulking is used to fill these gaps

to complete a project. This simple caulking cannot handle the thermal expansion due to the

changing seasons, ultimately leaving a leak point in the structure. This expansion joint

becomes the main source of leakages in the structure which can ruin the interiors of the

building if not sealed or treated confidently. Waterproofing these joints often an overlooked

aspect of waterproofing design and detailing.

Keywords: Building, Expansion joints, Material, Techniques

1

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Conference on: Trends and Challenges of Civil Engineering in Todays Transforming World

I.

A.

INTRODUCTION

Defination

The term expansion joint as used refers to the isolation joints provided within a Building

to permit the separate segments of the structural frame to expand and contract in response to

Temperature changes without adversely affecting the building's structural integrity or

serviceability.

B.

Overview of Expansion Joint

The word joint is used in building parlance to cover elements which have to perform

quite different functions, e.g. beam-column joints and isolation joints. In the former the joint

has to provide continuity of structural action between the members meeting at the joint. In the

latter the joint has to ensure separation between the adjacent members to allow one member

to move independently of the other.

C.

The four basic reasons for requiring joints

The member or structure cannot be constructed as a monolithic unit in one placement of

concrete.

The member has to be of limited size so it can be handled by cranes, etc.

The structure or member on one side of the joint needs to be able to move relative to that

on the other.

The design assumptions for the structure or building need the joint at that point, so the

analysis is simplified.

II.

TYPES OF JOINTS IN CONCRETE

i) Construction Joints

ii) Isolation Joints

2

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Conference on: Trends and Challenges of Civil Engineering in Todays Transforming World

iii) Contraction Joints

iv) Expansion Joints

Figure 1: Types of Joints in Concrete

Source: http://www.expertsmind.com & http://www.pavement.com

III. EXPANSION JOINT

A.

Details of expansion joint

The normal practice in runways, bridges, buildings and road construction is to provide

expansion joints between cutting slabs of reinforced concrete at designing intervals and at

intersections with other constructions. These joint filers are then covered with sealing

compounds.

Concrete expands slightly when the temperature rises. Similarly, concrete shrinks upon

drying and expands upon subsequent wetting. Provision must cater for the volume change by

way of joint to relieve the stresses produced. An Expansion joint is actually a gap, which

allows space for a building to move in and out of. The movement of the building is caused

most frequently by temperature changes, the amount of expansion and contraction of building

depends upon the type of material it is constructed out of. A steel framed building will move

by a different amount then a concrete framed one. In case of a small building, the magnitude

of expansion is less and therefore, no joint is required either in the floor or roof slab. But in

case of the long building, the expansion is very large and may be as much as 25 mm.

Therefore, buildings longer than 30 m are generally provided with one or more expansion

joints.

Having successful determination the predicted movement along the three principal axis

of the Expansion joint gap, the designer and Specifier are now faced with a more critical

choice, that of choosing of material to seal the joint gap itself from the element. This is a

particular important building envelope design consideration, especially when moisture and

water are present.

3

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Conference on: Trends and Challenges of Civil Engineering in Todays Transforming World

Figure 2: Expansion Joint

Source: https://www.google.co.in/#q=EXPANSION+JOINT+++++images

Figure 3: Movement at an Expansion Joint

Source: https://www.google.co.in/#q=movement+at+an+expansion+joints+images

B.

Problems due to Expansion Joint

The main problems of expansion joints are

Leakage of Water

Pest attack

Poor workmanship

But the side effects developed by the water leakage and pest attack are very dangerous

and tedious

4

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Conference on: Trends and Challenges of Civil Engineering in Todays Transforming World

1) The problem caused by water leakage :

In rainy season water travels from the expansion joints and goes into the walls which

creates discomfort for people

Also the paints of the walls are affected by weather.

The steel members get corroded and results in to risk of structural failure.

The electric lines in expansion joints can be short circuited.

2) Problems due to pest attack :

The pest attack on the wooden pads or the Shalitex board of expansion joints and also

travels from electric pipes and spreads in the whole structure.

3) Problems due to poor workmanship :

The expansion joints provided only on the superstructure can cause failure of foundation.

The expansion joints not provided on the parapet walls can result into uneven cracks on

parapet walls.

C.

Need of Expansion Joints

If not provided the structure shall be subjected to internal compressive stresses and these

stresses may be so high that structure may fail.

