Professional Documents

Culture Documents

AHU - With Recovery Fan Startup Checklist

Uploaded by

tekken123jo0 ratings0% found this document useful (0 votes)

377 views2 pagesCopyright

© Attribution Non-Commercial (BY-NC)

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

377 views2 pagesAHU - With Recovery Fan Startup Checklist

Uploaded by

tekken123joCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 2

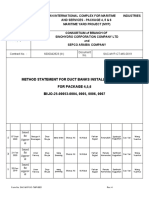

Installation Integrity 2006 WLL

H.V.A.C Commissioning Management START-UP COMMISSIONING INSPECTION TEST SHEET

Operating and Maintenance Manuals (Air Handling Unit with Recovery Fan)

Testing and Balancing www.i2ime.com

Contract Integrated District Cooling Plant @ The Pearl, Qatar Ref QA-PCA01a

Client CAT International Qatar W.L.L Date

Plant reference AHU- (Supply Fan) Job ref

Location / area serving Sheet 1 of 2

FAN FAN - MOTOR HUMIDIFIER RECOVERY FAN & MOTOR

Manufacturer Manufacturer Capacity kg/h Manufacturer (Fan)

Type / Make Frame size Power kW Fan Capacity

Size Serial no. Manufacturer (Motor)

Serial no. Power kW HEATER Serial no.

Ordered duty Air Volume l/s Electrical supply volts / phase / hertz Capacity kW Power kW

External Static Press Pa Motor current (FLA) amps Electrical supply volts / phase / hertz Electrical supply volts / phase / hertz

Service Factor Motor current (FLA) amps

Pre-start up Inspection Y/N Notes Start up Inspection Y/N Notes

Item Mechanical: Item Mechanical:

1 Equipment matches the submittal data 1 Motor rotation correct During Start-up.

2 Mounting checked (shipping bolts removed) 2 Outdoor air damper open

3 Alignment by Millwright or installer 3 Supply air damper wide open

4 Pulleys aligned and belt tension correct 4 Fire / Smoke damper open

5 Equipment guards installed 5 Balance dampers open

6 Fan rotates freely Electrical:

7 Fun & Motor lubricated per MFG recommendations 6 Electrical interlocks verified

8 Smoke and fire dampers (or combination) in place 7 Status indicators verified (Local / Remotes)

9 Smoke detectors are installed (if applicable) 8 Motor Amps - Rated ____ Actual ____

10 Air Temp sensor, and filter diff. pressure gauge correct location 9 Motor Volts - Rated ____ Actual ____

11 Duct insulation provided 10 VFD (if any) settings to match motor were applicable

12 Balanced dampers installed, positioned and locked 11 VFD (if any) vendor representative onsite

13 Access doors for all dampers installed (Ducts and Plenums) START-UP DATA:

14 Condensate lines provided and clear @ 12.5 Hz @25.0 Hz @ 37.5 Hz @ 50.0 Hz

15 Cooling coil clean and clear - piping correct connection Measured Amps

16 Ductwork flexible connectors installed Measured Votage

17 Ductwork sealed as required and leak tested STATIC PARAMETER

18 Sound Attenuator installed Intake Air Static Pressure : Pa

19 Louvers (outdoor) installed Supply Air Static Pressure: Pa

20 Start-up Filters Installed. External Static Pressure: Pa

Electrical: Deficiency Corrected:

21 Electrical connections / termination complete (MCC Sign-off)

22 Isolator switch installed & terminated :

- Supply Fan

- Heater

- Humidifier

- Recovery Fan

23 Overload protection in place (sized correctly)

24 AHU internal lightings complete and functional.

Others:

25 Equipment manufacturers submittal, performance data,

fan curves, dimensions, as-built drawings. * indicates unobtanable ** indicates not stated *** not applicable

WITNESS

Vendor / Installer Representative i2i Representative BAYTUR Representative KEO Representative

Name: Name: Name: Name:

Date: Date: Date: Date:

Signature: Signature: Signature: Signature:

Installation Integrity 2006 WLL

H.V.A.C Commissioning Management START-UP COMMISSIONING INSPECTION TEST SHEET

Operating and Maintenance Manuals (Air Handling Unit with Recovery Fan)

Testing and Balancing www.i2ime.com

Contract Integrated District Cooling Plant @ The Pearl, Qatar Ref QA-PCA01a

Client CAT International Qatar W.L.L Date

Plant reference AHU- (Return Fan) Job ref

Location / area serving Sheet 2 of 2

FAN FAN-MOTOR

Manufacturer Manufacturer

Type / Make Frame size

Size Serial no.

Serial no. Power kW

Ordered duty Air Volume l/s Electrical supply volts / phase / hertz

External Static Press Pa Motor current (FLA) amps

Service Factor

Pre-start up Inspection Y/N Notes Start up Inspection Y/N Notes

Item Mechanical: Item Mechanical:

1 Equipment matches the submittal data 1 Motor rotation correct During Start-up.

2 Mounting checked (shipping bolts removed) 2 Return air damper open

3 Alignment by Millwright or installer 3 Extract air damper wide open

4 Pulleys aligned and belt tension correct 4 Fire / Smoke damper open

5 Equipment guards installed 5 Balance dampers open

6 Fan rotates freely Electrical:

7 Fun & Motor lubricated per MFG recommendations 6 Electrical interlocks verified

8 Smoke and fire dampers (or combination) in place 7 Status indicators verified (Local / Remotes)

9 Smoke detectors are installed (if applicable) 8 Motor Amps - Rated ____ Actual ____

10 Air Temp sensor, and filter diff. pressure gauge correct location 9 Motor Volts - Rated ____ Actual ____

11 Duct insulation provided 10 VFD (if any) settings to match motor were applicable

12 Balanced dampers installed, positioned and locked 11 VFD (if any) vendor representative onsite

13 Access doors for all dampers installed (Ducts and Plenums) START-UP DATA:

14 Sound attenuator installed @ 12.5 Hz @25.0 Hz @ 37.5 Hz @ 50.0 Hz

15 Ductwork flexible connectors installed Measured Amps

16 Ductwork sealed as required and leak tested Measured Votage

17 Louvers(extract) installed STATIC PARAMETER

18 Start-up Filters Installed. Return Air Static Pressure : Pa

Exhaust Air Static Pressure: Pa

Electrical: External Static Pressure: Pa

19 Electrical connections / termination complete (MCC Sign-off) Deficiency Corrected:

20 Isolator switch installed & terminated :

- Return Fan

- Recovery Fan

21 Overload protection in place (sized correctly)

22 AHU internal lightings complete and functional.

* indicates unobtanable ** indicates not stated *** not applicable

WITNESS

Vendor / Installer Representative i2i Representative BAYTUR Representative KEO Representative

Name: Name: Name: Name:

Date: Date: Date: Date:

Signature: Signature: Signature: Signature:

You might also like

- 6 Tech Specs Hvac 130116 PDFDocument186 pages6 Tech Specs Hvac 130116 PDFBay MưaNo ratings yet

- Soldier pile wall analyzed with limit equilibrium and non-linear methodsDocument15 pagesSoldier pile wall analyzed with limit equilibrium and non-linear methodsYousif Mohammed Yousif100% (1)

- 200622-Fcu & Refrigerant Pipe & Insulation SizeDocument1 page200622-Fcu & Refrigerant Pipe & Insulation Sizegukan rajNo ratings yet

- AHU ChecklistDocument11 pagesAHU ChecklistRavi SharmaNo ratings yet

- Presentation On Evalaution of Buckle of PipesDocument20 pagesPresentation On Evalaution of Buckle of PipesJose BijoyNo ratings yet

- York - AHU - Selection PDFDocument172 pagesYork - AHU - Selection PDFAhmed NabilNo ratings yet

- Glass in Buildings CAEDocument63 pagesGlass in Buildings CAEJackson Tan100% (4)