The amount of expansion as already stated depends upon the extent of change of

temperature, the extent of the structure, and on the coefficient of linear expansion of the

material.

But of these three parameters changes in temperature and coefficient of linear expansion

cannot be controlled.

It is only the extent of the structure which can be reduced to limit the expansion the

structure within specified limits.

Based on these concepts it is seen that the structure 30 meters long when subjected to

temperature change of 50 degrees F expands about 10 mm.

Small buildings usually do not require any expansion joint, but if the continuous length

of the structure exceeds 45 meters expansion joint should be provided.

5

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Conference on: Trends and Challenges of Civil Engineering in Todays Transforming World

D.

Factors affecting on Expansion Joints

Thermal

The different materials in buildings expands and contracts

according to their different co-efficient of expansion related to

temperature change so stresses devolved in such conditional can

be minimized by expansion Joints.

Wind

The stresses developed in storms and hurricanes can be

minimize.

Loads

Bending moments due to load snow, rain, vibrations, can be

decreased by expansion joints.

Earth quake

The thrust on the building can be decreased by expansion joints

during earthquake.

E.

Location of Expansion Joints

Change in Materials: Wood to Steel, Concrete to Steel, flexible to rigid

Material direction change: Steel deck flutes

Building shapes: T, H, O, X, Y, C and others

Building size, typically greater than 30m in any direction, can be larger or smaller areas

Additions, regardless of shape or size

Equipment isolation, Atriums, Skylights

Non load bearing walls or in some cases load bearing

6

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Conference on: Trends and Challenges of Civil Engineering in Todays Transforming World

Figure 4: Location of Expansion Joints

Source: https://www.google.co.in/#q=Location+of+Expansion+Joints+images

F.

Construction of Expansion Joint

The expansion joint is to be provided from the foundation to the top floor of the building.

The one side of the expansion joint is first constructed to desired level, then the Fiberboard is

placed where Expansion joint is to be provided then the other side is constructed. The

fiberboard is sealed with sealing compounds. Thus the whole construction of the building is

done.

G.

Material & Techniques

The gap of expansion joints is never left open. It is filled with a compressible material so

as to make it water tight. The following materials are required to render the expansion joint

watertight.

Joint filler

Sealing compound

Water bars

1) Joint filler: Bitumen, bitumen containing cellular materials, cork strips, rubber, mineral

fiber, expanded plastic, pith, coconut, etc. are the usual joint filler materials. Joint filler

should be compressible material tightly fitted in the gap. Being compressible, they

7

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Conference on: Trends and Challenges of Civil Engineering in Todays Transforming World

readily allow free expansion of adjacent parts. It should regain 75% of its original

thickness when external pressure is removed from it. They should be rigid, durable and

resistant to decay.

2) Sealing compound: its function is to seal the joint against passage of moisture and to

prevent the ingress of dust, grit or other foreign matter into the joint. It should be tint

less, non-toxic, insoluble and readily workable. Mastic or Hot-applied bituminous

sealing compound is mostly used for the purpose.

3) Water bars: the function bars are to seal the joints against passage of water. Water bars

may be made of rubber, P.V.C., G.I. sheet, copper, or aluminum sheets. G.I. Water bar

should not be used under corrosive conditions. Width of water bar may be varied from

the 15cm. to 20cm.and thickness should not be less than 0.56 mm. they are given U or V

fold to allow expansion and contraction at the joints.

H.

Installation of Expansion joint

Expansion joint installation is a specialty, and project documents should emphasize the

need for a heightened care required to complete the task. The contract documents should

require that the contractor call a pre-construction meeting of parties involved in performing

the work at and around the expansion joints, to educate all involved parties about their

responsibilities in installing the expansion joints and ensure that the following conditions are

met:

1) The expansion joints in the floor should be straight and should align, without offset, with

expansion joints in vertical planes such as double columns and walls.

2) The expansion joint separation should not be used as a place for tolerance build-up from

other construction activities.

3) The expansion joint gap should have a consistent width throughout. If the gap is cast at a

temperature other than the specified mean temperature, and/or post-tensioned concrete is

used, the adjustment in the gap width may be needed to ensure that the specified joint has

the specified movement capability. A design example published in the 2009 PTI Journal

illustrates the design steps needed.