- Method StatementDocument31 pagesMethod StatementMuneeb KhanNo ratings yet

- Hvac Engineer Interview 70 Question AnswersDocument12 pagesHvac Engineer Interview 70 Question AnswersRobin DittoNo ratings yet

- Final Training Manual - SYSTEMDocument3 pagesFinal Training Manual - SYSTEMsarmad009No ratings yet

- TAQA Approved Vendor List 30.05.2021Document328 pagesTAQA Approved Vendor List 30.05.2021Bala KrishnaNo ratings yet

- 230313-MEP Client RequirementDocument19 pages230313-MEP Client RequirementSelcen yeniçeriNo ratings yet

- FAHU SubmittalDocument62 pagesFAHU SubmittalEngr.MmosaadNo ratings yet

- BOQ HVAC-Ginger ManesarDocument4 pagesBOQ HVAC-Ginger Manesarmascotengineers100% (1)

- Samsung VRF Installation Trend For BuildingDocument55 pagesSamsung VRF Installation Trend For BuildingNaseemNo ratings yet

- 5 NDT Method For ConcreteDocument1 page5 NDT Method For ConcreteRamzi BEN AHMEDNo ratings yet

- Installation Procedures & GuidelinesDocument8 pagesInstallation Procedures & GuidelinesAdnan KhanNo ratings yet

- L&T MLCP East Block HVAC Heat Load SUMMARYDocument3 pagesL&T MLCP East Block HVAC Heat Load SUMMARYSatheesh Kumar NatarajanNo ratings yet

- Fire Sprinkler Installation MethodDocument19 pagesFire Sprinkler Installation Methodمقاول تكييف كهرباء وصحيNo ratings yet

- Air Handling Units (AHU) Pre-Commissioning TestsDocument2 pagesAir Handling Units (AHU) Pre-Commissioning TestsJaya PrathabNo ratings yet

- Dasco 1-9Document9 pagesDasco 1-9Ahmed AzadNo ratings yet

- Bottomgrass Engineering & HVAC Services: Indoor Section Coompressor SectionDocument1 pageBottomgrass Engineering & HVAC Services: Indoor Section Coompressor SectionSubodh MurkewarNo ratings yet

- TS-02 Ventilation Fans - Toilet & BasementDocument11 pagesTS-02 Ventilation Fans - Toilet & BasementPraveen KumarNo ratings yet

- PMG-ENG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part6 PDFDocument1 pagePMG-ENG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part6 PDFAditya PranotoNo ratings yet

- Fracture MechanicsDocument12 pagesFracture Mechanicsramachadra122No ratings yet

- AHU ChecklistDocument11 pagesAHU Checklistmohammad hamdanNo ratings yet

- B23-00 (2014) Standard Specification For White Metal Bearing Alloys (Known Commercially As  Œbabbitt Metalâ )Document4 pagesB23-00 (2014) Standard Specification For White Metal Bearing Alloys (Known Commercially As  Œbabbitt Metalâ )Fanir ZNo ratings yet

- Refrigerant Piping Work1Document13 pagesRefrigerant Piping Work1Le Manh HieuNo ratings yet

- Method Statement For Hvac Equipments InstallationDocument15 pagesMethod Statement For Hvac Equipments InstallationzahidNo ratings yet

- PPM Checklist RegisterDocument9 pagesPPM Checklist Registermarmarzamani10% (1)

- MAS ScheduleDocument48 pagesMAS ScheduleKUMAARRRNo ratings yet

- GODREJ Commissioning FormatsDocument59 pagesGODREJ Commissioning Formatsalisha karimNo ratings yet

- Material Takeoff for Residential ConstructionDocument10 pagesMaterial Takeoff for Residential ConstructionjatinNo ratings yet

- Particular HVACDocument49 pagesParticular HVACAdnan Khan100% (1)

- HVAC LifeDocument8 pagesHVAC LifeNadeem QaisarNo ratings yet

- TLE9 Q2 Wk.-1-3 Mod1 DrafRoofPlan V2docxDocument38 pagesTLE9 Q2 Wk.-1-3 Mod1 DrafRoofPlan V2docxJayson Cajate100% (1)

- Axial & Jet Fans SpecificationDocument8 pagesAxial & Jet Fans SpecificationRamakrishnanNo ratings yet

- HubantDocument3 pagesHubantAr Aditya SagarNo ratings yet

- Hvac Boq-07082014Document18 pagesHvac Boq-07082014Kohilan NahivNo ratings yet

- Acuv SDocument32 pagesAcuv Sanoopkumar1231150No ratings yet

- Paper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Document7 pagesPaper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Congson JeffNo ratings yet

- ACUSDocument36 pagesACUSOsama.ShawkyNo ratings yet

- Chemical Filtration UnitDocument5 pagesChemical Filtration UnitpsjjoshiNo ratings yet

- Chillers CatalogueDocument42 pagesChillers CatalogueAlaa FaiqNo ratings yet

- Room Noise Level TestDocument3 pagesRoom Noise Level TestNeguib FarahNo ratings yet

- HVAC Interview Test PDFDocument5 pagesHVAC Interview Test PDFHarendra kumarNo ratings yet

- Bilt Middle East LLC: Inspections and Testing PlanDocument1 pageBilt Middle East LLC: Inspections and Testing Plansarmad009No ratings yet

- Vav HvacDocument47 pagesVav HvacMuraryspotty100% (1)

- Nizwa HvacDocument35 pagesNizwa HvaczfrlNo ratings yet

- Domestic - MTD SilentDocument6 pagesDomestic - MTD SilentVan Vinh NguyenNo ratings yet

- 1315977722iitm Hvac TD00Document131 pages1315977722iitm Hvac TD00Kay KarthiNo ratings yet

- 213902376-5921C32B (Fahu-C9-03)Document10 pages213902376-5921C32B (Fahu-C9-03)Designer ForeverNo ratings yet

- Sr. No. Location Type TR Qty: Area SheetDocument20 pagesSr. No. Location Type TR Qty: Area SheetNandan Raje100% (1)

- APMRG1 Series: Packaged Air ConditionersDocument32 pagesAPMRG1 Series: Packaged Air Conditionerszaid jamaluNo ratings yet

- Fire Pump Field Acceptance Test QCDD FormDocument6 pagesFire Pump Field Acceptance Test QCDD FormMahmoud HassanNo ratings yet

- 254-SCCAD Base 5, 8430 Mexico RD., Ofallon, MO 63366 - MEP DwgsDocument18 pages254-SCCAD Base 5, 8430 Mexico RD., Ofallon, MO 63366 - MEP DwgsMirelNo ratings yet

- مشروع توزيع الكهرباء لمستشفى كاملDocument280 pagesمشروع توزيع الكهرباء لمستشفى كاملhunkbsrNo ratings yet

- IIT Kanpur Air-Conditioning Works Bill of QuantityDocument10 pagesIIT Kanpur Air-Conditioning Works Bill of QuantityErnest OdhiamboNo ratings yet

- 750 TR Chiller Load LineDocument2 pages750 TR Chiller Load Linecalvin.bloodaxe4478No ratings yet

- Condensate TrapsDocument3 pagesCondensate Trapsalamdar321No ratings yet

- Systems Design Report From HapDocument5 pagesSystems Design Report From HapRoberto TraspalacioNo ratings yet

- Division 15 Mechanical IBS HVACDocument164 pagesDivision 15 Mechanical IBS HVACmasahinNo ratings yet

- Chilled Water Buffer TankDocument4 pagesChilled Water Buffer TankThiraviam Ayyappan100% (1)

- Drain Pump DaikinDocument2 pagesDrain Pump DaikinJonathan GanNo ratings yet

- M - HW - Pipework INSPECTION CHECKLISTDocument1 pageM - HW - Pipework INSPECTION CHECKLISTmandelaria01No ratings yet

- CH Aly080dDocument2 pagesCH Aly080dEngineer HassanNo ratings yet

- Preformance Sheet (Ahu+accu)Document48 pagesPreformance Sheet (Ahu+accu)cranky.clay67No ratings yet