4) Forms should be strong with tight joints so as to allow concrete next to the forms to be

thoroughly vibrated to ensure proper consolidation, to prevent seepage of concrete and

irregularities in joint shape, and to avoid voids within concrete or on concrete surface.

5) The forms should be removed promptly after initial curing of concrete to prevent them

from being squeezed or becoming dislodged due to the joint movement.

8

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Conference on: Trends and Challenges of Civil Engineering in Todays Transforming World

6) Once formed, the expansion joint gaps in the decks and floors need to be protected from

damage by construction traffic throughout their length. At crossing points, joints should

be protected with plates or ramps.

7) Joints in the walls should be free of mortar protrusion, masonry ties, protruding shelf

angles, and other obstructions that might hinder the movement or obstruct installation of

the expansion joint system.

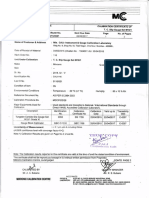

TABLE I: - C/C SPACING OF EXPANSION JOINT IN VARIOUS ELEMENTS

Sr.

No.

1.

2.

3.

4.

Description of elements

Walls

i) Load bearing walls one brick

and more in thickness and having

cross-walls at intervals.

ii) Load bearing walls without any

cross-walls

Roofs

i) Ordinary roof slabs of RCC on

unframed construction protected

by mud phuska.

ii) Thin unprotected RCC slabs.

Chhajjas, balconies and parapets.

Copings

Framed structures

c/c spacing

Reference

30 m

30 m

If wall acts as panel walls

between columns spaced not

more than 9 m c/c no joints are

required. Control joints may be

given over the center of openings

at half the spacing of expansion

joint.

IS 3414-1968: The

spacing of expansion

joints in various elements

of the structure

20 m to 30 m interval and at all

changes of direction points of

structure.

15 m

6 to 12 m.

Corresponding to joints in the

roof slabs.

At 30 m intervals and at corners

or change of direction points.

IV. CASE STUDY

A.

Site Visit

As we visited the some sites of untreated or poorly constructed expansion joints, we

encountered very major problems in maintaining, installing and treating expansion joints.

i) A part of a whole expansion joint is treated ii) The gap for movement of overlapped slab

which is not very durable and not much care is not provided as a result the cracks are

is taken off in treating.

formed in the cover.

9

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Conference on: Trends and Challenges of Civil Engineering in Todays Transforming World

iii) In this picture the joint and the treatment iv) Here the Shalitex board is not properly

are at different places.

installed so water can penetrate from

cavities.

v)

In

this

joint

pest

has

completely vi) A typical failure at an expansion joint

demolished the Fiberboard as it is not junction.

covered to resist this sort of problem and

weather effects.

B.

Treatment methods for expansion joints in various elements

1) Walls: The joints in the wall are not left exposed. They are covered with covering sheets

which may be of aluminum, hard board, AC sheet or timber plank. Normally A.C. sheet

is used to cover the joint. The covering sheet is fixed to the wall on one side of the joint

with screws and on the other side by screws through oval shaped slots. The oval slots

permit movement at the joint without causing any damage to the covering sheet.

Expansion joint in the roof shall invariably be provided with joint filler and water bar.

Joint in floor shall be invariably sealed to prevent accumulation of dirt, dust, therein.

The joints in the wall are not left exposed. They are covered with covering sheets

which may be of aluminum, hard board, AC sheet or timber plank. Normally A.C. sheet

is used to cover the joint. The covering sheet is fixed to the wall on one side of the joint

with screws and on the other side by screws through oval shaped slots. The oval slots

permit movement at the joint without causing any damage to the covering sheet.

Expansion joint in the roof shall invariably be provided with joint filler and water bar.

Joint in floor shall be invariably sealed to prevent accumulation of dirt, dust, therein.

10

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Conference on: Trends and Challenges of Civil Engineering in Todays Transforming World

Figure 5: Expansion Joint treatment in walls

Source: https://www.google.co.in/#q=Material+%26+Techniques+of+Expansion+Joints+images

2) Framed Walls: In case of framed structure, it is necessary to provide two frames, one on

either side of the expansion joint. The treatment of joints is similar to those given to the

masonry wall expansion joint.