- Pacu 02-Py100fa - 1,645 CFMDocument2 pagesPacu 02-Py100fa - 1,645 CFMAnonymous qOBFvINo ratings yet

- EL-QT-CTB-S - 20180420B-ESTRUAGUA LATAM-SOPLADORES TURBO-Floculación-Ficha Tecnica Jul1018Document2 pagesEL-QT-CTB-S - 20180420B-ESTRUAGUA LATAM-SOPLADORES TURBO-Floculación-Ficha Tecnica Jul1018mafevalle4201No ratings yet

- East Halmahera Ferronickel Development Project (P3Fh Project)Document2 pagesEast Halmahera Ferronickel Development Project (P3Fh Project)nailulfalah17No ratings yet

- Plan Set Example Box Culvert 20skewDocument15 pagesPlan Set Example Box Culvert 20skewBhupender SinghNo ratings yet

- 5 - Threaded Fasteners PDFDocument41 pages5 - Threaded Fasteners PDFViven Sharma100% (1)

- Top-Down Synthesis of Nanostructured Materials: Mechanical and Thermal Processing MethodsDocument9 pagesTop-Down Synthesis of Nanostructured Materials: Mechanical and Thermal Processing MethodsGloria HendersonNo ratings yet

- COMSOL Application Note Thermal Management of Buildings Lowres NewDocument20 pagesCOMSOL Application Note Thermal Management of Buildings Lowres NewSamar SinghalNo ratings yet

- Protective Concrete Coating GuideDocument3 pagesProtective Concrete Coating GuideTori SmallNo ratings yet

- Havells LV and HT Aerial Bunched Cables OverviewDocument23 pagesHavells LV and HT Aerial Bunched Cables OverviewJinto JacobNo ratings yet

- Cladire Birouri Etaj CurentDocument6 pagesCladire Birouri Etaj CurentpintileirobertNo ratings yet

- Lot Detail for Repair and Renovation work at Langalzora High School Upazilla Kalihati District-TangailDocument8 pagesLot Detail for Repair and Renovation work at Langalzora High School Upazilla Kalihati District-Tangailfireballhunter646No ratings yet

- Ap T188 11Document82 pagesAp T188 11adjiNo ratings yet

- Project ReportDocument19 pagesProject ReportHimank Chawla100% (1)

- Mechanical PO Cash Flow ReportDocument9 pagesMechanical PO Cash Flow ReportOmkarNo ratings yet

- Splined ShaftDocument2 pagesSplined Shaftjmpateiro1985No ratings yet

- Example 10B - 1 - Ideal Ammonia Vapor-Compression RefrigeratorDocument22 pagesExample 10B - 1 - Ideal Ammonia Vapor-Compression RefrigeratorAshfaq Ali KhanNo ratings yet

- General Duty Valves For Plumbing Piping PDFDocument12 pagesGeneral Duty Valves For Plumbing Piping PDFfatima tanjutcoNo ratings yet

- Greenheck DGXDocument72 pagesGreenheck DGXBrad GNo ratings yet

- Experimental Investigation On Octagonal Concrete Filled Steel Stub Columns Under Uniaxial Compression, 2018 (Jiong-Yi Zhu) PDFDocument11 pagesExperimental Investigation On Octagonal Concrete Filled Steel Stub Columns Under Uniaxial Compression, 2018 (Jiong-Yi Zhu) PDFPhan Đào Hoàng HiệpNo ratings yet

- Compact Refrigerator ManualDocument16 pagesCompact Refrigerator Manualvictor nuñezNo ratings yet

- NDT Certificate Inspection ReportsDocument9 pagesNDT Certificate Inspection ReportsikponmwonsaNo ratings yet

- Steel Sheet PilesDocument20 pagesSteel Sheet PilesEko PrasetyoNo ratings yet

- Assignment # 4 (Chapter 5) Due 3:00 PM of February 07, 2008 1Document2 pagesAssignment # 4 (Chapter 5) Due 3:00 PM of February 07, 2008 1Adam SchellNo ratings yet