Figure 6: Expansion Joint treatment in Framed walls

Source: https://www.google.co.in/#q=Material+%26+Techniques+of+Expansion+Joints+images

3) Roofing Slab: The gap of the joint should be sealed with a water bar and sealing

compound. In order to prevent cracks in the masonry above or below the expansion joint

R.C.C or plain concrete bed blocks should be provided in the masonry below the

expansion joint in the slab.

Figure 7: Expansion Joint treatment in Roofing Slab

Source: https://www.google.co.in/#q=Material+%26+Techniques+of+Expansion+Joints+images

11

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Conference on: Trends and Challenges of Civil Engineering in Todays Transforming World

C.

Some new methods used for treatment of Expansion joint in present time

1) In this method a combination of fiber tape and adhesive material is used to cover the

expansion joint.

i) In newly constructed building or in treatment of

ii) Now the adhesive materials are properly

expansion joint in existing building the cleaning of

mixed.

expansion joint is required in the first step.

iii) Now water is applied on the surface where the

iv) The fiber tape is instantly placed over the

adhesive is to be placed so moisture in chemicals is

coating so it can properly cure.

not absorbed by the surface.

Then the first layer of adhesive chemicals is coated.

v) The second coat is done over the tape. After the half an hour curing the 3 rd coating of adhesive chemical is

introduced. When flooring is done 15 mm gap is left on treated joint. The provided gap is then filled up with

silicon gel.

12

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Conference on: Trends and Challenges of Civil Engineering in Todays Transforming World

2) Treatment by simple slab construction

Figure 8: Treatment by simple slab construction

Source: https://www.google.co.in/#q=Expansion+joint+Treatment+by+simple+slab+construction+images

As shown in figure the overhanging slab is constructed on the expansion joint.

3) Treatment using rubber gasket and aluminium sheet:

Figure 9: Treatment using rubber gasket and aluminium sheet

Source: https://www.google.co.in/#q=treatment+using+rubber+gasket+and+aluminium+sheet+images

V.

CONCLUSION

It is important that at the design stage the designer recognises the factors that may affect

a buildings performance and makes provisions to accommodate any likely movement.

Adequate provision shall be made for expansion and contraction appropriate to the

service conditions of the structure.

New methods used with latest materials are more advantageous and provides faster

workmanship as well as long life to expansion joint with water tight provision.

13

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Conference on: Trends and Challenges of Civil Engineering in Todays Transforming World

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

JAMES. M. FISHER S.E, Steel conference, expansion joints, where, when and how?

Expansion Joints in Buildings: Technical Report No. 65, http://www.nap.edu/catalog/9801.html

Mohammad Iqbal, D. Sc., P.E., S.E., Esq. October, 2010

Structural Design - Discussions on design issues for structural engineers Joint Publication of NCSEA |

CASE | SEI

Kris zielonka P.eng. Technical manager situra INC., A study of Practices in design, detailing and water

proofing, expansion joint in North America.

Technical note 63, joints in concrete buildings, sept 2004.

Gurcharan Singh, Building construction and materials, standard book house, 12th edition 2012

http://www.expertsmind.com

http://www.pavement.com

http://www.stpltd.com/html/Presentation/Sealants%20and%20Additives/ShaliSeal%20PS%20PG.pdf

http://www.heidelbergcement.com/uk/en/hanson/products/blocks/technical_information/thermalite_move

ment_control.htm

http://besser.tsoa.nyu.edu/impact/f95/Cdwa/MATERIAL.HTML

http://www.nbmcw.com/articles/waterproofing-construction-chemicals/3202-treating-expansion-jointswith-koster-joint-tape-system.html

https://www.google.co.in/?gws_rd=cr&ei=llT3UpPSEoyCrgemnYHwDA#q=Wind+effect+on+buildings+i

mages

https://www.google.co.in/?gws_rd=cr&ei=llT3UpPSEoyCrgemnYHwDA#q=Thermal+effect+on+building

s+images

https://www.google.co.in/?gws_rd=cr&ei=llT3UpPSEoyCrgemnYHwDA#q=Loads+effect+on+buildings+

images

https://www.google.co.in/?gws_rd=cr&ei=llT3UpPSEoyCrgemnYHwDA#q=Earth+quake++effect+on+bu

ildings+images

https://www.google.co.in/?gws_rd=cr&ei=llT3UpPSEoyCrgemnYHwDA#q=Problems+due+to+Expansio

n+Joint+images

14

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- From CP 114 To BS8110 EssayDocument10 pagesFrom CP 114 To BS8110 EssayAlan CheungNo ratings yet

- 02 DESIGN OF CONNECTION AS PER IS 800 (2007) - AIKTC DR Ganesh KameDocument108 pages02 DESIGN OF CONNECTION AS PER IS 800 (2007) - AIKTC DR Ganesh KameDrGanesh Kame67% (6)

- Module 7: Testing The Tensile Strength of Steel BarsDocument5 pagesModule 7: Testing The Tensile Strength of Steel BarsPrincess Tamani ManzanoNo ratings yet

- Design of Nonstructural Systems and ComponentsDocument42 pagesDesign of Nonstructural Systems and ComponentsJV LopezNo ratings yet

- Dffa b10333 00 7600Document8 pagesDffa b10333 00 7600BlAdE 12No ratings yet

- Sustainable Environments (MSC) - University of GalwayDocument4 pagesSustainable Environments (MSC) - University of Galwaybashir isahNo ratings yet

- Brick WorkDocument2 pagesBrick WorkvinitbardeNo ratings yet

- Dominique Torres ResumeDocument1 pageDominique Torres ResumeDominique TorresNo ratings yet

- Determination of Maximum Span Between PipeDocument7 pagesDetermination of Maximum Span Between PipeNabil Al-KhirdajiNo ratings yet

- Purushothaman - ResumeDocument5 pagesPurushothaman - Resumeicq4joyNo ratings yet

- Allowable Stress DesignDocument11 pagesAllowable Stress DesignLyka Marie DesepedaNo ratings yet

- Insights Into Sustainable EngineeringDocument24 pagesInsights Into Sustainable Engineeringcmanning17No ratings yet

- End To End Embedded Power Product Selection GuideDocument60 pagesEnd To End Embedded Power Product Selection GuideYoucefChaabnaNo ratings yet

- Abhishek Kumar CVDocument3 pagesAbhishek Kumar CVKuldeep TyagiNo ratings yet

- Greentec Company Profile V 3.2 PDFDocument46 pagesGreentec Company Profile V 3.2 PDFxolilevNo ratings yet

- Boehm 1991Document10 pagesBoehm 1991Cesar de la LuzNo ratings yet

- AME CET India PDFDocument10 pagesAME CET India PDFAMECET 2020No ratings yet

- BrickworksDocument17 pagesBrickworksSyerifaizal Hj. MustaphaNo ratings yet

- Slip Gauge Pg-1 PDFDocument1 pageSlip Gauge Pg-1 PDFaliNo ratings yet

- Joshua Bourgeois - Construction ProfessionalDocument2 pagesJoshua Bourgeois - Construction ProfessionalVersatile337No ratings yet

- Basic Mechanical EngineeringDocument25 pagesBasic Mechanical EngineeringKhairulNo ratings yet

- Fema 274Document10 pagesFema 274Sergio Echeverría RNo ratings yet

- Division 3&4 Concrete&MasonryDocument9 pagesDivision 3&4 Concrete&MasonryAceron Torres MalicdanNo ratings yet

- BIMDocument8 pagesBIMMuhd ZulFadliNo ratings yet

- Implementation of Lean Construction Techniques For Minimizing The Risks Effect On Construction ProjectDocument49 pagesImplementation of Lean Construction Techniques For Minimizing The Risks Effect On Construction ProjectJohn PaulNo ratings yet

- DESIGN CalculationDocument47 pagesDESIGN CalculationZayyan Romjon100% (2)

- Retaining Wall Analysis & Design (ACI318Document13 pagesRetaining Wall Analysis & Design (ACI318Aziz ul HakeemNo ratings yet

- A Project Review Seminar On Designe and Implimentation of Application Specific Low Power MultipliersDocument16 pagesA Project Review Seminar On Designe and Implimentation of Application Specific Low Power MultipliersSaiKishoreNo ratings yet

- Lecture 1 Ce Laws, Ethics and ContractsDocument51 pagesLecture 1 Ce Laws, Ethics and ContractsCjoy De Roxas100% (1)

- FlairsTech - SE Introduction 01Document58 pagesFlairsTech - SE Introduction 01tahazamzamNo ratings yet